A picture is worth 1,000 (well chosen) words...

Thanks for your reply and the prompts to post further ideas publicly in the forum.

- - -

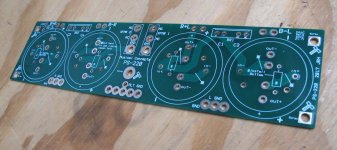

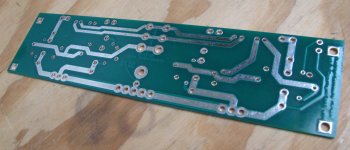

I figured I would post an abstract of my ideas, portion to why I am modeling this in the ways that I have. It is a challenge to clearly convey my [mental battles] abstract ideas... a picture serves to better illustrate the challenges of ~ squeezing ~ 2 reasonably large power supplies, without sacrifice into one small'ish, very tight chassis pan. I always start with the amp core and work my way outwards. After all, *the amplifier* is the power supply, gotta get that right before doing any other work on the amplifier circuit. (of course, my way, my approach) this may not suit others, we each have different design goals and more importantly, budgets which influence or result.

*for note, my main amps... my musical reference are dual mono (tube amps)... in order to work effectively in my listening set up... Said amplifier chassis best fit the footprint within my main listening rig(s). Constantly re-routing cables, stressing spade to speaker wire interface (is unacceptable) by constantly bending cables and repositioning everything is a P.I.T.A... This may be hard to understand. Conventional stereo / 2 channel amps, just do not work well for me… as my amps do not fit in a rack, or in between the speakers.

My principle goal, was that, I wanted to increase power supply capability in a mono approach, not halve the power (in dual secondary) transformer configuration. Though I am thinking of stacking two toroids in *future* XL280 amp / chassis build. First, I must test, proof of concept... to see if there is a meaningful difference, to warrant the extra effort. Second, said build, will mean and amps chassis that will never allow a top cover... A whole other story, save for later...

Images: front amp is a XL280 chassis, with 1 inch greater width, yet this idea is (utterly ridiculous) not a good idea and impossible, there is no room for driver circuit, not to mention magnetic issues. **the image is simply to help me illustrate a point to others.

The 2 DH200 chassis's behind have the exact same power supply,

divided and effectively doubled over stock amplifier. A given.

I am leaning to using stock transformers for these reasons (on first build)

#1) for 625va size. [I want to hear them, as proof of concept]

#2) they permit more room to adapt later. [choice of capacitors, wiring ease] Mundorf MLytic HC

#3) be able to compare them to 400va toroid ~ and ~ while remote

#4) be able to build separate higher voltage front end supplies,

as they are XL280 power transformers… (pretty unlikely, an even longer story)

**the only way that I will know is to try this, model it and experiment.

***a portion of my interests is to test the "limits of 200 series" chassis, to see IF THE *BIG AMP AUTHORITY* of the 500/600 series amps is possible in the 200 body. To see how much is related to the higher B+ and how much is the higher output power. A 3rd variable, potential "voltage sag" under transient loads, in the 'smaller supplies'. The P230 mono, with 6 outputs, has redefined my views in the BIG AMP ARENA, I have had to re-think my ideals and certain tenets, based on extensive comparative listening over many time… The P230m amps have a new found liquidity and effortless ease, also surprising 'lack of veil' in the mid-band, compared to my *true dual mono* 500/600, which has really confounded me... I am struggling to figure it out, isolate it.

Hi Ozark HiFi Doctor,

Okay, cool. It's merely a practical thing. I can see that.

From private message...

"Your reply to me really would be a great reply to my post. In this way, someone else in similar circumstances can consider your solution to that problem."

-Chris

Thanks for your reply and the prompts to post further ideas publicly in the forum.

- - -

I figured I would post an abstract of my ideas, portion to why I am modeling this in the ways that I have. It is a challenge to clearly convey my [mental battles] abstract ideas... a picture serves to better illustrate the challenges of ~ squeezing ~ 2 reasonably large power supplies, without sacrifice into one small'ish, very tight chassis pan. I always start with the amp core and work my way outwards. After all, *the amplifier* is the power supply, gotta get that right before doing any other work on the amplifier circuit. (of course, my way, my approach) this may not suit others, we each have different design goals and more importantly, budgets which influence or result.

*for note, my main amps... my musical reference are dual mono (tube amps)... in order to work effectively in my listening set up... Said amplifier chassis best fit the footprint within my main listening rig(s). Constantly re-routing cables, stressing spade to speaker wire interface (is unacceptable) by constantly bending cables and repositioning everything is a P.I.T.A... This may be hard to understand. Conventional stereo / 2 channel amps, just do not work well for me… as my amps do not fit in a rack, or in between the speakers.

My principle goal, was that, I wanted to increase power supply capability in a mono approach, not halve the power (in dual secondary) transformer configuration. Though I am thinking of stacking two toroids in *future* XL280 amp / chassis build. First, I must test, proof of concept... to see if there is a meaningful difference, to warrant the extra effort. Second, said build, will mean and amps chassis that will never allow a top cover... A whole other story, save for later...

Images: front amp is a XL280 chassis, with 1 inch greater width, yet this idea is (utterly ridiculous) not a good idea and impossible, there is no room for driver circuit, not to mention magnetic issues. **the image is simply to help me illustrate a point to others.

The 2 DH200 chassis's behind have the exact same power supply,

divided and effectively doubled over stock amplifier. A given.

I am leaning to using stock transformers for these reasons (on first build)

#1) for 625va size. [I want to hear them, as proof of concept]

#2) they permit more room to adapt later. [choice of capacitors, wiring ease] Mundorf MLytic HC

#3) be able to compare them to 400va toroid ~ and ~ while remote

#4) be able to build separate higher voltage front end supplies,

as they are XL280 power transformers… (pretty unlikely, an even longer story)

**the only way that I will know is to try this, model it and experiment.

***a portion of my interests is to test the "limits of 200 series" chassis, to see IF THE *BIG AMP AUTHORITY* of the 500/600 series amps is possible in the 200 body. To see how much is related to the higher B+ and how much is the higher output power. A 3rd variable, potential "voltage sag" under transient loads, in the 'smaller supplies'. The P230 mono, with 6 outputs, has redefined my views in the BIG AMP ARENA, I have had to re-think my ideals and certain tenets, based on extensive comparative listening over many time… The P230m amps have a new found liquidity and effortless ease, also surprising 'lack of veil' in the mid-band, compared to my *true dual mono* 500/600, which has really confounded me... I am struggling to figure it out, isolate it.

Attachments

Elegant solution to dual mono.

I have had great success, with dual secondary 625va toroids associated to the PS200 / PS220 circuit board, power supplies. They are or appear to be without compromise. I used a DH220 based amp (for years) driving Maggies, never noticeably clipped or ran out of power [admittedly] was mindful of the amps power capability, but never noticed any lack of authority or power.

I am going to build up (the dual secondary toroid shown, on top) with the new PS220 board with (4) 80v/10,000 Mundorf MLyitc AG caps...in place of the of the *exemplary* Jensen 4-Pole caps, as shown. Save the Jensens for yet another project... The amps chassis shown is a XL-280 (it is a future project) I want to try everything that I can before, committing a plan.

...Yes... yet another [proof of concept] project...

My intent is to be comparing the board mounted Mundorf MLyitc AG, to the Mundorf MLytic HC in a point to point wired configuration (the only way to do it) This affordable, very well engineered PC board is fabulous sounding, permits easy installation and can be used stereo/mono or dual mono... in essence is scalable to any type of build... can use 2 pole or 4 pole caps. *Is not limited to Hafler amp use...

Note: I am not a sadist, that wants to rework every build and every piece of gear that I own. I am continuing to see / hear meaningful evolution and progress ~ and ~ forming a first hand basis of understanding of each and every step in evolution of my personal amplifier ideas. The gear just ~ GETS OUT OF THE WAY ~ of the music, narrowing the musical gap to my musical reference gear.

I have had great success, with dual secondary 625va toroids associated to the PS200 / PS220 circuit board, power supplies. They are or appear to be without compromise. I used a DH220 based amp (for years) driving Maggies, never noticeably clipped or ran out of power [admittedly] was mindful of the amps power capability, but never noticed any lack of authority or power.

I am going to build up (the dual secondary toroid shown, on top) with the new PS220 board with (4) 80v/10,000 Mundorf MLyitc AG caps...in place of the of the *exemplary* Jensen 4-Pole caps, as shown. Save the Jensens for yet another project... The amps chassis shown is a XL-280 (it is a future project) I want to try everything that I can before, committing a plan.

...Yes... yet another [proof of concept] project...

My intent is to be comparing the board mounted Mundorf MLyitc AG, to the Mundorf MLytic HC in a point to point wired configuration (the only way to do it) This affordable, very well engineered PC board is fabulous sounding, permits easy installation and can be used stereo/mono or dual mono... in essence is scalable to any type of build... can use 2 pole or 4 pole caps. *Is not limited to Hafler amp use...

Note: I am not a sadist, that wants to rework every build and every piece of gear that I own. I am continuing to see / hear meaningful evolution and progress ~ and ~ forming a first hand basis of understanding of each and every step in evolution of my personal amplifier ideas. The gear just ~ GETS OUT OF THE WAY ~ of the music, narrowing the musical gap to my musical reference gear.

Attachments

Last edited:

I have had great success, with dual secondary 625va toroids associated to the PS200 / PS220 circuit board, power supplies. They are or appear to be without compromise. I used a DH220 based amp (for years) driving Maggies, never noticeably clipped or ran out of power [admittedly] was mindful of the amps power capability, but never noticed any lack of authority or power.

I am going to build up (the dual secondary toroid shown, on top) with the new PS220 board with (4) 80v/10,000 Mundorf MLyitc AG caps...in place of the of the *exemplary* Jensen 4-Pole caps, as shown. Save the Jensens for yet another project... The amps chassis shown is a XL-280 (it is a future project) I want to try everything that I can before, committing a plan.

...Yes... yet another [proof of concept] project...

My intent is to be comparing the board mounted Mundorf MLyitc AG, to the Mundorf MLytic HC in a point to point wired configuration (the only way to do it) This affordable, very well engineered PC board is fabulous sounding, permits easy installation and can be used stereo/mono or dual mono... in essence is scalable to any type of build... can use 2 pole or 4 pole caps. *Is not limited to Hafler amp use...

Note: I am not a sadist, that wants to rework every build and every piece of gear that I own. I am continuing to see / hear meaningful evolution and progress ~ and ~ forming a first hand basis of understanding of each and every step in evolution of my personal amplifier ideas. The gear just ~ GETS OUT OF THE WAY ~ of the music, narrowing the musical gap to my musical reference gear.

Can you identify your source for the dual secondary toroid? I looked at Musical Concepts TP-202 and it has some great features like electrostatic shield and steel banding, but it does not indicate that it has dual secondaries with center taps.

Do you have any specific advice in cutting the outlet for the IEC connector?

Finally, I am not a fan of binding posts and intended to remove them on my amp and substitute terminal strips (as Vandersteen uses for its IIce speakers). Any thoughts on this change? Since I am already modifying the chassis by adding a cutout for the IEC socket, retaining value is not really an issue for me - which also appears to be a non-issue with you.

Hi Halauhula,

A barrier strip is a better connection as long as you use the proper connectors with it.

-Chris

Thank you for correcting me: barrier block, not terminal strip.

I was planing to use ordinary ring terminals, tin coated copper, but with tin cleaned and treated with Cramolin, followed by Silclear from Mapleshade Audio. I know there is another compression-style terminals available from Michael Percy, but I am not sure they are worth it given that I already have a nearly whole-life supply of Silclear.

Hi Halauhula,

Barrier block / strip is just one type of terminal strip. I wasn't trying to correct you, it's just what I call them.

Tin covered copper is fine by itself as the screw will create a gas tight seal with the copper base material where it breaks through the tin. Applications of any goo will not help you any more than just plain mechanical force. In calibration labs we try to use pure copper, cleaned before use.

-Chris

Barrier block / strip is just one type of terminal strip. I wasn't trying to correct you, it's just what I call them.

Tin covered copper is fine by itself as the screw will create a gas tight seal with the copper base material where it breaks through the tin. Applications of any goo will not help you any more than just plain mechanical force. In calibration labs we try to use pure copper, cleaned before use.

-Chris

I looked at the Mouser and Digikey catalogs, and they call them barrier blocks, so I think I should follow your lead and use the more specific term to avoid confusion.

Do you know of any vendor that sells pure copper ring terminals and copper screws in hobbyist quantities? My Google searches have been unsuccessful. I guess I could abrade the tin off the terminals I have, and polish them before use....

Do you know of any vendor that sells pure copper ring terminals and copper screws in hobbyist quantities? My Google searches have been unsuccessful. I guess I could abrade the tin off the terminals I have, and polish them before use....

(Plitron brand) dual secondary toroid

Hi Halauhula, The toroid shown is/are from 45v/ 625va, Plitron. I spoke with John, I think (understood him to say) that he had a few left. Might be worth a call, if you are interested... I believe Plitron purchase minimum (may be steep for DIY approach / budgets) thought it was 500.00 minimum order.

The IEC plug installation was done by penciling the cut out on the chassis, using with an 1/8" bit, drilling just inside of the actual desired opening. I did not overlap the drilled holes, left some metal in between (I was concerned the bit may torque / migrate) I am on the fence, may try drilling without 'leaving metal' between the holes, next time.

I took my time, 'tracing slowly', to create the opening. Slightly expanding the hole gradually, then checking for fit, and squareness, to the chassis. I used a 'for metal' carbide bit, later understood, was told that a ceramic tile bit is preferred (it will last longer) but cautioned that controlling its movement, not letting it bounce, is important, not to break/shatter the bit.

I tore up (spent) the 12.00 bit in the two chassis openings. Which, for learning and the actual result, is OK by me. I will pick up a different carbide bit for next project, try it out.

**A large component of my interest in installing the IEC jack (or better said, completely removing the captive cord) is that there is a tendency for the stranded wire to become frayed *unnoticeably* at the external chassis attach point, on much of the older vintage gear, and could possible be a current limiting effect, for amps especially. For me, making my builds 'the best they can be', is an imperative... also **eliminating variables and unknowns... is also very important to collective evolution of this class of gear.

***Having / using far better power cords is an added bonus... compliments the rest of the cabling that I use... I own or use no 18 gauge *zip cords*, except for lamps; do not want it to limit my audio systems...

Good luck,

Ozark

Can you identify your source for the dual secondary toroid? I looked at Musical Concepts TP-202 and it has some great features like electrostatic shield and steel banding, but it does not indicate that it has dual secondaries with center taps.

Do you have any specific advice in cutting the outlet for the IEC connector?

Hi Halauhula, The toroid shown is/are from 45v/ 625va, Plitron. I spoke with John, I think (understood him to say) that he had a few left. Might be worth a call, if you are interested... I believe Plitron purchase minimum (may be steep for DIY approach / budgets) thought it was 500.00 minimum order.

The IEC plug installation was done by penciling the cut out on the chassis, using with an 1/8" bit, drilling just inside of the actual desired opening. I did not overlap the drilled holes, left some metal in between (I was concerned the bit may torque / migrate) I am on the fence, may try drilling without 'leaving metal' between the holes, next time.

I took my time, 'tracing slowly', to create the opening. Slightly expanding the hole gradually, then checking for fit, and squareness, to the chassis. I used a 'for metal' carbide bit, later understood, was told that a ceramic tile bit is preferred (it will last longer) but cautioned that controlling its movement, not letting it bounce, is important, not to break/shatter the bit.

I tore up (spent) the 12.00 bit in the two chassis openings. Which, for learning and the actual result, is OK by me. I will pick up a different carbide bit for next project, try it out.

**A large component of my interest in installing the IEC jack (or better said, completely removing the captive cord) is that there is a tendency for the stranded wire to become frayed *unnoticeably* at the external chassis attach point, on much of the older vintage gear, and could possible be a current limiting effect, for amps especially. For me, making my builds 'the best they can be', is an imperative... also **eliminating variables and unknowns... is also very important to collective evolution of this class of gear.

***Having / using far better power cords is an added bonus... compliments the rest of the cabling that I use... I own or use no 18 gauge *zip cords*, except for lamps; do not want it to limit my audio systems...

Good luck,

Ozark

Hi Halauhula, The toroid shown is/are from 45v/ 625va, Plitron. I spoke with John, I think (understood him to say) that he had a few left. Might be worth a call, if you are interested... I believe Plitron purchase minimum (may be steep for DIY approach / budgets) thought it was 500.00 minimum order.

The IEC plug installation was done by penciling the cut out on the chassis, using with an 1/8" bit, drilling just inside of the actual desired opening. I did not overlap the drilled holes, left some metal in between (I was concerned the bit may torque / migrate) I am on the fence, may try drilling without 'leaving metal' between the holes, next time.

I took my time, 'tracing slowly', to create the opening. Slightly expanding the hole gradually, then checking for fit, and squareness, to the chassis. I used a 'for metal' carbide bit, later understood, was told that a ceramic tile bit is preferred (it will last longer) but cautioned that controlling its movement, not letting it bounce, is important, not to break/shatter the bit.

I tore up (spent) the 12.00 bit in the two chassis openings. Which, for learning and the actual result, is OK by me. I will pick up a different carbide bit for next project, try it out.

**A large component of my interest in installing the IEC jack (or better said, completely removing the captive cord) is that there is a tendency for the stranded wire to become frayed *unnoticeably* at the external chassis attach point, on much of the older vintage gear, and could possible be a current limiting effect, for amps especially. For me, making my builds 'the best they can be', is an imperative... also **eliminating variables and unknowns... is also very important to collective evolution of this class of gear.

***Having / using far better power cords is an added bonus... compliments the rest of the cabling that I use... I own or use no 18 gauge *zip cords*, except for lamps; do not want it to limit my audio systems...

Good luck,

Ozark

Thank you very much for your detailed explanation on the cutting process for the IEC socket, and your reference to Plitron. I did not know they had such a high minimum order - two decades ago, they did advertise in Audio Amateur so I assumed they sold at hobbyist $. I've been looking at their toroidal isolation transformer assemblies (sold through their subsidiary), so I will see if I can combine the orders.

AnTek does not provide two independent, center tapped secondaries

Hi!

AnTek was the first place I checked (I also checked Toroid Corp. and Avel), but the AnTeks are not what I am looking for:

The AnTeks only have two secondaries at the required voltages, which provides for a center tap. Accordingly, each channel does not have its own winding. To do that, one would need four secondaries or two tapped secondaries.

Thank you, however, for trying to help me. I appreciate it.

Hi!

AnTek was the first place I checked (I also checked Toroid Corp. and Avel), but the AnTeks are not what I am looking for:

The AnTeks only have two secondaries at the required voltages, which provides for a center tap. Accordingly, each channel does not have its own winding. To do that, one would need four secondaries or two tapped secondaries.

Thank you, however, for trying to help me. I appreciate it.

If you mean using two transformers, well no: stacking toroids is probably not possible because the height of two toroids stacked, plus dividing plate between the two transformers, would exceed the internal height of the Hafler chassis - one could not reinstall the cover. This is true even for the 250-300 VA Anteks, as their deign approach is to reduce diameter rather than height (I had already thought of this idea).

If you mean a single transformer with two independent secondaries, each secondary cert tapped, then yes!

If you mean a single transformer with two independent secondaries, each secondary cert tapped, then yes!

Plitron website (was a joke!) is useless.

@Halauhula

I tried navigating Plitrons website for ~ over 20 minutes, kept running into limits (dead end links) forgot the exact messages ...no results found... Even searching >minimum purchase amount< ...nothing useful... ever popped up.

It became maddening, I gave up. Looking (and now with) limited interest in their products all together... it seems like they do not want to interact with or do business with 'the public' or the outside world.

@Halauhula

I tried navigating Plitrons website for ~ over 20 minutes, kept running into limits (dead end links) forgot the exact messages ...no results found... Even searching >minimum purchase amount< ...nothing useful... ever popped up.

It became maddening, I gave up. Looking (and now with) limited interest in their products all together... it seems like they do not want to interact with or do business with 'the public' or the outside world.

Have a look at this place. i used them back 4-5 years ago. Very happy with them. Shipping can be expensive, but tell em what you want & they will give you a quote.

Primrose Audio - toroid power transformers for audio builders

Primrose Audio - toroid power transformers for audio builders

Have a look at this place. i used them back 4-5 years ago. Very happy with them. Shipping can be expensive, but tell em what you want & they will give you a quote.

Primrose Audio - toroid power transformers for audio builders

Wow! This is great! Thank you for the reference.

- Home

- Amplifiers

- Solid State

- Hafler DH-200/220 Mods