Christian.

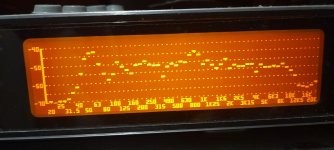

As promised, these are plots of the output in the central area of the graphite eps panel in front of the voice coils at about 4cm distance from the panel.

And of the output at 4cm also but at about 18cm ,(7inches) across the panel away from the main driving area.

The first picture shows the high output of the main (primary)driving area.

The second picture shows the lower output of the panel at 7inches.

These are single point measurements, so do not show the overall output of the panel.

This is why I regard the central area as being pistonic in nature, similar to having a cone speaker in the centre of the panel.

This makes the panel more of a point source and less defuse.

DMLs are never pure DML, they are also bending wave.

How much they operate in these 3 modes depends on panel materials and how you much you damp them.

Steve.

As promised, these are plots of the output in the central area of the graphite eps panel in front of the voice coils at about 4cm distance from the panel.

And of the output at 4cm also but at about 18cm ,(7inches) across the panel away from the main driving area.

The first picture shows the high output of the main (primary)driving area.

The second picture shows the lower output of the panel at 7inches.

These are single point measurements, so do not show the overall output of the panel.

This is why I regard the central area as being pistonic in nature, similar to having a cone speaker in the centre of the panel.

This makes the panel more of a point source and less defuse.

DMLs are never pure DML, they are also bending wave.

How much they operate in these 3 modes depends on panel materials and how you much you damp them.

Steve.

Attachments

That does look like our Corflute... The thicker one doesn't as it has circular voidsThis is the proplex 4mm ,the one in my previous post was the 6mm.

The 4mm looks very similar to the correx type material, but I have not compared the two, so am not sure if they are the same ?

If anyone knows the answer , please let us know?

I think I have seen 3mm signage correx, which seemed quite flimsy, but I am not sure?

Steve.

Is it rigid or can you squish it /flex it a bit with your fingers?

Which thickness sounded the best to you?

Eucy

Last edited:

I have the 3mm board exact looks like this one.This is the proplex 4mm ,the one in my previous post was the 6mm.

The 4mm looks very similar to the correx type material, but I have not compared the two, so am not sure if they are the same ?

If anyone knows the answer , please let us know?

I think I have seen 3mm signage correx, which seemed quite flimsy, but I am not sure?

Steve.

I remember I was surprised by it on the first listen. The sound was much neutral then I expect. I expected it should be an over-damp sound because the material is soft and "rubberish", rigidity is very low. I can cut it by a paper cutter easy.

However the surprise was fade out very soon. After 3 days listen I feel it sounds very "boring". And I can't find it has any signature advance the EPS, PLY or canvas. Overall I lost the interest to make more test on this material. I won't say this is a bad sounding material. I guess someone may like it's neutral to a little warm tone.

There is another corrugated board which is transparent Acrylic I may going to try.

Eucy, Hkguy6.

I have not tried the 3mm panels, the 2mm was definitely too thin and floppy.

JohnnoG was going to send me some samples, but never sent them.

On pages 282 and 283 and 286 287 there's plots and recordings of the proplex.

On page 291 there are comparison recordings with the crate ply.

With some comments about the sound.

The heavier 6mm proplex needs a more powerful exciter to drive it with ease, so it would be unfair to comment on how this would improve the sound?

The recordings should give an idea how they sound.

Acrylic does have a bright harshness to its sound, although I have not tried the 3mm.

Steve.

I have not tried the 3mm panels, the 2mm was definitely too thin and floppy.

JohnnoG was going to send me some samples, but never sent them.

On pages 282 and 283 and 286 287 there's plots and recordings of the proplex.

On page 291 there are comparison recordings with the crate ply.

With some comments about the sound.

The heavier 6mm proplex needs a more powerful exciter to drive it with ease, so it would be unfair to comment on how this would improve the sound?

The recordings should give an idea how they sound.

Acrylic does have a bright harshness to its sound, although I have not tried the 3mm.

Steve.

May I get more details? Maybe a pic of the thin strips mod. Thanks!Hkguy6.

Using thin strips of paper in the voice coil area can help inject a little life into heavier panels.

Steve.

I think the boring sound from this material may not because it's weight heavy. Compare with the ply, this material is far lighter.

There are some more recordings of the 6mm and 4mm proplex on page 198.

Sorry I tend to call anything heavier than eps as heavy.

I used the paper mainly on the large 3mm ply panels I have.

It helps if you can measure the changing response as you move the strips of paper across the exciter area surface.

Otherwise it's a bit hit and miss .

I did post some pictures but I don't want to search through this site anymore than I have to.

I will see if I can take some more pictures with measurements.

Steve.

Sorry I tend to call anything heavier than eps as heavy.

I used the paper mainly on the large 3mm ply panels I have.

It helps if you can measure the changing response as you move the strips of paper across the exciter area surface.

Otherwise it's a bit hit and miss .

I did post some pictures but I don't want to search through this site anymore than I have to.

I will see if I can take some more pictures with measurements.

Steve.

Hey guys,

I've read lots of posts on this thread, but not the entire 321 pages, and I couldn't find a comparison of the different exciters brand available.

I know the sound mainly depends on the board, and there are hips of good informations here, but I am wondering if certain brands design more quality exciters than others.

There are indeed different price range, and I'd like to know if there are different qualities (Dayton, Visaton, Monacor, Tectonic Audio Labs, PUI Audio...).

Thanks

I've read lots of posts on this thread, but not the entire 321 pages, and I couldn't find a comparison of the different exciters brand available.

I know the sound mainly depends on the board, and there are hips of good informations here, but I am wondering if certain brands design more quality exciters than others.

There are indeed different price range, and I'd like to know if there are different qualities (Dayton, Visaton, Monacor, Tectonic Audio Labs, PUI Audio...).

Thanks

I'm not familar Monacor. But I'm quite sure the others brand you listed are rebranded from a single manufacturer BillionSound. So that should not has much quality different between the brand. But between the model of the exciter.

You may search "BillionSound" in this thread to read more.

You may search "BillionSound" in this thread to read more.

It strange. Even ply is the heavier but I never feel ply sounds boring. It's even brighter and has better timbre then EPS. Honestly I will say corrugated board sounds quite similar with EPS. Just lack of speed and less lifely.There are some more recordings of the 6mm and 4mm proplex on page 198.

Sorry I tend to call anything heavier than eps as heavy.

I used the paper mainly on the large 3mm ply panels I have.

It helps if you can measure the changing response as you move the strips of paper across the exciter area surface.

Otherwise it's a bit hit and miss .

I did post some pictures but I don't want to search through this site anymore than I have to.

I will see if I can take some more pictures with measurements.

Steve.

Larger size ply just affect the efficiency but not much on the sound signature. Or maybe I didn't try some really BIG ply. The bigger I have is only 40x60cm.

Hello Steve.Christian.

My exciters are 4 ohms .

With my exciter, eps panel combination, the high frequencies do not reach the edge of the panel.

The hf is mostly produced in the central area ,especially if the cancellations in this area are delt with .

Ply and proplex for instance, with my combination or exciter and panel will reach 20k across the whole panel even at the edges.

Probably at a slightly lower volume, similar to the other frequencies.

I will make some plots of this ,to demonstrate the differences.

Even though the ply and and proplex show a higher output of HF across the panel,they sound lacking, I can only describe it as a restrained sound.

They lack a brightness or life to the sound ?

Podiums had the same sort of sound, the more I listened the more i noticed , which was probably why I preferred the sound from the back ?

It is strange when the measurements say one thing, but my ears say another.

I'm not saying that the heavier panels don't sound good.

The proplex panel for instance, is a very good all round performer with low colouration, no box or frame needed, simple, works perfectly.

If I was to hear this at an audio show , costing thousands of pounds, I would be impressed.

For me at home, I would still want to improve it a little.

Steve.

Thank you for the feedback

For the exciter impedance... oops!... I have kept in my notes the posts #3433 #4419 where you linked to the TEAX25C10-8/HS... but checking just right now, I understand I missed the sentence just before the link in #3433 "This is basically my exciters ,not so cheap now and it seems to be only in 8 ohms?"

So... up to which point the specifications of your exciters is different????

Too bad!

The rest of your post gathers probably more phenomena than the "simple" force at the driving point from the model :

- the absorption of the wave traveling from the exciter to the edge with a higher absorption in EPS than in plywood or Proplex

- the combination of those sources across the whole panel at the listening position which might be not in favor of a long travelling distance according to your experience.

It remind me the tentative I did to measure the panel at short distance at the driving point and somewhere to the edge (#4152, #4160 )

... just say the measurements don't cover the whole question, or don't describe what matters. Let's not give upIt is strange when the measurements say one thing, but my ears say another.

Christian

Hi Eucy,Hi Christian ..

Can you please explain further how you draw that last conclusion .. It seems upside down to me

Eucy

I think you are speaking about the last point :

* "a high mechanical impedance material will go higher."

by making the connection between :

- my measurements which seem to show a wider bandwidth for materials stiffer and/or heavier

- the simplified model that evaluate the driving force. When increasing the mechanical impedance (R3 in the model), the force (out) increases at high frequency.

Could you detail more your experience? What is your ranking among the materials to give the wider bandwidth?

All the pieces of the jigsaw don't fit for now...

Christian

Hi hkguy6It strange. Even ply is the heavier but I never feel ply sounds boring. It's even brighter and has better timbre then EPS. Honestly I will say corrugated board sounds quite similar with EPS. Just lack of speed and less lifely.

Larger size ply just affect the efficiency but not much on the sound signature. Or maybe I didn't try some really BIG ply. The bigger I have is only 40x60cm.

I wondered if you've thought about trying to get hold of some Paulownia ply to try

There are Chinese sources for the ply

We grow it in Australia now but there's no local source of ply

It's very light (SG ~ 0.3) and has good acoustic properties according to the attached paper

Eucy

Attachments

Thanks I will check it locally.

The ply I used now is quite satisfy in small to middle size. My PUI exciters can handle them well in single.

Honestly I don't think I will like the large(60cm up) ply. Large panel is not good for my small room. Bigger will cause more room problems to solve. It also difficult to free hanging. I'm not prefer framed board sound. Even just sit the ply on ground with foam under will damp the sound too much for me.

The ply I used now is quite satisfy in small to middle size. My PUI exciters can handle them well in single.

Honestly I don't think I will like the large(60cm up) ply. Large panel is not good for my small room. Bigger will cause more room problems to solve. It also difficult to free hanging. I'm not prefer framed board sound. Even just sit the ply on ground with foam under will damp the sound too much for me.

When I use smaller panels I scale down the thickness to produce a more flexible panel.It strange. Even ply is the heavier but I never feel ply sounds boring. It's even brighter and has better timbre then EPS. Honestly I will say corrugated board sounds quite similar with EPS. Just lack of speed and less lifely.

Larger size ply just affect the efficiency but not much on the sound signature. Or maybe I didn't try some really BIG ply. The bigger I have is only 40x60cm.

1mm seems to be a good compromise.

With the exception of the 3mm crate ply, which is light and very flexible, I find that making ply panels smaller tends to make the panel too rigid, yes, giving it a brighter sound ,but also brings in a harshness to the sound, similar to glass.

Large ply panels will give a fuller sound but will bring with it the low frequency resonances and colourations.

Which would need sorting out somehow.

Hopefully in my recordings you can hear that I try to make the panels disappear, no panel noise or signatures.

The crate ply still has its problems, but I was hoping that placing a fabric dome in the centre might solve these issues, by minimising the coil cavity noise and distortions within the coil area.

This project , I have not got around to yet , so the outcome is unknown yet ?

Steve.

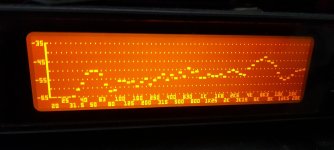

While I was unsuccessfully trying to apply my strips of paper on the two proplex panels, I took some plots , the first at 1m the second at about 2inches.

Usually I'm trying to correct strong peaks and dips in the response.

But as you can see ,There is not much to correct , if anything.

This is a very well behaved panel.

Although I did notice something interesting while playing around with the fluted panel.

In the third picture you can see a hump in the response.

This is beaming out to the side of the panel, but slightly to the front, but only on the side with the open flutes on ,not the closed sides.

If this was up close to a wall and toed in to face you ,it would beam those frequencies back in towards you.

So i would recommend having the open flutes pointing up and down to minimise the problem .

Strange but interesting.

Steve.

Usually I'm trying to correct strong peaks and dips in the response.

But as you can see ,There is not much to correct , if anything.

This is a very well behaved panel.

Although I did notice something interesting while playing around with the fluted panel.

In the third picture you can see a hump in the response.

This is beaming out to the side of the panel, but slightly to the front, but only on the side with the open flutes on ,not the closed sides.

If this was up close to a wall and toed in to face you ,it would beam those frequencies back in towards you.

So i would recommend having the open flutes pointing up and down to minimise the problem .

Strange but interesting.

Steve.

Attachments

Thank you SteveChristian.

As promised, these are plots of the output in the central area of the graphite eps panel in front of the voice coils at about 4cm distance from the panel.

And of the output at 4cm also but at about 18cm ,(7inches) across the panel away from the main driving area.

The first picture shows the high output of the main (primary)driving area.

The second picture shows the lower output of the panel at 7inches.

These are single point measurements, so do not show the overall output of the panel.

This is why I regard the central area as being pistonic in nature, similar to having a cone speaker in the centre of the panel.

This makes the panel more of a point source and less defuse.

DMLs are never pure DML, they are also bending wave.

How much they operate in these 3 modes depends on panel materials and how you much you damp them.

Steve.

Sorry to answer late... so important activities on going those days!

I have digitized your measurements. In other words enter manually the estimated values I read on the pictures in a spread sheet.

Here are the 2 curves

Here is their differences (blue) and a tentative of smoothing (red)

I don' know what to think about it except that quickly the attenuation is around 6dB (from 200Hz) to come near 9dB from 2k and then increasing above 10/12k.

The loss in HF was expected but the loss from 200Hz less...

Does it mean the wave don't travel far in EPS?

In my last post based on outdoor measurements, EPS shown an higher damping than the 2 other "competitors" 'XPS, plywood)

Christian

Attached the pdf of the OpenOffice file; Let me know if you want the OO or xls version.

Attachments

Hello SteveWhile I was unsuccessfully trying to apply my strips of paper on the two proplex panels, I took some plots , the first at 1m the second at about 2inches.

Usually I'm trying to correct strong peaks and dips in the response.

But as you can see ,There is not much to correct , if anything.

This is a very well behaved panel.

Although I did notice something interesting while playing around with the fluted panel.

In the third picture you can see a hump in the response.

This is beaming out to the side of the panel, but slightly to the front, but only on the side with the open flutes on ,not the closed sides.

If this was up close to a wall and toed in to face you ,it would beam those frequencies back in towards you.

So i would recommend having the open flutes pointing up and down to minimise the problem .

Strange but interesting.

Steve.

If you have to make a ranking of the materials you have tested according to a smoothness criteria, would it be Proplex the winner?

Christian

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker