I consider coating carbon fiber with hard wax oil.

Carbon-Platte, Abm.: 645 mm x 445 mm x 0,3 mm, EUR 36.10 --> www.carbonscout-shop.de

Arguments against?

Hi, it´s hard to see if you can get any reasonable results with hardwax oil on CF then. I quess that epoxy resin impregnated CF is pretty much homogenic material that will not respond to your hardwax oil treatment then...

But I cannot offer any wisdom if this is true or false. Maybe you should try it...

As suggested earlier I treated 50x50 cm 3-layer 3 mm balsa boards with hardwax oil and had the following result: The resonances are gone, but the sound is boring and muffled with massively reduced sensitivity. The damping seems to be a plague vs. cholera issue in DMLs. But the use of wood remains an interesting topic, e.g. the way Oliver Goebel does, with end grain balsa and epoxy/cloth cover layers.

esp@cenet — Bibliographic data

In the Visaton forum someone claims to have very good results with maple veneer.

.... I consider coating carbon fiber with hard wax oil.

Carbon-Platte, Abm.: 645 mm x 445 mm x 0,3 mm, EUR 36.10 --> carbonscout-shop.de

Arguments against?

Hi el'Ol!

If you have some Balsa plywood left you could probably try this: Cut out a rectangular panel in a way that the woodfibres are running diagonal (into the direction of the corners). There should be a difference - at least my panel showed better performance. You could also try to just impregnate it on the outer portion (like a frame).

Balsa is like a sponge - if you impregnate it, it will soak up much and you end up with a "new" material with a set of completely different properties. As Mikadosan noted, CFK will behave in a different way - maybe barely noticeable.

I agree that wood has nice sonic properties (i've experimented a lot with Balsa), but in the way Oliver Göbel uses it, it has a completely different purpose (in fact sonically it has nothing to do with Balsa plywood) because the properties of Balsa are very much dependent of direction (anisotropic).

If you take a closer look at the Göbel patent (btw thanks for the link - i was not able to find it) you can see that he takes some effort to prevent the epoxy resin from getting into the porous structure of the wood. As you might know end-grain Balsa is extremely rigid in compression for it's density - a quite unique material. On the other hand the speed of sound (for longitudinal and bending waves) is very low in this direction and as a panel it's quite flabby - this is more than enough damping. The stiffness of the panel is controlled by the top layers of the sandwich and varies much with direction (high stiffness in diagonal direction, low stiffness in axial direction) . If you inspect the lasercuts on the edges which act as a diffusor (maybe also as damper due to silicone in the slots) you can imagine that mainly the axial modes are scattered while the energy of the tangential modes is reflected/supported. Together with the panel stiffness in this direction he balances out the relative strength of axial and tangential modes and obiously a even modal response and high modal density is the result.

Apart from this panel features there are much more interacting factors which go far beyond the material discussion lasting forever in this threads.

From this you can see that Oliver Göbel is an extremely smart designer who exactly knows what he is doing - and there is absolutely no concurrence in his design! Just deep understanding in acoustics.

IMO there is not much hope to find any ready-made material you can cut, varnish (or whatever), stick on a few exciters and expect to achieve high-end quality results. I don't doubt that many people here have achieved very good results (although fighting with problems) with big Gatorfoam panels or honeycomb stuff, but who wants to have door-sized panels hanging around in his living room? Your wife???

regards

Markus

Bending Wave Transducer from Oliver Göbel

Hi Markus,

yes i fully agree:

Oliver Göbels devices are landmark designs for me too.

At least they point to many of the problems which have to

be solved, when designing a flexurally rigid bending wave

loudspeaker.

Even if one should find different solutions for certain

problems, we still can ask:

"Are all problems adressed adequately, which are adressed so

cleverly in the Göbel bending wave transducer."

There is one design decision in the Göbel devices which makes them

strong on the one hand, but the decision is a drawback on the other

hand:

The design renounces reproduction of low- to mid bass frequencies

entirely.

IMO the design cannot simply be "upsized" to produce low frequencies

with appropriate quality, while maintaining its qualities in the mid

to high frequency range.

The size of the device is so small, that the full advantage of

diffuse radiation cannot be gained from bass up to the lower

midrange, where it would be desirable to circumvent acoustic

problems in common living rooms.

The panels are too small compared to wavelength (in air) to

achieve typical DML radiation characteristics even in the

lower midrange.

That design decision makes the device living room friendly:

To me it is a very convenient - and elegant - product for

the music lover, who does not want to invest too much space

for his hobby.

Now for the fanatic point of view:

The Göbel system is said to have high resolution and detail.

I do not feel that it is good to combine such a system with a

monopolar AND monophone subwoofer:

The lower the frequency, the more room acoustics will affect the

result. Below some hundred Hz - where those DML virtues are needed

at most - the DML potential

- Diffuse sound radiation

- Directionality (which a DML has too with increased size, especially when operating as a dipole)

- Possibility of dipole operation

is lost due to small size (piston like action of the panel) and

the combination with a monopolar and monophone subwoofer.

If the Göbel transducer was available for DIY i would

integrate it with a 2 Way system having a crossover frequency

1,5 - 2,5 Octaves higher than necessary for that "satellite mode",

which must be a torture for the device at higher levels.

Would it be an interesting goal for you to try a "no compromise"

fullrange bending wave transducer with dimensions in the region

of say a Quad ESL 63 ?

I think for acceptability of dimensions some of the well known and

successful ESL designs may serve as a parallel.

Kind regards

...

From this you can see that Oliver Göbel is an extremely smart designer who exactly knows what he is doing - and there is absolutely no concurrence in his design! Just deep understanding in acoustics.

...

Hi Markus,

yes i fully agree:

Oliver Göbels devices are landmark designs for me too.

At least they point to many of the problems which have to

be solved, when designing a flexurally rigid bending wave

loudspeaker.

Even if one should find different solutions for certain

problems, we still can ask:

"Are all problems adressed adequately, which are adressed so

cleverly in the Göbel bending wave transducer."

There is one design decision in the Göbel devices which makes them

strong on the one hand, but the decision is a drawback on the other

hand:

The design renounces reproduction of low- to mid bass frequencies

entirely.

IMO the design cannot simply be "upsized" to produce low frequencies

with appropriate quality, while maintaining its qualities in the mid

to high frequency range.

The size of the device is so small, that the full advantage of

diffuse radiation cannot be gained from bass up to the lower

midrange, where it would be desirable to circumvent acoustic

problems in common living rooms.

The panels are too small compared to wavelength (in air) to

achieve typical DML radiation characteristics even in the

lower midrange.

That design decision makes the device living room friendly:

To me it is a very convenient - and elegant - product for

the music lover, who does not want to invest too much space

for his hobby.

Now for the fanatic point of view:

The Göbel system is said to have high resolution and detail.

I do not feel that it is good to combine such a system with a

monopolar AND monophone subwoofer:

The lower the frequency, the more room acoustics will affect the

result. Below some hundred Hz - where those DML virtues are needed

at most - the DML potential

- Diffuse sound radiation

- Directionality (which a DML has too with increased size, especially when operating as a dipole)

- Possibility of dipole operation

is lost due to small size (piston like action of the panel) and

the combination with a monopolar and monophone subwoofer.

If the Göbel transducer was available for DIY i would

integrate it with a 2 Way system having a crossover frequency

1,5 - 2,5 Octaves higher than necessary for that "satellite mode",

which must be a torture for the device at higher levels.

Would it be an interesting goal for you to try a "no compromise"

fullrange bending wave transducer with dimensions in the region

of say a Quad ESL 63 ?

I think for acceptability of dimensions some of the well known and

successful ESL designs may serve as a parallel.

Kind regards

Last edited:

If one would upsize the device, not to get DML operation in lower frequencies, but the way that the wave speed increases the same factor as the panel size, and maybe make it to stay above coincidende the whole range, would this "torture" the device less at high levels?

I am still thinking about carbon fiber.

What is the difference between hard/damping/hard, as usual for this porpose, and damping/hard/damping, as I am planning, in terms of wave propagation?

I am still thinking about carbon fiber.

What is the difference between hard/damping/hard, as usual for this porpose, and damping/hard/damping, as I am planning, in terms of wave propagation?

Hi Oliver,

when i think about hard/damping/hard there might come a

(rather high) frequency where the two hard layers do not

move in phase anymore.

When the hard layers have preferably mass and the damping

layer has preferably compliance this could happen.

If that frequency is in the audio band things get complicated.

When the damping core has a compliance orthogonal to the plane

it might get difficult to get high frequencies "through" the panel.

So damping/hard/damping seems to be a good configuration to me,

especially if you manage to avoid high frequencies to be absorbed

by the damping layer using appropriate contact area and coupling

of the exciter.

BTW i think your general suggestion of upsizing the Göbel device is OK.

But when making the panel core stiffer (thicker) and more massive,

damping has to increase too if you want to keep the same Qs of the

resulting modes.

Kind Regards

when i think about hard/damping/hard there might come a

(rather high) frequency where the two hard layers do not

move in phase anymore.

When the hard layers have preferably mass and the damping

layer has preferably compliance this could happen.

If that frequency is in the audio band things get complicated.

When the damping core has a compliance orthogonal to the plane

it might get difficult to get high frequencies "through" the panel.

So damping/hard/damping seems to be a good configuration to me,

especially if you manage to avoid high frequencies to be absorbed

by the damping layer using appropriate contact area and coupling

of the exciter.

BTW i think your general suggestion of upsizing the Göbel device is OK.

But when making the panel core stiffer (thicker) and more massive,

damping has to increase too if you want to keep the same Qs of the

resulting modes.

Kind Regards

...Even if one should find different solutions for certain problems, we still can ask:

"Are all problems adressed adequately, which are adressed so cleverly in the Göbel bending wave transducer."...

...The design renounces reproduction of low- to mid bass frequencies entirely...

...The size of the device is so small, that the full advantage of diffuse radiation cannot be gained from bass up to the

lower midrange, where it would be desirable to circumvent acoustic problems in common living rooms.

The panels are too small compared to wavelength (in air) to achieve typical DML radiation characteristics even in the

lower midrange.

I think the tricks he uses to fill the gap below coincidence and above the subwoofer is quite a good compromise to get an soft transition to the dynamic bass driver. I have not heard the Göbel system so far but i could imagine that it sounds better than a abrupt crossover from the diffuse soundfield to a pressure transducer. I also think the maximum size of the panel was largely decided by aesthetic factors.

In a commercial point of view he did the right thing. He designed a system which is affordable and maybe kicks most competitors' @$§. It's very hard for an nearly unknown manufacturer to start with an exotic product without ending in a financial disaster.

...Now for the fanatic point of view:

...I do not feel that it is good to combine such a system with a

monopolar AND monophone subwoofer:

The lower the frequency, the more room acoustics will affect the

result. Below some hundred Hz - where those DML virtues are needed

at most - the DML potential

- Diffuse sound radiation

- Directionality (which a DML has too with increased size, especially when operating as a dipole)

- Possibility of dipole operation

is lost due to small size (piston like action of the panel) and

the combination with a monopolar and monophone subwoofer.

I agree - the subwoofer topic is a thread for itself -

here is another fanatic point of view:

If people would spend just 20% of the money of their audio systems and invest it in some basic room acoustics correction and would stop to f#$& around in inappropriate rooms with inappropriate speaker/listenening possitions, life would be a lot easier. I've seen/heard things over the years - unbelievable!

Excellent systems costing a fortune sounding like sh!§. (I'm sorry - but it's the truth!)

...Would it be an interesting goal for you to try a "no compromise"

fullrange bending wave transducer with dimensions in the region

of say a Quad ESL 63 ?

I think for acceptability of dimensions some of the well known and

successful ESL designs may serve as a parallel.

I will NOT replace my beloved Quads!!!

The ESL63 behaves to some extent like a bending wave transducer due to its' annular ring stators which are delayed progressively from the center to the outside. So there is some decorrelation between the sections of the membrane.

I personly think that the size regarding width is marginal to unacceptable even for the most tolerant female audio enthusiasts.

If there would be any attempt in designing a "no compromise" fullrange bending wave transducer it would incorporate an appropriate exciter design from scratch or at least nxt licensing to get access to superior drive units. The suspension in my Dayton exciters got quite soft from instant low frequency operation during testing and the voicecoil tends to tumble because of improper glue application during manufacturing. I also suspect some loss of sensitivity over the time due to the softening of the suspension - I have to investigate this closer. Sensitivity is barely acceptable in the available exciters. The not infinitly small diameter of the voicecoil seems to be the reason for some serious irregularities in high frequency dispersion as well as some resonances between the panel and the magnetsystem/suspension are contribiuting to this.

The panel design will be another story.

So the list of problems to solve is long.

regards

Markus

Last edited:

...

So the list of problems to solve is long.

...

That's undisputed Markus !

I agree, that one cannot be successful in building a

fullrange bending wave transducer with those

toy exciters commercially available.

Regards

If one would upsize the device, not to get DML operation in lower frequencies, but the way that the wave speed increases the same factor as the panel size, and maybe make it to stay above coincidende the whole range, would this "torture" the device less at high levels?

I don't know if I have understood your question right but you can figure out by yourself what happens when you manipulate a certain factor in your panel.

For a panel with constant size the following interrelationships apply:

high stiffness → high wave propagation speed → low coincidence frequency → high efficiency → low modal density

low stiffness → low wave propagation speed → high coincidence frequency → low efficiency → high modal density

and:

higher mass → lower coincidence frequency → lower efficiency

lower mass → higher coincidence frequency → higher efficiency

Basicly there is a gain of efficiency above coincidence frequency.

It can be seen that the design parameters are conflicting (of course) and can not be adjusted independently.

The output from some pistonic action is not considered here.

I am still thinking about carbon fiber.

What is the difference between hard/damping/hard, as usual for this porpose, and damping/hard/damping, as I am planning, in terms of wave propagation?

If you keep the panel mass constant, the hard/damping/hard version will be most likely stiffer.

Regards

Markus

I don't know if I have understood your question right but you can figure out by yourself what happens when you manipulate a certain factor in your panel.

I mean higher stiffness, same mass per surface (carbon instead of epoxy) -> higher wave speed, but larger size so the modal density stays the same.

I mean higher stiffness, same mass per surface (carbon instead of epoxy) -> higher wave speed, but larger size so the modal density stays the same.

Yes.

You should consider that epoxy is a part of the CFK and always has some influence on the properties of the composite in certain directions. LamiCens can help here.

-m

Hi,

I have been following this thread, a few questions if I may?

Is there a difference between the Dayton and the buyout?

Parts-Express.com:*Surface Transducer Turns Virtually Anything Into A Speaker | CYBER09 stick on speaker exciter tactile transducers sound transducers nxt sonic impact 5029 5029 sound pads hidden speakers daex25 Marcato DIY projects fbr1

Parts-Express.com:*Dayton DAEX25 Sound Exciter Pair | stick on speaker exciter tactile transducers sound transducers nxt sonic impact 5029 5029 sound pads hidden speakers daex25 cyber121

Has anyone tried these?

Parts-Express.com:*Sonic Splash SSP 4.0 Transducer | full range shaker ibeam tactile bass shaker transducer tactile transducer butt shaker seat shaker

Gary

I just bought 30 (15 pairs) of the buyouts at PE. They should be here Monday.

Last edited:

Alexit lacquer on 12cm cone speaker. Damping is clearly visible.

Good result indeed ...

hello all,

here is one of the latest versions of my stereo panel

http://img697.imageshack.us/img697/8061/p1111090844.jpg

8 transducers in a config inspired from Michael GERZON

2x at left & 2x at right, & 2+2 centered in the common return path

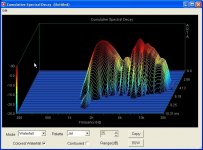

response measured a 2cm, 20cm & 2m, nice work of the syncRTA

the same with a "classic" RTA would be impossible

http://img692.imageshack.us/img692/7167/gdpano2cm20cm2m.gif

respectively green 2cm, blue 20cm, red 2m

and the same with a bass-box added (YAMAHA, blue trace)

http://img208.imageshack.us/img208/4440/gdpanobass.gif

POL

here is one of the latest versions of my stereo panel

http://img697.imageshack.us/img697/8061/p1111090844.jpg

8 transducers in a config inspired from Michael GERZON

2x at left & 2x at right, & 2+2 centered in the common return path

response measured a 2cm, 20cm & 2m, nice work of the syncRTA

the same with a "classic" RTA would be impossible

http://img692.imageshack.us/img692/7167/gdpano2cm20cm2m.gif

respectively green 2cm, blue 20cm, red 2m

and the same with a bass-box added (YAMAHA, blue trace)

http://img208.imageshack.us/img208/4440/gdpanobass.gif

POL

Last edited:

Mistyping ? Please check.

Hello Markus,

a verbose description of the parameter interrelations is helpful

but i feel for the effect of mass (density) there is a mistyping

in your former post concerning coincidence frequency.

I overlooked it, because you described the effect of mass

on efficiency correctly ...

I would put it this way:

Effect of stiffness variation, when other parameters are kept constant

-------------------------------------------------------------------

higher stiffness -> higher propagation velocity -> lower coincidence frequency

higher stiffness -> higher propagation velocity -> lower modal density

higher stiffness -> higher propagation velocity -> higher efficiency

lower stiffness -> lower propagation velocity -> higher coincidence frequency

lower stiffness -> lower propagation velocity -> higher modal density

lower stiffness -> lower propagation velocity -> lower efficiency

Effect of mass (density) variation, when other parameters are kept constant

-------------------------------------------------------------------------

higher mass -> lower propagation velocity -> higher coincidence frequency

higher mass -> lower propagation velocity -> higher modal density

higher mass -> lower propagation velocity -> lower efficiency

lower mass -> higher propagation velocity -> lower coincidence frequency

lower mass -> higher propagation velocity -> lower modal density

lower mass -> higher propagation velocity -> higher efficiency

For the propagation velocity i have not found a simple

english source so far, but i am shure someone will find a link

in english language ...

Biegewelle – Wikipedia

Kind regards

I don't know if I have understood your question right but you can figure out by yourself what happens when you manipulate a certain factor in your panel.

For a panel with constant size the following interrelationships apply:

high stiffness → high wave propagation speed → low coincidence frequency → high efficiency → low modal density

low stiffness → low wave propagation speed → high coincidence frequency → low efficiency → high modal density

and:

higher mass → lower coincidence frequency → lower efficiency

lower mass → higher coincidence frequency → higher efficiency

Basicly there is a gain of efficiency above coincidence frequency.

It can be seen that the design parameters are conflicting (of course) and can not be adjusted independently.

The output from some pistonic action is not considered here.

If you keep the panel mass constant, the hard/damping/hard version will be most likely stiffer.

Regards

Markus

Hello Markus,

a verbose description of the parameter interrelations is helpful

but i feel for the effect of mass (density) there is a mistyping

in your former post concerning coincidence frequency.

I overlooked it, because you described the effect of mass

on efficiency correctly ...

I would put it this way:

Effect of stiffness variation, when other parameters are kept constant

-------------------------------------------------------------------

higher stiffness -> higher propagation velocity -> lower coincidence frequency

higher stiffness -> higher propagation velocity -> lower modal density

higher stiffness -> higher propagation velocity -> higher efficiency

lower stiffness -> lower propagation velocity -> higher coincidence frequency

lower stiffness -> lower propagation velocity -> higher modal density

lower stiffness -> lower propagation velocity -> lower efficiency

Effect of mass (density) variation, when other parameters are kept constant

-------------------------------------------------------------------------

higher mass -> lower propagation velocity -> higher coincidence frequency

higher mass -> lower propagation velocity -> higher modal density

higher mass -> lower propagation velocity -> lower efficiency

lower mass -> higher propagation velocity -> lower coincidence frequency

lower mass -> higher propagation velocity -> lower modal density

lower mass -> higher propagation velocity -> higher efficiency

For the propagation velocity i have not found a simple

english source so far, but i am shure someone will find a link

in english language ...

Biegewelle – Wikipedia

Kind regards

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- PIEZO NXT type panel