When my turntable is turned on and off, there is a loud crackling sound from the horn. I replaced the capacitor 10NF connected in parallel to the switch. It seems that there has been no improvement. Experienced people, please tell me where the malfunction occurred? I have two TD124, and the other one won't make any noise.

One suggestion.

You are working with the AC mains, so follow all safety precautions and unplug the thing when you are working on it. Insulate all connections you are working on in tests and certainly once you're done.

Install an MOV rated for well over your line voltage, across the line and past the switch (motor side). It would be nice to have a fuse before it (line side) in case it sees a big spike and shorts. The MOV would help save your equipment from damage.

The crackling is probably caused by the switch arcing. Try replacing the switch with any other kind of switch rated for the current and voltage just to test. If that noise is gone, you have a bad switch. If you had a snap sound, that is likely inductive kick from the motor winding and the MOV should stop that. The MOV will extend the life of a power switch.

-Chris

You are working with the AC mains, so follow all safety precautions and unplug the thing when you are working on it. Insulate all connections you are working on in tests and certainly once you're done.

Install an MOV rated for well over your line voltage, across the line and past the switch (motor side). It would be nice to have a fuse before it (line side) in case it sees a big spike and shorts. The MOV would help save your equipment from damage.

The crackling is probably caused by the switch arcing. Try replacing the switch with any other kind of switch rated for the current and voltage just to test. If that noise is gone, you have a bad switch. If you had a snap sound, that is likely inductive kick from the motor winding and the MOV should stop that. The MOV will extend the life of a power switch.

-Chris

Do you have the microswitch or the large open contact switch? Also is the ground wire between the motor and chassis connected?

What sort of capacitor did you use for replacement?

Is the tone arm grounded through its own ground cable to the pre-amp? Chassis grounded or not?

Some pictures of the wiring differences between the two tables would help me to possibly understand where the problem lies.

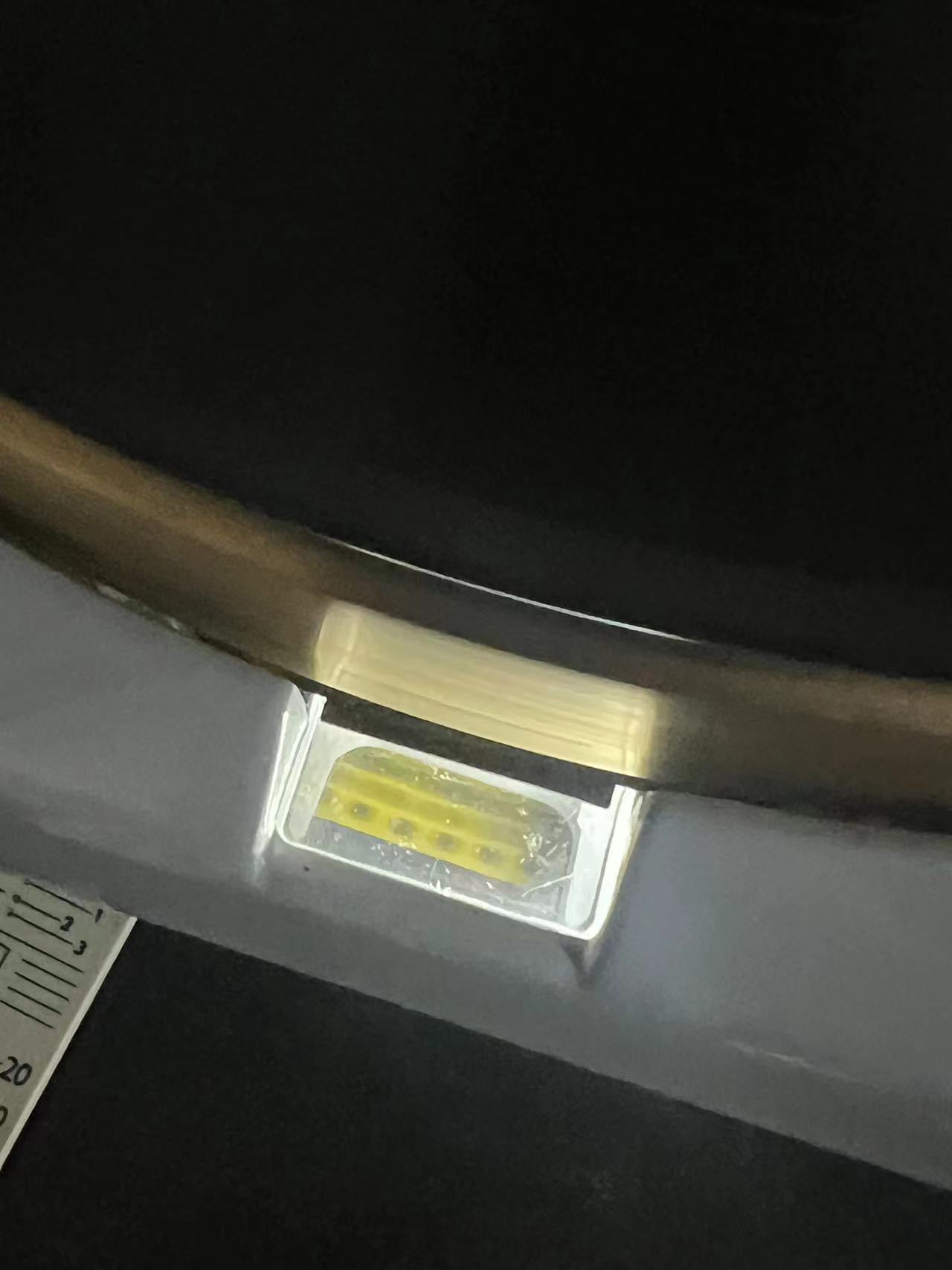

What is the strobe light source? It does not look like the stock neon lamp. (If not disconnect it and see if the pop goes away.)

I have a 124MKII and there are no audible pops when I turn the motor on and off. No chassis GND, but the arm is grounded to the pre-amp.

What sort of capacitor did you use for replacement?

Is the tone arm grounded through its own ground cable to the pre-amp? Chassis grounded or not?

Some pictures of the wiring differences between the two tables would help me to possibly understand where the problem lies.

What is the strobe light source? It does not look like the stock neon lamp. (If not disconnect it and see if the pop goes away.)

I have a 124MKII and there are no audible pops when I turn the motor on and off. No chassis GND, but the arm is grounded to the pre-amp.

Thank you for your reply. Based on your prompt, I checked again and found that I made a foolish mistake. I actually installed a 1NF capacitor.Do you have the microswitch or the large open contact switch? Also is the ground wire between the motor and chassis connected?

What sort of capacitor did you use for replacement?

Is the tone arm grounded through its own ground cable to the pre-amp? Chassis grounded or not?

Some pictures of the wiring differences between the two tables would help me to possibly understand where the problem lies.

What is the strobe light source? It does not look like the stock neon lamp. (If not disconnect it and see if the pop goes away.)

I have a 124MKII and there are no audible pops when I turn the motor on and off. No chassis GND, but the arm is grounded to the pre-amp.

I have reinstalled a capacitor with a capacity of 6N8, and the switch has almost no noise. I took pictures.

Actually, I have added another 6N2 capacitor now, with a total capacity of 12N4. The noise inside the horn can be ignored when turning on and off the turntable. I am very satisfied.

Once again, I would like to express my gratitude to those who have helped me. My next plan is to make a base with a transparent lid.

Additionally, the light bulb I am using is a regular LED light.

Last edited:

One suggestion.

You are working with the AC mains, so follow all safety precautions and unplug the thing when you are working on it. Insulate all connections you are working on in tests and certainly once you're done.

Install an MOV rated for well over your line voltage, across the line and past the switch (motor side). It would be nice to have a fuse before it (line side) in case it sees a big spike and shorts. The MOV would help save your equipment from damage.

The crackling is probably caused by the switch arcing. Try replacing the switch with any other kind of switch rated for the current and voltage just to test. If that noise is gone, you have a bad switch. If you had a snap sound, that is likely inductive kick from the motor winding and the MOV should stop that. The MOV will extend the life of a power switch.

-Chris

Thank you for your reply. I have resolved the issue and installed the wrong capacitor.Check the microswitch on the signal lines

Looking good. I would recommend tinting the LED lamp with orange nail polish or similar.Thank you for your reply. Based on your prompt, I checked again and found that I made a foolish mistake. I actually installed a 1NF capacitor.

I have reinstalled a capacitor with a capacity of 6N8, and the switch has almost no noise. I took pictures.

Actually, I have added another 6N2 capacitor now, with a total capacity of 12N4. The noise inside the horn can be ignored when turning on and off the turntable. I am very satisfied.

Once again, I would like to express my gratitude to those who have helped me. My next plan is to make a base with a transparent lid.

Additionally, the light bulb I am using is a regular LED light.

View attachment 1310752

View attachment 1310753

View attachment 1310754

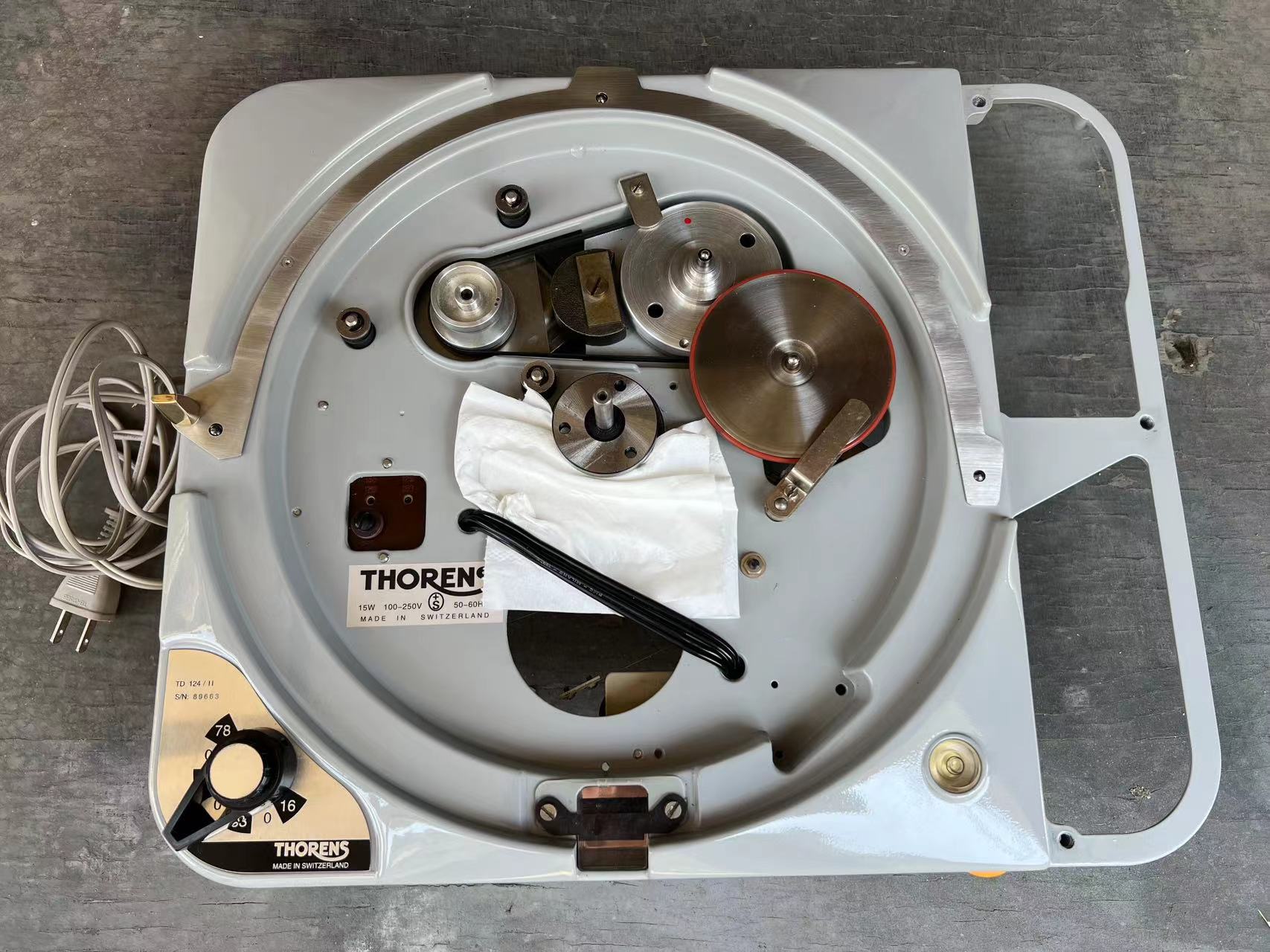

When TD124 was first purchased, there was no clutch, no spindle, and no rotating plate. I purchased or DIY the parts bit by bit. Today I made a clutch, and the final result was better than I had imagined. It was laser cut using a 1MM stainless steel plate, with the same thickness as the original. I plan to make another 1.5mm piece to try, because the brass plate I used is very heavy, and separating the copper plate is a bit difficult. The 1mm stainless steel plate is a bit soft.

I followed Anatech's suggestion to replace the LED with beige, which is indeed more attractive. I opened the LED light bulb and found a capacitor inside. I removed the capacitor. In the absence of capacitors, the LED appears to be flashing, but the dial appears clearer. It's a good thing.

If anyone needs this drawing, I can publish the CAD file here. I spent a lot of time drawing this blueprint.

I followed Anatech's suggestion to replace the LED with beige, which is indeed more attractive. I opened the LED light bulb and found a capacitor inside. I removed the capacitor. In the absence of capacitors, the LED appears to be flashing, but the dial appears clearer. It's a good thing.

If anyone needs this drawing, I can publish the CAD file here. I spent a lot of time drawing this blueprint.

Last edited:

Very nice. Sharing is what it's all about here.

I see that you removed the platter from the spindle.

Here is shown how to adjust the platter: https://www.soundfountain.com/amb/td124page.html

in case you want to do a perfect job.

Hugo

I see that you removed the platter from the spindle.

Here is shown how to adjust the platter: https://www.soundfountain.com/amb/td124page.html

in case you want to do a perfect job.

Hugo

- Home

- Source & Line

- Analogue Source

- Restoring and Improving A Thorens TD-124 MKII