Yes, sound diffracts all the way around the box, although the intensity is lost with more and more angle so the effect is strong behind the box 180deg, but past that its one more diffaction, past 270deg one more and so on. Roughly, stronger effect is seen past 90degrees than towards listening window. Sound expands like a bubble, most of it goes outward away from the box, except some of it diffracts around corner. The diffracted "direct sound" that continues past the corner loses some intensity to the back wave that emits or something like that 😀 Its also more path length so more intensity drop in that already.

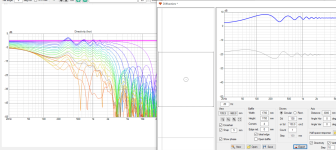

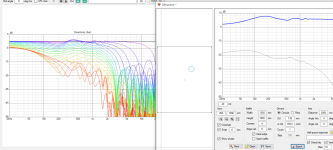

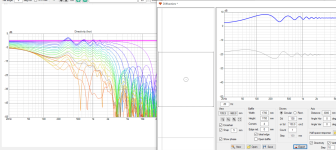

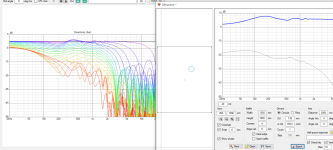

Quick test with Vcad diffraction tool. If driver was measured on a ~170cm square baffle there would be similar effects in the normalized response as in hifi compass measurements, bump off axis around ~300Hz.

Here is some dimensions of the IEC setup which is probably used "always with proper measurements" http://www.rjbaudio.com/Audiofiles/IEC baffle.jpg , Hificompass probably uses IEC setup more or less accurately. Here is approximation of that

Quick test with Vcad diffraction tool. If driver was measured on a ~170cm square baffle there would be similar effects in the normalized response as in hifi compass measurements, bump off axis around ~300Hz.

Here is some dimensions of the IEC setup which is probably used "always with proper measurements" http://www.rjbaudio.com/Audiofiles/IEC baffle.jpg , Hificompass probably uses IEC setup more or less accurately. Here is approximation of that

Last edited:

How would the above sim relate to the differences measured between the different drivers?

Would that be the driver itself or interaction with iec baffle?

Would that be the driver itself or interaction with iec baffle?

Not a bad guessIf driver was measured on a ~170cm square baffle there would be similar effects in the normalized response as in hifi compass measurements, bump off axis around ~300Hz.

From Hificompass site

Measurement setup specification

Test baffle size – 1650x850 mm

Measuring equipment:

- measuring microphone Brüel & Kjær 4133

- microphone preamplifier Brüel & Kjær 2639

- preamplifier power supply Brüel & Kjær 2804

- sound card EMU-0202USB

- DSP Xilica XM2040

- low THD power amplifier

Off axis magnitude response – the family off-axis frequency responses measured at different angles at tested voltage 2,83V at 315mm distance from intersection point between the main acoustic axis and test baffle plain.

The baffle is a factorWould that be the driver itself or interaction with iec baffle?

JanRSmith, when there is difference between drivers I suspect the measurement setup or processing of the measurements differs somehow. It could be the baffle vibrates in case of IEC measurement. In case of different drivers on same box it could be difference in measurement procedure or window settings while processing the impulse responses to frequency responses. Or something along the lines.

400Hz for example, is such a long wavelength small drivers and boxes have very little options to show interference there, especially constructive interference bump which means there is either no interference or destructive interference below that frequency. This basically limits the source to diffraction backside of the box, on a small boxed speaker.

400Hz for example, is such a long wavelength small drivers and boxes have very little options to show interference there, especially constructive interference bump which means there is either no interference or destructive interference below that frequency. This basically limits the source to diffraction backside of the box, on a small boxed speaker.

There is one thing we can rely on, always, sound wavelength 😎Not a bad guess

edit. to anyone new to the game of sound: Implication to this is that any interference pattern we see is tied to certain length, path length difference of the interfering sounds, and this can be solved /estimated with trigonometry so certain interference pattern can be estimated back to physical size. Conversely, same physical size (and positioning and so on) will always yield same interference every time we measure. This is what enables the simulators to work, sound behaves as expected with physical objects, size of things. edit. Also phase is involved like touched in the following post below, but in general we can assume drivers are mostly used on their pistonic bandwidth so phase differences make less effect on the responses, and most can be explained with the path length differences of sound sources.

Last edited:

As the baffle is known it's behaviour can be subtracted from the measurements to show what is from the driver alone if anyone thinks it important enough to do for themselves.The baffle is a factor, but also the driver behaviour, perhaps more so i would think.

You can do reasoning about this.The baffle is a factor, but also the driver behaviour, perhaps more so i would think.

Drivers are pistonic up to some frequency. This means every point along the cone move in unison together, at the same time and as much far to same direction as the next point. Also, we like our drivers to be equalized flat so the sound would come through without coloration due to varying frequency response. This is what everyone wants, and the manufacturers try to provide, right.

Lets assume we have dialed in flat frequency response on-axis over the bandwidth a driver in question is pistonic. Driver in infinite baffle for example. Now, there could be interference to an angle, where some point of the cone is further away than some other. Take two points, one from either side of the cone and observe their path length difference to some angle, and you'd get some interference at frequencies whose wavelength is ~similar or shorter than this path length difference.

Now, at frequency where the cone is not pistonic anymore, but for example the outer edge moves in other phase than the center of the cone it gets more complicated. In addition to the path length difference to an observation angle there is phase difference due to parts of the cone moving out of sync. This seems to happen when wavelength is roughly diameter of the driver, depending on the material and geometry of things and so on. But in general it can be roughly estimated without looking any measurements, just generalizing from datasheets, that any cone is pistonic roughly up to its diameter wavelength. For a ~6" driver this would be about 2kHz or so. Few kilohertz. This is few octaves above 400Hz.

So we can assume with quite good confidence that at 400Hz any 6" driver would work pistonic, if its any good driver and not broken one. Also, worst case any two points of the driver are mostly about ~15cm or so apart, so about point source to about ~60cm wavelength, ~500Hz. From here we could reason interference at 400Hz is most likely from somewhere else than from the driver, the driver works as single sound source roughly to 500Hz, possibly to few kHz.

If there was interference around kilohertz or few, its very likely its from the driver breaking up. Could be edge diffraction still up until a frequency the driver beams strongly enough its easy to evaluate if some interference magnitude indicates for cone break up or edge diffraction. 10db hump can't be edge diffraction for example.

What all this means it can be zoned in to possible culprits for interference, quite close just with imagination and estimating math. Closer can get with proper maths or estimating with simulation, comparing to datasheet etc. When wavelength gets short enough to some complex shape, like depth of the cone, or some random shaped baffle edge, or something like this, its gets hard to imagine the results as there is too much variables to imagine it accurately. Still, everything obeys the same laws of sound propagation as the simple case so some simplified conclusions can be drawn, like estimating roughly what it might be. Strong interference would show up at wavelengths about the size of the object. Key thing is to realize that interference needs multiple sound sources with phase/ path length difference. Breaking up cone could be thought as multiple sound sources.

Last edited:

The reasoning, while i can follow it and sounds logical, does not explain what with stiff cones the hificompass measurements seem to be better in that frequency range.

I will dig into this when back from a conference. Interesting 😎

I will dig into this when back from a conference. Interesting 😎

Yeah 🙂 Relying on the foundation laid on the above post, relationship with sound wavelength and objects and assuming all the drivers are made as well as possible (not broken) there should not be any difference at these wavelengths with this size drivers when equalized flat (normalized).

Any difference that shows up is likely from some other sound source varying, like the measurement baffle diffraction changing between the measurements (different baffle, different driver position), or the measurement setup changing in some other ways etc. In other words it seems unlikely secondary sound source thats responsible for the ripple in measurements at these frequencies would be the driver (of this size) itself when equalized flat. So to me, based on the reasoning above, it looks like more likely something else than the drivers themselves are culprit for the differences.

Any difference that shows up is likely from some other sound source varying, like the measurement baffle diffraction changing between the measurements (different baffle, different driver position), or the measurement setup changing in some other ways etc. In other words it seems unlikely secondary sound source thats responsible for the ripple in measurements at these frequencies would be the driver (of this size) itself when equalized flat. So to me, based on the reasoning above, it looks like more likely something else than the drivers themselves are culprit for the differences.

Hi, for example 400Hz mode inside the box could happen if there is ~42cm internal dimension. If such mode exists and it emits through the cone for example, then same thing would apply as the sound through the cone in general, it would be roughly omnidirectional like sound from the cone at the same frequency, when cone is small compared to wavelength. So again we could reason its likely something else. Resonance inside box would come late to direct sound, but be roughly equally late to any particular direction and should disappear with normalized graph, in other words same interference to any direction.

While all this is speculation based on wavelength its still not certain what actually makes the difference. Hopefully it helps to narrow down options and figure out a test which would rule out or confirm some feature that makes it, or contributes to it.

While all this is speculation based on wavelength its still not certain what actually makes the difference. Hopefully it helps to narrow down options and figure out a test which would rule out or confirm some feature that makes it, or contributes to it.

I wonder if the baffle diffraction simulations calculates the distance the sound has to travel to reach the diffraction point. Because the more the sound travels through the air, the more its power decreases.

Hificompass measurements are in standardized baffle (no box), so there should be no difference between 6,5" drivers at 4-500Hz

https://hificompass.com/en/speakers/measurements

https://hificompass.com/en/speakers/measurements

But there are differences. Some are quite close to the sim, some are quite off.

I think @Patrick Bateman was on to this with his cabinets are waveguides thread. The cabinet is making the ~400hz (depends) directivity wobble. I tend to agree. Not a box mode.

Yes... There ARE driver to driver variations in polar response. If this was all related to the test baffle shape/size and the drivers were purely pistonic in the 100 - 1k range, then all the drivers would have the same normalized polar response. It is true that there are some general trends common to all four drivers, but the differences indicate something else is going on. My speculation is that while the cones may be fully pistonic in the 100-1k region, the rubber surround is adding some out-of-phase radiation at some frequencies.But there are differences. Some are quite close to the sim, some are quite off

Is it important? is it audible? I don't know. I tend to think it is insignificant. But it is measurable, and it will influence the calculation of DI and ER.

Another point to add about the rubber surround: The material is highly damped, so it would be rare to measure any resonant behavior from a surround in this frequency range, such as a CSD plot. But that does not mean the surround is behaving as a rigid body. Common sense tells us a soft rubber ring will not be a rigid body at any frequency. When driven by the cone edge (i.e. the forcing function) it will more likely have a chaotic response where it follows the cone at some frequencies, and at other frequencies it will have various levels of out-of-phase radiation. Because it is a highly damped material, it will have low stored energy and the motion will die out very quickly when the forcing function stops.

in other news, construction is continuing. I have made the cherry panels which will encase the midrange cabinet. It is so nice to work with hardwood again. So much less dust than working with plywood (or MDF which is worse). Less heat build up in the tools.

The front baffles have been routed and profiled, the rest of the panels (sides, rear, top) will get profiled tomorrow. Final profiling will be done on the fully assembled box, and I anticipate it will be a well-rounded shape with 2" radius compound bevels on all edges.

j.

The front baffles have been routed and profiled, the rest of the panels (sides, rear, top) will get profiled tomorrow. Final profiling will be done on the fully assembled box, and I anticipate it will be a well-rounded shape with 2" radius compound bevels on all edges.

j.

Attachments

- Home

- Loudspeakers

- Multi-Way

- Purifi + Waveguide Project