re: AJT

I haven't ever dealt with these special EE type laminations, I just heard about them. Some outfit in NJ, USA made them originally I think. They do normally need a doubly wide back side to the E for the pushed together setup.

I have gotten some longer E lams from Tempel Steel, FR-5731HS/0142 that were intended for constant voltage xfmrs, but they have a normal back side. I do see an EI175L/0182 extra long lamination listed with a thicker back side though. Should work. 1-3/4" wide tongue. A little big maybe.

One problem though, pushing the EEs all the way together will block the bolt holes in these. You will have to use clamps.

For trying to do a SE design with (normal length?) EEs end to end, that would seem to have a problem holding the lams together without bolt holes at the open end. Maybe some clamps somehow. The very long center tongue that way would certainly lower leakage L.

The long EE scheme would seem to make the most sense for P-P though. Since they eliminate butt joints and have a high % of the grain oriented the right way. Like a toroid that can be opened up for a winding bobbin yet no gaps or joints effectively. Maximum permeability this way. Long Es have low leakage L too.

Tempel sent me a 50 lb box sample a number of years ago, don't know if they would do that now or especially overseas.

I haven't ever dealt with these special EE type laminations, I just heard about them. Some outfit in NJ, USA made them originally I think. They do normally need a doubly wide back side to the E for the pushed together setup.

I have gotten some longer E lams from Tempel Steel, FR-5731HS/0142 that were intended for constant voltage xfmrs, but they have a normal back side. I do see an EI175L/0182 extra long lamination listed with a thicker back side though. Should work. 1-3/4" wide tongue. A little big maybe.

One problem though, pushing the EEs all the way together will block the bolt holes in these. You will have to use clamps.

For trying to do a SE design with (normal length?) EEs end to end, that would seem to have a problem holding the lams together without bolt holes at the open end. Maybe some clamps somehow. The very long center tongue that way would certainly lower leakage L.

The long EE scheme would seem to make the most sense for P-P though. Since they eliminate butt joints and have a high % of the grain oriented the right way. Like a toroid that can be opened up for a winding bobbin yet no gaps or joints effectively. Maximum permeability this way. Long Es have low leakage L too.

Tempel sent me a 50 lb box sample a number of years ago, don't know if they would do that now or especially overseas.

Last edited:

Read the fine print for Plitron, very little tolerance for DC offsets. My 2 cents on that.

The McIntosh is really not terribly complex if you go to the basic circuit as used in the 50W-2 or the MC-30, interstage transformer coupled and capacitively coupled respectively.

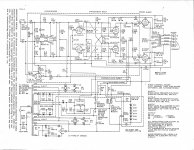

Compare to the Audio Research shown below!

The McIntosh is really not terribly complex if you go to the basic circuit as used in the 50W-2 or the MC-30, interstage transformer coupled and capacitively coupled respectively.

Compare to the Audio Research shown below!

Attachments

re: AJT

I haven't ever dealt with these special EE type laminations, I just heard about them. Some outfit in NJ, USA made them originally I think. They do normally need a doubly wide back side to the E.

I have gotten some longer E lams from Tempel Steel, FR-5731HS/0142 that were intended for constant voltage xfmrs, but they have a normal back side. I do see an EI175L/0182 extra long lamination listed with a thicker back side though. Should work. 1-3/4" wide tongue. A little big maybe.

For trying to do a SE design with EEs end to end, that would seem to have a problem holding the lams together without bolt holes at the open end. Maybe some clamps somehow. The very long center tongue that way would certainly lower leakage L.

The EE scheme would seem to make the most sense for P-P though. Since they eliminate butt joints and have a high % of the grain oriented the right way. Much like a toroid that can be opened up for a winding bobbin yet no gaps or joints effectively. Maximum permeability this way. Long Es have low leakage L too.

Tempel sent me a 50 lb box sample a number of years ago, don't know if they would do that now or especially overseas.

smoking-amp, i was thinking scrap-less lams, low leakage flux can be a motivator to proceed.....i was also considering cutting off about 6 mm on the open end of the lams so i can stack them like an EI, but no shop here would like to do it for me...

i wished i was on your side of the pond, access to materials surely helps me to try working on some ideas....

I'm not real sure about the lower leakage L with a gap in the center between the EEs. Low leakage comes from making the air path really long, so that the steel path is more attractive. But with the air gap in the center, the flux can escape easily at the mid-point. So this is probably not a good criteria for using the EE for SE design. One would definitely want to put active primary on both halves at the very least, to encourage the flux to go the full way around.

I think I may look into the extra long Es for making an EE P-P design though, that looks like a really attractive alternative to toroids. One can get two standard bobbins on the center as well, for doing balanced winding designs.

I think laminations get thermally annealed after being cut to avoid stress in the material from affecting the magnetic properties (and to oxidise the surfaces). Cutting them up is probably counter productive. Although maybe wouldn't matter for a SE with a gap anyway.

Hmm, I just realized a curious alternative way to do these merged EE cores. If you put the usual I lams at the back side of the long E's (butt joined extension), then push the long Es together until the legs cover both the normal E back and the I piece. You get a correctly aligned grain direction in the I lam as a benefit and it doubles the back side too. All it takes are normal long Es. No flux crossing the butt joint still. It will probably shorten up the bobbin area to a normal bobbin though. Well, I might as well just order some that are made correctly with double thick backs I guess, seeing as they have them available.

I think I may look into the extra long Es for making an EE P-P design though, that looks like a really attractive alternative to toroids. One can get two standard bobbins on the center as well, for doing balanced winding designs.

I think laminations get thermally annealed after being cut to avoid stress in the material from affecting the magnetic properties (and to oxidise the surfaces). Cutting them up is probably counter productive. Although maybe wouldn't matter for a SE with a gap anyway.

Hmm, I just realized a curious alternative way to do these merged EE cores. If you put the usual I lams at the back side of the long E's (butt joined extension), then push the long Es together until the legs cover both the normal E back and the I piece. You get a correctly aligned grain direction in the I lam as a benefit and it doubles the back side too. All it takes are normal long Es. No flux crossing the butt joint still. It will probably shorten up the bobbin area to a normal bobbin though. Well, I might as well just order some that are made correctly with double thick backs I guess, seeing as they have them available.

Last edited:

Hmm, I just realized a curious alternative way to do these merged EE cores. If you put the usual I lams at the back side of the long E's (butt joined extension), then push the long Es together until the legs cover both the normal E back and the I piece. You get a correctly aligned grain direction in the I lam as a benefit and it doubles the back side too. All it takes are normal long Es. No flux crossing the butt joint still. It will probably shorten up the bobbin area to a normal bobbin though. Well, I might as well just order some that are made correctly with double thick backs I guess, seeing as they have them available.

If I understand you correctly, that's exactly the idea behind MD laminations (click for a German manufacturer's catalogue, then scroll to page 60).

Best regards!

Marantz 8/9 are better than Mac, and it dont have the +60yo marketing compaign.I've never had the chance to listen to any vintage McIntosh stuff but everyone/everywhere seems to rave about them. I have heard some of their newer stuff and really loved it, but its just WAY out of my price range.

So what makes their old tube stuff so sought after? Other than the fact that I think their stuff is cool looking, is there something special/unique about their designs? Are their any clones/schematics available for the DIYer to recreate "the magic?"

Love to hear your thoughts.

Mac tube circuits has too many parts to get the McIntosh sound w/any unquality tubes.

Last edited:

MD Laminations page 60? (back cover?)

Here is an example (although a rather large size lamination) page 24:

http://www.tempel.com/images/uploads/documents_pdfs/TempelTransformerCatalogue.pdf

One wouldn't use the I lams, just push the extra long E lams all the way together. The doubly thick back to the E handles magnetic flux for two lams. No butt joints without the I lams, so no kink in the permeablity curve versus Bflux like for the usual E-I setup. (So effectively close to a toroid.)

Here is an example (although a rather large size lamination) page 24:

http://www.tempel.com/images/uploads/documents_pdfs/TempelTransformerCatalogue.pdf

One wouldn't use the I lams, just push the extra long E lams all the way together. The doubly thick back to the E handles magnetic flux for two lams. No butt joints without the I lams, so no kink in the permeablity curve versus Bflux like for the usual E-I setup. (So effectively close to a toroid.)

Last edited:

If I understand you correctly, that's exactly the idea behind MD laminations (click for a German manufacturer's catalogue, then scroll to page 60).

Best regards!

page 60 is the back seite, the last page...perhaps another page?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- What makes the old McIntosh stuff so good?