MYSTERY SOLVED!!!

If true then maybe the Pioneer TS-W1200PRO could be used as a cheap alternative to the Definimax4012HO in bass horns such as Tapped Horns and Front Loaded Horns.. ....Measuring the T/S parameters on one of these could be very revealing, if the measurements come close to matching the published parameters then i suspect that what we are dealing with here is a PIONENCE DEFINILAB12 !!

If true then maybe the Pioneer TS-W1200PRO could be used as a cheap alternative to the Definimax4012HO in bass horns such as Tapped Horns and Front Loaded Horns.. ....Measuring the T/S parameters on one of these could be very revealing, if the measurements come close to matching the published parameters then i suspect that what we are dealing with here is a PIONENCE DEFINILAB12 !!

An externally hosted image should be here but it was not working when we last tested it.

Attachments

Last edited:

LMAO - it might be some sort of EM hybrid - one reviewer of the Pioneer said Pioneer doesn't honor those sold through Amazon

http://ecx.images-amazon.com/images/I/71zYpx8WdNL._SL1000_.jpg

4012HO (I think)

http://ecx.images-amazon.com/images/I/91JKeQdHxvL._SL1500_.jpg

here's an image of the Pioneer's sticker saying "Made In China" http://mco-s1-p.mlstatic.com/bajo-p...petencia-spl-13318-MCO3094530048_092012-F.jpg

http://ecx.images-amazon.com/images/I/71zYpx8WdNL._SL1000_.jpg

4012HO (I think)

http://ecx.images-amazon.com/images/I/91JKeQdHxvL._SL1500_.jpg

here's an image of the Pioneer's sticker saying "Made In China" http://mco-s1-p.mlstatic.com/bajo-p...petencia-spl-13318-MCO3094530048_092012-F.jpg

Last edited:

tb46 - do you think 5/8" BB would be a better choice than 1/2" for a post 1188 build? - how much volume would a smoothing stub add? - ah! - I missed the drawing of how it fits - how might it change overall response? What might be a good way to attach a removable aperture plate that can take the pounding & pressure, not rattle and allow the driver to fit?

here's Guits' video of his K15's wings bending under playback of a drum solo

https://goo.gl/photos/ByhFAJ6sWffwZin67

here's Guits' video of his K15's wings bending under playback of a drum solo

https://goo.gl/photos/ByhFAJ6sWffwZin67

Last edited:

The plot thickens

Ok , yes .... China ... Good point .... If it is made in China then it isn't an Eminence product unless they have opened a plant in China right?

I did some searching and i figured out that there are other brands that use this same frame, some of them are even well known names such as TC Sounds! and other brands such as DC Audio, Hybrid Audio, Ampere Audio ....... There is also a 15" and an 18" version of this basket ...

So either Eminence is selling their baskets to other builders, or Eminence is buying some of their cast frame baskets from some other manufacturer .....

I know who can tell me who makes that basket, i have access to a few custom competition car audio sub builders, there is actually a group of them on facebook, they formed the group to trade raw parts ..... I will ask them and post here on DIYaudio with what i find out 🙂

LMAO - it might be some sort of EM hybrid - one reviewer of the Pioneer said Pioneer doesn't honor those sold through Amazon

http://ecx.images-amazon.com/images/I/71zYpx8WdNL._SL1000_.jpg

4012HO (I think)

http://ecx.images-amazon.com/images/I/91JKeQdHxvL._SL1500_.jpg

here's an image of the Pioneer's sticker saying "Made In China" http://mco-s1-p.mlstatic.com/bajo-p...petencia-spl-13318-MCO3094530048_092012-F.jpg

Ok , yes .... China ... Good point .... If it is made in China then it isn't an Eminence product unless they have opened a plant in China right?

I did some searching and i figured out that there are other brands that use this same frame, some of them are even well known names such as TC Sounds! and other brands such as DC Audio, Hybrid Audio, Ampere Audio ....... There is also a 15" and an 18" version of this basket ...

So either Eminence is selling their baskets to other builders, or Eminence is buying some of their cast frame baskets from some other manufacturer .....

I know who can tell me who makes that basket, i have access to a few custom competition car audio sub builders, there is actually a group of them on facebook, they formed the group to trade raw parts ..... I will ask them and post here on DIYaudio with what i find out 🙂

we know Eminence has some of their products made in China - it'll be interesting to fine out if some of their baskets and other parts are made there.

in email conversation with jessman, we're wondering if the K-aperture versions will have audible chuffing at high outputs. The speakers I normally use in K don't have a lot of excursion. My K-18 with an Eminence having ~6mm xmax could produce an air stream from the top of the slot that could be felt 8 feet away - but never exhibited audible chuffing on music. Jessman said the tall offset 1260W tapped pipe chuffed on test tones. What do you guyz think? In home use I doubt if I'd ever push the cabinet from post 1188 into chuffing but if used for sound reinforcement - ?

when I covered the upper 6-8" of this slot, subjective speed was "slower" and less articulate - but it was running

all the way up to ~1K2 as a two way system.

there are four closet pole dowel braces to the wings. The back panel bends a bit but my house walls

bent just as much - there's no smoothing stub - it has a curved reflector/port panel

I've never heard of Metro's T15 having a problem with chuffing (?) - here's the late Gregg Baker's homemade T15

https://www.youtube.com/watch?v=-povGo16gRI

in email conversation with jessman, we're wondering if the K-aperture versions will have audible chuffing at high outputs. The speakers I normally use in K don't have a lot of excursion. My K-18 with an Eminence having ~6mm xmax could produce an air stream from the top of the slot that could be felt 8 feet away - but never exhibited audible chuffing on music. Jessman said the tall offset 1260W tapped pipe chuffed on test tones. What do you guyz think? In home use I doubt if I'd ever push the cabinet from post 1188 into chuffing but if used for sound reinforcement - ?

when I covered the upper 6-8" of this slot, subjective speed was "slower" and less articulate - but it was running

all the way up to ~1K2 as a two way system.

there are four closet pole dowel braces to the wings. The back panel bends a bit but my house walls

bent just as much - there's no smoothing stub - it has a curved reflector/port panel

An externally hosted image should be here but it was not working when we last tested it.

I've never heard of Metro's T15 having a problem with chuffing (?) - here's the late Gregg Baker's homemade T15

https://www.youtube.com/watch?v=-povGo16gRI

Last edited:

If TB46 comes up with a dimensioned plan then I'll have Jessman kobble one up

Metro's T15 - did its foldback stub also smooth? - from their graph it looks like

they had two dips

Gregg ended up using a little round duct port

but I'm not sure whether his data was good - I've never see the insides of a real T15 to tell

if they employed the large rectangular duct or not (?)

Gregg's plan

Metro's T15 - did its foldback stub also smooth? - from their graph it looks like

they had two dips

Gregg ended up using a little round duct port

but I'm not sure whether his data was good - I've never see the insides of a real T15 to tell

if they employed the large rectangular duct or not (?)

An externally hosted image should be here but it was not working when we last tested it.

Gregg's plan

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

Hi freddi,

Without the Karlsson 'wings' many European hybrid-horn subs (quasi 6th order) look like this.

Cheers,

Djim

Without the Karlsson 'wings' many European hybrid-horn subs (quasi 6th order) look like this.

Cheers,

Djim

Hi freddi,

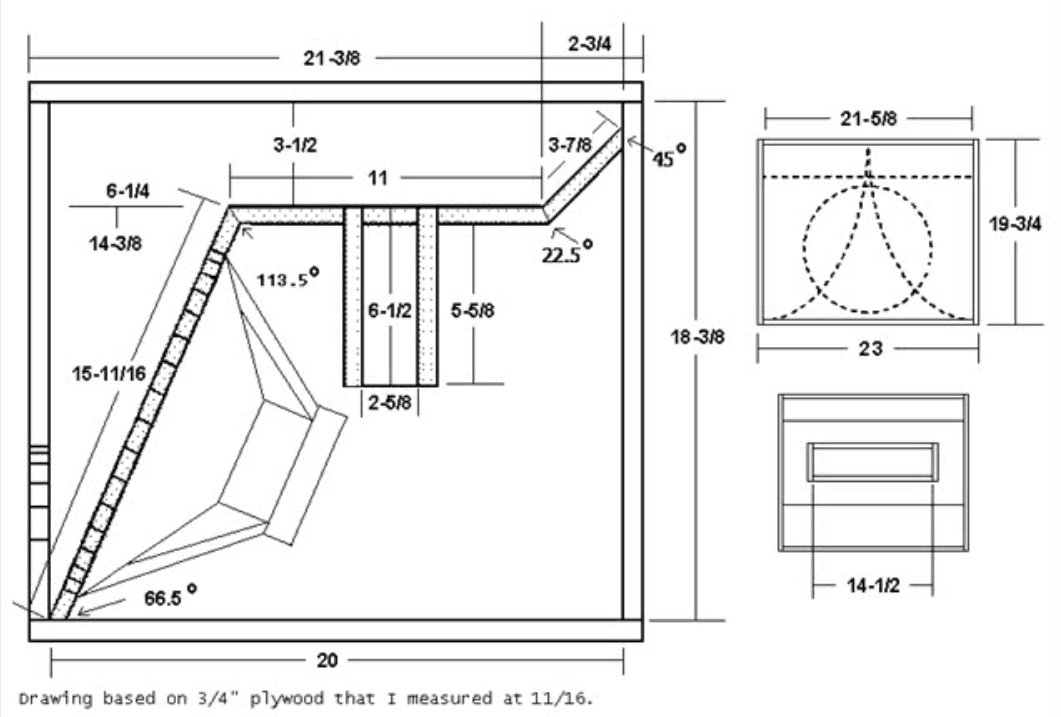

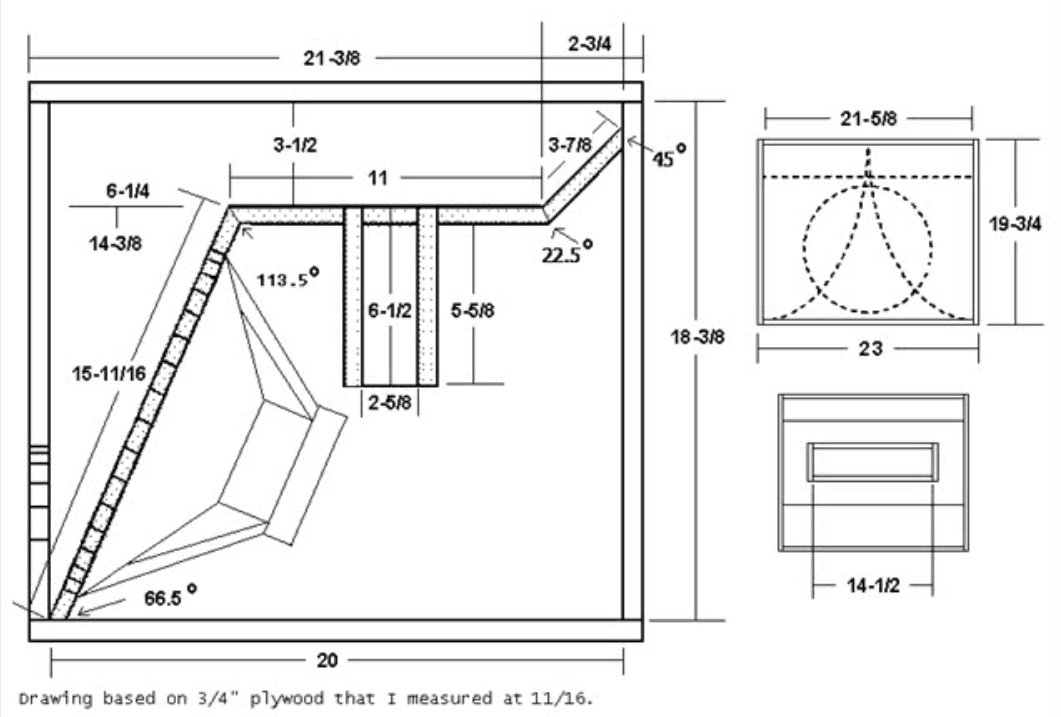

Post #1663: "...do you think 5/8" BB would be a better choice than 1/2" for a post 1188 build?...What might be a good way to attach a removable aperture plate that can take the pounding & pressure, not rattle and allow the driver to fit?"

I know we were drawing all this w/ 1/2"nom. plywood, but for a high output 15" PA driver I would suggest 3/4"nom. BB plywood, and center bracing in all the ducts. Out of time constraints I'm leaving the sketch @ 1/2"nom. (0.469"). I would mount the aperture plate against 1" square (or so) battens slightly inserted into the sides/top/bottom boards; I would make it the size of the full inserted front board, that way you can get to all internal ducts/stubs to change the stuffing (for the ducts remove the driver). It would be great if MMJ could simulate this in AkAbak w/ top and bottom stubs as he suggested in Post #1657. I'll attach another sketch w/ those duct placements. I reduced the box size as much as I felt comfortable doing, and I took some liberties w/ the duct dimensions in the Hornresp simulation, and the stubs need to be simulated (or omitted).

Regards,

Post #1663: "...do you think 5/8" BB would be a better choice than 1/2" for a post 1188 build?...What might be a good way to attach a removable aperture plate that can take the pounding & pressure, not rattle and allow the driver to fit?"

I know we were drawing all this w/ 1/2"nom. plywood, but for a high output 15" PA driver I would suggest 3/4"nom. BB plywood, and center bracing in all the ducts. Out of time constraints I'm leaving the sketch @ 1/2"nom. (0.469"). I would mount the aperture plate against 1" square (or so) battens slightly inserted into the sides/top/bottom boards; I would make it the size of the full inserted front board, that way you can get to all internal ducts/stubs to change the stuffing (for the ducts remove the driver). It would be great if MMJ could simulate this in AkAbak w/ top and bottom stubs as he suggested in Post #1657. I'll attach another sketch w/ those duct placements. I reduced the box size as much as I felt comfortable doing, and I took some liberties w/ the duct dimensions in the Hornresp simulation, and the stubs need to be simulated (or omitted).

Regards,

Attachments

A friend helped me solve THE BASKET CASE

After talking to some folks in this sub-builders parts exchange group on facebook i was able to find out some things about what most of them consider the "generic 12 spoke basket"

The basket used in the Lab12 and the Pioneer Pro12 and so many other drivers (from so many different brands) is in fact extremely common, the most prolific "12 spoke" ever made they say!

A local custom builder friend named Pat said that he believed the major source of these baskets is a manufacturing plant in China called "XY" ...... So i looked into it..

To be precise the company is called: Shenzhen XY Electronic Co. Ltd in Guangdong province, which is in the southern part of mainland China.

Pat provided the link to this video, and starting at about 3:00 in you can watch as our Lab12 baskets are made, the machine used to make them, and even the respectable hard working Chinese guy who operates it!

https://www.youtube.com/watch?v=Qu451vvbNRI

It is possible that some other Chinese factories also have this particular mold but "XY" is supposedly where the majority of these frames originate. I was also informed that "There are no good or bad versions of this frame. They're all the same and yes they cut the aluminum with zinc, every one of them".

After talking to some folks in this sub-builders parts exchange group on facebook i was able to find out some things about what most of them consider the "generic 12 spoke basket"

The basket used in the Lab12 and the Pioneer Pro12 and so many other drivers (from so many different brands) is in fact extremely common, the most prolific "12 spoke" ever made they say!

A local custom builder friend named Pat said that he believed the major source of these baskets is a manufacturing plant in China called "XY" ...... So i looked into it..

To be precise the company is called: Shenzhen XY Electronic Co. Ltd in Guangdong province, which is in the southern part of mainland China.

Pat provided the link to this video, and starting at about 3:00 in you can watch as our Lab12 baskets are made, the machine used to make them, and even the respectable hard working Chinese guy who operates it!

https://www.youtube.com/watch?v=Qu451vvbNRI

It is possible that some other Chinese factories also have this particular mold but "XY" is supposedly where the majority of these frames originate. I was also informed that "There are no good or bad versions of this frame. They're all the same and yes they cut the aluminum with zinc, every one of them".

Last edited:

I'm not buying the claimed 105dB {measured exactly how?}

But I found one site claiming some believable T/S:

Free-Air Resonance (Fs) 40 Hz

Equivalent Compliance (Vas) 45.6 liters

Total Speaker Q Value (Qts) 0.38

Electrical Q Value (Qes) 0.39

Electrical Resistance of Voice Coil (Re) 3.5 ohms {per each of two coils?}

Mechanical Q Value (Qms) 10.7

Specs ripped from:

Pioneer TS-W1200PRO PRO-Series 1500W 12" Subwoofer

But I found one site claiming some believable T/S:

Free-Air Resonance (Fs) 40 Hz

Equivalent Compliance (Vas) 45.6 liters

Total Speaker Q Value (Qts) 0.38

Electrical Q Value (Qes) 0.39

Electrical Resistance of Voice Coil (Re) 3.5 ohms {per each of two coils?}

Mechanical Q Value (Qms) 10.7

Specs ripped from:

Pioneer TS-W1200PRO PRO-Series 1500W 12" Subwoofer

Last edited:

Hi freddi,

Just some questions:

Post #1666: "...If TB46 comes up with a dimensioned plan then I'll have Jessman kobble one up..."

Right now I'm not sure which one we are talking about? The one from Post #1188 (or an optimized one w/ that fold) is relatively easy as I already have a drawing. Or, the one w/ the top and bottom stubs as in Post #1668? For the second one I really need some help from the AkAbak specialists for the length and number of stubs (e.g.: 2ea. on the top, and 2ea. on the bottom, or some other number?), and the Karlson aperture output.

Have you made a decision on the plywood thickness?

Regards,

Just some questions:

Post #1666: "...If TB46 comes up with a dimensioned plan then I'll have Jessman kobble one up..."

Right now I'm not sure which one we are talking about? The one from Post #1188 (or an optimized one w/ that fold) is relatively easy as I already have a drawing. Or, the one w/ the top and bottom stubs as in Post #1668? For the second one I really need some help from the AkAbak specialists for the length and number of stubs (e.g.: 2ea. on the top, and 2ea. on the bottom, or some other number?), and the Karlson aperture output.

Have you made a decision on the plywood thickness?

Regards,

they cut the aluminum with zinc, every one of them".

Was just researching cold chamber die casting, and machine looks just

like one in video. For Zinc alloys containing 12% to 27% Aluminum...

Attachments

Last edited:

Hi Y'all,

There is even a North America Die Casting Association NADCA, who knew? 🙂

https://www.diecasting.org/wcm/Die_...spx?hkey=01ccba73-b463-4980-b3b4-a2c28815a015

Regards,

There is even a North America Die Casting Association NADCA, who knew? 🙂

https://www.diecasting.org/wcm/Die_...spx?hkey=01ccba73-b463-4980-b3b4-a2c28815a015

Regards,

Welcome to the Machine

Kenpeter,

Yes , that does look incredibly similar! 🙂

The 105db number is an "in vehicle" or 1/8th space (.5 pi) figure which yes, is sort of cheating since the industry standard is to use halfspace (2pi , as in an open field) figures ..... The real halfspace efficiency of that driver is probably more along the lines of 95db @1w/1m in the midbass or lower midrange region, and begins to taper off above 500hz according to the only response graph that we could find for that driver, and that taper actually sounds about right based upon the voicecoil's inductance value which is a bit high by Pro standards and will cause an early impedance rise at higher frequencies therefore less power delivered by the amplifier up there, resulting in a tapering in response even if the cone (and moving mass) is light .....

Kenpeter, here is a link to the Pioneer's PDF with T/S parameters:

http://www.manualsearcher.com/pioneer/ts-w1200pro/manual

Was just researching cold chamber die casting, and machine looks just

like one in video. For Zinc alloys containing 12% to 27% Aluminum...

Kenpeter,

Yes , that does look incredibly similar! 🙂

I'm not buying the claimed 105dB {measured exactly how?}

But I found one site claiming some believable T/S:

Free-Air Resonance (Fs) 40 Hz

Equivalent Compliance (Vas) 45.6 liters

Total Speaker Q Value (Qts) 0.38

Electrical Q Value (Qes) 0.39

Electrical Resistance of Voice Coil (Re) 3.5 ohms {per each of two coils?}

Mechanical Q Value (Qms) 10.7

The 105db number is an "in vehicle" or 1/8th space (.5 pi) figure which yes, is sort of cheating since the industry standard is to use halfspace (2pi , as in an open field) figures ..... The real halfspace efficiency of that driver is probably more along the lines of 95db @1w/1m in the midbass or lower midrange region, and begins to taper off above 500hz according to the only response graph that we could find for that driver, and that taper actually sounds about right based upon the voicecoil's inductance value which is a bit high by Pro standards and will cause an early impedance rise at higher frequencies therefore less power delivered by the amplifier up there, resulting in a tapering in response even if the cone (and moving mass) is light .....

Kenpeter, here is a link to the Pioneer's PDF with T/S parameters:

http://www.manualsearcher.com/pioneer/ts-w1200pro/manual

Last edited:

Freddi ,

That Metro T-15 has always seemed like an interesting modern adaptation of K-tech , the response is reduced by 5db above 500hz but is fairly smooth from 500hz all the way up to 3khz .... Which driver does that box use? , wasn't it a B&C model of some sort? I would like to see what the raw response of that driver is ...... Perhaps that same K-wing contour could be used on a Karlflex with a very narrow slot above .........

The T-15 does also have the classic Karlson "W" shaped dips in response (in this case located at 220hz and 400hz) , i was able to eliminate those issues with a carefully adjusted driver offset (S1 stub section) and Freddi-mod cavity in the Karlflex (Akabak was immensely valuable for getting those sections all figured out) ....

That Metro T-15 has always seemed like an interesting modern adaptation of K-tech , the response is reduced by 5db above 500hz but is fairly smooth from 500hz all the way up to 3khz .... Which driver does that box use? , wasn't it a B&C model of some sort? I would like to see what the raw response of that driver is ...... Perhaps that same K-wing contour could be used on a Karlflex with a very narrow slot above .........

The T-15 does also have the classic Karlson "W" shaped dips in response (in this case located at 220hz and 400hz) , i was able to eliminate those issues with a carefully adjusted driver offset (S1 stub section) and Freddi-mod cavity in the Karlflex (Akabak was immensely valuable for getting those sections all figured out) ....

Last edited:

6.1mm xmax, which ain't shabby, but also isn't Lab12.

Bumped but not double stacked, what sort of xlim then?

In-band excursion can be controlled by Karlson or other

loading. Only air we want moved anyway...

Bumped but not double stacked, what sort of xlim then?

In-band excursion can be controlled by Karlson or other

loading. Only air we want moved anyway...

Last edited:

Almost unreadable as it was, but fixable...

Can we math from this a reasonable half space sensitivity?

And that cutaway looks looks like plenty xlim without

hitting anything, but voice coil could jump completely

out the gap, what assures its return without damage?

The front nose of the pole doesn't look rounded or

any such thing that would help. I also don't see any

shorting rings, so not quite like definimax either...

Can we math from this a reasonable half space sensitivity?

And that cutaway looks looks like plenty xlim without

hitting anything, but voice coil could jump completely

out the gap, what assures its return without damage?

The front nose of the pole doesn't look rounded or

any such thing that would help. I also don't see any

shorting rings, so not quite like definimax either...

Attachments

Last edited:

Hi kenpeter,

Here is a simple vented enclosure @ 1W into 2 Ohm (nominal; Eg=1.41 Re=1.75):

Regards,

Here is a simple vented enclosure @ 1W into 2 Ohm (nominal; Eg=1.41 Re=1.75):

Regards,

Attachments

Last edited:

Hornresp screenshot is showing absurd numbers, I should only look at the graph?

93.7dB at 1W I would believe, but not at 0.0548 Watts, and not at 13% efficiency.

This would be equivalent to 106.32dB at 1W. Worse exaggeration than Pioneer's

105dB in-car at 1W. Not even if it were 2.83V into 2ohms.

93.7dB at 1W I would believe, but not at 0.0548 Watts, and not at 13% efficiency.

This would be equivalent to 106.32dB at 1W. Worse exaggeration than Pioneer's

105dB in-car at 1W. Not even if it were 2.83V into 2ohms.

Last edited:

- Home

- Loudspeakers

- Subwoofers

- New sub design? Constricted Transflex, simple build (series tuned 6th order)