Hey Scott,You've got a pair with 380A and 380B. I'll be speaking with Thomas at Markaudio about some of the reported communications above though. The drivers are produced, and intended to be supplied in, matched pairs and if distributors are not doing so because they can't be bothered, they are wasting everybody's time. These are not a standard product, but produced on a semi-custom basis, each of which is taken into the chamber for measurement, and then individually matched to the target tolerance. When you purchase an MAOP model, that is part of what you are buying.

Any progress on the cabinet design ...

From a commercial point of view in this sector I would have preferred:

1) Top flagship items maintained.

2) New flagship items announced

3) Overlap period (maybe small)

4) Old flagship items discontinued.

It seems to me that we are moving from point 1 to a point that is currently unknown.

We're not talking about consumer-facing finished products like Apple's, but about speakers that designers can invest a lot of time into developing their finished products.

1) Top flagship items maintained.

2) New flagship items announced

3) Overlap period (maybe small)

4) Old flagship items discontinued.

It seems to me that we are moving from point 1 to a point that is currently unknown.

We're not talking about consumer-facing finished products like Apple's, but about speakers that designers can invest a lot of time into developing their finished products.

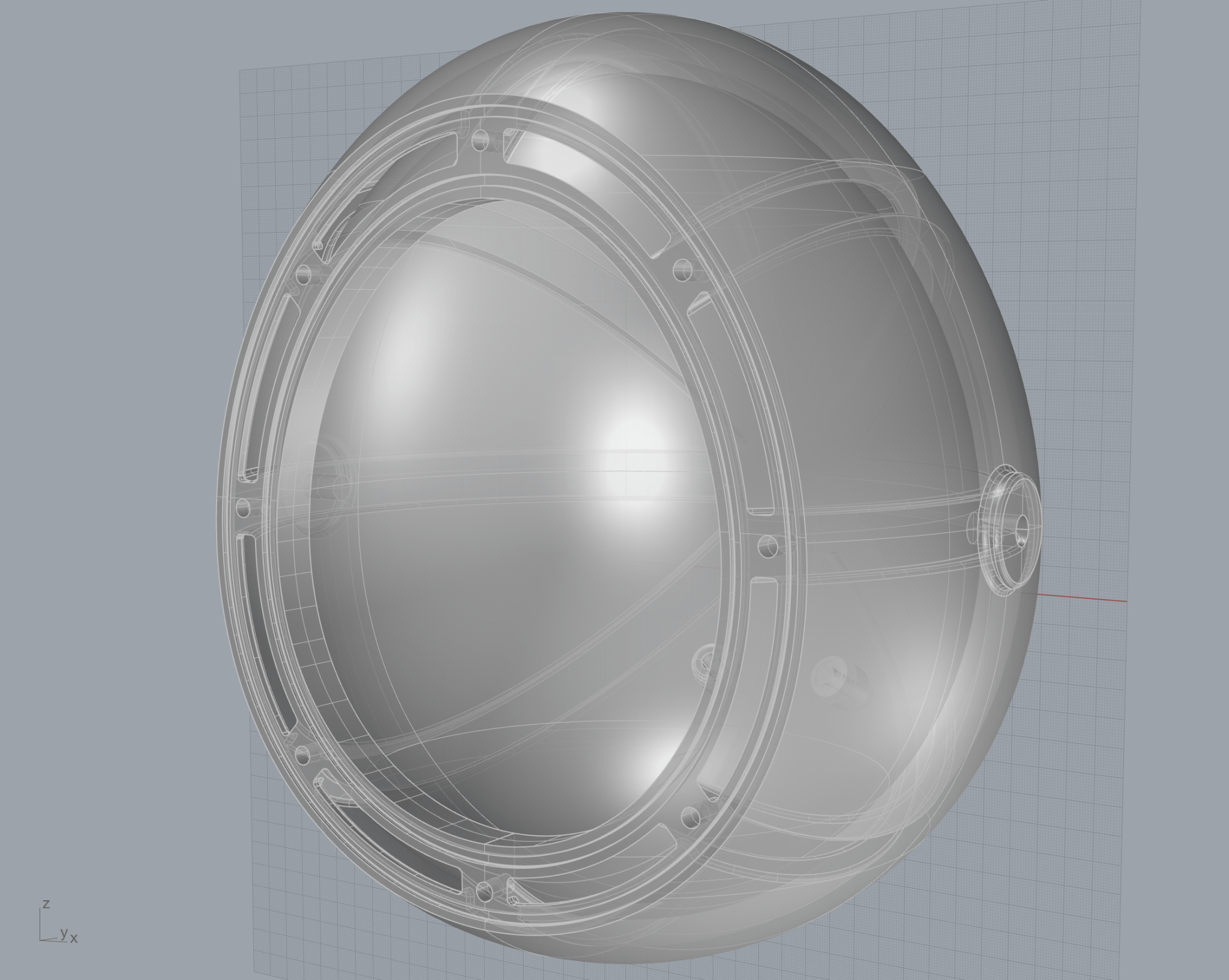

Closed this parenthesis on the departure of MAOP 10, I would like to illustrate the personal guidelines and the temporal succession of events in the realization of my previous project which guided me in the definition of the new, egg-shaped project, which uses Markaudio 10 MAOP.

1) It all started for fun about three years ago. A friend of mine had just bought a 3D printer and I proposed to him to make an acoustic speaker instead of the usual puppets. The intention was to make a good quality pair of desktop speakers for my daughter. In other words: a pair of near field monitors for computers

2) I have been passionate about hi-fi for more than 40 years (lots of books on electronics, acoustics and almost a degree in physics and my dream has always been to create something on my own) and so I started doing simulations, cad modeling (part of my current job).

3) The finished project (surfaces connected with G2 continuity, golden ratio used in certain dimensional proportions, connections between surfaces with variable radius etc.) was printed in 3D.

4) The finished result far exceeded expectations in terms of sound quality.

5) I thought that if I freed the small Markaudio speakers from the weight of their first octave, the sound would improve a lot and so I moved on to designing the sub.

6) At first I modeled the sub using a TB W5-1138SM with a bass reflex port. However, after the first prototype, I switched to a sub with passive woofers because the reflex duct (rectangular type and made with internal panels) was too long to be determined precisely unless I did many expensive tests as well as being at the limit of a BR type agreement.

7) The new system flies and the speakers are absolutely not locatable. The dynamics, precision, spatiality and accuracy are truly incredible for such a small system and the system seems quite insensitive to the listening position.

Other considerations and construction details (I was really obsessive in the construction) can follow if you are interested.

Fabio

1) It all started for fun about three years ago. A friend of mine had just bought a 3D printer and I proposed to him to make an acoustic speaker instead of the usual puppets. The intention was to make a good quality pair of desktop speakers for my daughter. In other words: a pair of near field monitors for computers

2) I have been passionate about hi-fi for more than 40 years (lots of books on electronics, acoustics and almost a degree in physics and my dream has always been to create something on my own) and so I started doing simulations, cad modeling (part of my current job).

3) The finished project (surfaces connected with G2 continuity, golden ratio used in certain dimensional proportions, connections between surfaces with variable radius etc.) was printed in 3D.

4) The finished result far exceeded expectations in terms of sound quality.

5) I thought that if I freed the small Markaudio speakers from the weight of their first octave, the sound would improve a lot and so I moved on to designing the sub.

6) At first I modeled the sub using a TB W5-1138SM with a bass reflex port. However, after the first prototype, I switched to a sub with passive woofers because the reflex duct (rectangular type and made with internal panels) was too long to be determined precisely unless I did many expensive tests as well as being at the limit of a BR type agreement.

7) The new system flies and the speakers are absolutely not locatable. The dynamics, precision, spatiality and accuracy are truly incredible for such a small system and the system seems quite insensitive to the listening position.

Other considerations and construction details (I was really obsessive in the construction) can follow if you are interested.

Fabio

The "egg" project".

1) Double shell enclosure (3D printed with carbon reinforced plastic) joined by internal ribs with cavities to be filled with composite in epoxy resin and fiberglass. The 3D printing possibility are truly amazing.

2) ... to be continued

1) Double shell enclosure (3D printed with carbon reinforced plastic) joined by internal ribs with cavities to be filled with composite in epoxy resin and fiberglass. The 3D printing possibility are truly amazing.

2) ... to be continued

Last edited:

- Home

- Loudspeakers

- Full Range

- Alpair MAOP 10.2