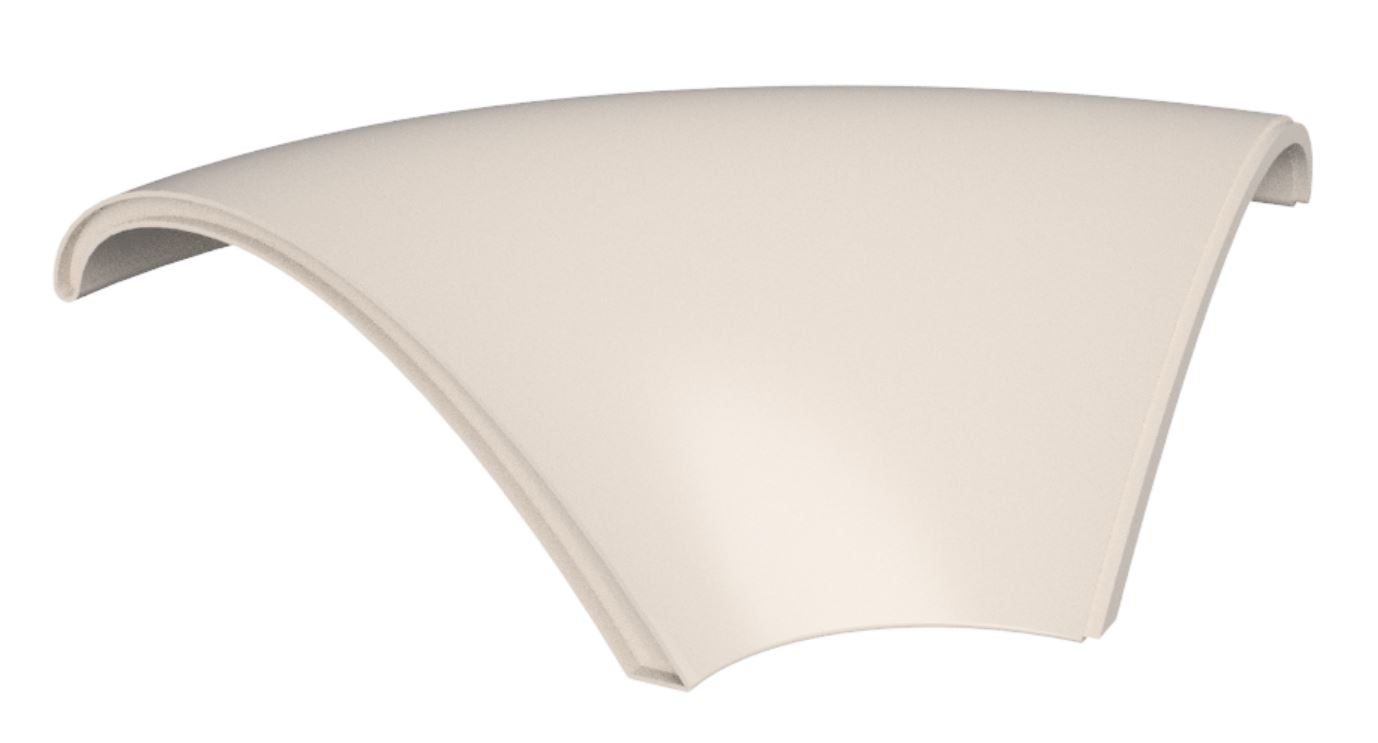

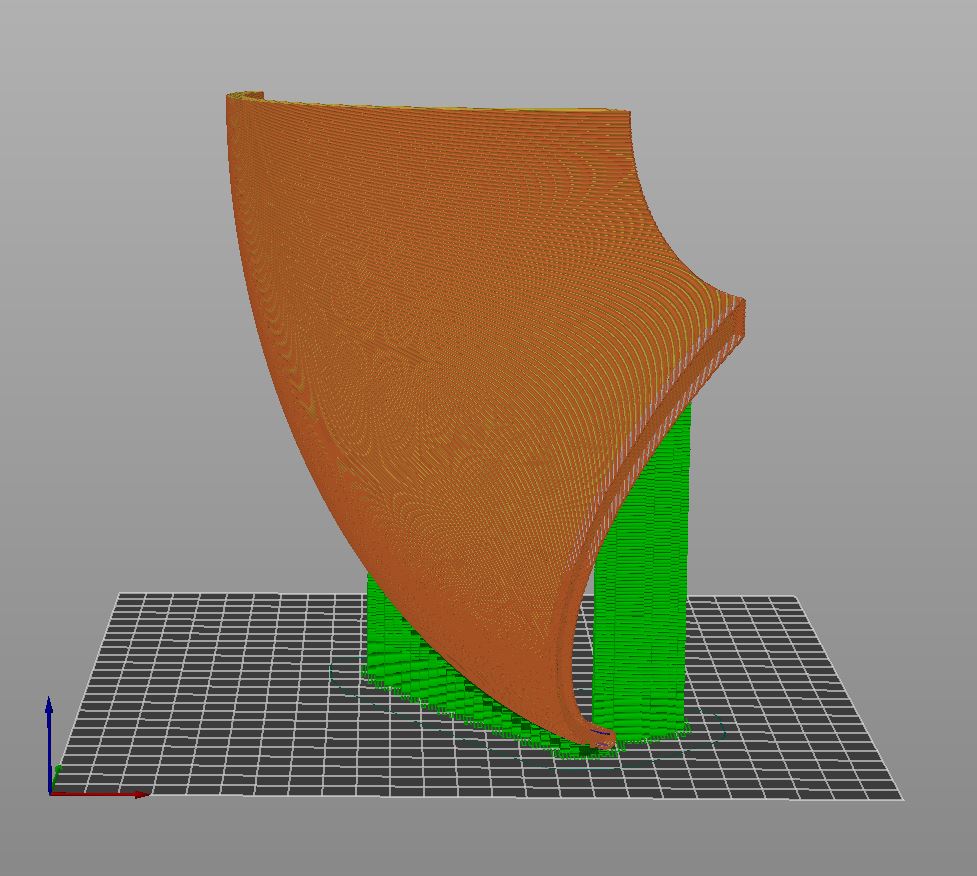

The latest developmnet in the petal construction -

Hi all,

I've seen few projects using a TC9FD18 with a WG. I thought I would have a go too!

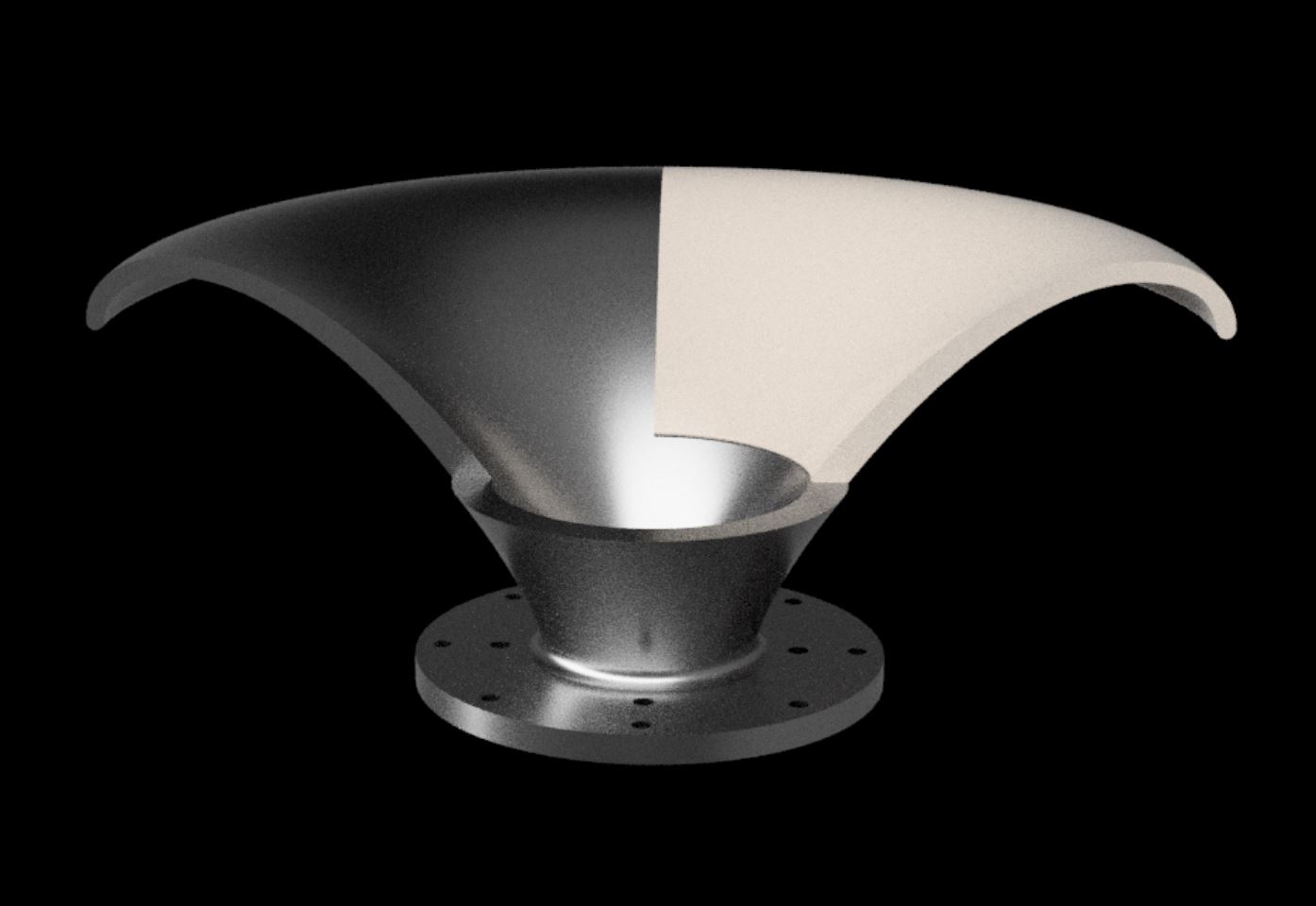

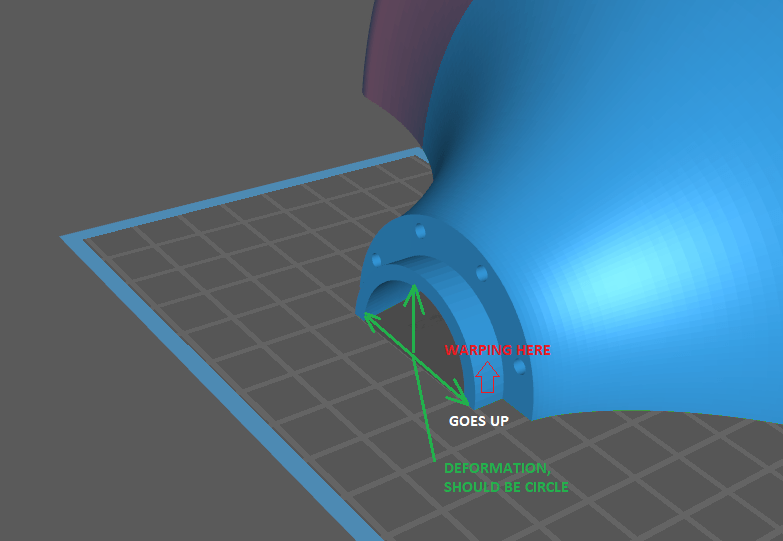

I'm trying my first "whole cabinet" print (50hrs) on a Phrozen Mega 8k. The band at the top is due to vacuum pulling up the liquid within that part of the cabinet. I should have put a tiny 1mm hole at the very apex to prevent this suction/deformation. Quarter symmetry report attached.

I took a wild guess at 30deg exit angle 🤔

I may delve into complex sources....

I've seen few projects using a TC9FD18 with a WG. I thought I would have a go too!

I'm trying my first "whole cabinet" print (50hrs) on a Phrozen Mega 8k. The band at the top is due to vacuum pulling up the liquid within that part of the cabinet. I should have put a tiny 1mm hole at the very apex to prevent this suction/deformation. Quarter symmetry report attached.

I took a wild guess at 30deg exit angle 🤔

I may delve into complex sources....

Last edited:

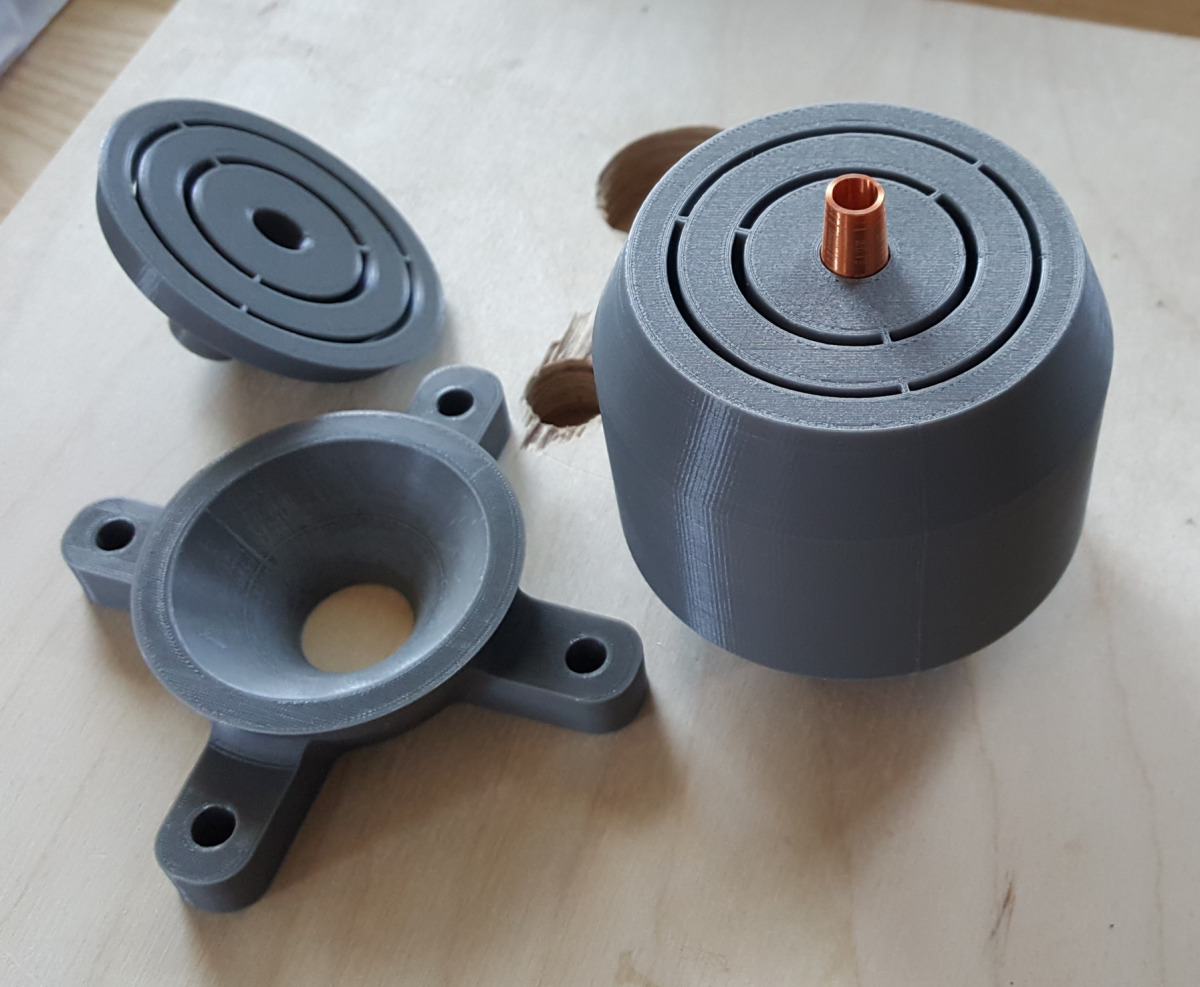

...and finally assembling an ESP. Next week I would like to measure as much of it as possible.

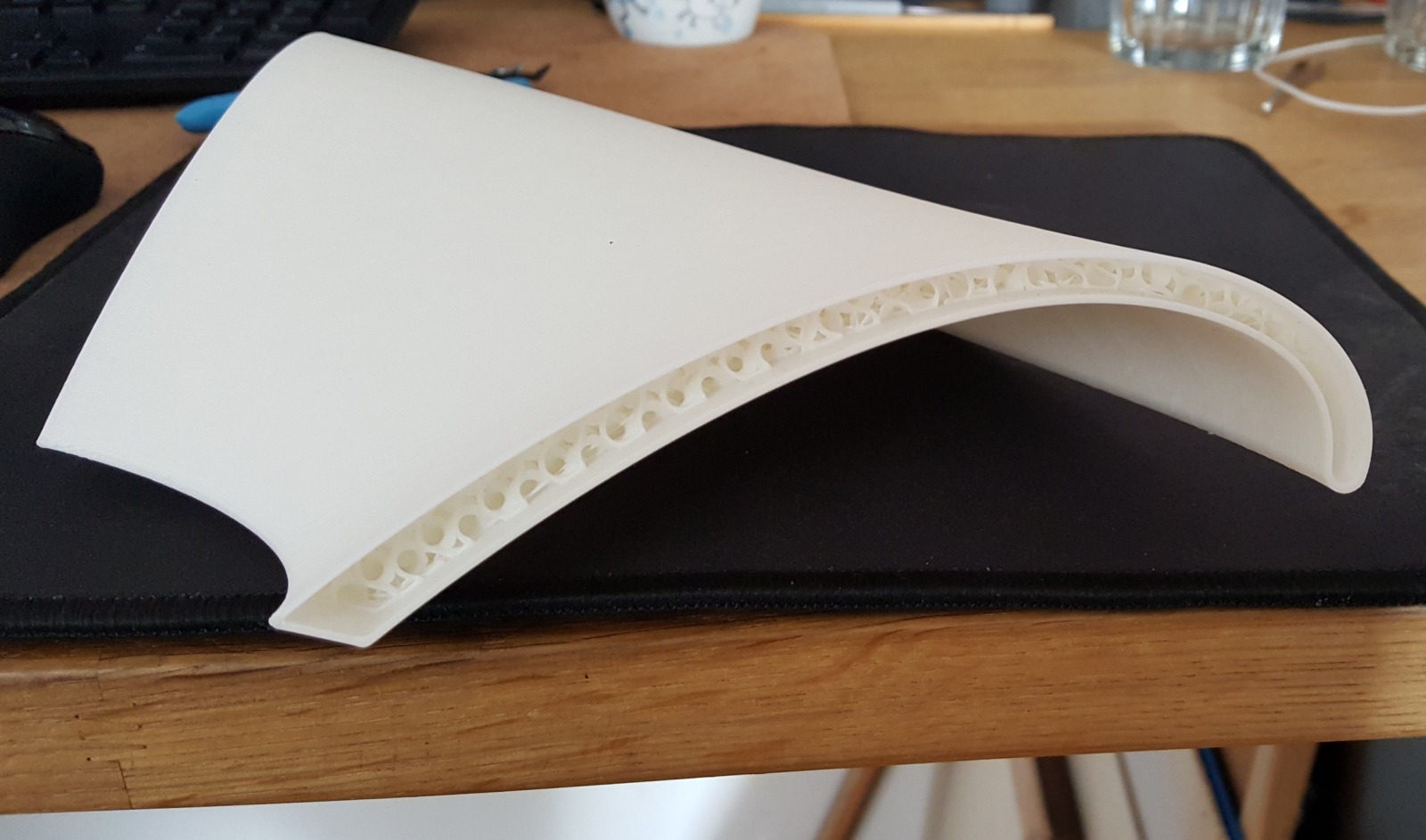

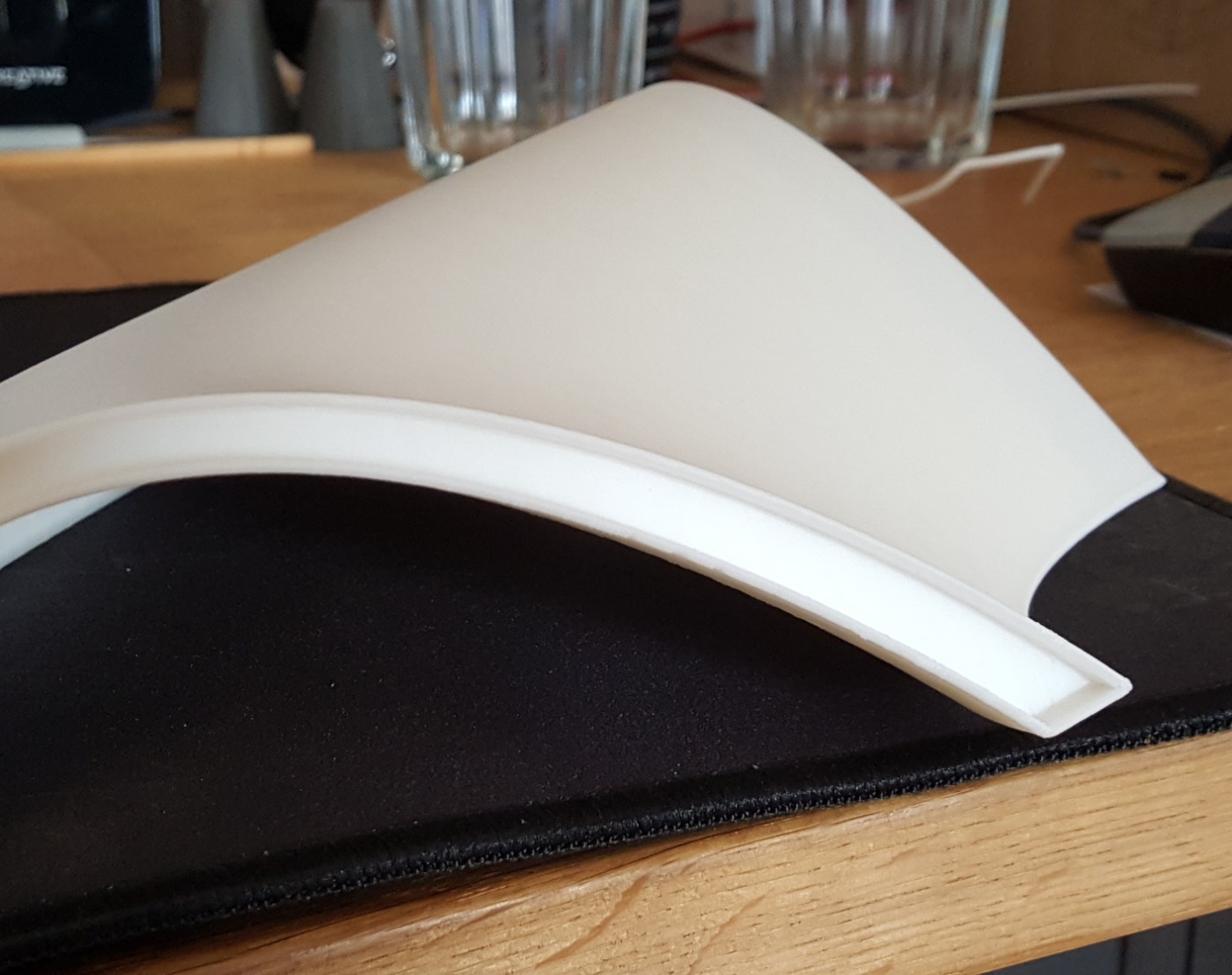

Printed. Couldn't hope for a better result -

There's the "gyroid" infill, probably still too dense. I will make it less dense on the next one. Anyway, anything thin enough can be poured through if desired (probably not needed though).

There's the "gyroid" infill, probably still too dense. I will make it less dense on the next one. Anyway, anything thin enough can be poured through if desired (probably not needed though).

Last edited:

Beautiful!!Printed. Couldn't hope for a better result -

View attachment 1069043 View attachment 1069044

There's the "gyroid" infill, probably still too dense. I will make it less dense on the next one. Anyway, anything thin enough can be poured through if desired (probably not needed though).

Making it in quarters (i.e. 4 petals) is the way to go. This waveguide is 15" -

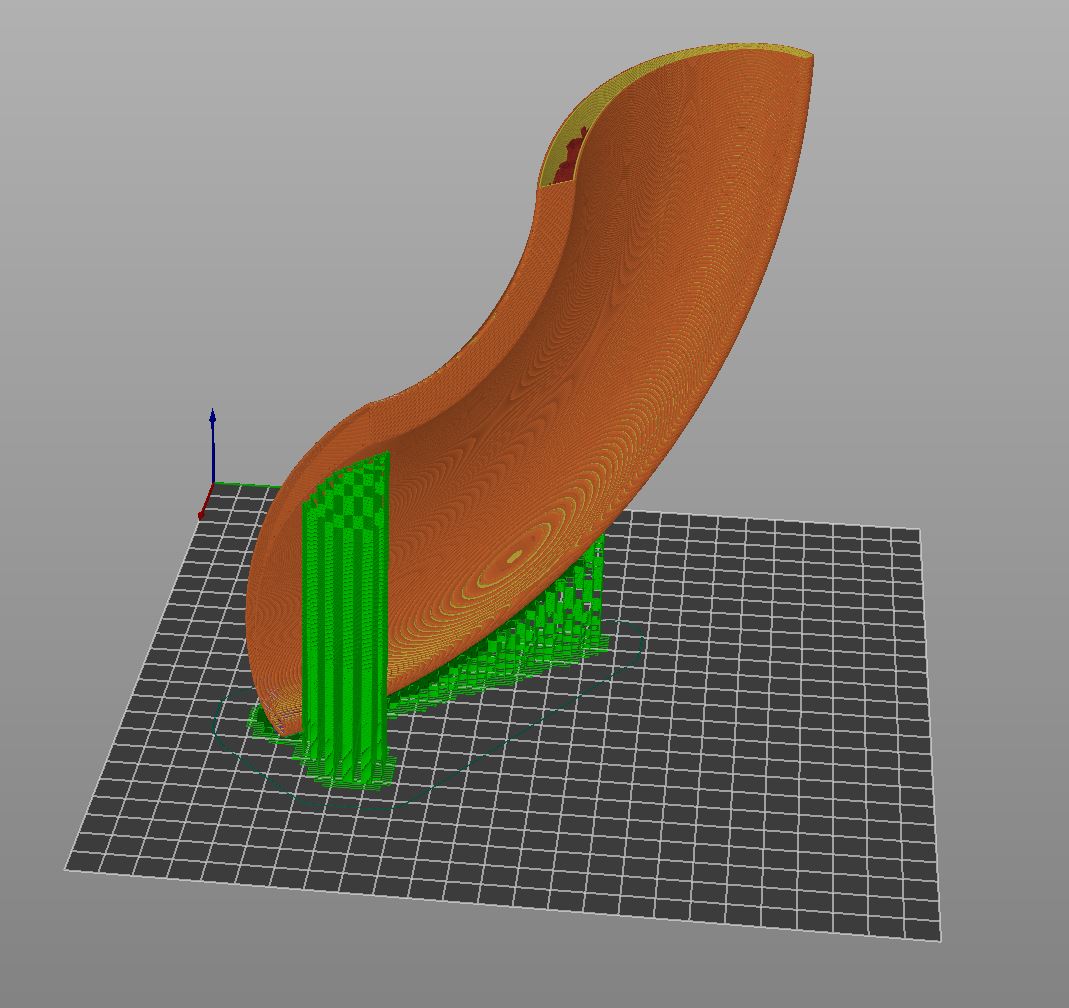

This is how it's printed -

It took me some time to get to this point... Now I'm pretty satisfied with the whole process.

It took me some time to get to this point... Now I'm pretty satisfied with the whole process.

Try SuperPP resin from 3Dmaterials. It's like polypropylene, good damping. Use flexible build plate. Warping can be an issue with resin printers, especially thin walls like this if you like to use multiple driver plates: (that's why there are rigid resins with ceramics)

Dyes used for casting epoxy should work and give you nice transparent waveguides.

Dyes used for casting epoxy should work and give you nice transparent waveguides.

Are you talking to limacon? Because I use FDM printing...

With Ender 6 (semi-closed) and PLA, there's absolutely no warping on these parts (haven't tried anything else than PLA here). Damping can be added by filling the petals before assembling. That's why I leave the top side open.

With Ender 6 (semi-closed) and PLA, there's absolutely no warping on these parts (haven't tried anything else than PLA here). Damping can be added by filling the petals before assembling. That's why I leave the top side open.

Last edited:

I'm talking about SLA - much better surface and speed with fast resins but more likely to deform. That's why you print throat at once and do petals at some distance. Casting epoxy isn't cheaper than UV resin only cheapest polyester that smell awfully. Those who have SLA LCD printer please write here if you prefer rigid resin with microbaloons or PP like? Standard resins (cheapest) is too brittle.

Casting polyurethane is less than 15 €/kg, FDM filament around 18€/kg. For a pair of 15" waveguides I need ~1.4 kg of filament and around 1.2 kg of the filler, that makes around 45 €. I don't believe switching to SLA could be cheaper or any better in the end (not counting a large-format SLA printer).

How do you finish the surface of SLA prints?

How do you finish the surface of SLA prints?

Last edited:

Yes true - better quality resin is almost 50€/litre. Of course you can hollow the model and pour epoxy. 13" SLA is 700$ EXW plus 4$/kg shipping railways to Europe.

BTW, I've just filled one petal with the polyurethane (Dawex GAFORM R55 - a local product). It runs through even the denser infill smoothly. Temperature - if left in the cup it reaches almost 70°C. When poured into the petal I measured around 45°C peak - not an issue. There's also a slower version (GAFORM D500), that would be even less warm but it's not needed, 50°C is still safe. Perhaps if I wanted the fill also the throat part, I would need the slower one.

Acoustically, it's pretty much dead now, overall I'm really pleased with the result.

Acoustically, it's pretty much dead now, overall I'm really pleased with the result.

Last edited:

Good insane or bad insane? I don't expect it to work all that well!To me this is insane 🙂

I'm only not sure I would go for a WG with a 3" direct radiator...

I was sort of inspired by @Illusus truncated Dayton waveguide

https://www.diyaudio.com/community/...for-the-tc9-or-10f.321666/page-2#post-6908384

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)