Hi Garethllywelyn,

Some years ago I designed a transistor matching jig and gave the design to the community here. It is very effective and there have been a few boards designed for it. I think there was a thread with an Adcom GFA-565 that covered it, and possibly other threads.

When matching transistors, it is critical they are at identical temperatures. They must be compared at the same time precisely. Using a beta test function cannot achieve this and you would be surprised at how far apart those matched parts can be. Often better than just fishing out a pair, but not really matched.

I just made differential pair with a current source for tail current. You measure between the collectors using a meter which becomes a null detector. The collector loads are 0.1% resistors and matches better than 1% can be made easily. This process has a thermal component, so time must be allowed to have the devices settle into thermal equilibrium. I pre-sort my parts using a beta test and group similar gains, then run through that pool. The two parts are placed in direct contact with each other and a foam "hat" placed over them. The entire test setup is then covered with a box (bowl or whatever) to block air currents. It uses a bipolar power supply, but a pair of 9V batteries would work also. I typically run abound 11 VDC trying for a 10 V collector - emitter drop across the parts.

The DUT jacks are critical, you have to use good quality ones from a proper supplier. I have tried various Asian sources and they are all poor quality so far. There is a circuit for PNP and another for NPN. The jacks are laid out so they can accommodate all pin outs, four contacts each.

I'll try to find some information on it.

Some years ago I designed a transistor matching jig and gave the design to the community here. It is very effective and there have been a few boards designed for it. I think there was a thread with an Adcom GFA-565 that covered it, and possibly other threads.

When matching transistors, it is critical they are at identical temperatures. They must be compared at the same time precisely. Using a beta test function cannot achieve this and you would be surprised at how far apart those matched parts can be. Often better than just fishing out a pair, but not really matched.

I just made differential pair with a current source for tail current. You measure between the collectors using a meter which becomes a null detector. The collector loads are 0.1% resistors and matches better than 1% can be made easily. This process has a thermal component, so time must be allowed to have the devices settle into thermal equilibrium. I pre-sort my parts using a beta test and group similar gains, then run through that pool. The two parts are placed in direct contact with each other and a foam "hat" placed over them. The entire test setup is then covered with a box (bowl or whatever) to block air currents. It uses a bipolar power supply, but a pair of 9V batteries would work also. I typically run abound 11 VDC trying for a 10 V collector - emitter drop across the parts.

The DUT jacks are critical, you have to use good quality ones from a proper supplier. I have tried various Asian sources and they are all poor quality so far. There is a circuit for PNP and another for NPN. The jacks are laid out so they can accommodate all pin outs, four contacts each.

I'll try to find some information on it.

Thankyou that would be great to learn about this tester of yoursHi Garethllywelyn,

Some years ago I designed a transistor matching jig and gave the design to the community here. It is very effective and there have been a few boards designed for it. I think there was a thread with an Adcom GFA-565 that covered it, and possibly other threads.

When matching transistors, it is critical they are at identical temperatures. They must be compared at the same time precisely. Using a beta test function cannot achieve this and you would be surprised at how far apart those matched parts can be. Often better than just fishing out a pair, but not really matched.

I just made differential pair with a current source for tail current. You measure between the collectors using a meter which becomes a null detector. The collector loads are 0.1% resistors and matches better than 1% can be made easily. This process has a thermal component, so time must be allowed to have the devices settle into thermal equilibrium. I pre-sort my parts using a beta test and group similar gains, then run through that pool. The two parts are placed in direct contact with each other and a foam "hat" placed over them. The entire test setup is then covered with a box (bowl or whatever) to block air currents. It uses a bipolar power supply, but a pair of 9V batteries would work also. I typically run abound 11 VDC trying for a 10 V collector - emitter drop across the parts.

The DUT jacks are critical, you have to use good quality ones from a proper supplier. I have tried various Asian sources and they are all poor quality so far. There is a circuit for PNP and another for NPN. The jacks are laid out so they can accommodate all pin outs, four contacts each.

I'll try to find some information on it.

Do you mean this one?Hi Garethllywelyn,

Some years ago I designed a transistor matching jig and gave the design to the community here. It is very effective and there have been a few boards designed for it. I think there was a thread with an Adcom GFA-565 that covered it, and possibly other threads.

When matching transistors, it is critical they are at identical temperatures. They must be compared at the same time precisely. Using a beta test function cannot achieve this and you would be surprised at how far apart those matched parts can be. Often better than just fishing out a pair, but not really matched.

I just made differential pair with a current source for tail current. You measure between the collectors using a meter which becomes a null detector. The collector loads are 0.1% resistors and matches better than 1% can be made easily. This process has a thermal component, so time must be allowed to have the devices settle into thermal equilibrium. I pre-sort my parts using a beta test and group similar gains, then run through that pool. The two parts are placed in direct contact with each other and a foam "hat" placed over them. The entire test setup is then covered with a box (bowl or whatever) to block air currents. It uses a bipolar power supply, but a pair of 9V batteries would work also. I typically run abound 11 VDC trying for a 10 V collector - emitter drop across the parts.

The DUT jacks are critical, you have to use good quality ones from a proper supplier. I have tried various Asian sources and they are all poor quality so far. There is a circuit for PNP and another for NPN. The jacks are laid out so they can accommodate all pin outs, four contacts each.

I'll try to find some information on it.

https://www.diyaudio.com/community/threads/matching-transistors-measuring-the-results.307138/

I'd be eternally grateful if an idiots guide could be written up for it.

Yes, that is it.

Operation is extremely simple. Select the tail current your circuit runs at. A good balance between self heating and speed to stabilizing things seemed to be around 3 mA approximately. All you need to do is isolate it from temperature changes and air currents, and give things time to settle down. That means it is tedious, but getting close matches is well worth it. Your distortion is reduced, and the amplifier is more stable thermally for DC offset drift. Your matched pair should have a touch of grease between the parts, and have heat shrink or some kind of wrap to hold the parts together when you use them. The wrap also helps a small amount to block air currents.

Your measurement is simple. The closer to zero between the two collectors, the better. The readings will be in mV, so a meter having good accuracy and a few decimals to the right of the decimal will be better than a cheap, old 3 1/2 digit meter with 100 mV low scale. Of course you can use a sensitive analogue meter with a centre zero. You might want to short the analogue meter until the parts are installed and stable.

The critical parts are the 100R 0.1% metal film, low TC resistors in the collectors (4) and the resistors I put in the bases. That allows you to measure the DC beta under those conditions, something you would probably rarely do. Those were 0.1% as well just to make sure other factors would not throw the match off.

Found a picture of a rough one I use. It was made quickly, and it works great. Notice the 3mm LEDs are mounted inside the pass transistors for the current sources to maintain temperature equilibrium. There is a block of foam under the transistor the LED pokes through to help keep the temperature stable. The capacitors are only there to prevent anything from oscillating, values are not critical and I used film caps in later builds. There are two sets of jacks for each DUT position, the larger outer ones accept an adapter for surface mount transistors. The leads from the top are EBCE so you can use transistors with different pinouts.

Note we are placing the transistors in exactly the same configuration they are used in. All this is, is a differential pair (long tailed pair) in open loop configuration. That's all. That is why it works so well.

Operation is extremely simple. Select the tail current your circuit runs at. A good balance between self heating and speed to stabilizing things seemed to be around 3 mA approximately. All you need to do is isolate it from temperature changes and air currents, and give things time to settle down. That means it is tedious, but getting close matches is well worth it. Your distortion is reduced, and the amplifier is more stable thermally for DC offset drift. Your matched pair should have a touch of grease between the parts, and have heat shrink or some kind of wrap to hold the parts together when you use them. The wrap also helps a small amount to block air currents.

Your measurement is simple. The closer to zero between the two collectors, the better. The readings will be in mV, so a meter having good accuracy and a few decimals to the right of the decimal will be better than a cheap, old 3 1/2 digit meter with 100 mV low scale. Of course you can use a sensitive analogue meter with a centre zero. You might want to short the analogue meter until the parts are installed and stable.

The critical parts are the 100R 0.1% metal film, low TC resistors in the collectors (4) and the resistors I put in the bases. That allows you to measure the DC beta under those conditions, something you would probably rarely do. Those were 0.1% as well just to make sure other factors would not throw the match off.

Found a picture of a rough one I use. It was made quickly, and it works great. Notice the 3mm LEDs are mounted inside the pass transistors for the current sources to maintain temperature equilibrium. There is a block of foam under the transistor the LED pokes through to help keep the temperature stable. The capacitors are only there to prevent anything from oscillating, values are not critical and I used film caps in later builds. There are two sets of jacks for each DUT position, the larger outer ones accept an adapter for surface mount transistors. The leads from the top are EBCE so you can use transistors with different pinouts.

Note we are placing the transistors in exactly the same configuration they are used in. All this is, is a differential pair (long tailed pair) in open loop configuration. That's all. That is why it works so well.

Attachments

You could do the math if you want. Does it matter? You basically want the closest match you can reasonably get.

Just figure out what the current is in each collector resistor. Compare as a percentage. I have figured it out before but truthfully, it didn't matter as you just want to know you have very close matches. You'll get a feel for it.

Just figure out what the current is in each collector resistor. Compare as a percentage. I have figured it out before but truthfully, it didn't matter as you just want to know you have very close matches. You'll get a feel for it.

Hi Guys,

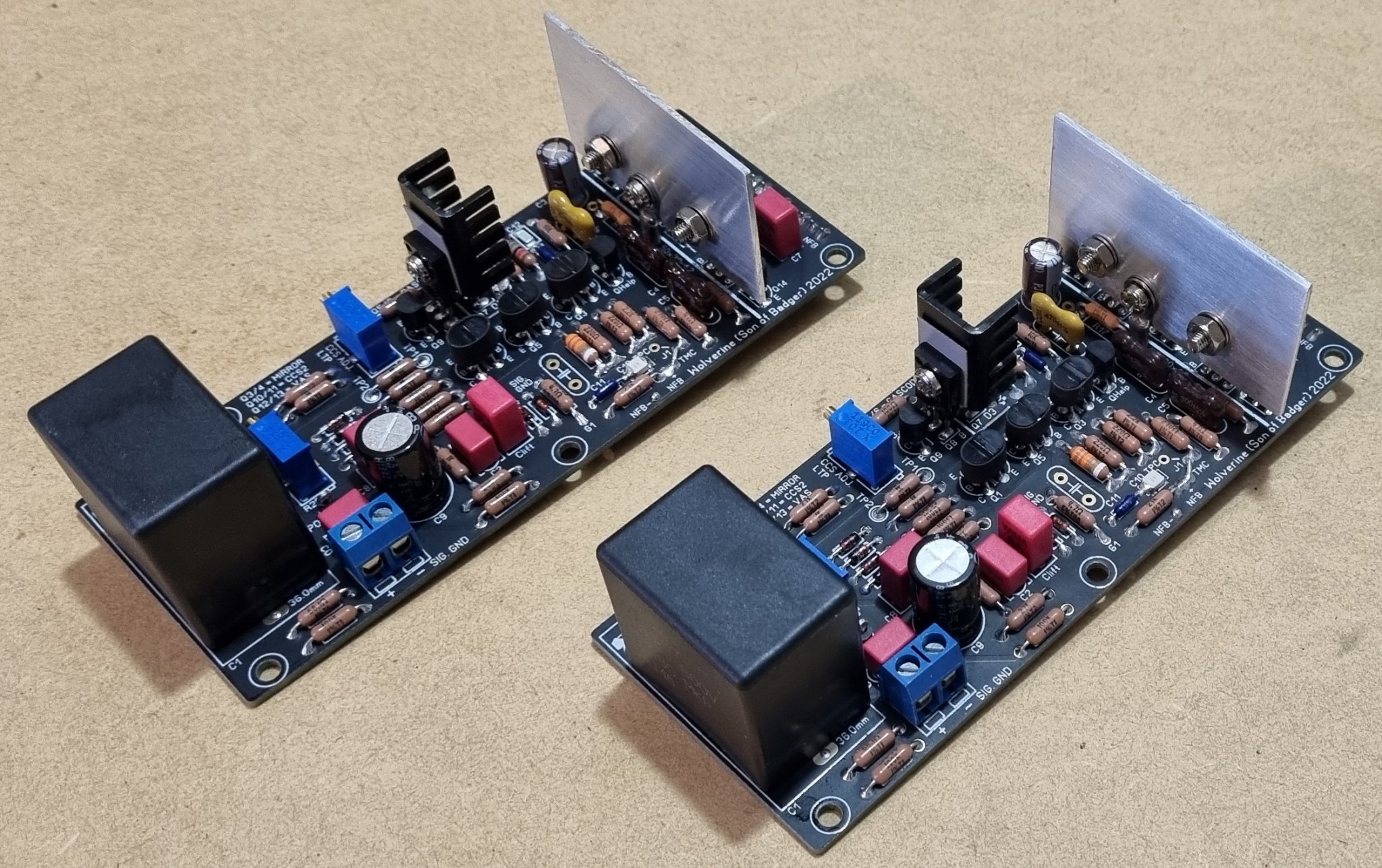

Here is a progress update on my build;

I have been building the input board late at night and here are a few tips along the way....

Remember to choose the type of potentiometer which suits your case layout i.e. horizontal screw or vertical screw.

Remember to raise up R17 (10k 1/2W - 1W) by approximately 2 mm for heat dissipation reasons.

Remember to clean the input board in between putting in all the resistors and small capacitors before the transistors since it will be easier clean once finished

Remember to fill the vias specifically around the TMC capacitors and the input capacitor, including the input capacitor bridge connection if you are using a large (> 15 mm pin spacing) input capacitor.

Dont over fill the solder pads with solder since you will end up with "blobs" which impact on the creepage and clearance distances - I have reworked quite a few solder joints due to this, after advice from Stuartmp.

Try an get an input terminal which is the rectangular clamp type rather than the machined pin type if you can (I will be swapping out mine pictured above at some point)

Hope this helps, keep an eye out for the new video coming soon.

Here is the YouTube link for the Wolverine build playlist:

Happy amplifier building

- Dan

Here is a progress update on my build;

I have been building the input board late at night and here are a few tips along the way....

Remember to choose the type of potentiometer which suits your case layout i.e. horizontal screw or vertical screw.

Remember to raise up R17 (10k 1/2W - 1W) by approximately 2 mm for heat dissipation reasons.

Remember to clean the input board in between putting in all the resistors and small capacitors before the transistors since it will be easier clean once finished

Remember to fill the vias specifically around the TMC capacitors and the input capacitor, including the input capacitor bridge connection if you are using a large (> 15 mm pin spacing) input capacitor.

Dont over fill the solder pads with solder since you will end up with "blobs" which impact on the creepage and clearance distances - I have reworked quite a few solder joints due to this, after advice from Stuartmp.

Try an get an input terminal which is the rectangular clamp type rather than the machined pin type if you can (I will be swapping out mine pictured above at some point)

Hope this helps, keep an eye out for the new video coming soon.

Here is the YouTube link for the Wolverine build playlist:

Happy amplifier building

- Dan

Your boards look amazing. Hopefully we will see many more like them.

I think you have set the standard for others to see what's possible with a bit of care, time and attention to detail.

Thank you for summarising the first stage of the build. I for one am certainly looking forward to the release of your next informative video on the build.

I think you have set the standard for others to see what's possible with a bit of care, time and attention to detail.

Thank you for summarising the first stage of the build. I for one am certainly looking forward to the release of your next informative video on the build.

I am struggling to find stock for Qhelp mentioned in the BOM, could another part be substituted?

I sent you a link and there is an alternate, check your PM.

Jeremy

New video is up,

Enjoy

- Dan

Hi Dan, congrats, amazing work! What kind of thermal pads did you use to insulate transistors from the heatsink? Will you use them also for the output devices?

Thank you, Gaetano.

Thanks Gaetano,Hi Dan, congrats, amazing work! What kind of thermal pads did you use to insulate transistors from the heatsink? Will you use them also for the output devices?

Thank you, Gaetano.

They are adhesive silicon thermal pads.

I will probably use a similar type for the output stage transistors but in T03P or TO264 size.

https://www.altronics.com.au/p/h7332-adhesive-silicon-rubber-to126-insulation-pad-pk-100/

Just a note, if you use similar to this try to choose the type which is only adhesive on one side if you can.

The ones without adhesive work just as well but adhesive is helpful when assembling T0220 sized heatsinks.

There is nothing wrong with mica and thermal paste or Kapton tape and thermal paste either but my personal preference is silicon thermal pads.

Hope this helps

-Dan

- Home

- Amplifiers

- Solid State

- DIY Class A/B Amp The "Wolverine" build thread