That link actually makes me wonder if some of the thoughts I had regarding vibrations, was not that far from the truth:

Reflections from the counterweight has to be dealt with, espeacially if there isn´t a ridig point along the arm tube. And yes a way to do that is to make the arm tube a lossy transmission line.

As far as I can see the rigid bearing CAN (not nessesary does) terminate to a certain degree the vibrations so you can transform the vibrations to heat outside the wand.

Please enlighten me if I am totally wrong here.

Koldby

A typical solution is to make a very lossy mount (rubber typically) for the counterweight...

_-_-bear

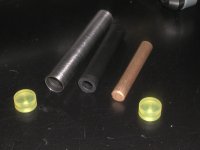

On my build, I used a principle called mass dampning. On the end stub, I used a short bronze rod suspended in an closed cell neoprene cylinder inserted in a thin wall titanium tube. The tube is capped with silicone plugs.

It is extremely effective at damping energies.

I have no means to actully make resonance measurements. But if you take a similar length and diameter solid rod as my stub, or a hollow tube the same length and diameter, and drop it from a given distance onto a solid surface, they will have a degree of "bounce" and "ringing". I also tried just the titanium tube with only the neoprene tube without the bronze rod..it had the same "bounce" and only slightly less "ringing"

But if you take my end stub with the bronze rod and drop it from the same distance, it exhibits practiacly no bounce at all with a very dull "thud"..no ringing or resononance, at least discernable by the ear.

Also the counter weight is solid copper, a very dense metal, and is decoupled with a delrin bushing.

The armwand itself is a multi-section affair. It has a thin walled titanium outer tube with a small diameter carbon fiber tube concentricly suspended along the inside length with small diameter Buna-N "O" rings that not only support the inner tube, but act as dampers as well.

In my 10.5 inch arm there are 10 "O" rings spaced along the length of the tube. If you look closely in one of the pictures with my "raw" parts, (even-tho I didn't use the outrigger counterweight eventually) you can see the carbon fiber rod "peeping" out of the arm tube.

Jeff Davison

It is extremely effective at damping energies.

I have no means to actully make resonance measurements. But if you take a similar length and diameter solid rod as my stub, or a hollow tube the same length and diameter, and drop it from a given distance onto a solid surface, they will have a degree of "bounce" and "ringing". I also tried just the titanium tube with only the neoprene tube without the bronze rod..it had the same "bounce" and only slightly less "ringing"

But if you take my end stub with the bronze rod and drop it from the same distance, it exhibits practiacly no bounce at all with a very dull "thud"..no ringing or resononance, at least discernable by the ear.

Also the counter weight is solid copper, a very dense metal, and is decoupled with a delrin bushing.

The armwand itself is a multi-section affair. It has a thin walled titanium outer tube with a small diameter carbon fiber tube concentricly suspended along the inside length with small diameter Buna-N "O" rings that not only support the inner tube, but act as dampers as well.

In my 10.5 inch arm there are 10 "O" rings spaced along the length of the tube. If you look closely in one of the pictures with my "raw" parts, (even-tho I didn't use the outrigger counterweight eventually) you can see the carbon fiber rod "peeping" out of the arm tube.

Jeff Davison

Attachments

Last edited:

Jeffery, I saw your post earlier on this... seems like a nice solution... I expected to see the mass suspended on two ends... so I am wondering if the end pieces make any difference other than keeping it in place, and how different the performance might be without the mass and just the foam inside the tube?

_-_-bear

I forgot to ask what sort of mill and/or lathe did you use for this job - wondering that of all the other builders in the thread as well!

_-_-bear

I forgot to ask what sort of mill and/or lathe did you use for this job - wondering that of all the other builders in the thread as well!

Last edited:

I used both Front Panel Express and eMacineshop.com. Alas, I don't have any mills or lathes readily at hand and no one too local to work with. Had to farm out my drawings.

The end pieces are not really used to keep the internals in place as they are a snug fit. I used the silicone endpiece plugs as an aesthetic part that happened to have damping properties as well.

I actually got the mass dampening idea watching Formula One.... A few years ago when Renault was winning the WDC, early in the season the front end of the car, in the nose, used mass dampening to stabilize the front better in corners from road surface vibrations ans F1 cars have very stiff suspension. The device was declared "illegal" when it was deemed to be an unfair advantage and a "moveable" device which was not allowed according to the sporting regulations.

Jeff

The end pieces are not really used to keep the internals in place as they are a snug fit. I used the silicone endpiece plugs as an aesthetic part that happened to have damping properties as well.

I actually got the mass dampening idea watching Formula One.... A few years ago when Renault was winning the WDC, early in the season the front end of the car, in the nose, used mass dampening to stabilize the front better in corners from road surface vibrations ans F1 cars have very stiff suspension. The device was declared "illegal" when it was deemed to be an unfair advantage and a "moveable" device which was not allowed according to the sporting regulations.

Jeff

Jeffery, I saw your post earlier on this... seems like a nice solution... I expected to see the mass suspended on two ends... so I am wondering if the end pieces make any difference other than keeping it in place, and how different the performance might be without the mass and just the foam inside the tube?

_-_-bear

I forgot to ask what sort of mill and/or lathe did you use for this job - wondering that of all the other builders in the thread as well!

Last edited:

Attachments

Last edited:

up and running

Hi, I used a very old Myford 7 Lathe for all the turned parts, including the ebony wand. The rest of the parts were made by hand, from scrap pieces of brass and ally.

Had a week or two to listen to it, and it does sound wonderful, the best sound i have ever had from vinyl.

The only thing i have changed from my initial parts is to remake the counterweight slightly heavier to place it nearer the pivot.

I found the most difficult part to make is the aluminium wand/upper magnet carrier, it was very tricky to get the hole for the suspension thread central and true, i guess i got lucky as it came out fine the first time. With the lightweight version, i had to remake this piece twice.

The other difficult part was carving and shaping the headshell end of the wand for the cartridge, also fileing out the slots for the cartridge mounting, but i was determined to make the headshell/wand in one piece.

Overall i am extremely happy with it, so happy infact, i have started making a lightweight version to fit on my suspended sub chassis turntable.

so happy infact, i have started making a lightweight version to fit on my suspended sub chassis turntable.

Hi, I used a very old Myford 7 Lathe for all the turned parts, including the ebony wand. The rest of the parts were made by hand, from scrap pieces of brass and ally.

Had a week or two to listen to it, and it does sound wonderful, the best sound i have ever had from vinyl.

The only thing i have changed from my initial parts is to remake the counterweight slightly heavier to place it nearer the pivot.

I found the most difficult part to make is the aluminium wand/upper magnet carrier, it was very tricky to get the hole for the suspension thread central and true, i guess i got lucky as it came out fine the first time. With the lightweight version, i had to remake this piece twice.

The other difficult part was carving and shaping the headshell end of the wand for the cartridge, also fileing out the slots for the cartridge mounting, but i was determined to make the headshell/wand in one piece.

Overall i am extremely happy with it,

Attachments

Last edited:

The diameter of the arm tube is .375". The Diameter of the end stub is .500"

I really didn't look further than the neoprene foam. I don't know if there is anything softer that is readily available... But the neoprene was an off the shelf solution that worked well in my experiments. True, that the assembly isn't really "tuned" as a true "Tuned mas dampner", but the principle works well enough for my arm.

Maybe Frank could adapt it and come up with a truely tuned mass damper for the toneatm counterweight end stub.... maybe even patent it ;^)

Jeff

I really didn't look further than the neoprene foam. I don't know if there is anything softer that is readily available... But the neoprene was an off the shelf solution that worked well in my experiments. True, that the assembly isn't really "tuned" as a true "Tuned mas dampner", but the principle works well enough for my arm.

Maybe Frank could adapt it and come up with a truely tuned mass damper for the toneatm counterweight end stub.... maybe even patent it ;^)

Jeff

Jeffrey - very nice , indeed...

Just wondering- what's the dia of the titanium tube?

and thinking out loud- would there be any benefit in using somthing softer than the closed cell foam....?

Last edited:

When measuring the lowest torsional mode on many tonearms, you'll find it to be between 300 and 500Hz. Normal modes(the fundamental) can be found from 1,3khz to 2,5kHz (up to 6kHz on the "stiffest" armwands I've measured).

That's very interesting data, and suggests to me that conventional wisdom of choosing the stiffest/lightest material in order to push the resonances up in frequency works against us, and that it's better leave the resonances below 500Hz and damp them if possible. Was that your thinking in your choice of wood?

The mass damping idea espoused later in this thread is fascinating. I've just bought another milling machine (not got it reassembled yet), but I can feel all sorts of project ideas coming on.

Attachments

Last edited:

Little update...

Hi,

Got my tonearm head shell, ebony wand, top magnet holder and the counter weight. The ebony wand was treated for more than 10 days using shellac, nitro cellulose and linseed oil to avoid tube resonances. Need to fine polish the metal parts before going for the final assembly. Frank, thanks a lot for this outstanding arm.

@JD : How is your arm performing ? Any further changes/improvements planned ?

Best regards,

Bins.

Hi,

Got my tonearm head shell, ebony wand, top magnet holder and the counter weight. The ebony wand was treated for more than 10 days using shellac, nitro cellulose and linseed oil to avoid tube resonances. Need to fine polish the metal parts before going for the final assembly. Frank, thanks a lot for this outstanding arm.

@JD : How is your arm performing ? Any further changes/improvements planned ?

Best regards,

Bins.

No changes, completely happy, performing flawlessly.

Tho I might add a set of racing stripes, bigger exhaust and a spoiler

JD

Tho I might add a set of racing stripes, bigger exhaust and a spoiler

JD

Hi,

@JD : How is your arm performing ? Any further changes/improvements planned ?

Best regards,

Bins.

Tho I might add a set of racing stripes, bigger exhaust and a spoiler

JD

Anders

try using some Linn Sondek springs.... they should fit nicely. Also look at a later plastic inner platter from a TD-160, the early plastic ones have a 10mm spindle.

The stiffer Linn springs and the lighter inner platter shouls offset the additional weight of the arm... just have to adjust for proper bounce balance.

JD

The stiffer Linn springs and the lighter inner platter shouls offset the additional weight of the arm... just have to adjust for proper bounce balance.

JD

Hi, Just finished my baby lightweight Schroeder clone. My intention was to fit this to my TD150, but i think it may be too heavy for the suspension.

I guess I'm pretty well commited to building this arm. Yesterday, I bought a lathe.

In researching the species of wood used with this arm, I've seen Ebony, Pernambuco, Cherry, and other exotics. I also found that Cedar has some very good properties when dealing with resonance. Has anyone used different or more common species in their builds?

Also, one process that is nagging at me: What is the best procedure for drilling the tonearm? I surmised that drilling from both ends would be the easiest. Either that, or acquiring a gunmakers bit to tackle it from one end.

In researching the species of wood used with this arm, I've seen Ebony, Pernambuco, Cherry, and other exotics. I also found that Cedar has some very good properties when dealing with resonance. Has anyone used different or more common species in their builds?

Also, one process that is nagging at me: What is the best procedure for drilling the tonearm? I surmised that drilling from both ends would be the easiest. Either that, or acquiring a gunmakers bit to tackle it from one end.

I suggest that you read this thread from the very first post. There is a lot of information here.

Because of the kind help from Herr Frank Schroeder, all of the participants have mostly declined from publishing or distributing blueprints.

The arm is covered by many patents, and tho it's technically not illegal to make an arm for yourself, it's out of courtesy and respect for the designer that we elect not to publish drawings that can be use to manufacture an arm.

This has been one of the pre-requisits we have all volunteerd to for the on going help and support from Herr Schroeder himself. He has been extremely helpful in our endeavors and has answered very critical questions on how his arm functions. He has always lead a guiding hand to help us make our arms. While he won't give away minute details of his trade secrets, he will give help in the succesfull completion of a very well designed and sounding arm.....almost as good as his own

It's not really rocket science, but you have to develop your own working drawings if you want to make one. We all can help in regards to how it functions, what to look out for etc...Just get your pen and paper out and start sketching.

Besides reading this thread, I would suggest also that you download easily available instructions - just to a web search- for setup and use of Schroeders arms. They will give you a deep insight into them. Also search the web for as many picutes of the arm you can find to start to develop your own drawings. Pictures can give a very good insight in how to "roll your own"

JD

Because of the kind help from Herr Frank Schroeder, all of the participants have mostly declined from publishing or distributing blueprints.

The arm is covered by many patents, and tho it's technically not illegal to make an arm for yourself, it's out of courtesy and respect for the designer that we elect not to publish drawings that can be use to manufacture an arm.

This has been one of the pre-requisits we have all volunteerd to for the on going help and support from Herr Schroeder himself. He has been extremely helpful in our endeavors and has answered very critical questions on how his arm functions. He has always lead a guiding hand to help us make our arms. While he won't give away minute details of his trade secrets, he will give help in the succesfull completion of a very well designed and sounding arm.....almost as good as his own

It's not really rocket science, but you have to develop your own working drawings if you want to make one. We all can help in regards to how it functions, what to look out for etc...Just get your pen and paper out and start sketching.

Besides reading this thread, I would suggest also that you download easily available instructions - just to a web search- for setup and use of Schroeders arms. They will give you a deep insight into them. Also search the web for as many picutes of the arm you can find to start to develop your own drawings. Pictures can give a very good insight in how to "roll your own"

JD

Does someone have " Blue Prints " for DIY Schroeder Tonearm?

I want to make!!!!

Thanks in advance.

Regards zeoN_Rider

Last edited:

- Home

- Source & Line

- Analogue Source

- DIY Schroeder Tonearm???