Here is a blast from the past. I designed this headphone amp years ago and just remembered how good it sounds and how easy it was to build. It’s a great project for anyone wanting to try etching their own PCBs. I used to do this all the time with laser printer toner transfers and HCl+H2O2 (muriatic acid and hydrogen peroxide).

This amp uses the OPA1688 opamp to drive 2x parallel OPA1688’s. This helps boost the output current. This was before the OPA1656 was available and I think changing to the latter will improve the output power. JPS64 did the home etch layout for me at the request of member Dibya - who I think also made this. Anyhow, kudos to JPS64 for a great layout and his generosity.

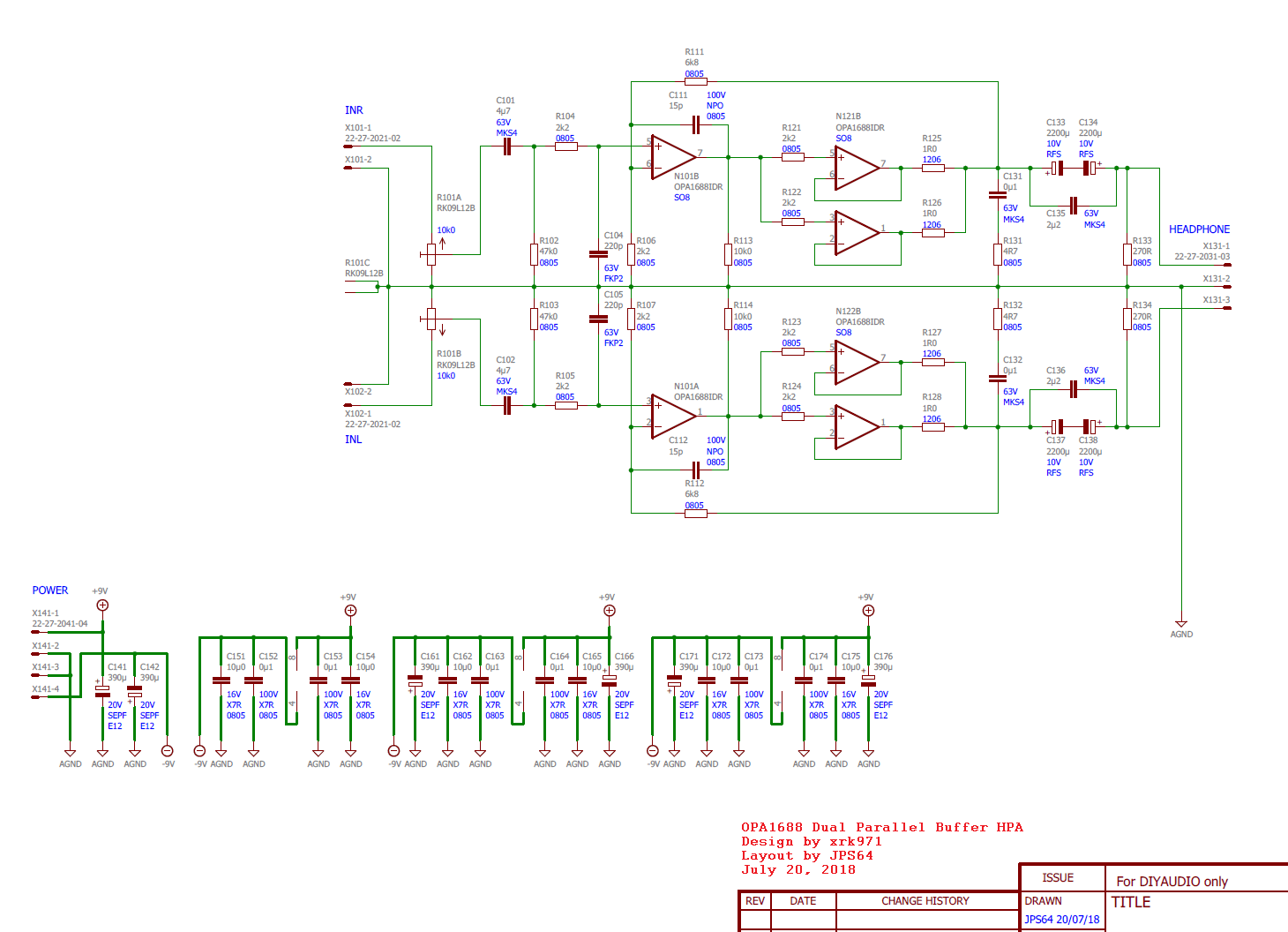

Here is the schematic:

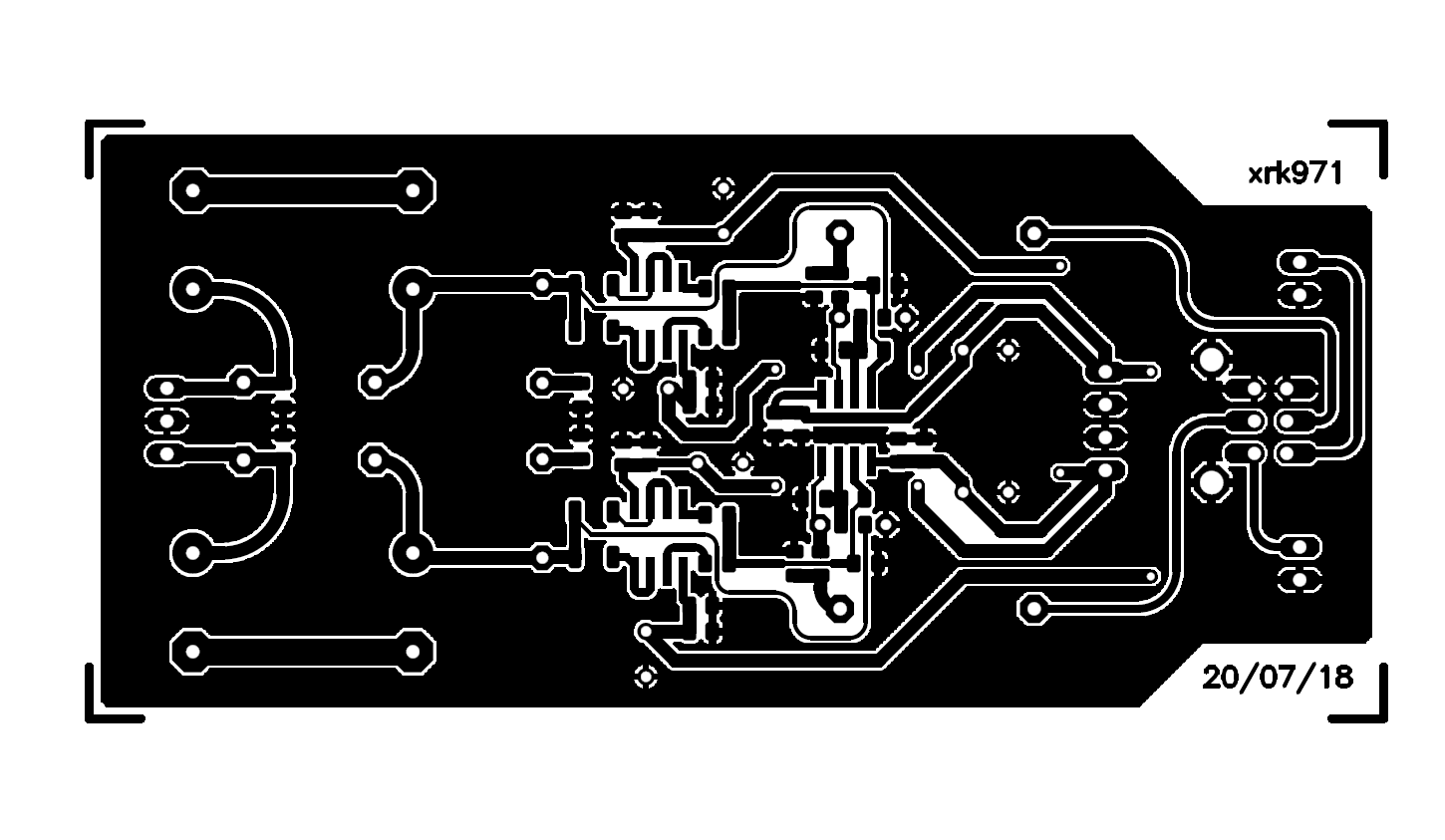

Here is the home etch layout:

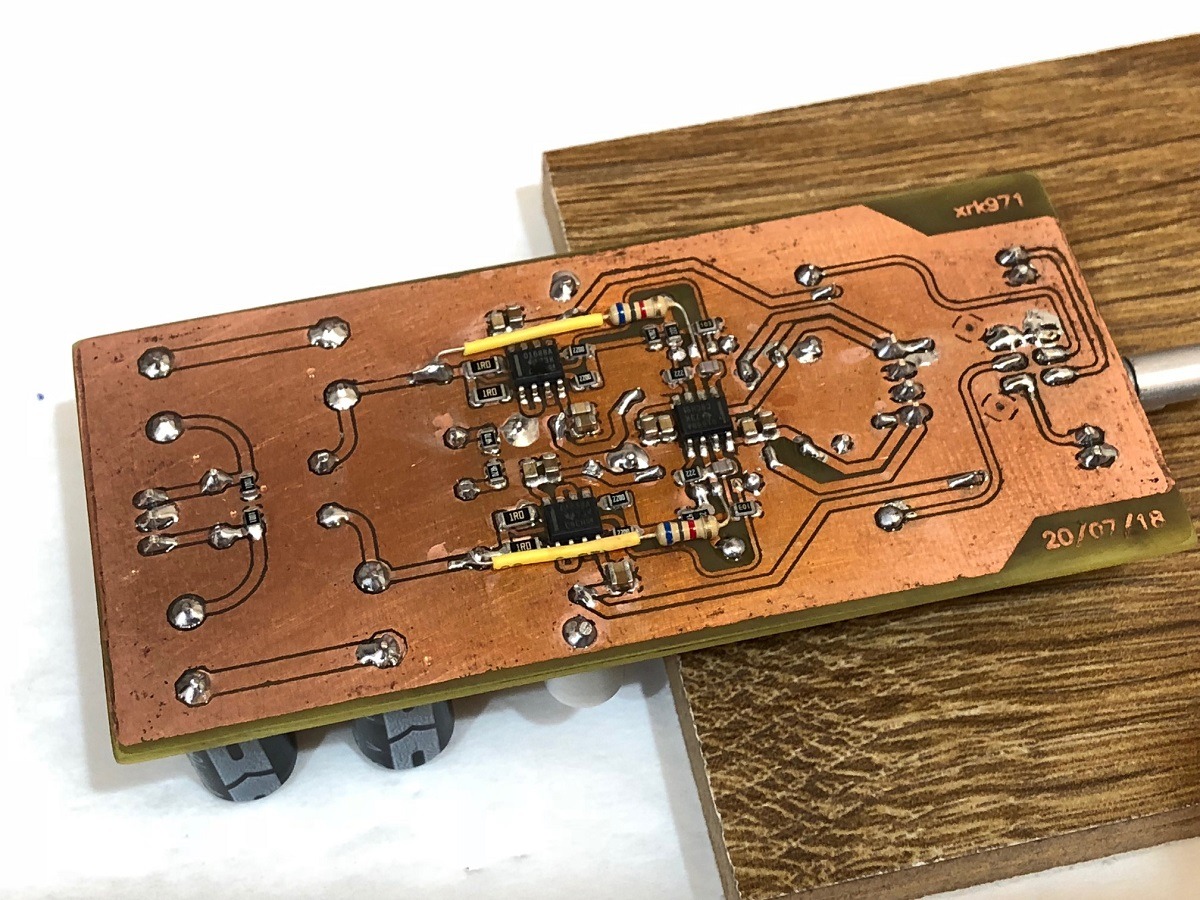

Built up:

Topside:

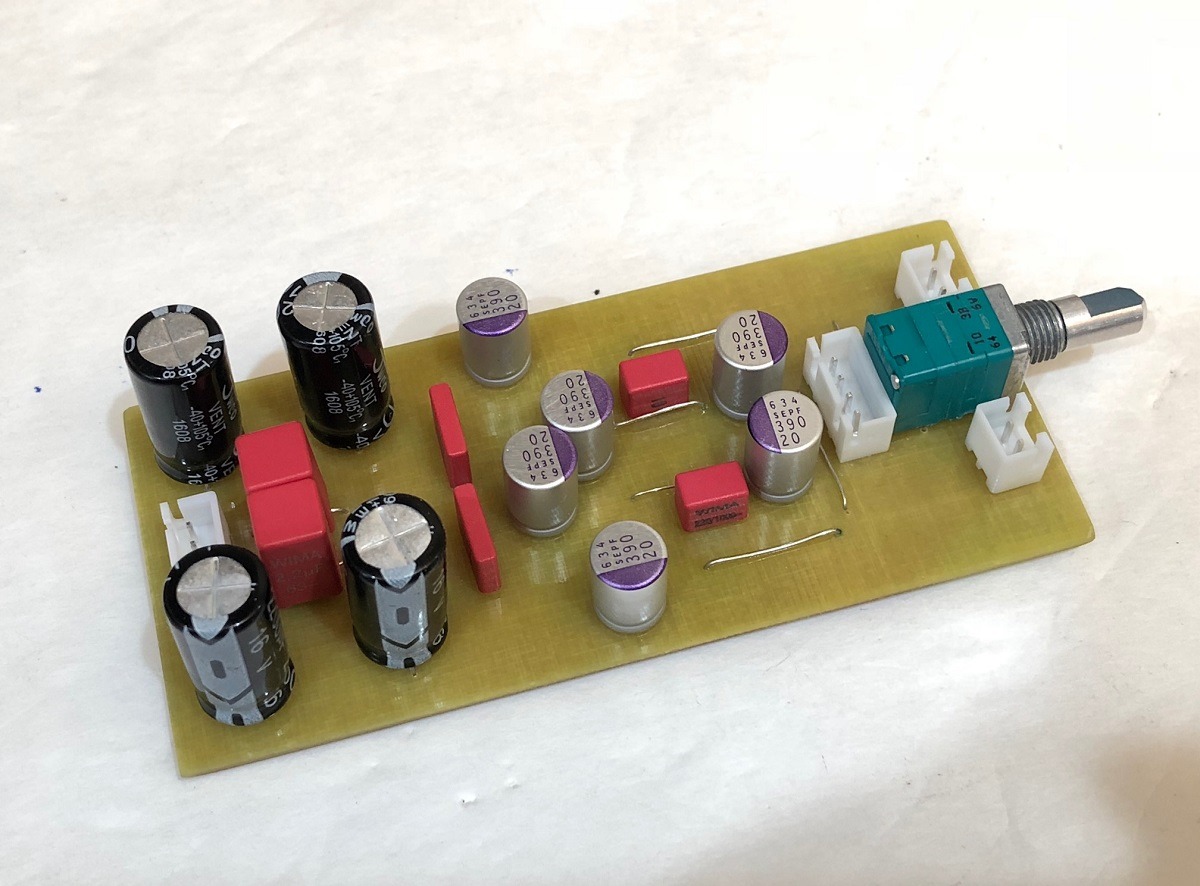

Assembled into chassis with an ultra low noise DCDC PSU (also home etched):

If you guys are interested in a real PCB, I’ll ask JPS64 to generate the Gerbers. But the point of this thread is to get folks to try the home etching method. I can explain more later but basically you make a laser print of the above layout on paper. Take that and iron it onto a blank copper faced PCB stock. The toner acts as acid resist. Then etch with acid peroxide solution and then drill holes if needed. This is why surface mount is nice - no drilling needed as the drill bits are very small and break easily with slightest side pressure. So a small Dremel drill press is a must.

It sounds great by the way. One of the easier home etched amps.

It was one of the nicest sounding amps in my collection at the time.

This amp uses the OPA1688 opamp to drive 2x parallel OPA1688’s. This helps boost the output current. This was before the OPA1656 was available and I think changing to the latter will improve the output power. JPS64 did the home etch layout for me at the request of member Dibya - who I think also made this. Anyhow, kudos to JPS64 for a great layout and his generosity.

Here is the schematic:

Here is the home etch layout:

Built up:

Topside:

Assembled into chassis with an ultra low noise DCDC PSU (also home etched):

If you guys are interested in a real PCB, I’ll ask JPS64 to generate the Gerbers. But the point of this thread is to get folks to try the home etching method. I can explain more later but basically you make a laser print of the above layout on paper. Take that and iron it onto a blank copper faced PCB stock. The toner acts as acid resist. Then etch with acid peroxide solution and then drill holes if needed. This is why surface mount is nice - no drilling needed as the drill bits are very small and break easily with slightest side pressure. So a small Dremel drill press is a must.

It sounds great by the way. One of the easier home etched amps.

It was one of the nicest sounding amps in my collection at the time.

Last edited:

Nice little amp - You can also get special laser printer transparencies (I'll be testing how good they transfer soon for a different project and if they survive and ironing). The transparencies then make it easier to stack a couple of layers of toner for a better transfer. If you want to use paper then a shiny paper works better (according to the mrs that uses it for arts and craft).

Cleanliness of the copper is paramount for a good transfer too so degreasing/wash with iso before if you find you have transfer issues.

Cleanliness of the copper is paramount for a good transfer too so degreasing/wash with iso before if you find you have transfer issues.

If using OPA1656 it is current limited to 200mA so P=I^2 x R gives 1.28W for 32ohm load. But that assumes voltage rails not reached. Assume +/-18v rails and we get P=V^2/R or 36v/2.83 for 12.7Vrms. This gives nearly 5W so it means it is current limited to about 1Wrms into 32ohms.Hi XRK, how much power output for this amp ? Is it larger than pocket class A ?

You can redo calcs for dual 9v batteries. These are closer to 8v or +/-8v or 16Vpp. This is 1W rms into 8ohms.

It’s bigger than PCA S laid out but could be made small with better layout and electrolytics all on one side of PCB.

Oops I meant 1W into 32ohms. And the current and voltage both support it. Never realized how powerful this could be for a couple of opamps. If you like where this is going check out my 8x parallel OPA1622 headphone amp. It’s technically capable of 10w into 8ohm speakers!If using OPA1656 it is current limited to 200mA so P=I^2 x R gives 1.28W for 32ohm load. But that assumes voltage rails not reached. Assume +/-18v rails and we get P=V^2/R or 36v/2.83 for 12.7Vrms. This gives nearly 5W so it means it is current limited to about 1Wrms into 32ohms.

You can redo calcs for dual 9v batteries. These are closer to 8v or +/-8v or 16Vpp. This is 1W rms into 8ohms.

It’s bigger than PCA S laid out but could be made small with better layout and electrolytics all on one side of PCB.

If you follow schematic above it should work. But note that OPA1656 is not available in DIP8 through hole. You will need to use small SOIC8 to DIP8 adapter. But it’s easy to solder those directly by hand. Skip the socket or adapter.

The bypass coupling caps are fine - need 2000uF electrolytic back to back on output though.

The bypass coupling caps are fine - need 2000uF electrolytic back to back on output though.

Hi, can you share me why you use back to back capacitor ?If you follow schematic above it should work. But note that OPA1656 is not available in DIP8 through hole. You will need to use small SOIC8 to DIP8 adapter. But it’s easy to solder those directly by hand. Skip the socket or adapter.

The bypass coupling caps are fine - need 2000uF electrolytic back to back on output though.

I typically use 25v to 16v to be safe. But technically, the DC is at close to 0v. The AC component doesn’t matter as this is dual rail design. So 10v should work.

You should use bipolar cap though or two in series back to back with +/+ facing each other or -/- facing each other to make a bipolar out of two polar caps.

You should use bipolar cap though or two in series back to back with +/+ facing each other or -/- facing each other to make a bipolar out of two polar caps.