Pyramid, fantastic! The purpose built generator is a much more attractive option than what has been pursued earlier. I appreciate all the work Ralph and Hans has done (thanks so much guys), but if this works out, seems to be the best option. Your work with sourcing the boards, and compiling a parts list is "icing on the cake". Most of this is over my head, but if there is anything I can do to help with this project, I am more than willing.

twystd

twystd

The only problem I see with this project is the sourcing of the uP and the control of the IP that runs it. While I'm waiting for the PCBs to arrive (~2 weeks), I've been tinkering with the numbers and it should be possible to do 0.01 Hz resolution which basically makes this a 4 channel SDS sinewave generator, which could be exploited commercially if I release the operating system into the public domain. The only way to control this from happening, is for me to program the chips and set the security bits so the chips cannot be read or duplicated. This also negates the need to have in-circuit programming capability or to create programming cables etc.

I do not want to get into selling parts piece work. What the project needs is a group buy or someone who is willing to stock 25-50 of the micros, send them to me for programming (no charge) and ship them back for distribution. The cheapest price I could find for the uP was ~$4.50 (@25 pcs) through Verical/Arrow so someone will have to step up and buy $112.50 worth of chips; they can re-sell them to DIYs interested in building this project at a modest profit (the un-programmed chips are $7.87 each from Mouser). If they sold for $10 (+ S&H), the distributor could more than double their investment.

I don't know how group buys work, but that is another possibility. All of the other parts and the PCBs can be purchased individually (or small groups as the PCBs are done in mulitples of 3) so the uP is the only stumbling block. Is there anyone that wants to handle this?

I do not want to get into selling parts piece work. What the project needs is a group buy or someone who is willing to stock 25-50 of the micros, send them to me for programming (no charge) and ship them back for distribution. The cheapest price I could find for the uP was ~$4.50 (@25 pcs) through Verical/Arrow so someone will have to step up and buy $112.50 worth of chips; they can re-sell them to DIYs interested in building this project at a modest profit (the un-programmed chips are $7.87 each from Mouser). If they sold for $10 (+ S&H), the distributor could more than double their investment.

I don't know how group buys work, but that is another possibility. All of the other parts and the PCBs can be purchased individually (or small groups as the PCBs are done in mulitples of 3) so the uP is the only stumbling block. Is there anyone that wants to handle this?

Last edited:

Hans-

That sounds reasonable. The breadboard version measured ~-42dB, but the port pins on the 8051 have weak pull-ups to Vcc, so the waveform was not symmetric (even with external pull-up resistors). The proto PCB uses an inverter between the uP and the filter inputs which can sink/source 4mA so it should measure closer to your simulations.😀

That sounds reasonable. The breadboard version measured ~-42dB, but the port pins on the 8051 have weak pull-ups to Vcc, so the waveform was not symmetric (even with external pull-up resistors). The proto PCB uses an inverter between the uP and the filter inputs which can sink/source 4mA so it should measure closer to your simulations.😀

The only problem I see with this project is the sourcing of the uP and the control of the IP that runs it. While I'm waiting for the PCBs to arrive (~2 weeks), I've been tinkering with the numbers and it should be possible to do 0.01 Hz resolution which basically makes this a 4 channel SDS sinewave generator, which could be exploited commercially if I release the operating system into the public domain. The only way to control this from happening, is for me to program the chips and set the security bits so the chips cannot be read or duplicated. This also negates the need to have in-circuit programming capability or to create programming cables etc.

I do not want to get into selling parts piece work. What the project needs is a group buy or someone who is willing to stock 25-50 of the micros, send them to me for programming (no charge) and ship them back for distribution. The cheapest price I could find for the uP was ~$4.50 (@25 pcs) through Verical/Arrow so someone will have to step up and buy $112.50 worth of chips; they can re-sell them to DIYs interested in building this project at a modest profit (the un-programmed chips are $7.87 each from Mouser). If they sold for $10 (+ S&H), the distributor could more than double their investment.

I don't know how group buys work, but that is another possibility. All of the other parts and the PCBs can be purchased individually (or small groups as the PCBs are done in mulitples of 3) so the uP is the only stumbling block. Is there anyone that wants to handle this?

I'm willing to help out with this. Are there comparable parts that can ve substituted, like the rc2 variant? Also, what package configuration is your pcb set up for? Any reason for 25 parts? I think we can buy directly from atmel by the piece.

It's a bit premature to buy parts at this point; I want to wait until the design is finished before releasing a BOM with part numbers as several components have already changed to do the 0.01 Hz step size.

The uP will be an Atmel AT89C51RB2-SLSUM. The package style is PLCC-44 (J lead) that will in fit in the socket on the PCB. RC2 and RD2 variants could be used, but they are more expensive.

25 parts comes from where the price starts falling, and also because I don't want to program 1-2 pcs at a time for the same reason I don't want to sell 1-2 pcs at a time. If I'm going to program chips, I'd prefer to set it up and flash a couple dozen at a time. If you buy from Atmel, you're going to pay MSRP which will be $7.87 for 1 pc and $6.14 for 25 pcs. If someone wants to search the web, you might be able to find them cheaper than $4.50/25.

The uP will be an Atmel AT89C51RB2-SLSUM. The package style is PLCC-44 (J lead) that will in fit in the socket on the PCB. RC2 and RD2 variants could be used, but they are more expensive.

25 parts comes from where the price starts falling, and also because I don't want to program 1-2 pcs at a time for the same reason I don't want to sell 1-2 pcs at a time. If I'm going to program chips, I'd prefer to set it up and flash a couple dozen at a time. If you buy from Atmel, you're going to pay MSRP which will be $7.87 for 1 pc and $6.14 for 25 pcs. If someone wants to search the web, you might be able to find them cheaper than $4.50/25.

It's a bit premature to buy parts at this point; I want to wait until the design is finished before releasing a BOM with part numbers as several components have already changed to do the 0.01 Hz step size.

The uP will be an Atmel AT89C51RB2-SLSUM. The package style is PLCC-44 (J lead) that will in fit in the socket on the PCB. RC2 and RD2 variants could be used, but they are more expensive.

25 parts comes from where the price starts falling, and also because I don't want to program 1-2 pcs at a time for the same reason I don't want to sell 1-2 pcs at a time. If I'm going to program chips, I'd prefer to set it up and flash a couple dozen at a time. If you buy from Atmel, you're going to pay MSRP which will be $7.87 for 1 pc and $6.14 for 25 pcs. If someone wants to search the web, you might be able to find them cheaper than $4.50/25.

Sounds like a plan. Most places are out of stock on the rb2-slsum variant anyway, with an expected ship in November. To me, the $3 difference in price between the bottom ($4.50) and mean (around $7.50) is immaterial. Thats only a few dollars per project.

Socket on the pcb? Excellent. I thought we'd have do do some smt soldering.

Your offer and efforts and knowkedge gained from your other efforts are very generous and obviously critical.

Pyramid,

What are the switching times of the Atmel going up and going down without load or alternatively with a predetermined load.

I could include this in my simulation.

Before you finalise things, it could help in finding ways to improve beyond the -42dB that you measured with no extra costs.

Hans

What are the switching times of the Atmel going up and going down without load or alternatively with a predetermined load.

I could include this in my simulation.

Before you finalise things, it could help in finding ways to improve beyond the -42dB that you measured with no extra costs.

Hans

Hans-

The rise & fall times of the inverter output are ~19nS.

The reason the breadboard version is -42dB is the filter input is directly connected to the uP port pin, which is a poor way to do this. I wasn't concerned with absolute performance at this stage and there wasn't an invertor on the PCB I'm using to breadboard this so I made the direct connection. The result was the top of the waveform was distorted as the port pins cannot drive a 22K load very well. Without an external pull up resistor, the distortion was ~1.5% and you could see the distortion on a scope. I added a 1K pull up to the uP pin and it improved to 0.8%, but the invertor can drive a load much better than this so the symmetry and distortion should both improve on the prototype PCB I laid out.

I'll let you know the actual performance when I receive the boards in a couple of weeks and build one up. I have the frequency generating code working now, but I'm not going to start the user interface until I have hardware to debug it with.

The rise & fall times of the inverter output are ~19nS.

The reason the breadboard version is -42dB is the filter input is directly connected to the uP port pin, which is a poor way to do this. I wasn't concerned with absolute performance at this stage and there wasn't an invertor on the PCB I'm using to breadboard this so I made the direct connection. The result was the top of the waveform was distorted as the port pins cannot drive a 22K load very well. Without an external pull up resistor, the distortion was ~1.5% and you could see the distortion on a scope. I added a 1K pull up to the uP pin and it improved to 0.8%, but the invertor can drive a load much better than this so the symmetry and distortion should both improve on the prototype PCB I laid out.

I'll let you know the actual performance when I receive the boards in a couple of weeks and build one up. I have the frequency generating code working now, but I'm not going to start the user interface until I have hardware to debug it with.

Rif-

$3 is immaterial for one board, but I still need someone to stock 25-50pcs which might be a material difference for someone. I'm trying to keep costs down, and it doesn't take long for the price to creep up substantially when you add a few bucks here and a couple more there. Even the cost of the PCB goes up quickly with size.

$3 is immaterial for one board, but I still need someone to stock 25-50pcs which might be a material difference for someone. I'm trying to keep costs down, and it doesn't take long for the price to creep up substantially when you add a few bucks here and a couple more there. Even the cost of the PCB goes up quickly with size.

I'm following the proposal by Pyramid with great interest, but like I say, the details are over my head. However if it helps to make this happen, I'm willing to help with costs/effort.

As an update, Tom and I have been working on driving a 3 phase 30 watt Papst motor. It's way smoother than the 2 phase motor Tom was driving before. One thing we've found out, the Hurst (hope I have that right) motor is much easier to drive, but has a lot more vibration. The Papst is more difficult to get the amp/power supply situation stable. We have been unable to get the 3 small amps, and a 24V 6A supply stable. I'm pretty surge it is the start up surge, before the transformer cores magnetize, triggering the protection circuitry in the supply, that is causing the problem. We are working on that angle, and will post when we find out more.

Jethro, with it's probably unnecessarily large amps, supplies, and ballast resistors drives the Papst motor NO problem. The problems with Jethro is added expense, and I think the added noise, from the power supplies and amps (also the not ready for prime time 3 phase generator). I think something in between Jethro, with it's 600 watts of amps, 600 watts (three 200 watt) 50V dual rail supplies, and 4 ohm 100 watt ballast resistors, and Ralph's 100 watt $5 dollar amps, IIRC 120 watt supply, and 1.5 ohm ballast resistors is in order.

I have located some $16 amps that are a step up in both quality and power, a 24V 15 amp supply, 2.5 ohm ballast resistors, and 30VA R core 15:230V transformers with electrostatic shields between primaries and secondaries . I will be running a 2 channel signal generator, and Han's post # 238 splitter. The costs including the generator ($67.99), would be ~ $250. I will order the parts tomorrow, build ASAP, and post back. If and when the dedicated 3 phase generator becomes available, I will build that, and retire the dual channel signal generator to shop duties.

In spite of what I've been told, Ohms law pretty much works at around 120V and 60hz in the power section (power supply, amps, ballast resistor, transformer). It's only when you vary from that, that back EMF becomes a factor in the power section. I believe that a generous amount of headroom has to be designed into the power section of this project to deal with that, and especially stability.

twystd

As an update, Tom and I have been working on driving a 3 phase 30 watt Papst motor. It's way smoother than the 2 phase motor Tom was driving before. One thing we've found out, the Hurst (hope I have that right) motor is much easier to drive, but has a lot more vibration. The Papst is more difficult to get the amp/power supply situation stable. We have been unable to get the 3 small amps, and a 24V 6A supply stable. I'm pretty surge it is the start up surge, before the transformer cores magnetize, triggering the protection circuitry in the supply, that is causing the problem. We are working on that angle, and will post when we find out more.

Jethro, with it's probably unnecessarily large amps, supplies, and ballast resistors drives the Papst motor NO problem. The problems with Jethro is added expense, and I think the added noise, from the power supplies and amps (also the not ready for prime time 3 phase generator). I think something in between Jethro, with it's 600 watts of amps, 600 watts (three 200 watt) 50V dual rail supplies, and 4 ohm 100 watt ballast resistors, and Ralph's 100 watt $5 dollar amps, IIRC 120 watt supply, and 1.5 ohm ballast resistors is in order.

I have located some $16 amps that are a step up in both quality and power, a 24V 15 amp supply, 2.5 ohm ballast resistors, and 30VA R core 15:230V transformers with electrostatic shields between primaries and secondaries . I will be running a 2 channel signal generator, and Han's post # 238 splitter. The costs including the generator ($67.99), would be ~ $250. I will order the parts tomorrow, build ASAP, and post back. If and when the dedicated 3 phase generator becomes available, I will build that, and retire the dual channel signal generator to shop duties.

In spite of what I've been told, Ohms law pretty much works at around 120V and 60hz in the power section (power supply, amps, ballast resistor, transformer). It's only when you vary from that, that back EMF becomes a factor in the power section. I believe that a generous amount of headroom has to be designed into the power section of this project to deal with that, and especially stability.

twystd

What you are trying is to use a brute force method, which is not a very elegant way to solve the problem.I'm following the proposal by Pyramid with great interest, but like I say, the details are over my head. However if it helps to make this happen, I'm willing to help with costs/effort.

As an update, Tom and I have been working on driving a 3 phase 30 watt Papst motor. It's way smoother than the 2 phase motor Tom was driving before. One thing we've found out, the Hurst (hope I have that right) motor is much easier to drive, but has a lot more vibration. The Papst is more difficult to get the amp/power supply situation stable. We have been unable to get the 3 small amps, and a 24V 6A supply stable. I'm pretty surge it is the start up surge, before the transformer cores magnetize, triggering the protection circuitry in the supply, that is causing the problem. We are working on that angle, and will post when we find out more.

Jethro, with it's probably unnecessarily large amps, supplies, and ballast resistors drives the Papst motor NO problem. The problems with Jethro is added expense, and I think the added noise, from the power supplies and amps (also the not ready for prime time 3 phase generator). I think something in between Jethro, with it's 600 watts of amps, 600 watts (three 200 watt) 50V dual rail supplies, and 4 ohm 100 watt ballast resistors, and Ralph's 100 watt $5 dollar amps, IIRC 120 watt supply, and 1.5 ohm ballast resistors is in order.

I have located some $16 amps that are a step up in both quality and power, a 24V 15 amp supply, 2.5 ohm ballast resistors, and 30VA R core 15:230V transformers with electrostatic shields between primaries and secondaries . I will be running a 2 channel signal generator, and Han's post # 238 splitter. The costs including the generator ($67.99), would be ~ $250. I will order the parts tomorrow, build ASAP, and post back. If and when the dedicated 3 phase generator becomes available, I will build that, and retire the dual channel signal generator to shop duties.

In spite of what I've been told, Ohms law pretty much works at around 120V and 60hz in the power section (power supply, amps, ballast resistor, transformer). It's only when you vary from that, that back EMF becomes a factor in the power section. I believe that a generous amount of headroom has to be designed into the power section of this project to deal with that, and especially stability.

twystd

Having 3 amps capable of delivering 100 Watts each, driven by a 150 Watt power supply, should be more than enough to drive a 30 Watt motor.

And I find it even hard to believe that the papst motor is also using 30Watt when running stable, because that would mean an efficiency of close to zero.

I think the start-up procedure has to be changed either with varistors or with larger resistors that are stepped down in value at start-up.

Hans

Hans I totally agree with you about the brute force method being not so elegant. I can't believe I didn't think of the varistor approach, that really is a very simple, and therefore elegant method of solving the startup surge problem.

As far as the motor really using 30 watts, the only thing I can tell you is that there was some conflicting information about the power requirements of the Papst motors. I decided to find out for myself, so I put a 10 ohm resistor in series with the motor running on single phase 120V power. Using the voltage drop across the resistor I was able to see that it does draw 30 watts at 120V, with single phase power, using a faking capacitor.

I came to the conclusion that the impedance of each phase of this motor, and they do seem to vary slightly, was 1440 ohm. I based all my calculations on that measurement, at 120V and 60hz. Since that measurement was done when reverse EMF was applied, Ohms law worked.

I've since realized that the impedance of the motor probably varies with frequency, as the motor works as a generator as well as a load, and that Ohms law only works if you measure the impedance at that frequency. For example, when I keep the input voltage to the amps constant, and change the frequency, therefore the RPMs, the voltage across the phases increases. This is in spite of the input voltage to the amplifiers remaining constant. Seems logical that the impedance changes with frequency (that's pretty evident with the formula for inductive reactance). I'm pretty sure, and it's beyond me, that the math of forward and reverse voltage interacting at frequency is pretty complicated.

twystd

As far as the motor really using 30 watts, the only thing I can tell you is that there was some conflicting information about the power requirements of the Papst motors. I decided to find out for myself, so I put a 10 ohm resistor in series with the motor running on single phase 120V power. Using the voltage drop across the resistor I was able to see that it does draw 30 watts at 120V, with single phase power, using a faking capacitor.

I came to the conclusion that the impedance of each phase of this motor, and they do seem to vary slightly, was 1440 ohm. I based all my calculations on that measurement, at 120V and 60hz. Since that measurement was done when reverse EMF was applied, Ohms law worked.

I've since realized that the impedance of the motor probably varies with frequency, as the motor works as a generator as well as a load, and that Ohms law only works if you measure the impedance at that frequency. For example, when I keep the input voltage to the amps constant, and change the frequency, therefore the RPMs, the voltage across the phases increases. This is in spite of the input voltage to the amplifiers remaining constant. Seems logical that the impedance changes with frequency (that's pretty evident with the formula for inductive reactance). I'm pretty sure, and it's beyond me, that the math of forward and reverse voltage interacting at frequency is pretty complicated.

twystd

One day when wanting a project I tried this. The LM324N was the worst possible choice. The 324 has very bad crossover distortion as it's seemingly unsolvable problem, so solve that first. By adding a 3K3 resistor to each output I could remove that problem ( to - ve rail as shown ). The final bit of thinking is an inverting buffer that could by cancellation remove the compromise that was caused ( curve distortion of SE class A ). As this is a very cheap circuit it might be worth a try. The limiter is both good and bad. The limiter graph shows the good side as it is nicely on it's way to being a sine shape. LED's tend to be better than many things as voltage references. 3 times better than a 1N4148 I think when temperature changing output. The point where I take the limiter output from makes the 750 K value something that needs adjustment, that's the bad bit. Even so it shouldn't be hard to find what it needs. Try the highest value you can. 2.5 Vrms suits the LM324N. It is a sweet spot. Using 2 x NE5532 could give lower distortion. I doubt it will as the frequency is low which does much to hide LM324N's problems. Most of the distortion comes from the limiters square - sine compromise.

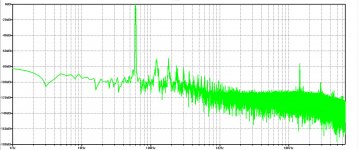

I didn't do this circuit for showing here. Just a bit of fun. If you look the spectrum is very a OK and a useful 2.5 Vrms. You only need adjust one side to get minor speed adjustments. It will provide all that's required in terms of ppm and very small adjustments. COG/NPO usually are 30 ppm, with many resistors this can reduce to about 15 ppm total. It can be that using higher grade resistors makes it worse ( 50 ppm verses 15 ppm ). I was told COG are made to work well with the old MRS25 type resistors which set the style of others. Like many stories it might need checking. 2 x 318 K is about 50 Hz. The two arrowed values ( 10 K used ) are the ones to adjust. To be clear, one side can be fixed and one adjusted if a small frequency change. Try both sides. Ideally a small voltage rise with frequency. In theory you need that. It is possible you can even get 45 RPM using just one side. Don't rule out needing 20% higher voltage for 45 to offset the inductance.

This ready made seems far better.

Assembled Low Distortion Audio Range Oscillator 1KHz Sine Wave Signal Generator | eBay

Results of LM324 State Variable Filter Oscillator.

I didn't do this circuit for showing here. Just a bit of fun. If you look the spectrum is very a OK and a useful 2.5 Vrms. You only need adjust one side to get minor speed adjustments. It will provide all that's required in terms of ppm and very small adjustments. COG/NPO usually are 30 ppm, with many resistors this can reduce to about 15 ppm total. It can be that using higher grade resistors makes it worse ( 50 ppm verses 15 ppm ). I was told COG are made to work well with the old MRS25 type resistors which set the style of others. Like many stories it might need checking. 2 x 318 K is about 50 Hz. The two arrowed values ( 10 K used ) are the ones to adjust. To be clear, one side can be fixed and one adjusted if a small frequency change. Try both sides. Ideally a small voltage rise with frequency. In theory you need that. It is possible you can even get 45 RPM using just one side. Don't rule out needing 20% higher voltage for 45 to offset the inductance.

This ready made seems far better.

Assembled Low Distortion Audio Range Oscillator 1KHz Sine Wave Signal Generator | eBay

Results of LM324 State Variable Filter Oscillator.

Last edited:

Here is what I didn't say. Sine and Cosine are included. Although not as good the Cosine is totally useable as mostly the distortion is second harmonic which is less harmful in terms of vibration. The high order harmonics will be filtered by the motor inductance so can be ignored. I would encourage you not to use my circuit if wanting first time sucess. The SVF at ESP Audio is a better version. However this simple circuit is not far from what is required.

Hans I totally agree with you about the brute force method being not so elegant. I can't believe I didn't think of the varistor approach, that really is a very simple, and therefore elegant method of solving the startup surge problem.

As far as the motor really using 30 watts, the only thing I can tell you is that there was some conflicting information about the power requirements of the Papst motors. I decided to find out for myself, so I put a 10 ohm resistor in series with the motor running on single phase 120V power. Using the voltage drop across the resistor I was able to see that it does draw 30 watts at 120V, with single phase power, using a faking capacitor.

I came to the conclusion that the impedance of each phase of this motor, and they do seem to vary slightly, was 1440 ohm. I based all my calculations on that measurement, at 120V and 60hz. Since that measurement was done when reverse EMF was applied, Ohms law worked.

I've since realized that the impedance of the motor probably varies with frequency, as the motor works as a generator as well as a load, and that Ohms law only works if you measure the impedance at that frequency. For example, when I keep the input voltage to the amps constant, and change the frequency, therefore the RPMs, the voltage across the phases increases. This is in spite of the input voltage to the amplifiers remaining constant. Seems logical that the impedance changes with frequency (that's pretty evident with the formula for inductive reactance). I'm pretty sure, and it's beyond me, that the math of forward and reverse voltage interacting at frequency is pretty complicated.

twystd

What can also be tried is to use Triac's to turn on the trafo when the Sinewave is crossing zero volt.

This is also a very relaxed way for the main amps to come alive and relatively easy to implement.

Hans

Hey Hans

If you have any design ideas on start up and run for these 3 phase big motors I know both Twystd and myself would be interested.

I thought we needed higher resistance at start up then once the transformers get energized the load resistors could be removed/bypassed. (Timed relay). EBay has timed on or off relays with can handle the volt/current needed for under 10.00.

Well I am having fun building this stuff and learning some as I go. Thanks again for starting this thread and staying with it. This is DIYer's dream come true for motor control.

Tom

If you have any design ideas on start up and run for these 3 phase big motors I know both Twystd and myself would be interested.

I thought we needed higher resistance at start up then once the transformers get energized the load resistors could be removed/bypassed. (Timed relay). EBay has timed on or off relays with can handle the volt/current needed for under 10.00.

Well I am having fun building this stuff and learning some as I go. Thanks again for starting this thread and staying with it. This is DIYer's dream come true for motor control.

Tom

I haven't the time today to go further into the details of zero crossing,Hey Hans

If you have any design ideas on start up and run for these 3 phase big motors I know both Twystd and myself would be interested.

I thought we needed higher resistance at start up then once the transformers get energized the load resistors could be removed/bypassed. (Timed relay). EBay has timed on or off relays with can handle the volt/current needed for under 10.00.

Well I am having fun building this stuff and learning some as I go. Thanks again for starting this thread and staying with it. This is DIYer's dream come true for motor control.

Tom

but Nigel's idea of using a lamp might be worth the try.

Hans

- Home

- Source & Line

- Analogue Source

- Optimally driving a (VPI) synchronous turntable motor