Sure a heavily damped toroid will hum less loud and a slopy wound one will be noisier. Anyway, if you have a DC component, any toroid will get loud.

We had this problem decades ago. Even vacuum epoxy impregnating the coil, a shielding layer, dunking the whole thing into a cup of resin and outside metal shileding didn't help. All these things you do to call it an adiophile transformer simply failed.

Lock it away or use a DC filter, these are the only options in a DC problematic region.

PS a mains filter is no DC filter!

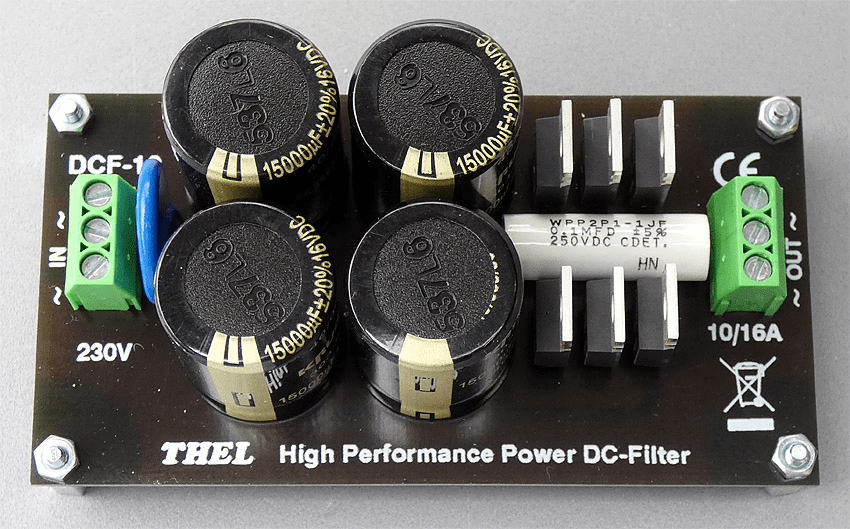

DC filter use diodes and very large, low voltage capacitors. A concept many don't understand. 10 Volt capacitor at 230V AC mains...

We had this problem decades ago. Even vacuum epoxy impregnating the coil, a shielding layer, dunking the whole thing into a cup of resin and outside metal shileding didn't help. All these things you do to call it an adiophile transformer simply failed.

Lock it away or use a DC filter, these are the only options in a DC problematic region.

PS a mains filter is no DC filter!

DC filter use diodes and very large, low voltage capacitors. A concept many don't understand. 10 Volt capacitor at 230V AC mains...

You say no. But propose a cure?NOT, absolutely not, but we have LC filters to cure that.

Because of the way toroidals are constructed they generally have higher coupling capacitance than EI transformers. This causes more high frequency noise to be passed. The fact that that can be filtered out does not change this inherent trait of toroidals. Does it?

Curious to hear what @Brian Gladstone has to say about this.

Hi,PS a mains filter is no DC filter!

DC filter use diodes and very large, low voltage capacitors. A concept many don't understand. 10 Volt capacitor at 230V AC mains...

I need to go out soon, for sake of argument I quickly connected this, this is definetly DC filter + rF filter, no change in buzz. Still it's very small, but hear able. That's without speakers, just trafos.

Hi, sorry I'll need to get out as said, see you tomorrow.You say no. But propose a cure?

Because of the way toroidals are constructed they generally have higher coupling capacitance than EI transformers. This causes more high frequency noise to be passed. The fact that that can be filtered out does not change this inherent trait of toroidals. Does it?

Curious to hear what @Brian Gladstone has to say about this.

Quick one again, I agree what you said, but point here is lower frequency buzz from trafos itself, not HF passing through

Buzzing with no load and no DC.for sake of argument I quickly connected this, this is definetly DC filter + rF filter, no change in buzz.

Is there any doubt left that culprit is low toroidal transformer quality? I would not order another transformer from the same source.

If the DC is higher than the diode voltage, it will still buzz. that is why some use two or more diodes, not only one.

This from https://www.thel-audioworld.de/module/Netzfilter/DCF-10.jpg is an example to block 2 Volt, not only 0.7V

This from https://www.thel-audioworld.de/module/Netzfilter/DCF-10.jpg is an example to block 2 Volt, not only 0.7V

https://www.thel-audioworld.de/module/Netzfilter/DC-Filter.htm

Watch out, mains voltage can kill you!

On the bottom of this page you find a very simple circuit for measuring the DC component in the mains. It gives a more stable reading than simply measuring DC (with an autorange multimeter).

For a 100k Ohme resistor you have to use a 2.2uF cap. then you can directly measure Volt DC at the AC mains.

The DC is not constant! It can change any time from nothing at all to a few Volt.

Watch out, mains voltage can kill you!

On the bottom of this page you find a very simple circuit for measuring the DC component in the mains. It gives a more stable reading than simply measuring DC (with an autorange multimeter).

For a 100k Ohme resistor you have to use a 2.2uF cap. then you can directly measure Volt DC at the AC mains.

The DC is not constant! It can change any time from nothing at all to a few Volt.

I made my own toros rewinding the secondaries from 220 to 12VAC , most owned from discarded industrial electrical apparatus or for lightning from archaic bi-pin bulbs. Most of them used for power tube amplifiers and output stages. They really perform quite well. At first attempt, I had the doubth about the induction B, and some manufaturers use as high as 1.7T.

One of 50W was my first blown transformer. I made two secondaries bifilar winding with 0.15mm enamel wire for my AM tube tuner. Suddlenly the receiver muted and the traffo got very hot. The fuse didn't blown. I unwind the traffo and discovered melted HV winding. So I made a test setup to measure insulating capabilities and discover that at 500VAC the insulation fail. I Try another (better quality) wire 0.18mm and rewound it again. It's currently performing OK.

In the future, I would like to build a CVT using toroids.

One of 50W was my first blown transformer. I made two secondaries bifilar winding with 0.15mm enamel wire for my AM tube tuner. Suddlenly the receiver muted and the traffo got very hot. The fuse didn't blown. I unwind the traffo and discovered melted HV winding. So I made a test setup to measure insulating capabilities and discover that at 500VAC the insulation fail. I Try another (better quality) wire 0.18mm and rewound it again. It's currently performing OK.

In the future, I would like to build a CVT using toroids.

Attachments

Hi tombo56,

I can see from flag you are Croatian as me.

In 90's I ordered many transformers from Elektrosklop, custom. They made for me as discrribed above oversized cores with lot of varnish-vacuuming-baking. They buzz today!

As kid I loved the buzz, small band turning on their tube Marshall amps, and buzz comes (that was from speakers, buzz was sign for a good party anyway!

But now my OCd doesn't allow any any more.

In the meantime I sealed many in epoxy, that also helped.

Bought several "made for audio" doughnuts, they are worst than Elektrosklop custom orders...

I suspected old trafos were made for 220 mains, now I have 230V, but than again I have trafos made for 230V, also they still buzz.....

Only one that I have and is almost quiet (best from about 20 pcs) is 500VA piece from British pro Amp, made for 240V primary...

Could be that oversized core + more primary windings is the solution?

I can see from flag you are Croatian as me.

In 90's I ordered many transformers from Elektrosklop, custom. They made for me as discrribed above oversized cores with lot of varnish-vacuuming-baking. They buzz today!

As kid I loved the buzz, small band turning on their tube Marshall amps, and buzz comes (that was from speakers, buzz was sign for a good party anyway!

But now my OCd doesn't allow any any more.

In the meantime I sealed many in epoxy, that also helped.

Bought several "made for audio" doughnuts, they are worst than Elektrosklop custom orders...

I suspected old trafos were made for 220 mains, now I have 230V, but than again I have trafos made for 230V, also they still buzz.....

Only one that I have and is almost quiet (best from about 20 pcs) is 500VA piece from British pro Amp, made for 240V primary...

Could be that oversized core + more primary windings is the solution?

Hi turbo, got the point, I can try with 2 or 3 diodes, probably will, but I doubt that's the problemIf the DC is higher than the diode voltage, it will still buzz. that is why some use two or more diodes, not only one.

And don't worry, I can measure 230 v safely 🤗

Transformers made by Toroidy are top quality products and used by many members of this forum. Based on my experience and many measurements, I find their marketing to be true.Bought several "made for audio" doughnuts, they are worst than Elektrosklop custom orders...

However, If there is a large DC component at mains, even best audio grade transformers will buzz, only less than standard ones.

Your description of symptoms, that only transformers above 200 VA have a buzzing problem, indeed points to DC being a cause. High power transformers have low primary resistance (just few ohms) so they can pull considerable current at low DC.

Your DC blocker from post #23 is good for 1.2 V. I would measure DC value first.

When doing specification for shop, ask for B 1,2T. Then they need to calculate core dimmensions for given power. Usualy they need to go with bigger core, so they have enough space for additional wire needed for lower B. On the end probably 50% more expensive.Hi tombo56,

I can see from flag you are Croatian as me.

In 90's I ordered many transformers from Elektrosklop, custom. They made for me as discrribed above oversized cores with lot of varnish-vacuuming-baking. They buzz today!

As kid I loved the buzz, small band turning on their tube Marshall amps, and buzz comes (that was from speakers, buzz was sign for a good party anyway!

But now my OCd doesn't allow any any more.

In the meantime I sealed many in epoxy, that also helped.

Bought several "made for audio" doughnuts, they are worst than Elektrosklop custom orders...

I suspected old trafos were made for 220 mains, now I have 230V, but than again I have trafos made for 230V, also they still buzz.....

Only one that I have and is almost quiet (best from about 20 pcs) is 500VA piece from British pro Amp, made for 240V primary...

Could be that oversized core + more primary windings is the solution?

@Drbulj how is the sine wave shape of your mains voltage, most probably doesn't look like anywhere near a pure sine, it can some time look more like triangle wave with wiggles and rounded peaks, those harmonics can make the transformer sing even more, and to filter out those LF harmonics would require relatively really big inductors and capacitors.

If you have an oscilloscope then, for safety reasons, check out the secondary output any of your transformers provided that the oscilloscope can handle the output VAC, or even better, if you have a fully isolated differential probe with sufficient voltage rating which can be connected directly to the mains.

If you have an oscilloscope then, for safety reasons, check out the secondary output any of your transformers provided that the oscilloscope can handle the output VAC, or even better, if you have a fully isolated differential probe with sufficient voltage rating which can be connected directly to the mains.

I’ve measured the common mode frequency response of a 500 VA toroid at >3 MHz (limit of my generator). It makes sense that it’s very wide since it’s just a capacitor of about 500pF between primary and secondary windings. I measured ~1.2nF on a 1.2 kVA transformer. In series mode, I measured the small signal bandwidth at >50 kHz.My question: If you could design a transformer that would couple the widest spectrum of noise from the mains to the secondary. Would not a toroidal be the transformer of choice?

I get my transformers wound by Tiger Toroids in Norfolk UK. Stephen Foster who runs the company explained to me that most commercial grade toroids use a strip wound core which is then overmoulded in plastic and the transformer then wound over this. The problem here is, the strip wound core is more often than not still loose inside the overmould, so it will easily rattle with DC on the mains, or even just in normal operation. Even if you try to put more varnish on a core like this, you won’t be fixing the problem inside the overmould, although acoustically, the varnish might attenuate the internal core buzzing or rattle. With an audio grade core, the overmould is not completely sealed and it is vacuum impregnated before they wind the core so as a result, the core doesn’t move. As mentioned by some above, the flux density is usually run lower and/or an oversize core is used to keep the transformer well away from core saturation which will cause buzzing. Once the transformer is wound, it is double vacuum impregnated and then potted. The result is an absolutely silent transformer even with DC on the mains, although I’d recommend a DC blocker on anything over 500VA because the primary DC resistance starts to get really low.

I get my transformers wound with an interwinding screen. This will drop the interwinding capacitance from 1.1 nF to ~100pF (measured on a 1.2 kVA) and with a GOSS band which substantially reduces the extraneous field which radiates out in the plane of the toroid - you can expect a 20 dB reduction in radiated noise.

I get my transformers wound with an interwinding screen. This will drop the interwinding capacitance from 1.1 nF to ~100pF (measured on a 1.2 kVA) and with a GOSS band which substantially reduces the extraneous field which radiates out in the plane of the toroid - you can expect a 20 dB reduction in radiated noise.

Last edited:

What do you mean by 'more high frequency noise to be passed'?You say no. But propose a cure?

Because of the way toroidals are constructed they generally have higher coupling capacitance than EI transformers. This causes more high frequency noise to be passed. The fact that that can be filtered out does not change this inherent trait of toroidals. Does it?

Curious to hear what @Brian Gladstone has to say about this.

A few things ... toroids have what is referred to as a 'square hysteresis' loop, which simple means they can be driven into saturation quickly. The advantages of this style of design far out weight the problems created. From my experience vacuum varnishing is not a good solution to this. Also, when you v varnish the core, you are adding additional stress to the core and will certainly degrade the performance (ie increase losses). Oversized cores make the transformer heavier, and if you have a good toroid engineer he would know how to increase the overall transformer efficiency on a larger core - but has no affect on noise.

Not all toroids are equal. Any problems encountered are specific, and can be somewhat attributed to the design - good engineers should know how to design and build toroids to solve some of the problems you are encountering.

Much of the DC offset on the mains is the result of non linear power supplies operating on the same power grid. (ie products with rectifiers, and especially devices with switching power supplies - like computers). This is a noise issue originating in the last 25 years, so it is a recent issue that the mains built decades ago was never designed to accommodate this.

In my opinion, to maintain all of the performances advantages of toroids, the most elegant solution is a DC blocking circuit. I know for a fact this is used in many high end audio and video systems, so it has been proven in the field.

Hope this helps.

Not all toroids are equal. Any problems encountered are specific, and can be somewhat attributed to the design - good engineers should know how to design and build toroids to solve some of the problems you are encountering.

Much of the DC offset on the mains is the result of non linear power supplies operating on the same power grid. (ie products with rectifiers, and especially devices with switching power supplies - like computers). This is a noise issue originating in the last 25 years, so it is a recent issue that the mains built decades ago was never designed to accommodate this.

In my opinion, to maintain all of the performances advantages of toroids, the most elegant solution is a DC blocking circuit. I know for a fact this is used in many high end audio and video systems, so it has been proven in the field.

Hope this helps.

Last edited:

Just the opposite - toroids can be driven at much higher induction levels than EI (or any laminated transformer). Winding resistance on a properly designed toroid will always be substantially lower. This is one of the reasons toroids are more efficient, as the winding losses are greatly reduced.

- Home

- Amplifiers

- Power Supplies

- Toroidal Power Transformers Questions