You need a crowbar to pry them loose. Never had any problems. In my EL509 things get very hot. No problem whatsoever. Mine is not heat resistant AFAIK.

I've heard of heat resistant silicone too though. Up to 200,300 or even higher.

Edit just did a search. Normal silicone sealant can handle from minus 40 up to 180 celcius.

I've heard of heat resistant silicone too though. Up to 200,300 or even higher.

Edit just did a search. Normal silicone sealant can handle from minus 40 up to 180 celcius.

Last edited:

Bas Horneman,

Your project appears to be moving along.

In reference to your Post # 83, I agree, a high voltage delay and or soft start circuit is a pretty good idea.

(Normally, I use circuits that do not need delay / soft start).

But you have a slow warming EL84 filament & cathode structure for the input tube, when the tube is cold, the plate voltage is at B+, and then you DC couple [that B+] to the 2A3 grid,

With the fast warm up filament of the 2A3, it can be a power-up problem (here comes your HV delay & soft start . . . to the rescue).

I had a friend that had an input stage with filament & cathode, that was DC coupled to the 2A3 grid.

At power-up the 2A3 plate current was over 200mA!

Ouch!

Some special circuitry solved that problem.

Your project appears to be moving along.

In reference to your Post # 83, I agree, a high voltage delay and or soft start circuit is a pretty good idea.

(Normally, I use circuits that do not need delay / soft start).

But you have a slow warming EL84 filament & cathode structure for the input tube, when the tube is cold, the plate voltage is at B+, and then you DC couple [that B+] to the 2A3 grid,

With the fast warm up filament of the 2A3, it can be a power-up problem (here comes your HV delay & soft start . . . to the rescue).

I had a friend that had an input stage with filament & cathode, that was DC coupled to the 2A3 grid.

At power-up the 2A3 plate current was over 200mA!

Ouch!

Some special circuitry solved that problem.

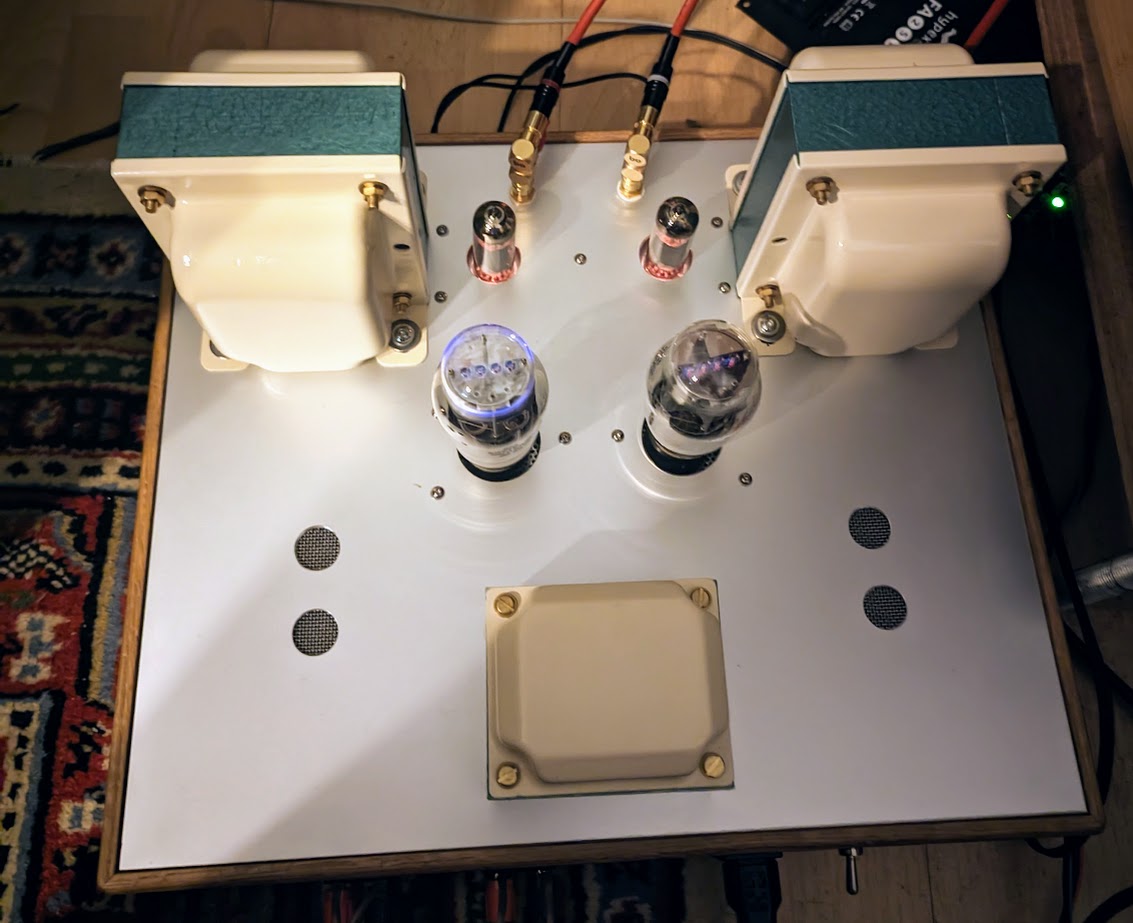

It's alive. The quietest amp I've ever built! My son who can usually hear the hiss, buzz or whatever... cannot hear anything from 50 cm's! Only around 10cm from the compression driver does he hear some slight hiss. He was baffled....thought it was off. This is my first parafeed amp.

Coupled it straight to my dac because the pre has an occasional issue.

The bad news is that I've never had or listened to a 2a3 based amp before. So can't compare. But so far it sounds very sweet and natural. But also clean. My kids are saying this is next level.

Quick picture in its makeshift place so I could have a quick listen.

Coupled it straight to my dac because the pre has an occasional issue.

The bad news is that I've never had or listened to a 2a3 based amp before. So can't compare. But so far it sounds very sweet and natural. But also clean. My kids are saying this is next level.

Quick picture in its makeshift place so I could have a quick listen.

I'll try to find out before I take some glamour shots..hopefully today during work break.How heavy is it?

The posts that got gave me the idea for this iron and tube (I have the 2004jr output transformer:

This is the post by Paul Joppa that convinced me to go for it (15 years ago):

Posted by Paul Joppa (P) on February 6, 2009 at 18:41:15

In Reply to: Last call: FS-100 plate chokes posted by mqracing on February 6, 2009 at 08:18:55:

Just a thought for anyone interested ...

In my experience, a larger impedance plate load always makes for better sound in parafeed. I've tried, or at least listened to, a wide variety of chokes as well as current sources. I once built a preamp with switched plate loads of 20, 24, 40, or 48 henries, for example (using 6BL7s parafeed to B7-5K) plus a current source - believe me, every inductance increase was an improvement.

Extrapolating that experience, here's a really wild idea - get a pair of these gapped for 60mA and couple to a TFA-2004Ni with a 27uF capacitor. If you can afford the nickel core TFA (still the best sounding OPT I've ever heard), this choke is neither inappropriate nor unreasonably expensive. Feed it with a 2A3 running 275v at 55mA - cathode resistor 910 ohms - or if you're feeling flush, one of those 2.5v 300Bs at 300v, 60mA (same cathode resistor).

Of course the greatest benefit will be in the bass, so use this to drive some ginormous efficient speakers with killer bass.

I predict you will never hear sound as good with a 2A3.

This was a reply to Mike's last call for these chokes:

On the bright side--- these are really great plate chokes--- and we can airgap them for a range of plate currents--- all of the units are designed to handle 500 vrms at 30 hertz AC signal. DC (plate current) capacities are listed below.

Each unit uses our EL coil design strategy (our SUPER designation). Each unit will be supplied with 18 gauge EE teflon lead wires. Each choke uses teflon insulation. We do NOT formally warrant this choke for high voltage applications. Each choke is wax impregnated. The nominal DCR (winding resistance) of this choke is 170 ohms.

- Home

- Amplifiers

- Tubes / Valves

- Building parafeed EL84 DC 2A3 amp