Think of it this way: as the wave leaves the source does it encounter any changes in slope, i.e. 2nd derivatives. If not then no diffraction. What is shown above does precisely that. The wave never encounters a slope change so this source would be free from any diffraction - until it met with room obstacles, which surely it must. But what is shown is very hard to implement - requires a wall reconstruction. And then there is the woofer. I'd put in three as close to the corner as possible (but there now, these will diffract.) Ideal solutions are nice, but usually have "gotcha"s and impracticalities.

I can put mine in the wall itself with no problems up to 8 inches deep. In the UK, the inner wall is thermalite block. Not sure if you get it in the US, but it's airated ceramic thhat you can cut with a saw or knife.

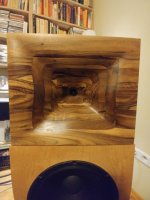

Driver is the JBL 2452, which is small for a 4 inch diaphragm driver.

Sure, I understand the appeal. It won't be a problem to generate, including the Fusion curves for the throat adaptor.... The appeal for this kind of waveguide is the ability to construct it at home with basic hand tools ...

Last edited:

I don't have a better photo on hand, but it is as simple as it looks.

Thanks!

Something "IRL"...

//

The idea as such of placing 1/8 of a spherical source into the corner is a lovely one. Unfortunately any practical implementation consisting of such an array of transducers will probably still leave much to be desired. The sizes and spacing would have to be much much smaller - basically it would have to be composed of very small fullrange drivers, covering the whole surface. Not impossible, only not very convenient, IMHO. I'd rather opt for a floor-to-ceiling line of small transducers along the 2-walled corner.

Last edited:

Relatively easily obtainable freestanding waveguide is a 3D printed one - a printer with 300x300 bed with 400 mm usable height could in theory print a waveguide of up to 40 cm (based on scaling the smaller one I tried). That is on the edge of what a hobby 3D printer could do. If height is not available, it could be still printed in two halves. Larger would have to be printed in more parts and that brings some other difficulties.

I think bmc0 has shown another practical use of 3D printing to create even bigger horns 🙂. https://www.diyaudio.com/forums/multi-way/354772-acoustic-horn-design-practical-2.html#post6214298

With a bit of care and thought this method could be used for a free standing horn as well. And with a bit more work, more options become available. Using printing (and possibly similar methods bmc0 used, but in reverse) to create the molds for example. It is doubtful the 3D printed materials are the best option for a waveguide. They do make a good prototype but I wouldn't end it there.

With a bit of care and thought this method could be used for a free standing horn as well. And with a bit more work, more options become available. Using printing (and possibly similar methods bmc0 used, but in reverse) to create the molds for example. It is doubtful the 3D printed materials are the best option for a waveguide. They do make a good prototype but I wouldn't end it there.

From what I've seen, 3D printing is fine for smaller pieces, parts or prototypes but I have yet to see a bigger print that would satisfy me regarding the print quality. Maybe there are such (professional) printers around - none I would know of. I know of a guy who designed big printer to use anorganic print materials (engineered stone, glass powder, just about anything like that) but I don't know how he's far with that. I asked him recently without an answer.

- I started to build a lathe-like machine for mold milling so I'll see how that goes. I still do think the axisymmetric waveguides won't be that hard to make, even big.

- I started to build a lathe-like machine for mold milling so I'll see how that goes. I still do think the axisymmetric waveguides won't be that hard to make, even big.

Ideal solutions are nice, but usually have "gotcha"s and impracticalities.

so true!!!

The sizes and spacing would have to be much much smaller - basically it would have to be composed of very small fullrange drivers, covering the whole surface.

only if you want to go higher in frequency, but if limited in frequency and used as a low frequency source what would be wrong?

It would be lovely if rippin' and gluin' was enough, though 😀 For best speakers in the world making a mold is just few more days (or maybe weeks if no prior experience and tools), well worth it in that case. Anyway, this is so exciting, million thanks to mabat for the millionth time 🙂

Sure, for low frequency only there would be no problem I guess. So something like Bose 2201 for the lows (up to 500 - 700 Hz) and a big free standing waveguide above that. Could work 🙂only if you want to go higher in frequency, but if limited in frequency and used as a low frequency source what would be wrong?

i envy those who are blessed with the ability to 3d print this stuff....i so long to hear these.....

to anyone who does PM me i have an experiment i would like to try in order to measure the results.

to anyone who does PM me i have an experiment i would like to try in order to measure the results.

I started to build a lathe-like machine for mold milling so I'll see how that goes. I still do think the axisymmetric waveguides won't be that hard to make, even big.

Finally something I can help with! I made a machine like this to turn fancy table legs for a furniture commission a few years ago. It only required a few cheap roller bearings, some threaded rod, scrap wood, and a palm router. I have no doubt a similar design could be used to cheaply and easily carve out an axisymmetric waveguide (or a mold of the same).

Attachments

Jack is printing a slightly scaled down version of that very same design for me right now... set up for a DE250 though.

I was notified that I might have violated license terms of one of the libraries I used in Ath. Therefore Ath is no longer available, at least until I solve this out somehow. Sorry about this.

It's right, I cannot distribute a closed-source software linked to the Gmsh SDK. I would have to go open source which I'm not willing to do at the moment, and as the commercial Gmsh licence is 50k EUR it's obvious what has to happen - this is the end of Ath in its general form. It's not the complete end of it - a new version supporting only axisymmetric waveguides will most probably continue (for that I don't need any third-party library at all). Sorry guys, this is life.

Last edited:

That's a bummer for lots of users out there, I'm sure...

Very sorry to read this and most likely, no solution is available to solve it.

Very sorry to read this and most likely, no solution is available to solve it.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)