Best for what? Pro sound driver makers may not agree.Titanium former is the best 🙂

Oh well, so much for a teaching momentRms determines the Qms (Q value of the main fs resonance in free air with temrinals open) and this affects Qts which is the Q value when the terminals are shortted (eg by an amplifier) - agin in free air. Qts is the ratio of sensitivity at fs to the sensitivity at the midband. In conclusion, Qts is normally completely dominated by the electrical damping (Qms>>Qes) so Rms influence on Qts and thus sensitivity at fs is small. Moreover, Rms does not affect the midband sensitivity at all, only around fs.

Right, my understanding is that Rms peters out at the driver's EDP = Fs/Qes' and T/S theory at its upper mass corner Fhm = 2*Fs/Qts'.

[Qes'/Qts']: [Qes/Qts] + any added series resistance [Rs]: http://www.mh-audio.nl/Calculators/newqts.html

Best for what? Pro sound driver makers may not agree.

I don't need their agreement for it to be true. They use fiberglass and/or aluminium because it's cheap and good enough. Not because it's the best behaved material.

Titanium is strong, light, durable, less prone to eddy current problems, good heatsink for windings.

As spider also contributes to mechanical losses that may be oversimplifying a bit.Why? Those hifi drivers need that "low loss rubber surround", because(of marketing)they are usually low sensitivity due the relative weak motor compared to cone size and moving mass, every 0.1dB counts. 🙂

Otherwise yeah, low loss rubber surround for low mechanical losses combined with a conductive voice coil former that creates eddy currents that manifests as high mechanical resistance (relative low Qms and high Rms) in the T/S parameters, SEAS drivers with alu VC formers as example. Brilliant! 🤓

Where and how the losses are incurred must have an impact on how it effects sound, SB Acoustics are reputable and have advertised that 'low loss surround', I trust there is more to it other than slight difference in sensitivity, where if you take SB10PGC21-4 as an example I'm only seeing below average sensitivity for that size category.

alpair 11ms is a driver that continues to impress me with it's resolving ability, it's standard Qms so tells me suspension design might be a major contributor to perceived distortion in a driver.

You would assume low loss/high Qms means less sound influence from the suspension, which in budget driver may be a good compromise to keep costs down with lesser quality/lower tolerance suspension and distribute those savings elsewhere (motor, cone etc.) .

Last edited:

Titanium former is the best 🙂

^Below its resonance and as a more available material.

^Below its resonance and as a more available material.An exception would be something like a cone midrange that doesn't need a lot of power/excursion - there paper and particularly Nomex paper is preferable. This is because the former as a tube has resonances of its own, and paper is usually a better material for mechanical damping. IF the driver needs long-term higher power then venting typically becomes an issue as most midranges are sealed enclosures: the result is that the better design is with *forward venting with a typical phase plug. Often these sorts of designs are best with a diaphragm that has more of an "exponential flare".

*

https://www.decware.com/HDT/phaseplug.gif

Dome midranges and tweeters having little depth/length to their formers (less of a "tube" structure with very little resonance) are almost always better with Titanium.

I suppose a Beryllium alloy (non-brittle) would be better still (with a high percentage of Be), but I've not seen anything like that for a former (..and even Titanium/alloy's are pretty rare for formers).

Last edited:

Most of the mechanical losses (woofer) are from the Spider, not the Surround in a traditional design.As spider also contributes to mechanical losses that may be oversimplifying a bit.

My guess is that most of the mechanical losses near "rest"/no-excursion are from the surround:Where and how the losses are incurred must have an impact on how it effects sound

..as-in that sub mm excursion range for a standard woofer.

Inverted roll surrounds tend to have lower mechanical losses and less cone damping (..though they also allow for greater problems with both linearity and non-linearity).

The reason for low Qms is that "all"the manufacturers are using aluminium as material for voice coil former. Aluminium is not a good material for formers as the lenz effect will act as a "brake" and thus will make Qms lower! It is just easier to make a more durable voice coil out of aluminum! Some was talkin about Be as a material for voice coil former and I suspect that Be will be very poor as Be is a fairly good conductor! Nomex, kraft paper, kapton, fiberglass and titanium is by far better material for voice coil.

There are several reasons for using Aluminum for the former (thermal dissipation, *strength vs. size vs. weight, etc. - "weighted" against cost).

*in particular you want a very thin former so that the overall thickness of the former + VC can pass-though as narrow a gap in the motor as possible (resulting in better applied force), and you don't want something prone to expansion/contraction (from the VC itself or resulting thermal stress) or torsion stress (from the suspension and modal behavior the cone generates). (..obviously you don't want it "buckling" either.)

A shorting ring (sleeve-type) is fairly effective for reducing Rmd relating to alternating magnetic flux and typically it's seen on the electrical side with lower inductance.

Note that Be in an alloy tends to result in relatively low conductivity, and most Be alloys don't overall have a lot of Be (..a "high" percentage would likely be less than 10% of the alloy though Titanium-Beryllium can go as high as 50-60%, but usually is closer to the 10% formulation - and even then is currently an "exotic" material). If it does result in higher conductivity, back to the shorting-ring sleeve or an "active" fixed counter-wound coil parallel to the former/VC (like the shorting-ring sleeve).

Despite all that, alternating magnetic flux (at least as its effect on the value of Qms) is usually a very low % component to Rmd (Rms in total) - and as a result: a low % component of Qms. However that isn't to say that it's not substantive, but even then I'd look at it's net contribution as a loss in efficiency.

*in particular you want a very thin former so that the overall thickness of the former + VC can pass-though as narrow a gap in the motor as possible (resulting in better applied force), and you don't want something prone to expansion/contraction (from the VC itself or resulting thermal stress) or torsion stress (from the suspension and modal behavior the cone generates). (..obviously you don't want it "buckling" either.)

A shorting ring (sleeve-type) is fairly effective for reducing Rmd relating to alternating magnetic flux and typically it's seen on the electrical side with lower inductance.

Note that Be in an alloy tends to result in relatively low conductivity, and most Be alloys don't overall have a lot of Be (..a "high" percentage would likely be less than 10% of the alloy though Titanium-Beryllium can go as high as 50-60%, but usually is closer to the 10% formulation - and even then is currently an "exotic" material). If it does result in higher conductivity, back to the shorting-ring sleeve or an "active" fixed counter-wound coil parallel to the former/VC (like the shorting-ring sleeve).

Despite all that, alternating magnetic flux (at least as its effect on the value of Qms) is usually a very low % component to Rmd (Rms in total) - and as a result: a low % component of Qms. However that isn't to say that it's not substantive, but even then I'd look at it's net contribution as a loss in efficiency.

Last edited:

Oh... I have been waiting for info like this for years 😀 Are you saying that - let's say two 8" woofers - with one having Qms of 1 and another maybe 5. That this is dominating at fs and actually means nothing at around 100-500hz?Rms determines the Qms (Q value of the main fs resonance in free air with temrinals open) and this affects Qts which is the Q value when the terminals are shortted (eg by an amplifier) - agin in free air. Qts is the ratio of sensitivity at fs to the sensitivity at the midband. In conclusion, Qts is normally completely dominated by the electrical damping (Qms>>Qes) so Rms influence on Qts and thus sensitivity at fs is small. Moreover, Rms does not affect the midband sensitivity at all, only around fs.

Because I have been tumbling the thought for way to long, that a driver with lower Qms might have higher losses, and therefore sounded less detailed at higher frequencies than a driver with higher Qms and therefore lower losses.

But in reality it's way more about performance, much closer to resonance?

I think the real question should be "What kind of non-linear damping leads to loss of detail?"

We know that any quantization effect will cause loss detail in small signals, including quantum mechanics(fortunately we are don't care the SPL around Planck constant levels?) Joking aside, Barkhausen effect is probably real in audio drivers. But is it a kind of damping or loss? And I'm pretty sure it has nothing to do with RMS or Qms.

Sliding of atomics leads to loss. But basic Mechanics of Materials tells us at low levels, materials behave linearly, only transition to non-linear range(yield) at higher stress. Does that mean, Stress–strain curve related non-linear will not cause loss of detail, but actually helps preserve small signals?

Then there's mechanical hysteresis. Is there any relationship between hysteresis and loss of detail in small signals? Or, does it actually amplify small signals by means of higher distortion at small levels?

We know that any quantization effect will cause loss detail in small signals, including quantum mechanics(fortunately we are don't care the SPL around Planck constant levels?) Joking aside, Barkhausen effect is probably real in audio drivers. But is it a kind of damping or loss? And I'm pretty sure it has nothing to do with RMS or Qms.

Sliding of atomics leads to loss. But basic Mechanics of Materials tells us at low levels, materials behave linearly, only transition to non-linear range(yield) at higher stress. Does that mean, Stress–strain curve related non-linear will not cause loss of detail, but actually helps preserve small signals?

Then there's mechanical hysteresis. Is there any relationship between hysteresis and loss of detail in small signals? Or, does it actually amplify small signals by means of higher distortion at small levels?

Member

Joined 2003

If the focus is just on Qms alone as a value, I would think the answer is yes, however the reason for change in Qms would generally be differing voice coil former material which affects other things being discussed here, eddy currents, thermal dissipation, size of magnetic gap, other resonances… more than just a singular Qms value. It’s hard to say that a change in voice coil former material has no effect beyond Qms.Oh... I have been waiting for info like this for years 😀 Are you saying that - let's say two 8" woofers - with one having Qms of 1 and another maybe 5. That this is dominating at fs and actually means nothing at around 100-500hz?

Wavecor for example specifically avoids aluminum voice coil former and as a result Qms is high on all their drivers. I recall some explanation somewhere in their tech documentation that the reason is simply “it sounds better”, maybe just marketing though 😉

Titanium is a wonderful material, as a metal though it is a rather poor thermal conductor, but still probably a fair bit better than fibreglass or kapton.

A pair of RS225 are around 20% cheaper than a pair of WF223, but again - does that mean better sound, or are we mostly just fiddling with tiny details here?

In my case, I'm still looking mostly at the 100-500Hz range - going 4 way.

In my case, I'm still looking mostly at the 100-500Hz range - going 4 way.

Member

Joined 2003

Well, there is every other aspect of the driver to consider beyond the voice coil former material...

Sometimes it feels like I'm hunting a minor technical detail, that might not mean that much in practical terms.Well, there is every other aspect of the driver to consider beyond the voice coil former material...

I run fully active, have lots of power, use subwoofers, like closed boxes, prefer sleek clean looks, and preferably not too big a box. I actually do not have a preferred cone material for woofers - though metal seems logical for cooling of the voice coil and piston-like motion.

Yes I think you are hunting for minor details.Sometimes it feels like I'm hunting a minor technical detail, that might not mean that much in practical terms.

I run fully active, have lots of power, use subwoofers, like closed boxes, prefer sleek clean looks, and preferably not too big a box. I actually do not have a preferred cone material for woofers - though metal seems logical for cooling of the voice coil and piston-like motion.

I've heard very good drivers with high and low QMS. I think cone material and other aspects(linear BL, inductance, surrond, construction details) all have bigger influence than QMS. For example, Audience A3 is a very low QMS driver with ALU former, close to 1.0, but it has very good BL and inductance, ventilation, and cone design. Actually I consider it as one of my best 3 inch fullrange driver. Stereophile also praise it for its midrange and HF clarity(https://www.stereophile.com/content/audience-clairaudient-one-loudspeaker).

Overall WF223 seems to be a better driver than RS225, but not because of QMS alone.

So.... What makes the wavecor better than the Dayton - besides Qms?Yes I think you are hunting for minor details.

I've heard very good drivers with high and low QMS. I think cone material and other aspects(linear BL, inductance, surrond, construction details) all have bigger influence than QMS. For example, Audience A3 is a very low QMS driver with ALU former, close to 1.0, but it has very good BL and inductance, ventilation, and cone design. Actually I consider it as one of my best 3 inch fullrange driver. Stereophile also praise it for its midrange and HF clarity(https://www.stereophile.com/content/audience-clairaudient-one-loudspeaker).

Overall WF223 seems to be a better driver than RS225, but not because of QMS alone.

Lower and more linear inductance(dual shorting devices) lower midrange distortion, better ventilation under spider, seems better suspension parts, in general better build quality.So.... What makes the wavecor better than the Dayton - besides Qms?

But I guess as you are focus on lower frequencies, RS225 has much better value and maybe works just as well.

If you are really bothered by QMS, you should take a look at SB23NBACS45 or SB23NRXS45. The paper cone works as piston under 400hz as well, and is cheaper.

Last edited:

Hmm, a point source driver is normally pistonic from Fs - VC diameter or dust cap diameter frequency, whichever is larger with its normal TL modes (can be visible cone flexing) up to the dust cap's breakup modes (HF 'hash'), so you're saying it's so 'limp' it begins uncontrolled distorting at only ~400 Hz?

If you play with Finecone you can see most cones start "flexing" in much lower frequencies than people normally thinks by looking at impedance or frequency response.Hmm, a point source driver is normally pistonic from Fs - VC diameter or dust cap diameter frequency, whichever is larger with its normal TL modes (can be visible cone flexing) up to the dust cap's breakup modes (HF 'hash'), so you're saying it's so 'limp' it begins uncontrolled distorting at only ~400 Hz?

For paper cone, sometimes you can see a sharp increase of 2nd order distortion in much lower frequency. But the "flexing" in still in phase, so you won't see a dip in frequency response just yet.

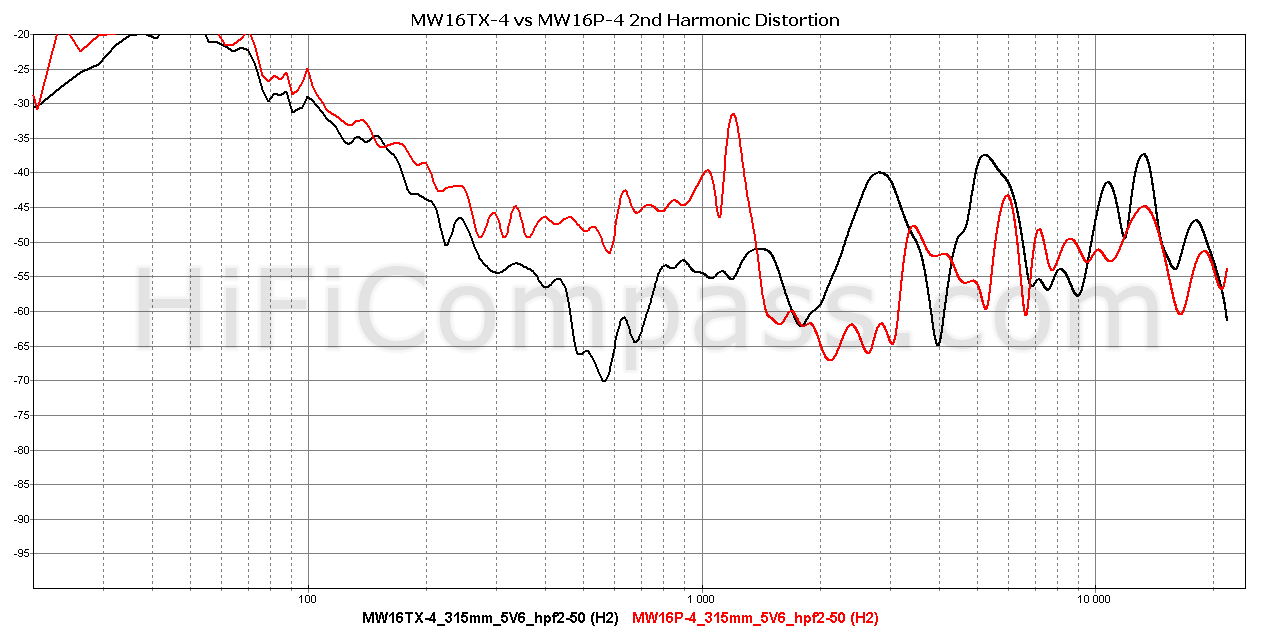

For example, compare MW16p and MW16TX with the same motor:

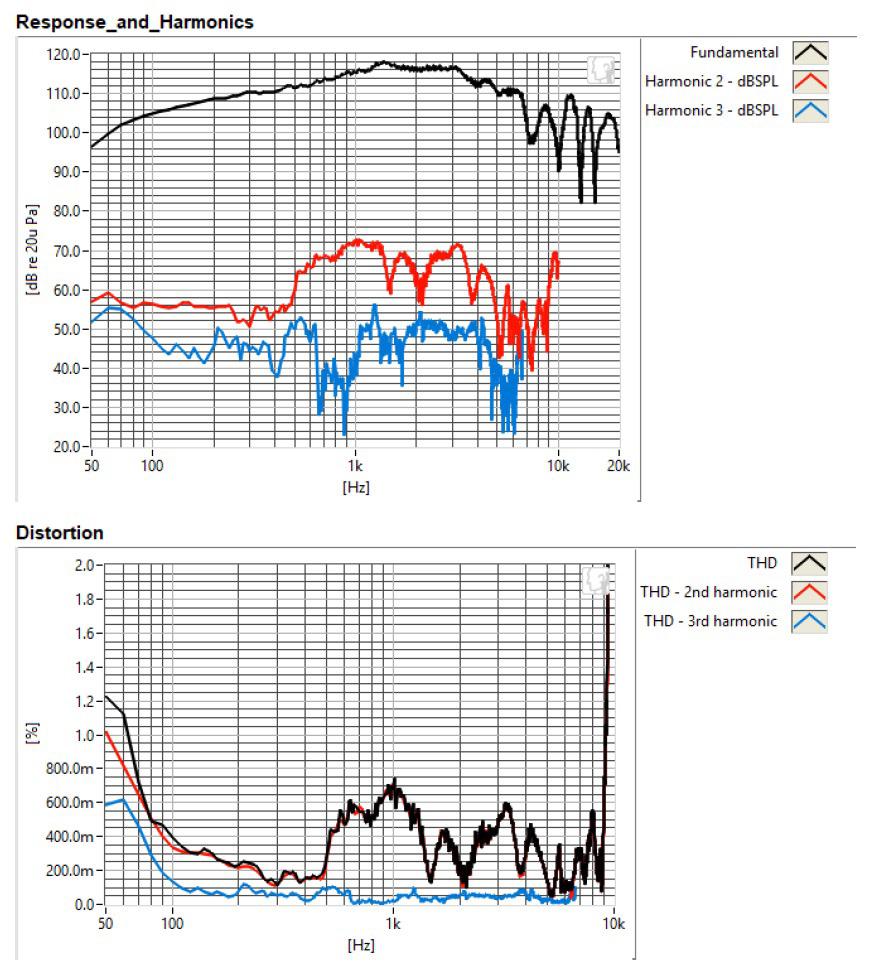

And for scanspeak 18we, you can see 2nd order distortion starts at about ~500hz, which clearly is not motor related distortion.

The same can be found if you compare distortion profile for SB23NBACS45 against SB23NRXS45 on hificompass.

- Home

- Loudspeakers

- Multi-Way

- The significance of high Qms..?