What does that mean, how to get 15db of gain? Dorectivoty is similar to what you compare to? so its not by narrowing pattern. Single equally loud reflection would make constructive interference about 6db, and of course destructive interference would need to be somewhere as well. So, it's just crazy amount of efficiency? 15db is what, about 50x better? 😀

There may be a price to pay, I'm still not sure. For a more rigorous analysis it would need a horn with different lengths of the extension (which would have to be cylindrical)... These are still just some examples, more or less random, not directly comparable.

+15dB but 100dB sens at 10kHz right? So tweeter (with low Fs) array can outperform? Tekton Audio maybe? Sica dome is 94dB.

I don't know the absolute values. You can "outperform" anything... depends on what you want, I guess.

So far there's around 70 downloads of the STLs for ATHEX 400-36/25. So I hope we see more of them as time passes... 🙂

(I have mine waiting to be assembled...)

(I have mine waiting to be assembled...)

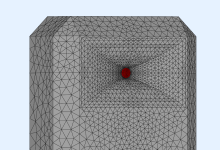

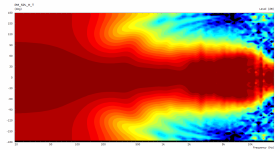

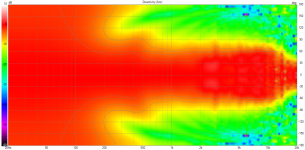

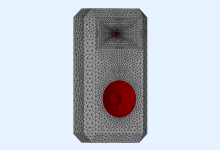

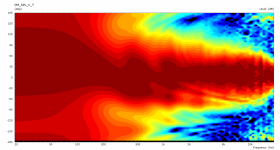

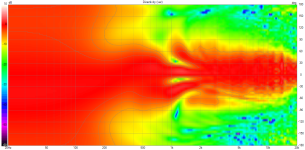

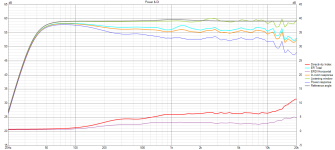

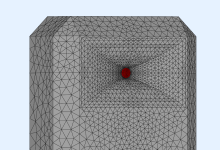

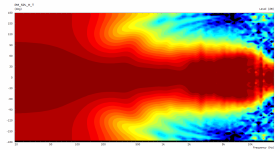

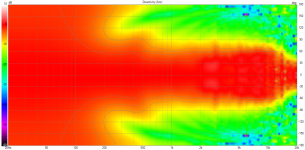

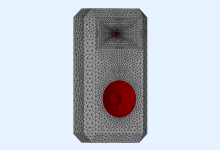

After my discovery that a narrow baffle means some issues, I did new simulation experiments for a 2-profile waveguide in a relatively simple bevelled enclosure.

- c. 40 cm width, simple 5 cm bevel edge:

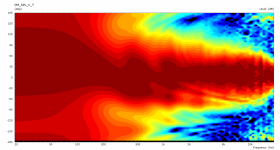

- 65 degree horizontal radiation pattern:

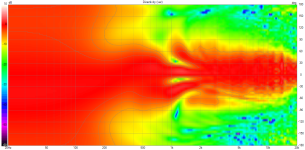

- vertical +- 50 degree:

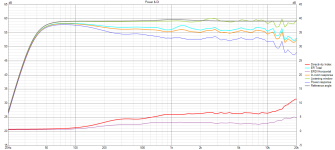

- what vCad shows:

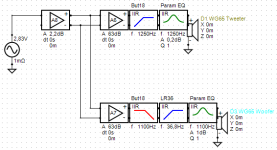

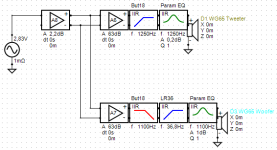

- the crossover for this:

- c. 40 cm width, simple 5 cm bevel edge:

- 65 degree horizontal radiation pattern:

- 10 inch woofer spaced at 1.2 lambda

- results in 75 cm height, 23 cm depth for acceptable volume:

- vertical +- 50 degree:

- what vCad shows:

- the crossover for this:

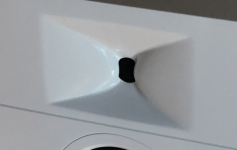

I've been cutting the test horns out of EPS foam on my cnc - it's very quick! It seems that a covering of microfibre cement makes a very nice hard yet sandable coating. Its probably possible to get a very nice finish with more sanding and more coats and then a varnish/epoxy finish. Definitely easier than my wooden gramophone style horns.

That's great to hear! I build nearly everything out of EPS these days, but have struggled with how to make the outermost layers stiff. I mostly use a sandwich of thin plywood on the faces, but it's tricky because the plywood and the foam tend to delaminate if you're not careful.

Polystyrene glue (gorilla glue) seems to work pretty well.

Here's a badly made cutting video - EPS dust sticks to everything! The whole horn took less than 30mins to make. It's quite fun.

I'd really recommend trying the 'flexible floor leveling compound' - it sticks to EPS so well and makes a great sandable base for other coverings or epoxy direct. I wonder what's in it?

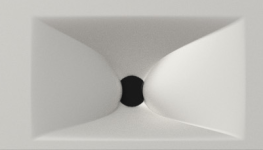

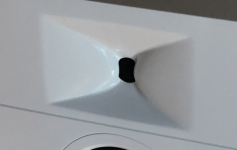

This is a 9 sided version if the ATHEX 400/460

https://drive.proton.me/urls/4CCA0YX40R#-Br7gAGC_-Ni

I'd really recommend trying the 'flexible floor leveling compound' - it sticks to EPS so well and makes a great sandable base for other coverings or epoxy direct. I wonder what's in it?

This is a 9 sided version if the ATHEX 400/460

https://drive.proton.me/urls/4CCA0YX40R#-Br7gAGC_-Ni

Wow!

Hypnotic!

Is that what we call Celotex (brand)?

Edit; Ah, no it's not the same.

It's very light and soft.

Resonance?

The process reminds me of when I turned my Le Cléac'h 550Hz horns from softwood except I would have been a Terminator with wood turning skills:😂

Hypnotic!

Is that what we call Celotex (brand)?

Edit; Ah, no it's not the same.

It's very light and soft.

Resonance?

The process reminds me of when I turned my Le Cléac'h 550Hz horns from softwood except I would have been a Terminator with wood turning skills:😂

Could this be semantic? Typical waveguides are are essentially conical. Once you account for throat angle measures and add the inevitable termination, they may look little like their starting shape.Conical horns are one of the worst types of horns.

Yes, plain old celotex from a skip. 150mm thick. It's incredibly light but very stiff when coated.

Continuing with the extended ATHEX 460-36, I quickly measured Selenium D2500Ti-Nd, a small 1" driver:

(Again, a pretty wide exit angle driver, not a good match. I only wonder what would change if made smooth all the way from the phase plug.)

Direct comparison with the Peerless 2535R00-08 (all else equal):

(Again, a pretty wide exit angle driver, not a good match. I only wonder what would change if made smooth all the way from the phase plug.)

Direct comparison with the Peerless 2535R00-08 (all else equal):

Last edited:

Mabat, is it possilbe to include the phase trace?

It gives an indication of how low they can be crossed.

It gives an indication of how low they can be crossed.

Try aluminium foil or even thin sheets, dependind on the curvature.how to make the outermost layers stiff

Athex could benefit of Jan Herich's method - Chisel slicer. I have sent him parametric curve from IGES export of Klipsch K402 horn and he generated gcode that was printed versy fast and very nice - 1 perimeter + sawtooth infill.

https://www.spacedelta3d.com/

https://www.spacedelta3d.com/

Attachments

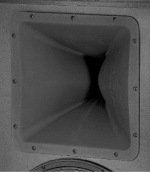

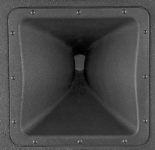

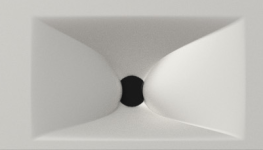

Ever since the loading tube has arrived, I am thinking about the role of diffraction slots in asymmetrical, baffle-mounted waveguides. Seemingly, we currently don't care about reflections too much around here anymore.

I am asking for experiences in practical design approaches in ath. Is it possible with the 2-profile setup to have the vertical profile only start later? Like with the waveguide of the Strass MF-2.1, which probably uses the old JBL 2380 https://www.diyaudio.com/community/threads/jbl2380a-myth-busting.268577/

And with a full-fledged 3D approach, has someone achieved similar to the GGNTKT M1 waveguide?

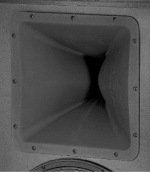

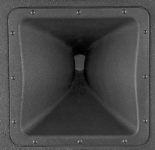

In my understanding, these waveguides, by using a slot feature, insert a shallower profile in a deeper profile, with different degrees of sophistication. But they do the same as the big old radial waveguides as the one @pelanj recently made from wood: https://www.diyaudio.com/community/...orns-picture-heavy-thread.402587/post-7435409

The length of the horizontal walls are increased. Just that they do not protrude, because the slot allows a shallower profile to be inserted into the deeper. The GGNTKT M1 waveguide uses the same recipe that was presented with the PT waveguides by JBL: On the horizontal plane, the profile is "pinched" somewhere behind the throat:

The distance/depth from the throat, together with the pinch, allows the horizontal profile to begin open only later in the waveguide, and hence follow a wider coverage angle, while still terminating flat with the baffle. This is a good solution to achieve pattern control for the narrower, vertical angle, while still allowing a wide radiation pattern for the horizontal.

I am asking for experiences in practical design approaches in ath. Is it possible with the 2-profile setup to have the vertical profile only start later? Like with the waveguide of the Strass MF-2.1, which probably uses the old JBL 2380 https://www.diyaudio.com/community/threads/jbl2380a-myth-busting.268577/

And with a full-fledged 3D approach, has someone achieved similar to the GGNTKT M1 waveguide?

In my understanding, these waveguides, by using a slot feature, insert a shallower profile in a deeper profile, with different degrees of sophistication. But they do the same as the big old radial waveguides as the one @pelanj recently made from wood: https://www.diyaudio.com/community/...orns-picture-heavy-thread.402587/post-7435409

The length of the horizontal walls are increased. Just that they do not protrude, because the slot allows a shallower profile to be inserted into the deeper. The GGNTKT M1 waveguide uses the same recipe that was presented with the PT waveguides by JBL: On the horizontal plane, the profile is "pinched" somewhere behind the throat:

The distance/depth from the throat, together with the pinch, allows the horizontal profile to begin open only later in the waveguide, and hence follow a wider coverage angle, while still terminating flat with the baffle. This is a good solution to achieve pattern control for the narrower, vertical angle, while still allowing a wide radiation pattern for the horizontal.

Acoustic results are what counts, you would need to compare those. The "loading tube", as suggested, has no effect on radiation pattern.

That's not true, I wouldn't use it if the results weren't good. Perhaps there are still things hidden below the surface of a frequency response curve (like they may be hidden every time), but nothing so far suggests so. The "loading tube" doesn't really make a diffraction slot.Seemingly, we currently don't care about reflections too much around here anymore.

Last edited:

Yes, you can create as many independent sections as you like, which, in effect, can provide such feature.I am asking for experiences in practical design approaches in ath. Is it possible with the 2-profile setup to have the vertical profile only start later?

It never seemed to work very well though, at least for what I tried.

Yeah, that was a tongue-in-cheek remark. And the HOMs ...

Anyway, results count, maybe there is a difference between a tubular extension and two parallel walls, a diffraction slot. But maybe not.

Interesting, I should try it. I think for my case the 3D approach should be superior, because the horizontal walls are not covered as deep into the waveguide, but I would like to see what it does.

For the 3D approach I have no idea how to make the slots at the side pinch into the throat profile, which the PT and the GGNTKT waveguides have in common. But maybe someone has an idea.

Anyway, results count, maybe there is a difference between a tubular extension and two parallel walls, a diffraction slot. But maybe not.

Yes, you can create as many independent sections as you like, which, in effect, can provide such feature.

Interesting, I should try it. I think for my case the 3D approach should be superior, because the horizontal walls are not covered as deep into the waveguide, but I would like to see what it does.

For the 3D approach I have no idea how to make the slots at the side pinch into the throat profile, which the PT and the GGNTKT waveguides have in common. But maybe someone has an idea.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)