The leading P in PM35AF (Post #222) indicates that the chip is manufactured in China. National doesn't/didn't have a fab in China.

Fresh from Deep Throat (my source in TI):

ICs produced after the TI acquisition of National Semiconductor in 2011 are marked according to the TI marking standard: National Semiconductor logo followed by YMLLLPG3, where the "P" indicates the A/T (Melaka plant A), and "G3" is the level of environmental friendliness of the package. The insolated package will be the same except there will be an "E3" rather than a "G3" as its environmental friendliness level is different.

I've attached a picture of a known genuine National Semiconductor LM3886T of ~2010 vintage. Pardon the image quality. The marking is done with laser - not silk screen.

For those who wish to mince words can use "counterfeit" rather than "fake" if that makes them feel better.

Tom

Ti does have a factory in China:

Texas Instruments News Center - News Releases

Ti does produce silk screen Lm3886:

Tomchr XY bought lm3886 kit #1 - factory number does exist:

PDF form Ti:

http://www.ti.com/lit/an/snoa039c/snoa039c.pdf

PM52AE:

P= wafer plant, China (sub-con)

M= assembly plant, Malacca, Malaysia

52 Y/W = 2015 / week 12-17

AE= The die run code is a two letter alpha code, ranging from AB through ZZ for each device

I thought LM3886 were all made in scotland?

Note found some die information that I didn't know was published (I'm slow ok) http://www.ti.com/lit/ml/snao202/snao202.pdf which shows its a 125mm wafer. Sadly not the process it was built on.

Note found some die information that I didn't know was published (I'm slow ok) http://www.ti.com/lit/ml/snao202/snao202.pdf which shows its a 125mm wafer. Sadly not the process it was built on.

Last edited:

I thought LM3886 were all made in scotland?

Note found some die information that I didn't know was published (I'm slow ok) http://www.ti.com/lit/ml/snao202/snao202.pdf which shows its a 125mm wafer. Sadly not the process it was built on.

And how does that help in the great "Fake" / "Real" debate???

Tom can't explain how there are so many photo's of PM printed NS chips on internet or the one's supplied by reputable sources.

Tom has chosen not to engage in every peeing contest on the Internet. He has work to do and has chosen to engage in more productive and rewarding activities. Interpret as you wish.

Tom

And how does that help in the great "Fake" / "Real" debate???

Well someone seemed to think that the presence of a TI fab in China meant that LM3886 were made there. The press release linked talked about a 200mm line being installed. This means it was not capable of making the LM3886 before you even start to consider the processes. Analog processes can be fiendishly complex*, hard to transfer and if you want to upgrade a fab to a new process it might be cheaper to start again from scratch. There is more but Tom will have forgotten more about NatSemi and TI processes than I ever knew. Safe to say that the LM3886 is VERY unlikely to have had the profitability to dual source, although dies might have been packaged elsewhere than Scotland.

Balance of probabilities, if it doesn't have a 'J' after the logo there is something odd going on. Not necessarily wrong, but certainly odd.

* digital processes are differently fiendish and mindboggling with the cost of mask sets. Margin for error is close to zero.

Assembly (putting dice into packages) and final test were done in East Melaka, Malaysia.

You're spot on with the complexities of processes, both analog and digital. You don't just move a process around or outsource it to others.

The Chinese subcontractor is most likely some generic CMOS plant such as TSMC used by a smaller company that National bought at one point. To keep making the products, they have to either port the products to a National process or keep using the subcontractor. The business case will decide which approach is chosen.

Tom

You're spot on with the complexities of processes, both analog and digital. You don't just move a process around or outsource it to others.

The Chinese subcontractor is most likely some generic CMOS plant such as TSMC used by a smaller company that National bought at one point. To keep making the products, they have to either port the products to a National process or keep using the subcontractor. The business case will decide which approach is chosen.

Tom

Got a new batch of xy kits.

Up and running.

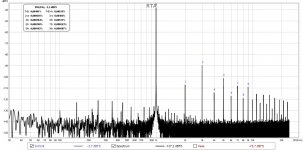

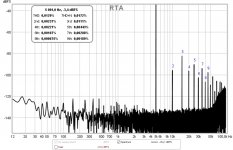

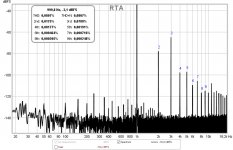

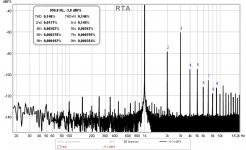

Close to posted thd measurement in this post at 8 ohm at 8 volts rms. 25 volt rails.

As my heatsink is small and insufficient heatpaste I got 0.1 % distortion at 3,5 ohm, 5.7 volts rms.

So heatsink is even more important than the board.

And thermal tape is horrible with this chip

Up and running.

Close to posted thd measurement in this post at 8 ohm at 8 volts rms. 25 volt rails.

As my heatsink is small and insufficient heatpaste I got 0.1 % distortion at 3,5 ohm, 5.7 volts rms.

So heatsink is even more important than the board.

And thermal tape is horrible with this chip

Attachments

Last edited:

So heatsink is even more important than the board.

Not sure I'd say it's "even more important". There are just more than one way to degrade the performance of an LM3886-based amp. Inadequate heat sinking is one.

Tom

Not the case, thought this was a DIY forum. TBH I just find $39 a pop for a pcb hard to swallow, and as TOMCR says make your own choice. Equally sounding amps, be they XY, chipamp, audiosector or ebay specials can be had as complete kit for the same money (and with real chips).

I know there is a lot of "gullibility" in the world of ready made HiFi, looks like the DIY arena is going the same route!

So you're saying that $39 for a DIY PCB is somehow equivalent to the "gullibility" of the hifi world? A PCB is that is exceedingly well engineered, documented, tested, supported and performs orders of magnitude ahead of the market? Did I mention it was $39? And this is somehow equivalent to the $1000 power cable world?

I would opine that you've perhaps lost your sense of perspective and understanding of economic value. If you're happy with the other kits you mention, why are you complaining about it here? Go buy your ebay kits and enjoy. Comparing this $39 PCB to hifi gullibility just makes you look ignorant and foolish.

Analog, Embedded Processing, Semiconductor Company, Texas Instruments - TI.com

free shipping today at least. Don't know for how long.

Nice for us norwegians that have a 40 dollar incl shipping tax/VAT free limit.

https://store.ti.com/LM3886TF/NOPB.aspx

Also like the link on the product page Searh for "Analog Input Class-D family"

free shipping today at least. Don't know for how long.

Nice for us norwegians that have a 40 dollar incl shipping tax/VAT free limit.

https://store.ti.com/LM3886TF/NOPB.aspx

Also like the link on the product page Searh for "Analog Input Class-D family"

Um... You know that genuine LM3886es are available from Mouser, Digikey, Newark/Farnell, et al., right?

Tom

I am looking at digikey and there is LM3886T and TF and then something called LM3886TF/NOPB which one is recommended for your done right amplifier?

I'm not Tom obviously, but if I remember correctly Tom uses the T (non-isolated tab) version as it transfers heat slightly better. You can search, but he did some testing using the Keratherm pads available on his website.

If memory serves - it was a 2-3W difference in output at clipping, so not a big difference to use the TF (isolated tab), which is easier to mount and not mess with thermal pads.

The TF-NOPB is the no lead version, which I think is the only version being produced currently (you can get other version until supply runs out). Don't think that makes any difference to the specifications - at least according to the datasheet.

If memory serves - it was a 2-3W difference in output at clipping, so not a big difference to use the TF (isolated tab), which is easier to mount and not mess with thermal pads.

The TF-NOPB is the no lead version, which I think is the only version being produced currently (you can get other version until supply runs out). Don't think that makes any difference to the specifications - at least according to the datasheet.

What he said!

/NOPB is indeed lead free (ROHS compatible). The only difference between the /NOPB and the others is that lead free solder is used on the pins of the /NOPB. Electrically, they're identical.

The TF is the all-plastic package. It's really nice to work with - especially for beginners - as there're no shoulder washers or thermal pads to worry about.

The T is the metal back package. Better heat transfer, but it does need to be insulated from the heat sink.

The "few watt more" only applies on hot heat sinks. If you keep the heat sink temperature below 55-60 ºC, the two versions (T and TF) perform identically.

Tom

/NOPB is indeed lead free (ROHS compatible). The only difference between the /NOPB and the others is that lead free solder is used on the pins of the /NOPB. Electrically, they're identical.

The TF is the all-plastic package. It's really nice to work with - especially for beginners - as there're no shoulder washers or thermal pads to worry about.

The T is the metal back package. Better heat transfer, but it does need to be insulated from the heat sink.

The "few watt more" only applies on hot heat sinks. If you keep the heat sink temperature below 55-60 ºC, the two versions (T and TF) perform identically.

Tom

- Home

- Amplifiers

- Chip Amps

- XY LM3886 Kit Review & Measurements