Hi Ed,

Parts arrived today. Thanks for the quick turnaround and excellent packing!

Cheers,

Owen

Parts arrived today. Thanks for the quick turnaround and excellent packing!

Cheers,

Owen

I am going to purchase a piece of 3/16" X 1/2" 6061 aluminum and attempt to make some heat spreaders to use along with flat-back heat sinks.

I'm going to try to use a flat bed sander to remove ~0.006-7" from the bar stock to match the thickness of the buffers.

If that is successful I'll make a jig to cut a rebate (lap) onto one edge of the prepared stock.

If all that is OK I'll drill and tap some holes. I'll have enough stock to make more. I need a proof of concept first. I'll keep you informed.

What are your thoughts for positioning of thermal insulators?

What are the particular surfaces which MUST be electrically isolated?

How will you dress the solder connection of the 49600 tab to the PCB?...I'm guessing that I don't want any goobers there.

I'm going to try to use a flat bed sander to remove ~0.006-7" from the bar stock to match the thickness of the buffers.

If that is successful I'll make a jig to cut a rebate (lap) onto one edge of the prepared stock.

If all that is OK I'll drill and tap some holes. I'll have enough stock to make more. I need a proof of concept first. I'll keep you informed.

What are your thoughts for positioning of thermal insulators?

What are the particular surfaces which MUST be electrically isolated?

How will you dress the solder connection of the 49600 tab to the PCB?...I'm guessing that I don't want any goobers there.

Last edited:

Ed,

I know we've all had a few discussions about heatsinks already, now spread over both threads and many months, but after working it through over email, qusp and I came to the conclusion that heatspreaders underneath the pcb and attached to an enclosure would probably be the ultimate solution. I think this is a variation on one of your earlier suggestions.

I've attached a model that I drew when thinking up ideas for a custom floor that was going to be made by hypertune but is on hold till we find out exactly what's going on there. I believe a similar result could be had with aluminium bars, that is essentially the backup plan that qusp and I have.

I have dimensions for the attached diagram, though the mounting holes are more diagramatic in their location everything else should fit and has space allowance for the components mounted to underside of the pcb.

Thought I'd share it and see if it helps with any alternative ideas you come up with. It's been frustrating experience so far and qusp, opc and I have all invested significant effort in trying organise to get hypertune over the line with this and we've had no joy so far.

If you go through with any order of 6061, let qusp and I know as it seems likely we'll place an order with onlinemetals in the near future so I think we may be interested in adding to your order if that is possible or convenient.

Cheers,

Chris

I know we've all had a few discussions about heatsinks already, now spread over both threads and many months, but after working it through over email, qusp and I came to the conclusion that heatspreaders underneath the pcb and attached to an enclosure would probably be the ultimate solution. I think this is a variation on one of your earlier suggestions.

I've attached a model that I drew when thinking up ideas for a custom floor that was going to be made by hypertune but is on hold till we find out exactly what's going on there. I believe a similar result could be had with aluminium bars, that is essentially the backup plan that qusp and I have.

I have dimensions for the attached diagram, though the mounting holes are more diagramatic in their location everything else should fit and has space allowance for the components mounted to underside of the pcb.

Thought I'd share it and see if it helps with any alternative ideas you come up with. It's been frustrating experience so far and qusp, opc and I have all invested significant effort in trying organise to get hypertune over the line with this and we've had no joy so far.

If you go through with any order of 6061, let qusp and I know as it seems likely we'll place an order with onlinemetals in the near future so I think we may be interested in adding to your order if that is possible or convenient.

Cheers,

Chris

Attachments

Last edited:

Chris, Your approach kicks my analysis back in gear with my first cup of coffee. 😉

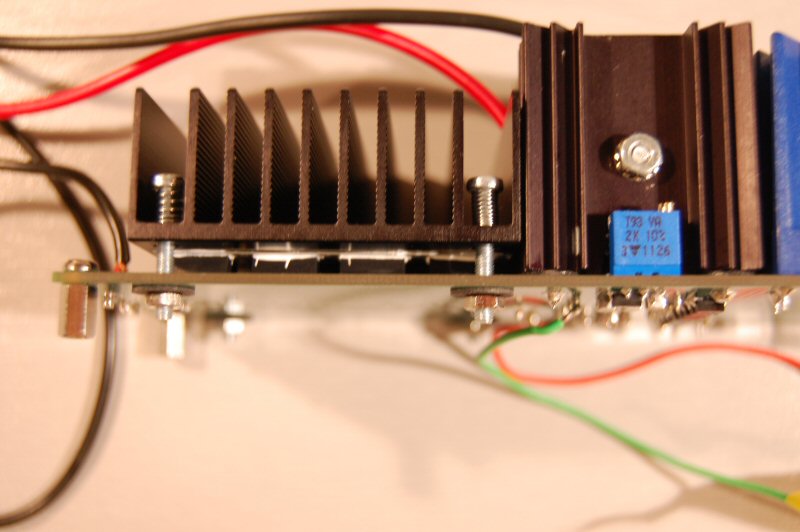

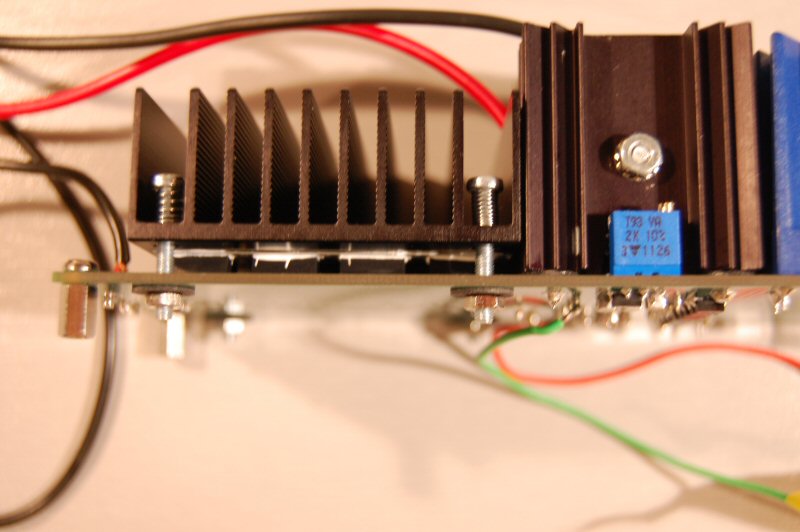

Over in the other thread, exa065 provided a view of his solution in post #444:

I share this to aid in our discussion. Help me work through my speculation to assure us all that I understand. 😉

My thoughts in my last post have the sink positioned just as exa065 does.

The bars I posted on above would obscure from view the ends of the buffers in exa065's photo.

I have obtained this enclosure from Fair Radio that I described over there in post #152:

My plan was to vent the enclosure and rely upon convection for cooling. Your approach would allow me to capitalize upon the ribbed section of my enclosure and dispense with internal buffer sinks.

Your below board schema have 4 areas of contact: 1 under each row of buffers, 1 under the op-amps and 1 under the transformer. I like your approach.

I was going to order aluminum stock this morning. That is now on hold for further discussion. 😉

Do I understand?

Over in the other thread, exa065 provided a view of his solution in post #444:

I share this to aid in our discussion. Help me work through my speculation to assure us all that I understand. 😉

My thoughts in my last post have the sink positioned just as exa065 does.

The bars I posted on above would obscure from view the ends of the buffers in exa065's photo.

I have obtained this enclosure from Fair Radio that I described over there in post #152:

An externally hosted image should be here but it was not working when we last tested it.

My plan was to vent the enclosure and rely upon convection for cooling. Your approach would allow me to capitalize upon the ribbed section of my enclosure and dispense with internal buffer sinks.

Your below board schema have 4 areas of contact: 1 under each row of buffers, 1 under the op-amps and 1 under the transformer. I like your approach.

I was going to order aluminum stock this morning. That is now on hold for further discussion. 😉

Do I understand?

Your below board schema have 4 areas of contact: 1 under each row of buffers, 1 under the op-amps and 1 under the transformer. I like your approach.

Do I understand?

You've got it perfectly Ed!

The idea was driven to try to avoid ventilation being necessary for the buffer heatsink and to minimise enclosure size/height (enclosure becomes the heatsink like you've said) since we're still doggedly marching down the path of the mini-block!

Without having it machined from a single block I am not sure how to secure the bar for the opamps in place other than to rely on friction. Any ideas?

You're having your first coffee and my head is overdue for a meeting with my pillow!

Sweet dreams! 😀

Note the data sheet gives a range of thicknesses. Direct measure of one of the LME49990 is 0.063". I think this is suitably close to 1/16" to allow heat sink compound to fill the gaps.

Select stock where the difference in thickness is equal to the thickness of the op-amps.

For registration I would extend the op-amp spreader to engage to outermost corner holes of the board.

Relief would have to be provided so the op-amp spreader and the buffer spreaders don't foul one another.

This becomes a simpler install than the fiddling I was going to do.

What stock do you want? How can I help? Are we having fun yet?

https://www.speedymetals.com/c-8351-6061.aspx

That is a link I had chosen to secure the goods.

Note the data sheet gives a range of thicknesses. Direct measure of one of the LME49990 is 0.063". I think this is suitably close to 1/16" to allow heat sink compound to fill the gaps.

Select stock where the difference in thickness is equal to the thickness of the op-amps.

For registration I would extend the op-amp spreader to engage to outermost corner holes of the board.

Relief would have to be provided so the op-amp spreader and the buffer spreaders don't foul one another.

This becomes a simpler install than the fiddling I was going to do.

What stock do you want? How can I help? Are we having fun yet?

https://www.speedymetals.com/c-8351-6061.aspx

That is a link I had chosen to secure the goods.

Last edited:

indeed if building your own, bottom is the way to go, I found its hotter under the board too as the heat from the buffers and the VAS is under there. that was our thinking, heat would be sunk to an external surface so ventilation in the case was not a factor.

it also means the amp is more easily tested under full load, with full access to the top of the board for probing, more room in the enclosure for neat layout, wire routing or other components and as you say a much easier install, just screw it down, done.

it also means the amp is more easily tested under full load, with full access to the top of the board for probing, more room in the enclosure for neat layout, wire routing or other components and as you say a much easier install, just screw it down, done.

Attachments

Last edited:

My guess at the moment is inside next 12 - 24hrs we'd let you know either way. We've tried again today to get in touch with Mark, I haven't heard how qusp has gone with that.

That lapses into the weekend here. Let's say 60 hours from now. That is into my Sunday evening. I could get material moving towards me on Monday.

qusp, I understand how this has the shipment of passives tied up. I remain willing to foot the bill for shipment of mine to me at any time.

qusp, I understand how this has the shipment of passives tied up. I remain willing to foot the bill for shipment of mine to me at any time.

if you guys have a proper cad file, can you post it? I wouldn't mind seeing what sort of quotes I can get from local machine shops.

nah just Maya and its not finished as i've been unwilling to spend any more time on it till it was definitely going to happen. I could output something they could use if it were, HYPERTUNE has just emailed me back, says he'll run them tomorrow or Monday! so lets see how that pans out, nobody make any purchases for alternatives just yet.

I do have a model for the heatsink hes going to run thats suitable if it comes to that. but nothing final for the floor based one

and Ed. sorry i'm not making any special trips to the post office for single people, that would be unfair and I havent actually bought all the satchels yet. it'll be shipping next week regardless and i'll grab some satchels on monday or tuesday when I do my next postal run for my business.

I do have a model for the heatsink hes going to run thats suitable if it comes to that. but nothing final for the floor based one

and Ed. sorry i'm not making any special trips to the post office for single people, that would be unfair and I havent actually bought all the satchels yet. it'll be shipping next week regardless and i'll grab some satchels on monday or tuesday when I do my next postal run for my business.

Last edited:

I guess I'm cautiously optimistic now? 😛

you said it😀

it does seem as hes back on the case, as the email Mark replied to, I only actually sent today. we do need to keep in mind this is a favor to the group, I think everyone is aware of that. easy to lose sight of that fact and the fact this is supposed to be a hobby sometimes; as its a hobby thats so closely tied to emotional release/music

Last edited:

Do you have a cost for the piece to be run by Hypertune?

Is this the same as posted by hochopeper above in post #364?

Is the list closed for participation?

Is this the same as posted by hochopeper above in post #364?

Is the list closed for participation?

I cant remember, nothing has changed since you opted out. i'm just collecting money, it has nought to do with meDo you have a cost for the piece to be run by Hypertune?

no, not that i'm aware of, though he did do something similar early in the piece and he may run with that now that i've made the suggestion. that is a design weve been working on for the floor of our custom cases, nothing to do with the group, we only posted it to help you guys with some ideas.Is this the same as posted by hochopeper above in post #364?

it is what it is at this stage, not a chance i'm going to interrupt the process to suggest improvements. it may be something similar but without the opamp part (though I have made this suggestion) or it may be basically what you were planning but with the threaded holes tapped exactly and including the bars down the sides contacting the PCB AND the buffers as one piece

dunno, not sure how many pieces of stock hes cut, but yes the group closed a long time ago and if he hasnt cut enough stock, that will likely be the end of it. i'd say there will be a couple extrasIs the list closed for participation?

ok well i've had a few emails today from Mark, asking final numbers etc so all looks to be going ahead. He had said to me last week he would try to get it done on Saturday or Monday, but seems like he was running it today, most importantly it seems its definitely on the go. was able to Add you Ed. so i'll have news in the following days, I gave him both designs and just said to do what was easiest for him and least costly as far as end mills for the CNC

ok well i've had a few emails today from Mark, asking final numbers etc so all looks to be going ahead. He had said to me last week he would try to get it done on Saturday or Monday, but seems like he was running it today, most importantly it seems its definitely on the go. was able to Add you Ed. so i'll have news in the following days, I gave him both designs and just said to do what was easiest for him and least costly as far as end mills for the CNC

So if there are any extras I would buy one.

Randy

- Status

- Not open for further replies.

- Home

- Group Buys

- The Wire LPUHP 16W Power Amp parts GB

ED

ED