Well 4655 and 4818 so there we have it. Many thanks!Vgs can be different in the associated MOSFETs though. Measurable between pins 1-3 (G,S).

At 1kHz in your photo. Useful for evaluation to some purposes. Like if it was a non polar to put in a passive speaker crossover.Uncle Der EE says 166 milliohms

But ESR is a 100kHz textbook characteristic. There the lytics lose purposeful abilities and pure ESR is revealed for all to see. To force 100kHz impedance test on the DER meter press its LCR Auto button until it will go to Rp mode. Go Rs on SER/PAL. Then press Freq until 100kHz. Now remeasure a capacitor. You are not in C mode so no more cap parameters to see but ESR is impedance and that's what you will see.

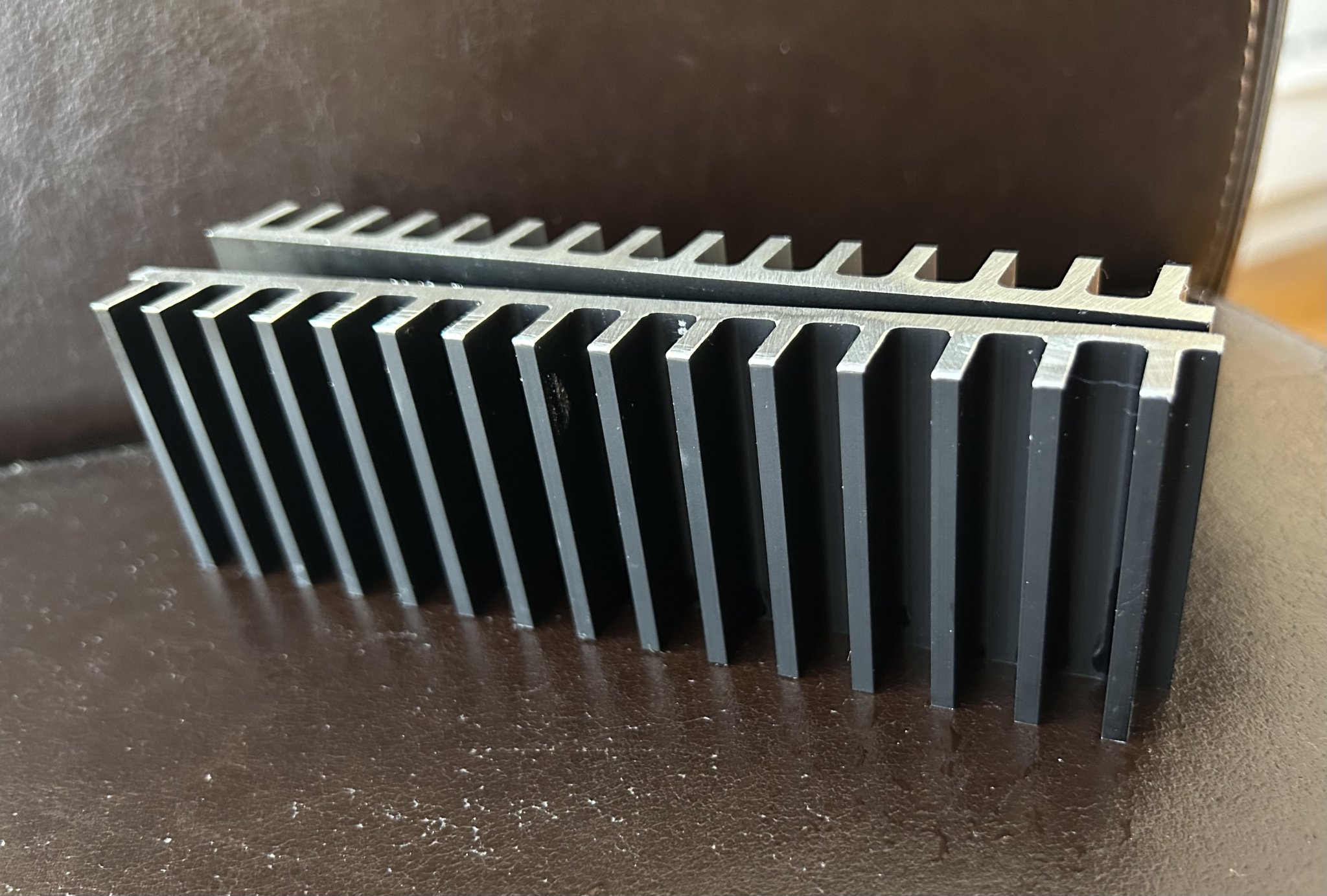

The 50 mm height otherwise fairly rightsized sinks from Fisher was rest noted I grabbed the 100 mm to cut in half. I was trying to be smart, made some jig for sawing aid, grabbed the hacksaw and made a darn bad job. Started curving, threw the silly jig away and did a much better job with the eye. Anyway since it started to drift at the beginning the two pieces deviated a mill or two here and there so out came the big banded table sander. It did a fair job, only tens of a mill deviating now. Good enough.

Now I shall only figure out an easy way to mount them temporary. Need some lunch for that.

Now I shall only figure out an easy way to mount them temporary. Need some lunch for that.

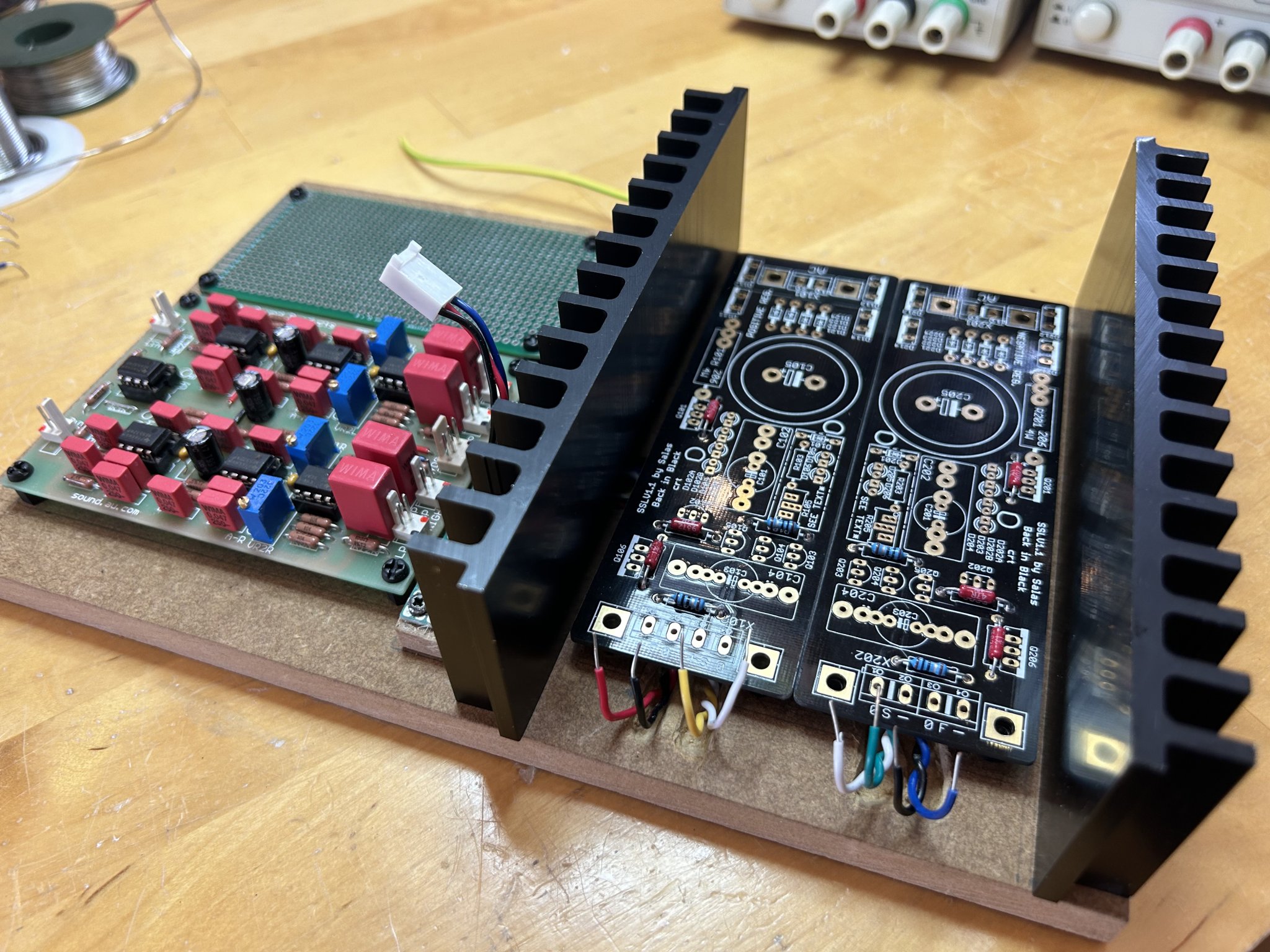

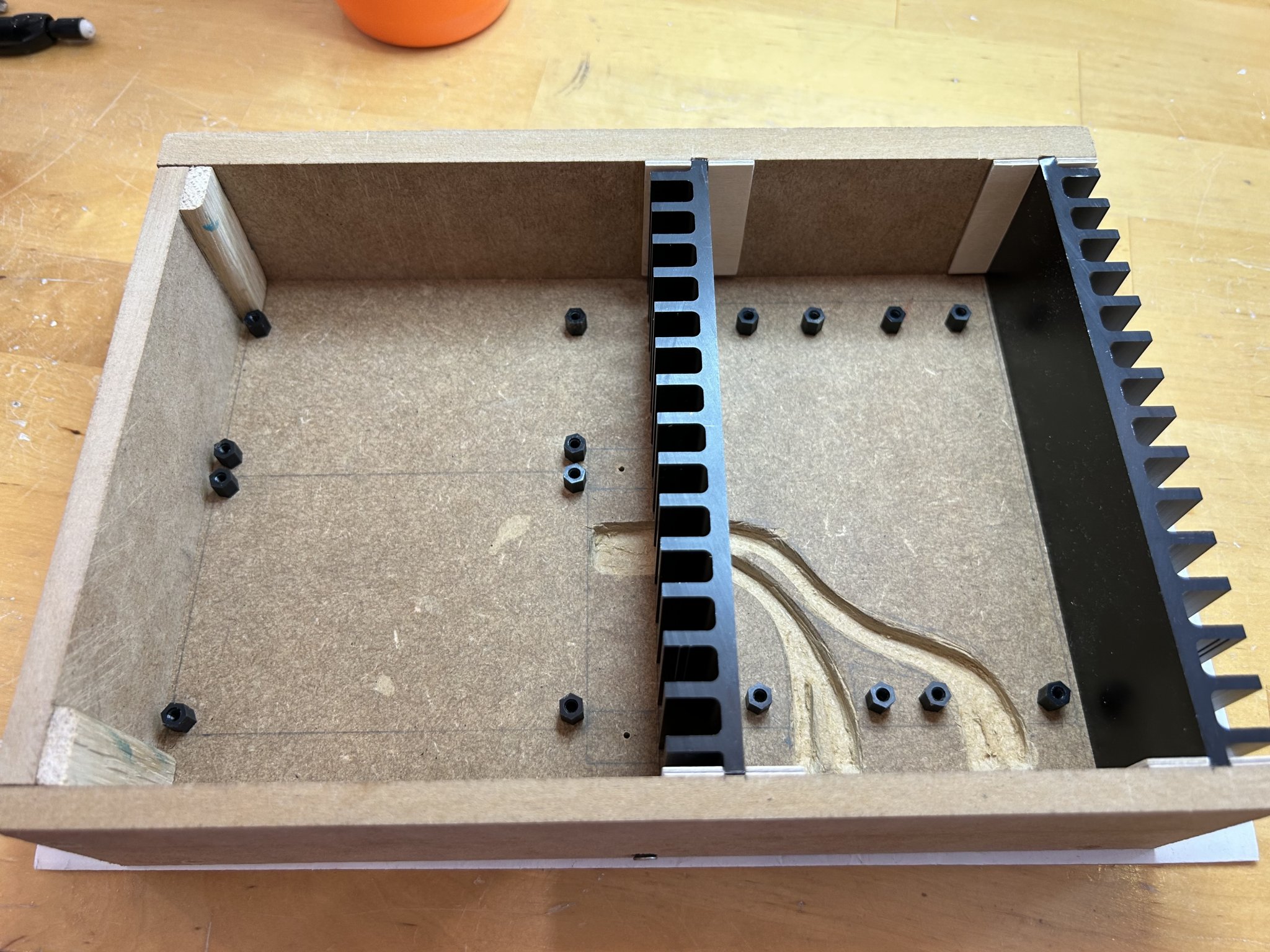

Btw looking at the last picture above visualizes that it might have been a smarter thermal architecture to split the SSLVs and mount one on respective side and the x-over in the middle. Hence I have now splitted them for the future, but will do the breadboard box as on the pic, side by side.

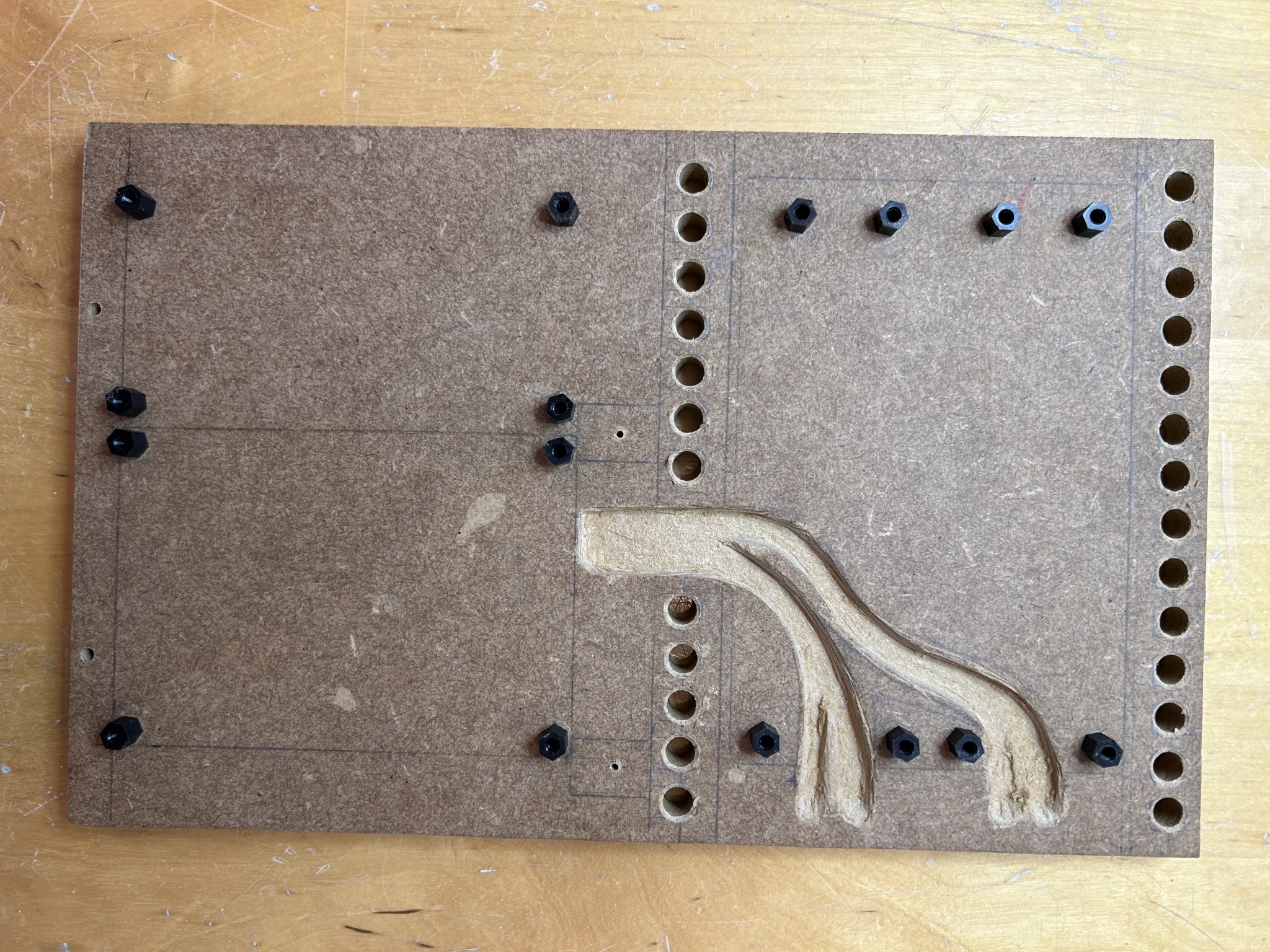

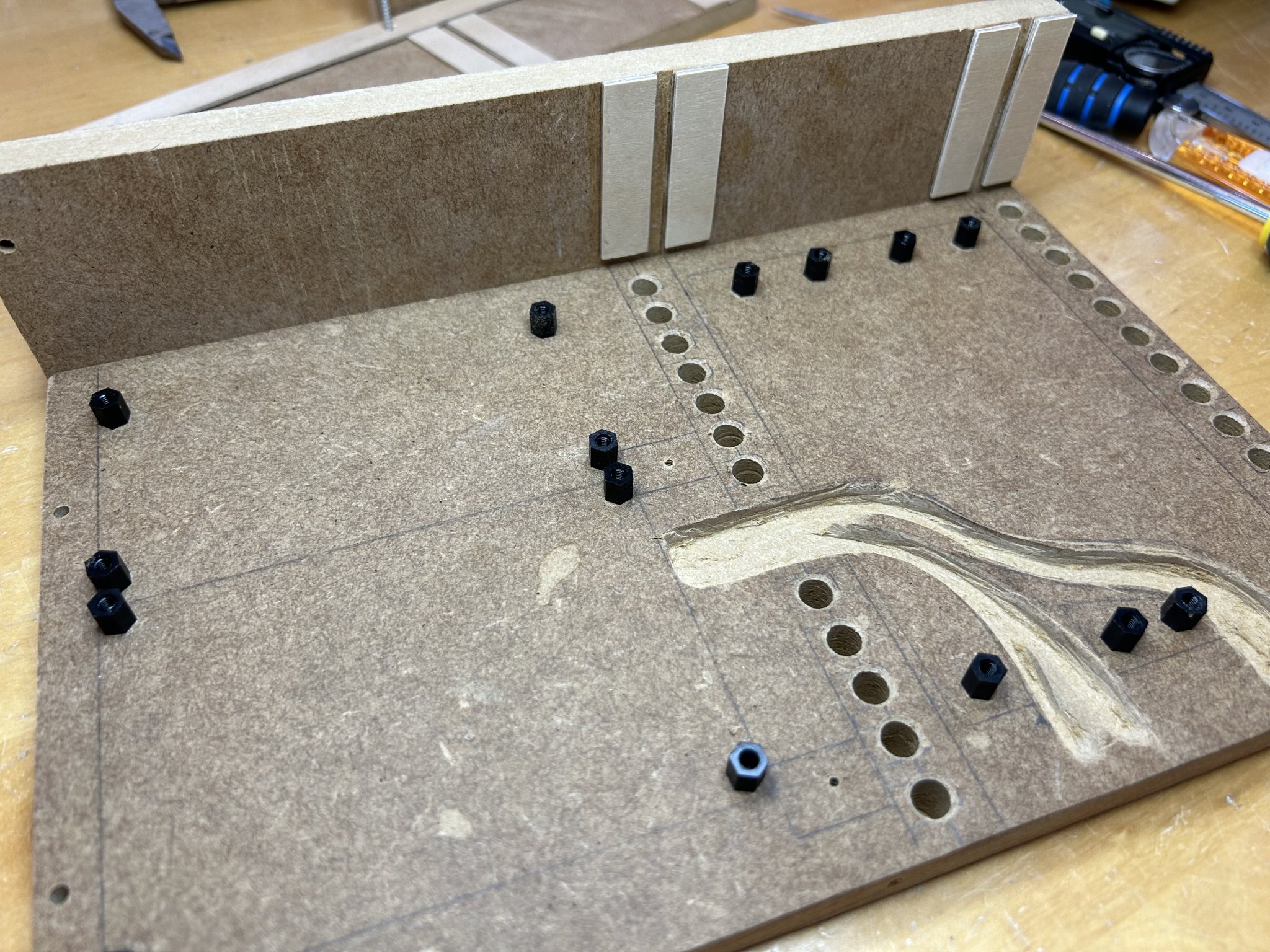

Long lunch. I have now made a box for the regs and the filter. It comes together IKEA style using just 10 same model screws for easy dissassembly and modding.

Made some airholes for the sinks (sinkholes?)

When tightening the screws they clamp the sinks so they stay put.

Now I can start populating. I did not want to do that before sinks are in place, since I usually mount the sinked components before other big comps for good reach. I solder them lightly from above mounted. Then I take it all out and solder from the bottom. That way I try to avoid tensions on the legs.

Its friday, maybe lunch? Cheers!

Made some airholes for the sinks (sinkholes?)

When tightening the screws they clamp the sinks so they stay put.

Now I can start populating. I did not want to do that before sinks are in place, since I usually mount the sinked components before other big comps for good reach. I solder them lightly from above mounted. Then I take it all out and solder from the bottom. That way I try to avoid tensions on the legs.

Its friday, maybe lunch? Cheers!

Last edited:

Its enough CCS for such a load. As for the greens that is what we expect at such low mA current. 1.9-2V forward drop. If you want to boost them a little there is a JFET at their tail and it has a degeneration resistor. Its their local small CCS. Put stronger K117GR there and smaller resistor.

- Home

- Amplifiers

- Power Supplies

- SSLV1.1 builds & fairy tales