hi tb46 - - I thought even the simple design in post 1188 looked pretty good - - - I think PHL may have used a PHL with specs something like my 15pzb40 http://www.teamaudio.fr/media/catalog/product/datasheet/phl/6030_6090.pdf

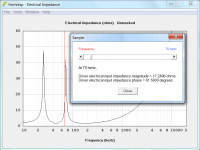

the input power @ any given frequency depends on the impedance @ that frequency given a constant Eg.

At 70 hertz, the driver electrical input impedance magnitude is 17.2496 ohms.

Attachments

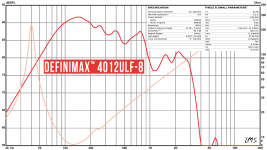

Pioneer TS-W1200PRO vs 4012ULF

Oh yes, good find Kenpeter! That 4012ULF has parameters that are not far off from what is published for the Pioneer (except for power handling and RE , and Le , and some motor strength , but they are still both motor strength monsters considering that they are only 12" drivers) ...

Inductance (per ohm) on the 4012ULF is somewhat higher, and the moving mass is also higher both of which are likely related to the heavier voicecoil used in the Eminence and explains why midbass efficiency and bandwidth is reduced producing that early dwindling of output at the higher frequencies on the 4012ULF relative to the TS-W1200PRO ...

_________________________4012ULF ---- TS-W1200PRO

INDUCTANCE PER OHM(Le/Re)= .69mh ---- .53mh

________MOVING MASS (MMS) = 153g ---- 135g

__MOTOR STRENGTH (BL^2/RE) = 120.9 ----- 89.28

_______________EBP (FS/QES) = 125 ----- 102

Keep in mind that that a very high voicecoil inductance tends to offset some benefits of having a high motor strength & EBP so in regards to those figures the two drivers are more closely matched than they appear, and when you consider that the Pioneer is less than half the price of the other driver you cannot deny that it is a fantastic bargain!

... Of course we are assuming that Pioneer's published parameters are accurate but we won't know for sure until someone with some test equipment measures one ...

... Of course we are assuming that Pioneer's published parameters are accurate but we won't know for sure until someone with some test equipment measures one ...

Kenpeter, in an attempt to answer your question about the mechanical limits (XLIM) on the Pioneer: i have no idea what that figure might be but what i can say with certainty is that a 12" driver with this much motor strength and such an incredibly tight suspension will have excellent control over it's cone movement, far superior to typical drivers with loose suspensions and weak motors... The likelihood of the VC jumping out of the gap is much reduced and probably nothing to be concerned about in this case ...

This is not a high excursion driver but with this much motor strength it doesn't necessarily need to be .... The strong motor improves output down near the fundamental tuning of our undersized 6th order box (so in the case of our 40hz TH or Karlflex we have better output around 40hz-50hz using a small cabinet)...

I have searched the internet high and low in an attempt to find another 12" $99 driver (which is not strictly a sub) that can produce nearly 120db of output down to 40hz in a 100L Tapped Horn (also works well in a 60L Karlflex) .... The Pioneer APPEARS to be an exceptionally good value ...... The only other option i can find that is value-comparable is the Soundqubed HDS212 which has a heck of a lot more XMAX but unfortunately due to the higher moving mass and higher voicecoil inductance it is very bandwidth limited, and is therefore strictly a subwoofer....

Oh yes, good find Kenpeter! That 4012ULF has parameters that are not far off from what is published for the Pioneer (except for power handling and RE , and Le , and some motor strength , but they are still both motor strength monsters considering that they are only 12" drivers) ...

Inductance (per ohm) on the 4012ULF is somewhat higher, and the moving mass is also higher both of which are likely related to the heavier voicecoil used in the Eminence and explains why midbass efficiency and bandwidth is reduced producing that early dwindling of output at the higher frequencies on the 4012ULF relative to the TS-W1200PRO ...

_________________________4012ULF ---- TS-W1200PRO

INDUCTANCE PER OHM(Le/Re)= .69mh ---- .53mh

________MOVING MASS (MMS) = 153g ---- 135g

__MOTOR STRENGTH (BL^2/RE) = 120.9 ----- 89.28

_______________EBP (FS/QES) = 125 ----- 102

Keep in mind that that a very high voicecoil inductance tends to offset some benefits of having a high motor strength & EBP so in regards to those figures the two drivers are more closely matched than they appear, and when you consider that the Pioneer is less than half the price of the other driver you cannot deny that it is a fantastic bargain!

... Of course we are assuming that Pioneer's published parameters are accurate but we won't know for sure until someone with some test equipment measures one ...

... Of course we are assuming that Pioneer's published parameters are accurate but we won't know for sure until someone with some test equipment measures one ... Kenpeter, in an attempt to answer your question about the mechanical limits (XLIM) on the Pioneer: i have no idea what that figure might be but what i can say with certainty is that a 12" driver with this much motor strength and such an incredibly tight suspension will have excellent control over it's cone movement, far superior to typical drivers with loose suspensions and weak motors... The likelihood of the VC jumping out of the gap is much reduced and probably nothing to be concerned about in this case ...

This is not a high excursion driver but with this much motor strength it doesn't necessarily need to be .... The strong motor improves output down near the fundamental tuning of our undersized 6th order box (so in the case of our 40hz TH or Karlflex we have better output around 40hz-50hz using a small cabinet)...

I have searched the internet high and low in an attempt to find another 12" $99 driver (which is not strictly a sub) that can produce nearly 120db of output down to 40hz in a 100L Tapped Horn (also works well in a 60L Karlflex) .... The Pioneer APPEARS to be an exceptionally good value ...... The only other option i can find that is value-comparable is the Soundqubed HDS212 which has a heck of a lot more XMAX but unfortunately due to the higher moving mass and higher voicecoil inductance it is very bandwidth limited, and is therefore strictly a subwoofer....

Last edited:

LAB12 "12 spoke" frame ......... Comedy

Another note about the generic "12 spoke" basket used for the LAB12 (and used on many many other subs made by many brands) ....

I received a message from another guy in that sub builder's parts exchange group on facebook , he sent me a quote that he snipped from an old conversation on caraudio dot com:

"Paul Roth, originally designed the 4-spoke “Venezuela” basket at least 20 years ago (maybe longer). The design was then copied by several people including a Russian vendor who later designed the 12-spoke basket you are talking about. The only critical difference between the 4-spoke and 12-spoke is the clearance under the suspension. The 4-spoke has 1.25” and the 12-spoke has 1.5”.

Sooooooo ok , let me get this straight

It was originally called the "Venezuela" basket which was redesigned into a 12-spoke by a Russian guy which in turn is now being made by a Chinese guy

which in turn is now being made by a Chinese guy in the "Shenzen XY" factory located in mainland China, then sent here to America to be glued onto a LAB12 motor along with a sticker that proudly says "MADE IN AMERICA"!!!!!

in the "Shenzen XY" factory located in mainland China, then sent here to America to be glued onto a LAB12 motor along with a sticker that proudly says "MADE IN AMERICA"!!!!!

NOW THAT'S COMEDY !!!! HAHA!

Another knowledgeable fellow in the FB discussion added: "No company I know of uses American baskets or magnets as a rule.. We only assemble subs here. If a sub says "Made in the USA" it usually barely makes the mark by use of creative bookwork or is an obvious lie."

A sticker that says "Assembled in America" would be more appropriate

As it turns out (even with a sub like the Lab12) the technology and the parts that go into these drivers are an international effort.

YAY TEAMWORK!

YAY TEAMWORK!

Another note about the generic "12 spoke" basket used for the LAB12 (and used on many many other subs made by many brands) ....

I received a message from another guy in that sub builder's parts exchange group on facebook , he sent me a quote that he snipped from an old conversation on caraudio dot com:

"Paul Roth, originally designed the 4-spoke “Venezuela” basket at least 20 years ago (maybe longer). The design was then copied by several people including a Russian vendor who later designed the 12-spoke basket you are talking about. The only critical difference between the 4-spoke and 12-spoke is the clearance under the suspension. The 4-spoke has 1.25” and the 12-spoke has 1.5”.

Sooooooo ok , let me get this straight

It was originally called the "Venezuela" basket which was redesigned into a 12-spoke by a Russian guy

which in turn is now being made by a Chinese guy

which in turn is now being made by a Chinese guy in the "Shenzen XY" factory located in mainland China, then sent here to America to be glued onto a LAB12 motor along with a sticker that proudly says "MADE IN AMERICA"!!!!!

in the "Shenzen XY" factory located in mainland China, then sent here to America to be glued onto a LAB12 motor along with a sticker that proudly says "MADE IN AMERICA"!!!!!NOW THAT'S COMEDY !!!! HAHA!

Another knowledgeable fellow in the FB discussion added: "No company I know of uses American baskets or magnets as a rule.. We only assemble subs here. If a sub says "Made in the USA" it usually barely makes the mark by use of creative bookwork or is an obvious lie."

A sticker that says "Assembled in America" would be more appropriate

As it turns out (even with a sub like the Lab12) the technology and the parts that go into these drivers are an international effort.

YAY TEAMWORK!

YAY TEAMWORK!

Last edited:

hi tb46 - - I thought even the simple design in post 1188 looked pretty good - - - I think PHL may have used a PHL with specs something like my 15pzb40 http://www.teamaudio.fr/media/catalog/product/datasheet/phl/6030_6090.pdf

Freddi ,

Those were what was used in the Metro T-15s? They look like some great drivers! I wish they provided a raw direct radiating response graph for those, i just wanted to know if they started off with a rising response, or if they were flat into the upper-mids to begin with ( I am trying to determine how that T-15 K-slot affected the upper frequencies).

By the way , i think i found the paper tube i will use for this Transylvania Power Company style slotted tube knockoff with the Selenium compression driver.

I'm going to guess the PHL were flat in the mids (?) here's a crude pipe I made a few years ago with a Dayton/Eminence - there's not a huge midrange difference between the quasi-K aperture and response with the aperture plate entirely removed but things seemed smoother with no blocking of the driver

An externally hosted image should be here but it was not working when we last tested it.

Hi freddi,

Post #1684: "re: wood thickness - do you think 5/8" BB would suffice? 5/8" can flex but with braces might do alright (?) - that would shave a bit of weight - that woofer alone is pretty heavy - 3/4" BB would be ok too. I'd like 1/2 to work weight wise ;^)"

I guess after that precise and decisive reply I just stay w/ 1/2"nom. (.469"actual) plywood.

One minor problem: I cannot find any drawings for the B&C 15PZB40, so I'm going w/ the drawing for the replacement B&C 15PZB100 as a drawing is available. It's a tad deeper than the 15PZB40, but, otherwise looks similar. The second (resultant) problem is that the speaker does not fit the box from Post #1188; the Beyma 15P1200Nd that the Post #1188 box was designed for has a neodymiun motor, and a smaller OD. The box will have to be a little bit wider (16.876"W_ext.), and about 1" deeper (19.0"D_ext), the height can stay the same (22.0"H_ext.). I am close to having a new drawing finished, but work is interfering w/ the hobby. So, you may have to wait a little until I find the time to do a new simulation, and fully dimension the drawing. Shouldn't take forever.

Regards,

Post #1684: "re: wood thickness - do you think 5/8" BB would suffice? 5/8" can flex but with braces might do alright (?) - that would shave a bit of weight - that woofer alone is pretty heavy - 3/4" BB would be ok too. I'd like 1/2 to work weight wise ;^)"

I guess after that precise and decisive reply I just stay w/ 1/2"nom. (.469"actual) plywood.

One minor problem: I cannot find any drawings for the B&C 15PZB40, so I'm going w/ the drawing for the replacement B&C 15PZB100 as a drawing is available. It's a tad deeper than the 15PZB40, but, otherwise looks similar. The second (resultant) problem is that the speaker does not fit the box from Post #1188; the Beyma 15P1200Nd that the Post #1188 box was designed for has a neodymiun motor, and a smaller OD. The box will have to be a little bit wider (16.876"W_ext.), and about 1" deeper (19.0"D_ext), the height can stay the same (22.0"H_ext.). I am close to having a new drawing finished, but work is interfering w/ the hobby. So, you may have to wait a little until I find the time to do a new simulation, and fully dimension the drawing. Shouldn't take forever.

Regards,

hi tb46 - - I'll get rough measurements of the basket/depth - - for the 15TBX40, its ~ 6.375" deep from the rear of the flange, flange diameter ~15.5", magnet diameter ~8.75", back plate diameter ~8", flange thickness ~ 0.5" - -have to find the 15PzB40 - can't remember if mine share the same basket/motor or not - that's not much help ;^)

my builder can make adjustments in material thickness - do you think the smoothing stub to be a worthwhile addition? how about the possibility of chuffing? It might be good to have some adjustment available in the vent. Many thanks !

since there's a mild rise indicated - maybe 15tbx40 is good - I'm hoping it will be interchangeable with 15pzb40/"whatever"

http://bcspeakers.s3.amazonaws.com/2013/03/11/16/08/44/296/file

Fs 38 Hz

Re 5.2

Ω

Qes 0.29

Qms 6.3

Qts 0.28

Vas 131 dm3 (4.6 ft3)

Sd 855 cm2 (132.5 in2)

η0 2.3 %

X max ± 9 mm

X Var ± 11 mm

Mms 141 g

Bl 24.6 T·m

Le 1.8 mH

my builder can make adjustments in material thickness - do you think the smoothing stub to be a worthwhile addition? how about the possibility of chuffing? It might be good to have some adjustment available in the vent. Many thanks !

since there's a mild rise indicated - maybe 15tbx40 is good - I'm hoping it will be interchangeable with 15pzb40/"whatever"

http://bcspeakers.s3.amazonaws.com/2013/03/11/16/08/44/296/file

Fs 38 Hz

Re 5.2

Ω

Qes 0.29

Qms 6.3

Qts 0.28

Vas 131 dm3 (4.6 ft3)

Sd 855 cm2 (132.5 in2)

η0 2.3 %

X max ± 9 mm

X Var ± 11 mm

Mms 141 g

Bl 24.6 T·m

Le 1.8 mH

Last edited:

Tidy Cats and ratios

Freddi ,

The green curve is the 7.73 cubic foot "Tidy Cat" cabinet? Is that just a standard K-cab? The driver's cone looks like it is not really obscured by the wings, not by much it seems .... Then at the other extreme the Inverted TH had K-wings that were covering most of the cone ...

Both cabs had the distinct "W" shaped dip in the midbass response , just like the Metro T-15 has to a lesser degree .... The driver offset/stub and Fredd-mod cavities can fix those issues, but Akabak is required to simulate that sort of system ..

......

Freddi , while on the subject ,i have another question for you regarding classic K-cabs: The back-to-front chamber ratio was generally 2:1 is that correct? or something different? I noticed many K-variants (even the T-15) seem to go with a roughly 2:1 ratio ..

.....

NOTE: That mild rising response of your 15TBX40 can be very useful ! Suitable for wings ! ..

Suitable for wings ! ..

I'm going to guess the PHL were flat in the mids (?) here's a crude pipe I made a few years ago with a Dayton/Eminence - there's not a huge midrange difference between the quasi-K aperture and response with the aperture plate entirely removed but things seemed smoother with no blocking of the driver

An externally hosted image should be here but it was not working when we last tested it.

Freddi ,

The green curve is the 7.73 cubic foot "Tidy Cat" cabinet? Is that just a standard K-cab? The driver's cone looks like it is not really obscured by the wings, not by much it seems .... Then at the other extreme the Inverted TH had K-wings that were covering most of the cone ...

Both cabs had the distinct "W" shaped dip in the midbass response , just like the Metro T-15 has to a lesser degree .... The driver offset/stub and Fredd-mod cavities can fix those issues, but Akabak is required to simulate that sort of system ..

......

Freddi , while on the subject ,i have another question for you regarding classic K-cabs: The back-to-front chamber ratio was generally 2:1 is that correct? or something different? I noticed many K-variants (even the T-15) seem to go with a roughly 2:1 ratio ..

.....

NOTE: That mild rising response of your 15TBX40 can be very useful !

Last edited:

K's Ks used ~2:1 - that's a wimpy out of spec Audio Nirvana 10" with 1mm xmax in a K15 - sounded about as good as it could other than the Karlsonator 12 where I think it went deeper in less overall bulk. Excursion was reduced in K15 vs reflex although the reflex below was tuned a bit lower than the Karlson

those poor B&C have laid around for a decade - I don't play/drive nor move at all ;^(

those poor B&C have laid around for a decade - I don't play/drive nor move at all ;^(

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

Modified enclosure. See Posts #1188, 1668, 1692, 1693

Hi freddi,

Post #1693: "...do you think the smoothing stub to be a worthwhile addition? how about the possibility of chuffing? It might be good to have some adjustment available in the vent..."

There are two more measurement you could get us if you find the 15PZB40, that is the depth from the frame/gasket to the dust cap, and the dust cap diameter.

Yes, a stub would be a worthwhile addition, but it should probably be added after some measurements of the basic enclosure. I you add the stub @ the bottom of the enclosure, e.g.: 2"H_int (see: Post #1668) you have the option of adding a little additional length to L12 (new L12=101.5cm, new S1=205.66cm^2), and still have enough room for a stub. The stub could be vented into the bottom of the front chamber, or into the back chamber below the driver. Just a lot of different ways to do that, and I would suggest you first build a prototyp, then measure it, and go from there. To evaluate chuffing you need a prototype, and you may have to play around w/ the shape of the Karlson aperture; there should be no chuffing from the ducts. If there is any vibration in the "wings" you may have to add a center brace to that panel.

I'll attach the modified drawing, and the Hornresp Export.

Regards,

Hi freddi,

Post #1693: "...do you think the smoothing stub to be a worthwhile addition? how about the possibility of chuffing? It might be good to have some adjustment available in the vent..."

There are two more measurement you could get us if you find the 15PZB40, that is the depth from the frame/gasket to the dust cap, and the dust cap diameter.

Yes, a stub would be a worthwhile addition, but it should probably be added after some measurements of the basic enclosure. I you add the stub @ the bottom of the enclosure, e.g.: 2"H_int (see: Post #1668) you have the option of adding a little additional length to L12 (new L12=101.5cm, new S1=205.66cm^2), and still have enough room for a stub. The stub could be vented into the bottom of the front chamber, or into the back chamber below the driver. Just a lot of different ways to do that, and I would suggest you first build a prototyp, then measure it, and go from there. To evaluate chuffing you need a prototype, and you may have to play around w/ the shape of the Karlson aperture; there should be no chuffing from the ducts. If there is any vibration in the "wings" you may have to add a center brace to that panel.

I'll attach the modified drawing, and the Hornresp Export.

Regards,

Attachments

Last edited:

K-stuff and things

Schlager tried a stub addition on the bottom of the box connecting to the front chamber and it works to smooth response and add volume to the front chamber .... Using a stub at the top of the cabinet connected to the front chamber (at the end of the interchamber vent) also works , and that is what i call the "Freddi-mod" ..

You can use both methods at once but it will likely add some height to the cabinet .... You also have to use akabak to get the stub dimensions adjusted correctly ..... If all goes well hopefully the total front chamber volume comes fairly close the old 2:1 (back:front) Karlson chamber ratio ...

It would also be a good idea to add some sort of abrupt reduction in CSA in the path (like my interchamber duct) in order to define your front chamber and back chambers .... Almost every K-cabinet i have seen uses this feature from the XKi , to the Karlsonator , Kuckoo clock , Karlflex and of course the old classic K-cabs too but unfortunately Hornresp does not allow for that in it's simulations so it is another task for Akabak . .

Schlager tried a stub addition on the bottom of the box connecting to the front chamber and it works to smooth response and add volume to the front chamber .... Using a stub at the top of the cabinet connected to the front chamber (at the end of the interchamber vent) also works , and that is what i call the "Freddi-mod" ..

You can use both methods at once but it will likely add some height to the cabinet .... You also have to use akabak to get the stub dimensions adjusted correctly ..... If all goes well hopefully the total front chamber volume comes fairly close the old 2:1 (back:front) Karlson chamber ratio ...

It would also be a good idea to add some sort of abrupt reduction in CSA in the path (like my interchamber duct) in order to define your front chamber and back chambers .... Almost every K-cabinet i have seen uses this feature from the XKi , to the Karlsonator , Kuckoo clock , Karlflex and of course the old classic K-cabs too but unfortunately Hornresp does not allow for that in it's simulations so it is another task for Akabak . .

Last edited:

Schlager tried a stub addition on the bottom of the box connecting to the front chamber and it works to smooth response and add volume to the front chamber .... Using a stub at the top of the cabinet connected to the front chamber (at the end of the interchamber vent) also works , and that is what i call the "Freddi-mod" ..

You can use both methods at once but it will likely add some height to the cabinet .... You also have to use akabak to get the stub dimensions adjusted correctly ..... If all goes well hopefully the total front chamber volume comes fairly close the old 2:1 (back:front) Karlson chamber ratio ...

It would also be a good idea to add some sort of abrupt reduction in CSA in the path (like my interchamber duct) in order to define your front chamber and back chambers .... Almost every K-cabinet i have seen uses this feature from the XKi , to the Karlsonator , Kuckoo clock , Karlflex and of course the old classic K-cabs too but unfortunately Hornresp does not allow for that in it's simulations so it is another task for Akabak . .

MMJ,

I have not been keeping up with this thread. Have there been any recent builds of the Karlflex? I am just wondering how real measurements are comparing to sims. With appropriate stuffing - what is the Group Delay from 100Hz to 50Hz?

Thanks

Link to current version of the simple Karlflex

XRK ,

The current (and probably final) official version of the simplified Karlflex can be found at post #1611 http://www.diyaudio.com/forums/subw...d-series-tuned-6th-order-162.html#post4481439

The measurements should look extremely similar to my prototype ... Group delay should be low according to Akabak unless using a scaled up 120 liter cabinet with a small driver having very strong motor ... .... For example the Definimax4012HO works well in a 60L cabinet , no need to go much larger than that with this alignment ..... The larger 100L and 120L cabinets were generally designed for 15" drivers (or 12s with weak motors, but that's not ideal)

MMJ,

I have not been keeping up with this thread. Have there been any recent builds of the Karlflex? I am just wondering how real measurements are comparing to sims. With appropriate stuffing - what is the Group Delay from 100Hz to 50Hz?

Thanks

XRK ,

The current (and probably final) official version of the simplified Karlflex can be found at post #1611 http://www.diyaudio.com/forums/subw...d-series-tuned-6th-order-162.html#post4481439

The measurements should look extremely similar to my prototype ... Group delay should be low according to Akabak unless using a scaled up 120 liter cabinet with a small driver having very strong motor ... .... For example the Definimax4012HO works well in a 60L cabinet , no need to go much larger than that with this alignment ..... The larger 100L and 120L cabinets were generally designed for 15" drivers (or 12s with weak motors, but that's not ideal)

Last edited:

- Home

- Loudspeakers

- Subwoofers

- New sub design? Constricted Transflex, simple build (series tuned 6th order)