Hi JT,

How is your transformer mounted?

If it is bolted, it looks like it could make an additional single turn with the copper pipe.

This bolt, pipe and chassis becomes a shorted winding over the secondaries and will overload/overheat the primary,

until something melts, hopefully the fuse.

Danny

A superb catch, and critical advice.

At an audio show at which I worked, my partner noticed a slight deformity and/or whitish burn mark on the top panel of the chassis cover of a Chinese built sub amp. Indeed, exactly as you describe, a long screw fastened the toroidal trafo, entering from the base then the screw top barely contacted the top panel, creating the unintended chassis coil you describe.

A friend drove to the local hardware store to buy a file required to shorten the bolt and clear the top panel. I still have the section of a blanket in which we punched a hole for the screw top, the blanket collecting filed metal particles.

Who knows what would have happened if one of our crew did not catch and investigate the visual cue on the top panel? Maybe while we slept the chassis heats up and ignites a fire. Most readers have no idea the magnitude of water flow from even one sprinkler head.

Hopefully the mains fuse and/or another safety circuit does its job, but as James Bongiorno (RIP) once said, it's best not to "tempt fate."

Hi Folks,

I just sold out of this amp and so they are on back order in my store. About 10-12 days before they will be in. Sorry for the inconvenience. I have some green 1.6mm, 2oz, HASL prototype PCBs if you are interested. $20 off so only $18/pair (only 2 pairs available).

I just sold out of this amp and so they are on back order in my store. About 10-12 days before they will be in. Sorry for the inconvenience. I have some green 1.6mm, 2oz, HASL prototype PCBs if you are interested. $20 off so only $18/pair (only 2 pairs available).

A superb catch, and critical advice.

At an audio show at which I worked, my partner noticed a slight deformity and/or whitish burn mark on the top panel of the chassis cover of a Chinese built sub amp. Indeed, exactly as you describe, a long screw fastened the toroidal traffo, entering from the base then the screw top barely contacted the top panel, creating the unintended chassis coil you describe.

A friend drove to the local hardware store to buy a file required to shorten the bolt and clear the top panel. I still have the section of a blanket in which we punched a hole for the screw top, the blanket collecting filed metal particles.

Moral of the story ... do not buy cheap Chinese amps.

(They are cheap for a reason!

Andy

For grins I connected my 5ohm PTT6.5 and RS28F TL’s to my 8ohm Alpha Nirvana today. Not expecting it to work well, but surprised that it sounds glorious. Not a problem at all driving this load:

As you posted yours, X ... I thought I would post my new spkrs (which have replaced my true-ribbon Maggies) being driven excellently by my 2x stereo AN 4Rs. (Don't think I posted them, previously.)

They use (each side):

* an SB Acoustics 'Satori' ribbon tweeter (AT60NC-4), and

* 4x SB Acoustics 6 1/2" Satori mid/bass drivers (MW16TX-4).

They are 2-way active and hand over to a pair of 15" sealed subs at 160Hz. A nanoDIGI 8x8 provides the XOs and EQ needed for the lack of baffles.

Don't know what the impedance graphs are but the drivers are nominally 4 ohm - with 'Re' specified as:

* AT60NC-4 : 3.9 ohms

* MW16TX-4 : 3.4 ohms.

Have never been able to get the red 'clip LEDs' to come on - even on transients, playing louder than I normally listen at!

And the room looks so much bigger, without the 'room dividers'!

Andy

Attachments

Baffle less speakers!

A new class of spkr, X - "zero baffle"!

(My inspiration was the Aussie Kyron "Gaias" ... they're A$250K! But they don't need subs.

Nice setup Andy! Are the AN’s in the black boxes next to the speakers?

Thanks - yes, the AN 4Rs are the black boxes next to the speakers.

Andy

I like the simplistic and smart design, so I ordered a pair of these PCB's.

My long time favorite is a slightly modified PNP JLH -69, I have hope that this will become my new favorite

Is there an LTspice sim with models I can download somewhere? Would be interested in playing around with the sim a bit.

My long time favorite is a slightly modified PNP JLH -69, I have hope that this will become my new favorite

Is there an LTspice sim with models I can download somewhere? Would be interested in playing around with the sim a bit.

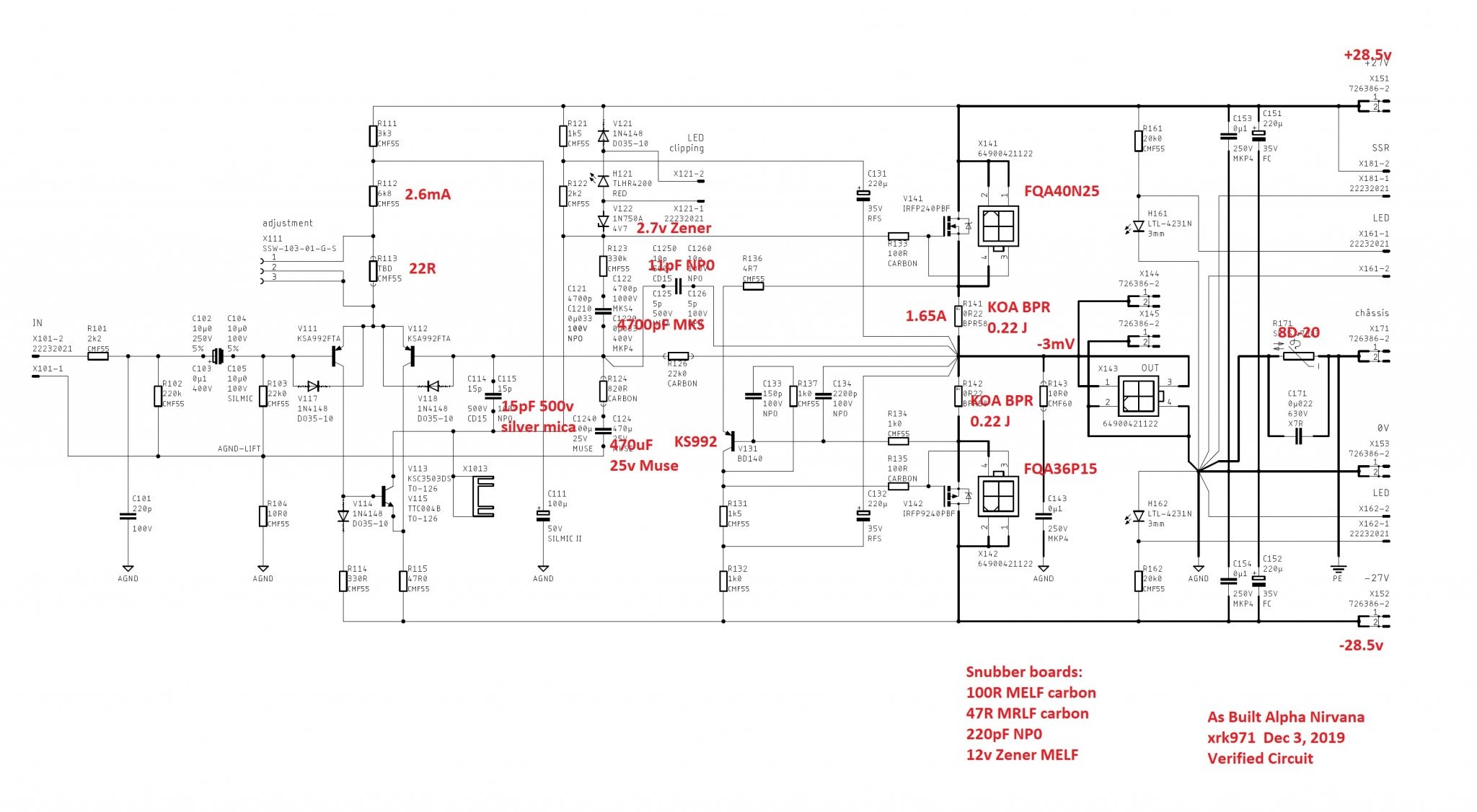

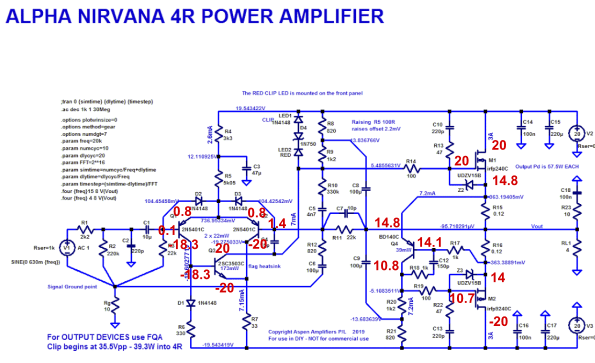

Sooo.... not the champagne moment I was hoping for last night. I have one board working in my test set up and the other not. The gate on the N channel is at the voltage rail of 20V, the gate of the P channel is at 10.5V and the dummy speaker load gets nice and warm! I haven't taken many measurements yet but what I have I've attached. I'm an assembler not an engineer so I'd really appreciate a little help. I built both 4R boards in parallel, with 0.22R bias resistors until I get heatsinking sorted.

I checked each resistor going in and also again before I started stuffing the rest of the components ( from known sources). I've checked both boards are the same and inspected for shorts and dry joints under a magnifier. I can swap the FET boards of the bad channel onto the good and the good still works so I know it's not the big FETs.

So my question is, is it safe and valid to troubleshoot the board with the FET boards disconnected? It would make it easier for me to do so.

I checked each resistor going in and also again before I started stuffing the rest of the components ( from known sources). I've checked both boards are the same and inspected for shorts and dry joints under a magnifier. I can swap the FET boards of the bad channel onto the good and the good still works so I know it's not the big FETs.

So my question is, is it safe and valid to troubleshoot the board with the FET boards disconnected? It would make it easier for me to do so.

Attachments

You need the output MOSFETs there to get the true system DC setpoints. You don’t need to connect a speaker load. Without the outputs, you can check the input stage and VAS. Just measure the output DC offset - looks like there is a major imbalance that’s either caused by a cold solder joint in the CCS (bottom circuitry on the P channel) or the VAS stage driving the gate in the N channel. The gate voltages are way off.

Please take notes on the DC voltages relative to GND at all active pins of all devices and annotate in red like you have done. We can debug and pinpoint the exact cause with this info. It sounds like it’s not melting the MOSFETs so you can take data. Be careful with probe tips not to short stuff. You can destroy parts very easily this way if not careful. Hugh said it’s like backing a car into a tight garage. Do it carefully and deliberately or you scrape the sides of your car.

Since you stuffed both boards in parallel and checked your resistor values before hand - it can only be a solder bridge or a cold solder joint - or a bad or reversed electrolytic cap. Check the 220uF bootstrap caps for reverse polarity or conductivity.

R113 should be 22R, you have a 200R pot there - did you set the pot to 22R? I know this is the 8ohm version.

Good luck!

Please take notes on the DC voltages relative to GND at all active pins of all devices and annotate in red like you have done. We can debug and pinpoint the exact cause with this info. It sounds like it’s not melting the MOSFETs so you can take data. Be careful with probe tips not to short stuff. You can destroy parts very easily this way if not careful. Hugh said it’s like backing a car into a tight garage. Do it carefully and deliberately or you scrape the sides of your car.

Since you stuffed both boards in parallel and checked your resistor values before hand - it can only be a solder bridge or a cold solder joint - or a bad or reversed electrolytic cap. Check the 220uF bootstrap caps for reverse polarity or conductivity.

R113 should be 22R, you have a 200R pot there - did you set the pot to 22R? I know this is the 8ohm version.

Good luck!

Last edited:

Thank you for taking the time to help. I checked the + & - rail to ground resistances, they settle about 400R on both boards. Can't see any low resistances on the other caps swapping the probes on my meter around. I have set the pots to exactly 22R...now... ahem! I really can't see any shorts or dry joints, wonder if I have a bad transistor? Annotated voltages on all transistors/FETs:

Thanks again!

Thanks again!

You were spot on Hugh, I had put the damn thing in the wrong way round. How embarrassing! Many thanks to you and X. Music is happening, I'm off to eat humble pie for lunch....Check Q3. You may have the wrong transistor, or the 2SC3503 is bad.

Hugh

Don't be embarrassed Simon, this switch happens even in manufacturing and it's just part of life.

I always kid that for every amp I build, I build twice, because either things fall on the floor and I have to find it then install it, or I put three wired actives in the wrong way, or insert backwards. Then I have to remove it, then re-install. So a ten second job becomes a ten minute job.

The price we pay for creativity........

After all these tribulations, your enjoyment of the music will be all more wonderful!

Hugh

I always kid that for every amp I build, I build twice, because either things fall on the floor and I have to find it then install it, or I put three wired actives in the wrong way, or insert backwards. Then I have to remove it, then re-install. So a ten second job becomes a ten minute job.

The price we pay for creativity........

After all these tribulations, your enjoyment of the music will be all more wonderful!

Hugh

- Home

- Group Buys

- Alpha Nirvana 39W SE Class A Amplifier GB