I found foam types confusing. Model makers use blue as it can be carved and sanded. XPS gets mentioned. This is recycled eps with a closer cell structure sometimes paper coated. Often pink but insulation boards may be blue. No idea how this fits in with the blue model makers use but that does have a higher density than others.

EPS is expanded Polystyrene. It comes in various densities ranging from 1-5lbs densities. I would use the higher densities of 2lbs and up.Can you clarify please , The 1/2" EPS you refer to , is that the same as polystyrene that is used as packaging when you unbox the average appliance these days , or is it the heavier density EPS grade that has a hardened skin on both sides ?

I have seen both labelled as "EPS" in suppliers i go to so i need to clarify which it is.

I have the sense that i should be testing thinner lightweight panels with a stiff facing material .

My list of options is now;

2.5 mm thick Poplar Ply with a 0.4 mm bonded walnut or Blackwood veneer on the front.

2 mm Balsa panels with a 0.5 mm Carbon Fibre sheet bonded on the back and front.

6 - 12 mm EPS bonded with canvas photo front and -as yet undecided rear skin for fully transmitting the sound wave energy.

6 - 12 mm EPS bonded front and back with a 0.4 mm Blackwood or Maple veneer.

What opinions do people have for pro's and cons ?

Selection of the adhesive type could create large variations in the above.

EPS=Expanded Polystyrene, white color. XPS=Extruded Polystyrene, pink and blue color.I found foam types confusing. Model makers use blue as it can be carved and sanded. XPS gets mentioned. This is recycled eps with a closer cell structure sometimes paper coated. Often pink but insulation boards may be blue. No idea how this fits in with the blue model makers use but that does have a higher density than others.

EPS is stuck together by tiny beads in which you can see it. XPS is one whole form there are no beads.

No worries, I certainly didn't take it that way.Not trying to be argumentative at all, just fleshing out my assumptions. Tone is hard in text.

Eric

Sorry man, sounds exactly the same to me. Also it is still skewed heavily to my left panel.I made another recording but this time i used some techniques to make the recording sound better see if you can tell the difference.

If you add a veneer to one side only, there's a pretty good chance it will warp over time due to fluctuations in humidity. To keep the structure balanced and minimize the amount of warp you really should add the same veneer to both sides.2.5 mm thick Poplar Ply with a 0.4 mm bonded walnut or Blackwood veneer on the front.

I like this one for sure, but you may want to try thinner CF layers. Also, balsa density varies a lot. Try to get balsa under 0.2 g/cc.2 mm Balsa panels with a 0.5 mm Carbon Fibre sheet bonded on the back and front.

On this I'd lean closer to the 6 mm EPS. I think any thicker would result in a panel far too stiff.6 - 12 mm EPS bonded front and back with a 0.4 mm Blackwood or Maple veneer.

Last edited:

If i want to play 2 way crossover

How low frequency can the big board reach?

What drivers and assembly are needed?

(Driver? Board size? Where is the driver placed?)

Sorry because the page count is already 499 pages

I don't know where to start... XD

Thank you very much for your reply and help

How low frequency can the big board reach?

What drivers and assembly are needed?

(Driver? Board size? Where is the driver placed?)

Sorry because the page count is already 499 pages

I don't know where to start... XD

Thank you very much for your reply and help

So I have been to the github data linked to here and looked through the documents including the spreadsheets (thanks for that BTW to whomever).

However this discussion, although great, is about to be 10K posts in length which is a formidable amount of information to search through. This is also not including the branch threads. Someone had suggested a wiki which might be 'old school' now (?) but I think that or some form of summary and/or organization would be a good idea. Some (a lot) of this thread is getting repetitive, and relying on new people to use search more effectively may not be the only answer as knowing what term(s) to search for is half the battle.

That or maybe we can ask an AI bot to put it all together since AI is so hot right now

However this discussion, although great, is about to be 10K posts in length which is a formidable amount of information to search through. This is also not including the branch threads. Someone had suggested a wiki which might be 'old school' now (?) but I think that or some form of summary and/or organization would be a good idea. Some (a lot) of this thread is getting repetitive, and relying on new people to use search more effectively may not be the only answer as knowing what term(s) to search for is half the battle.

That or maybe we can ask an AI bot to put it all together since AI is so hot right now

100 Hz - 300 Hz, depending on panel size and application, seems to be the main crossover range people here are using. It was mentioned in the PA DML thread that even if a large panel can reproduce lower than 100 Hz that coil overheating can be an issue and they may have to be high-passed anyway. BUT that was at PA levels which are going to be really loud, like 100 dB and higher.Add the above

Or,I only use DML for mids and highs(100Hz~200Hz? to 7KHz~10KHz?)

Then add extra subwoofer and treble

Do you have any recommendations?

10 kHz also seems to be the upper end of response before response starts rolling off considerably. However, most cannot hear to 20 kHz so depending on the listener and the music adding some EQ to augment the higher end might be enough (no tweeter). As mentioned by someone before, a tweeter is going to beam (unlike the DML) so you will want to get a small one for max dispersion, like a 3/4" dome or the like. Given the really high pass frequency it will probably be able to output a lot of SPL despite its small size. Parts Express and Madisound have a big selection of tweeters. Dayton Reference speakers are a good value.

The above is very general. There are exceptions. YMMV.

Last edited:

That's too much of a generalisation Deude...10 kHz also seems to be the upper end of response before response starts rolling off considerably

Much better results are achievable with careful material selection, design and detailing

As you point out, finding the details is the problem.

Other major problems are that there's no cohesion in this thread, there's heaps of general thoughts/concepts, but little to no convergence of designs/ideas, a reluctance for testing ideas of others, and little chance of any future blueprints for successful implementation of DML designs for a range of purposes

It has been described as the Wild West.. Probably appropriate

I'm conflating your two recent posts but I don't want to make this thread any bigger LoL 😜

Last edited:

My advice is now to glean whatever you can from all the stuff here, quietly test, test, test your own ideas, share them if you think it's useful, build something that you're happy with, and don't have too high an expectation of this forumIt is a fair summary. But take your best shot at it.

Eucy

Well I get your point but it seems to me that sharing this information in a usable manner is at least a good idea? At any rate what I remember from examining dozens of RTA analyses is that DMLs in general have a steep rolloff at around 10K. There are exceptions of course. If I implied they are all like that then that would be wrong.

A better generalization for crossover points would be very similar to conventional cone driver designs.

Like I said before all materials act as a filter and each material will have a different frequency response just like different cone drivers will have different optimal frequency response.

Popular crossover points for mid-woofers are usually 2k-6k. Most tweeters wont play below 2k and the smaller the tweeter with lower wattage the higher crossover point is needed.

A powered sub amps crossover low pass is usually 40hz-160hz. So basically you cant cross the panels higher then 160hz unless you modify it.

With DML's I have found that 1st order crossover sounds better then 2nd order crossover. All you need is a capacitor for the highs and a inductor for the lows.

I prefer the higher grade poly caps over electrolytics and the Air core inductors over solid core ones.

Like I said before all materials act as a filter and each material will have a different frequency response just like different cone drivers will have different optimal frequency response.

Popular crossover points for mid-woofers are usually 2k-6k. Most tweeters wont play below 2k and the smaller the tweeter with lower wattage the higher crossover point is needed.

A powered sub amps crossover low pass is usually 40hz-160hz. So basically you cant cross the panels higher then 160hz unless you modify it.

With DML's I have found that 1st order crossover sounds better then 2nd order crossover. All you need is a capacitor for the highs and a inductor for the lows.

I prefer the higher grade poly caps over electrolytics and the Air core inductors over solid core ones.

Last edited:

For those interested in a 2 way (2 exciters on the same panel) DML design I would start with this patent by Dr.Jose Bertagni.

https://patents.justia.com/patent/4997058

Lots of info in that patent. It tells you how to increase treble, bass and how to reduce intermodulations etc.

https://patents.justia.com/patent/4997058

Lots of info in that patent. It tells you how to increase treble, bass and how to reduce intermodulations etc.

Yes indeed...a more systemised listing would be great... Christian has contributed a lot in this regard.Well I get your point but it seems to me that sharing this information in a usable manner is at least a good idea? At any rate what I remember from examining dozens of RTA analyses is that DMLs in general have a steep rolloff at around 10K. There are exceptions of course. If I implied they are all like that then that would be wrong.

Above 10k...I was searching for some of my sweep tests just now to show you what can be achieved, but I realised that they were lost when I had a Windows 10 failure and I had to do a clean install... I'll have to do some repeat testing, but I'm achieving solid results up to about 16-18k

Steve will/could also attest to that

Yes this is the same configuration as the OB (subwoofer, full range, tweeter), using a first order crossover, I wonder how the DML sounds different from the 18" FR (mid-high)?A better generalization for crossover points would be very similar to conventional cone driver designs.

Like I said before all materials act as a filter and each material will have a different frequency response just like different cone drivers will have different optimal frequency response.

Popular crossover points for mid-woofers are usually 2k-6k. Most tweeters wont play below 2k and the smaller the tweeter with lower wattage the higher crossover point is needed.

A powered sub amps crossover low pass is usually 40hz-160hz. So basically you cant cross the panels higher then 160hz unless you modify it.

With DML's I have found that 1st order crossover sounds better then 2nd order crossover. All you need is a capacitor for the highs and a inductor for the lows.

I prefer the higher grade poly caps over electrolytics and the Air core inductors over solid core ones.

Is there a simple assembly list for this DML speaker?

Board material, driver model, simple assembly introduction...etc.

I want to set up a simple DML to listen for a while

If you have any information or ideas, welcome to recommend

Thank you very much for your reply and help

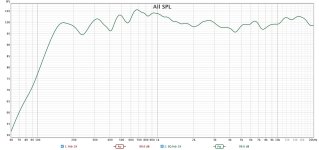

On FR sweeps I don't know if this will help but this is an REW FR sweep of my latest build. 3mm Poplar ply 300 by 1200 with foam supports on the long sides only.Yes indeed...a more systemised listing would be great... Christian has contributed a lot in this regard.

Above 10k...I was searching for some of my sweep tests just now to show you what can be achieved, but I realised that they were lost when I had a Windows 10 failure and I had to do a clean install... I'll have to do some repeat testing, but I'm achieving solid results up to about 16-18k

Steve will/could also attest to that

Attachments

That's some decent top end Burnt.my latest build

What drivers are you using?

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker