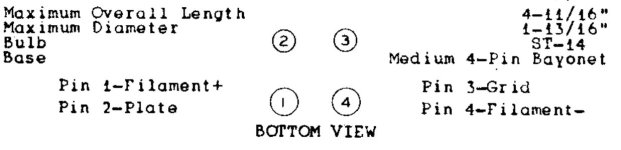

Today I tested DHT filament heating and max voltage I got with R.C regulator V9 was max 3.6V on DHT filaments. Input voltage around 8.8V. In the V9 R1 is 3.9 Ohm. Rf is 22 Ohm and DHT pin 1 and pin 4 resistance is 2.5 Ohm. It is connected like in post #715. Voltage drop between Rf and DHT is about 4.5V. Is this normal or I should decrease some R value?

Most valves of every type are designed to work with unregulated mains voltage supplies. Since these come with tolerances of ±5% or even worse, it becomes a serious consideration for the design of valves for a reasonable lifetime.I had not realized the link between the filament voltage at the socket to the filament heating temperature. I was fixated on the 0.25 amp current guide value. Just reset the Vfil to 4.75V. Measurement acoss the 19.5R resistor is 4.90V ie 0.251amps. What is the -5%? Is it an established safe de rating number for this tube?

It may not be obvious, but the equipment running heaters & filaments that underheated will fail quicker than if overheated. It's because the active elements that are consumed during operation must be driven up from the subsurface by temperature; they will become exhausted at the surface, if the temperature is too low.

The design response in cases that where documentary evidence is available: set the heat voltage to achieve correct running temperature at -5% of the recommended nominal voltage. We certainly have information to this effect from EIMAC for thoriated tungsten transmitters as well as consumer (coated) valves from Philips group.

Since we can now use regulators to stabilise the heat voltage to 1% or better, we can take advantage of this knowledge, and set the voltage at the -5% level (4.75V for a 5V nominal rating).

It may not apply to every type of valve; the modern European manufacturers like JJ and EML certainly require the voltage to be set to nominal 5.0V (looks like a case of partially forgotten knowledge).

testing of gm can potentially assist in determing the real intended optimum voltage.

Since we can now use regulators to stabilise the heat voltage to 1% or better, we can take advantage of this knowledge, and set the voltage at the -5% level (4.75V for a 5V nominal rating).

Thanks Rod for sharing this information with us.

However, as the valve starts aging with repeated on and offs the Rfil will rise and Vfil will also rise from the initial set value of 4.75V if I do not adjust the regulator (I think so). Where do you set the voltage Vfil at socket as the valve ages?

nash

Thanks Rod for sharing this information with us.

However, as the valve starts aging with repeated on and offs the Rfil will rise and Vfil will also rise from the initial set value of 4.75V if I do not adjust the regulator (I think so). Where do you set the voltage Vfil at socket as the valve ages?

nash

The filament resistance is stable is most DHTs, and does not require attention, but some very elderly 1920s era filaments may suffer from it.

Working through the confusion:

When the valve is new, the filament voltage is the proxy for temperature;

But temperature is really driven by power (V * I), so if you know the starting current (with satisfactory operation): - for example you found 4.75V 0.251A. Here the power is 1.19W; so if the resistance increases, the voltage will increase for constant current, but that will increase temprature and bring the resistance down again somewhat!

It is probably best to search for a nearby 1.19W power point, such as 4.9V 243mA. Try to find the nearest voltage to 4.75V that satisfies the 1.19W power envelope.

If the 01A shows signs of reduced emission, increasing the voltage to give 1.25 -1.3W dissipation to raise the temperature and see if the emission revives after some hours of operation. This is quite likely to rescue 01As at the last segment of their life. If you can test gm, increasing the power to just enough for the original value of gm is sufficient.

Working through the confusion:

When the valve is new, the filament voltage is the proxy for temperature;

But temperature is really driven by power (V * I), so if you know the starting current (with satisfactory operation): - for example you found 4.75V 0.251A. Here the power is 1.19W; so if the resistance increases, the voltage will increase for constant current, but that will increase temprature and bring the resistance down again somewhat!

It is probably best to search for a nearby 1.19W power point, such as 4.9V 243mA. Try to find the nearest voltage to 4.75V that satisfies the 1.19W power envelope.

If the 01A shows signs of reduced emission, increasing the voltage to give 1.25 -1.3W dissipation to raise the temperature and see if the emission revives after some hours of operation. This is quite likely to rescue 01As at the last segment of their life. If you can test gm, increasing the power to just enough for the original value of gm is sufficient.

How to make sure that my tubes 01a CX-301a are ok? One tube is not taking any current and no sound. Another is taking current 11mA (voltage between 10 Ohm resistor is 0.11V) and has some sound but no sound amplification. If I mix the pins 3 and 4 then what happens?

Last edited:

I meant mixing pin 2 and pin 3. 🙁 If I turn on filaments then I already started to hear some music and when I turn HV on then the volume stays same and maybe little bit improves sound quality. If I turn off HV and filaments stay on then music stops for a 2 seconds and then I hear again. I use the same Gyrator from Bartola with 6N23P and it plays with that. At the beginning filaments where swapped between pin 1 and pin 4. I do not think that affects.

It is probably best to search for a nearby 1.19W power point, such as 4.9V 243mA. Try to find the nearest

voltage to 4.75V that satisfies the 1.19W power envelope.

I tried three newish valves that the vendor claimed have gm of 925,925 and 950. All same structure late model globe RCA UX201A with the nickel pins. Measured voltages after about 40 minutes of operation. 4.75V at the socket gave 4.83V, 4.84V and 4.87V for the three across the 19.5R resistor. . Using the 4.84 number I got 4.84/19.5 is 0.248A times 4.75 is 1.18W.

Plugging in my used valves and adjusting to 4.75V at the socket yielded 4.77V and 4.77V for each across the resistor, again after hot operation. With the 1.18W target I readjusted them at 4.79V (socket) 4.80V(across R) and 4.80V {socket) 4.80 (across R). These valves are also the same type as the ones mentioned above. Is this correct?Is there any published number for power?

Thanks.

nash

In this case you connected Ua (of gyrator) to grid and use tube as grid_to_cathode diode.I meant mixing pin 2 and pin 3. 🙁

If the Ua is -for example- 150V and current via gyrator (grid_to_cathode diode) is 11mA, the grid dissipation will be more than 1.5W ... it's degrading thin grid wire, possible destroys it.

- Home

- Amplifiers

- Tubes / Valves

- 01A question