I only use 600v Teflon solid core wire. Why? Because I don’t have to worry about if my wire is good enough to carry whatever voltage it will see in a normal tube amp. You can get it cheap from ApexJr on the bay. 20 gauge is good enough for most stuff in a tube amp. 18ga on heater wiring is fine.

25$USD for 100 feet is not cheap IMHO... Last wire I bought was 600V PVC covered and I paid 68$CAD (now 99.95$CAD) for 1000 feet of #22 solid (no reason for #20 - #22 can handle 7 amperes in a chassis). Teflon is great for frying pans and trunk wiring looms, but it's pointless in a stationary chassis IMHO.

I also use #22 for heaters except in unique circumstances where I need to run 10+ amperes.

I also use #22 for heaters except in unique circumstances where I need to run 10+ amperes.

It’s mil spec silver plated copper wire that doesn’t burn or chafe easily. PVC dries out and cracks under long term heat exposure. Compared to retail it is less than half priced. He has lots of colors and gauges in both solid and stranded. You can buy 10 feet if you want and don’t need 1000 feet which makes good sense if you have no need for all that wire. When you buy 1000 feet it is all one color, if you need four colors you are talking serious money. So, yes it is cheaper per foot of your wire but to build one amp it is not economical.

I buy red and black by 1000ft spool, Grey, green, yellow, blue, purple, orange, white, and brown in 100ft spools (10$CAD)

Buying that much silver plated teflon covered wire would cost more than it's worth. I could literally build an entire tube amp for less than the cost of just those spools, too.

Frankly, in most amplifiers, you could use steel wire and not notice a difference, so silver plated teflon coated wire is a boutique item like Mundorf caps or other exotic audiophile parts...

Sure PVC dries over time, but unless you bend it, it doesn't break the insulation anyway.

Just my 0.02$ 🙂 To each their own, right?

Buying that much silver plated teflon covered wire would cost more than it's worth. I could literally build an entire tube amp for less than the cost of just those spools, too.

Frankly, in most amplifiers, you could use steel wire and not notice a difference, so silver plated teflon coated wire is a boutique item like Mundorf caps or other exotic audiophile parts...

Sure PVC dries over time, but unless you bend it, it doesn't break the insulation anyway.

Just my 0.02$ 🙂 To each their own, right?

That Teflon coated stuff is an S.O.B to strip if the proper tool isn’t right there in your hand. If you nick that silver plated wire at all it will break right off so you can’t fake the right tool either. Now where did it go? It was right here a second ago….

He then proceeds to grab a piece of THHN and strip it with his teeth…. That fancy Klein stripper tool will turn up in about a week.

He then proceeds to grab a piece of THHN and strip it with his teeth…. That fancy Klein stripper tool will turn up in about a week.

After 60 yrs the screws that hold mine together finally wore out.That fancy Klein stripper tool will turn up in about a week.

I spent my weekly allowance to get another! 😀

FWIW, my first 3 projects all used 500+ volts with wire rated for 60 volts... Never had an arc or any other issue. YMMV of course.

Best answer so far IMHO. 🙂

I imagine that the insulation voltage ratings used are for wire that may be handled regularly - not due to a risk of arcing inside a grounded chassis on a short run. There is no way the Chinese wiring in this kit would ever be rated for 350 volts if produced by a US manufacturer and subjected to UL testing. It's very thin PVC, much thinner than any on my scrap wire.

Last edited:

All the wire I use has no voltage rating, never had an issue. Bog standard PVC must be good for a few 1000 volts, I'd be very surprised if it broke down at 4-500v. Wiring that has a voltage rating also needs a testing regime and test gear. As most wire is used in low voltage applications it doesn't pay a manufacturer to test and rate wire to a HV standard, so, most of it is unmarked/rated.

Also your average valve amp is low current with short runs of wire, not much chance of an arc at 300 - 400v unless your using lots of capacitance. Heater wiring is often less than a foot or 30cm long, there's not the resistance to effect things much unless your powering multiple OP valves, then wiring can drop the voltage a tad.

For peace of mind buy some decent wire or ATX PC power supply's often have 300v rated wire and can supply enough wire to wire an amp. Washing machines are often a good source of quality copper wire.

Andy.

Also your average valve amp is low current with short runs of wire, not much chance of an arc at 300 - 400v unless your using lots of capacitance. Heater wiring is often less than a foot or 30cm long, there's not the resistance to effect things much unless your powering multiple OP valves, then wiring can drop the voltage a tad.

For peace of mind buy some decent wire or ATX PC power supply's often have 300v rated wire and can supply enough wire to wire an amp. Washing machines are often a good source of quality copper wire.

Andy.

I have lots of wire that I have removed from various sources that actually is rated 300V and I'm going to make use of it. The extra 50V - 100V involved can't be that big a deal.

A coat of paint will stop 300V.

The main risk is handling damage. You want lots of plastic so nicks don't go through. The next risk in house, industrial, and heavy equipment wiring is old age, though PVC suffers less than our old friend Cheap Rubber. That's why you pay for 300V or 600V testing.

Also the 300V covers conductors in the same cable or conduit. The majority of audio chassis wiring hardly touches. (If you like tight lashings, allow for that.)

I sure do not understand buying cheap kit with cheap wire, tubes, switches, capacitors, transformers..... and then replacing most of it. Why not pure DIY from known reputable makers?

The main risk is handling damage. You want lots of plastic so nicks don't go through. The next risk in house, industrial, and heavy equipment wiring is old age, though PVC suffers less than our old friend Cheap Rubber. That's why you pay for 300V or 600V testing.

Also the 300V covers conductors in the same cable or conduit. The majority of audio chassis wiring hardly touches. (If you like tight lashings, allow for that.)

I sure do not understand buying cheap kit with cheap wire, tubes, switches, capacitors, transformers..... and then replacing most of it. Why not pure DIY from known reputable makers?

When I was boy (now 53) there was at home a TV set full tube except by silicon rectifiers (The well common Adda Wells Gardner circuit). It had a 17" CRT and a plastic cabinet that in summer time it get very hot mostly on top. The set lasted more than 35 years running 8/10 hours diarily. It was wired with PVC wires of common size except done for fly back, horizontal yoke and obviously the anode of CRT. Never had problem with the wiring at all this time. The only serious issue was a burned power transformer and a shorted capacitor at the horizontal yoke return.

I sure do not understand buying cheap kit with cheap wire, tubes, switches, capacitors, transformers..... and then replacing most of it. Why not pure DIY from known reputable makers?

- The parts actually are high quality, backed up by xraytonyb and his oscilliscope tests, so the vast majority will NOT be replaced

- Novice knowledge and experience make a kit-in-a-box easier

- Lack of time and effort to track down parts from everywhere- all in one box

- "Reputable" = 4x the price

- Other factors

PVC dries out and cracks under long term heat exposure.

I'll be dead by then and the amp will be in a landfill.

Mmm, I must be the only one regularly finding cracked PVC wires in devices. It seems to be more of an issue with not too old devices though so probably it is a side issue for free when having stuff produced far far away.

Endorsing underrated wire is not the wisest thing one can advise to fellow members. It is plain stupid and unsafe, certainly with HV DC. If ones goal in life is to make stuff as cheap as possible then so be it but we should advise safe practices, not "how can we get away with it?". What is gained by "getting away with it" exactly?

Please take pride in the quality device you will build!

Endorsing underrated wire is not the wisest thing one can advise to fellow members. It is plain stupid and unsafe, certainly with HV DC. If ones goal in life is to make stuff as cheap as possible then so be it but we should advise safe practices, not "how can we get away with it?". What is gained by "getting away with it" exactly?

Please take pride in the quality device you will build!

Last edited:

There's no "HV DC" in any tube amp I've ever seen - 750VDC and under is considered "low voltage".

Most HVDC links use voltages between 100 kV and 800 kV.

Pedentry, perhaps... But I generally go by industrial standards...

The International Electrotechnical Commission (IEC) Standard IEC 61140:2016 defines Low voltage as 0 to 1000 V AC RMS or 0 to 1500 V DC[1] Other standards such as IEC 60038 defines supply system low voltage as voltage in the range 50 to 1000 V AC or 120 to 1500 V DC in IEC Standard Voltages[2] which defines power distribution system voltages around the world.

In electrical power systems low voltage most commonly refers to the mains voltages as used by domestic and light industrial and commercial consumers. "Low voltage" in this context still presents a risk of electric shock, but only a minor risk of electric arcs through the air.

Most HVDC links use voltages between 100 kV and 800 kV.

Pedentry, perhaps... But I generally go by industrial standards...

The International Electrotechnical Commission (IEC) Standard IEC 61140:2016 defines Low voltage as 0 to 1000 V AC RMS or 0 to 1500 V DC[1] Other standards such as IEC 60038 defines supply system low voltage as voltage in the range 50 to 1000 V AC or 120 to 1500 V DC in IEC Standard Voltages[2] which defines power distribution system voltages around the world.

In electrical power systems low voltage most commonly refers to the mains voltages as used by domestic and light industrial and commercial consumers. "Low voltage" in this context still presents a risk of electric shock, but only a minor risk of electric arcs through the air.

Circa 1960 I built a 4,5 KV DC Reg Supply, all toobz for a continuous wave Magnetron.

There was up to 6KV on & in this monster. There was a built in SYA function.

The SYA did trip once, the main contactor on the 220V supply contacts had welded closed.

Measuring the inrush later I found 450 Amps.

At Ferranti circa 1956 there was 2MV 7 330KV available for test. No toobz in that tho.

There was up to 6KV on & in this monster. There was a built in SYA function.

The SYA did trip once, the main contactor on the 220V supply contacts had welded closed.

Measuring the inrush later I found 450 Amps.

At Ferranti circa 1956 there was 2MV 7 330KV available for test. No toobz in that tho.

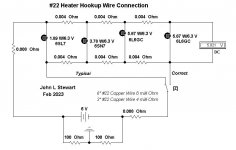

Heater Wiring, Typical & Correct.

This example is something ubiquitous in the 50s, but usually with #18 hookup wire,

Here is what happens with the ordinary, end fed heater potentials operated with #22 wire.

Not much of a problem in this case but would be more so if running an amp with PP 6AS7Gs.

And an even bigger problem for an OTL with a row of 6AS7Gs or 6C33s.

Running the heater supply in to opposite ends helps.

This example is something ubiquitous in the 50s, but usually with #18 hookup wire,

Here is what happens with the ordinary, end fed heater potentials operated with #22 wire.

Not much of a problem in this case but would be more so if running an amp with PP 6AS7Gs.

And an even bigger problem for an OTL with a row of 6AS7Gs or 6C33s.

Running the heater supply in to opposite ends helps.

Attachments

Why take a chance on under or unrated stuff? So to save a few dollars so people can say “he was a great guy, very frugal too!” at your funeral. No one ever says I wish I hadn’t done that the right way. If I’m going through the trouble of building something that I will be proud of doing it on the cheap it not on the list.

properly adjusted Klein strippers cut the Teflon jacket easily for me without knocking the wire. I’ve been doing it for forty plus years.

properly adjusted Klein strippers cut the Teflon jacket easily for me without knocking the wire. I’ve been doing it for forty plus years.

Teflon is for frying pans. No requirement for teflon in an amp. Klein is a rip off IMHO.

There's a difference between "frugal (cheap)" and being smart with your money.

Not only that, I'm absolutely proud that I can build great amplifiers without wasting money. I get a kick out of saying "You paid 2000$ for that? I built mine for 600$!"

Years of 24/7 operation says I'm not lying about the build quality, either 🙂

Yes, I actually use tube amps 24/7 here - along with the television they rarely power off.

There's a difference between "frugal (cheap)" and being smart with your money.

Not only that, I'm absolutely proud that I can build great amplifiers without wasting money. I get a kick out of saying "You paid 2000$ for that? I built mine for 600$!"

Years of 24/7 operation says I'm not lying about the build quality, either 🙂

Yes, I actually use tube amps 24/7 here - along with the television they rarely power off.

You are entitled i your opinion and to use whatever you like. I think differently and feel that using mil spec wire is a safe and smart way to go. Especially when the wire in a complete amp costs less than $5 and is tough enough to go to war! Most people will never use 1000’ in a lifetime, I’ve only built six amps in the past year and dozens overall and still wouldn’t put a dent in that much. My Klein stripper is over 20 and still has sharp edges and cuts cleanly. I use cheap tools only when I have to do so, they don’t last or do a great job. To each their own I guess. And throw away those old teflon pans, they’re dangerous!

- Home

- Amplifiers

- Tubes / Valves

- Wire voltages and wire gauges?