Some stones are better left unturned.

I know a few tricks that are used by high end vendors.

To incorporate even a variant of these(tricks) might make for strife.

I have a bootstrapped IPS already in the works where I have designed

around things that are IP.

Making a headphone amp and a Class A OPS stage for the IPS's would be

a cool addition.

PS - my next 2 IPS's might bring in the "police".

OS

I know a few tricks that are used by high end vendors.

To incorporate even a variant of these(tricks) might make for strife.

I have a bootstrapped IPS already in the works where I have designed

around things that are IP.

Making a headphone amp and a Class A OPS stage for the IPS's would be

a cool addition.

PS - my next 2 IPS's might bring in the "police".

OS

Last edited:

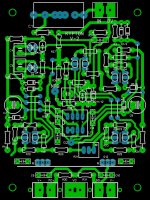

I will re-design "V" with diodes + JFET option.

Yup !!

Diodes , bigger "audiophile" cap - layout can be "looser" (less crowded).

(below) - tomorrow ! Will fine tune the schema , as well.

Good work , Thimios (main partner in crime)

PS - it's the "Kypton V-2" classic ....

OS

Attachments

I will try MAT02 as input pair soon.Yup !!

Diodes , bigger "audiophile" cap - layout can be "looser" (less crowded).

(below) - tomorrow ! Will fine tune the schema , as well.

Good work , Thimios (main partner in crime)!

PS - it's the "Kypton V-2" classic ....

OS

OS, what do you still need for your amps?

First , my dear friend vzaichenko's trafo arrived (with the bridges that the

dummies forgot). The caps have been returned for credit (bill says so).

My case is small(er) , 2 X 125mm by 175mm (1/8") aluminum interior panels with

attached angles at bottom will mount my capacitor banks/accessories .

NO big caps - smaller 35mm snap-ins ... 6 X 6800uF + per channel.

The panels will have the ability to be "lifted out" for tinkering.

I already machined most of the case , just 4 holes for the above panels.

Resistors, trimmers , all sorts of assorted stuff. you sent plenty of

small semi's/diodes , 13 of njw0302 (but no 0281's).

In Albany , many PC parts/hardware were recycled (many screws).

Here in Tennessee , things are "desperate" ... not much E-waste.

OS

My rest of parts........

No other pcb ,no chemicals ,no parts ,no money

This will be a long travel .....

Scrap some old ones - this one is better. I wanna see 1/2mhz

perfect squarewaves.

OS

My Arduinos have arrived. I'll be sending you a package in the next couple days. I'll load it up. I'm not sure how the 0281s were dropped from the order but I'll send some along. Are any other semis missing?

Nope , all the to-92's ... all the to-126's .

Need euro terminals/resistors ...

Do you have metal , J ?

PS - does that small trafo (Vpp-24-830) fit the Arduino ?

OS

Last edited:

First , my dear friend vzaichenko's trafo arrived (with the bridges that the

dummies forgot). The caps have been returned for credit (bill says so).

My case is small(er) , 2 X 125mm by 175mm (1/8") aluminum interior panels with

attached angles at bottom will mount my capacitor banks/accessories .

NO big caps - smaller 35mm snap-ins ... 6 X 6800uF + per channel.

The panels will have the ability to be "lifted out" for tinkering.

I already machined most of the case , just 4 holes for the above panels.

Resistors, trimmers , all sorts of assorted stuff. you sent plenty of

small semi's/diodes , 13 of njw0302 (but no 0281's).

In Albany , many PC parts/hardware were recycled (many screws).

Here in Tennessee , things are "desperate" ... not much E-waste.

OS

The credit did not come in yet - hope it comes soon, I will re-order 6800uF caps right away then. What are those "+ per channel"? Let me know the value and the quantity - easy to add them there

3mm (.1") 175 X 125mm (angle at bottom). No metal shops around here.

OS

No problem. I stock .093" and .125" 5052 aluminum. Give me a drawing. Preferably in inches.

Nope , all the to-92's ... all the to-126's .

Need euro terminals/resistors ...

Do you have metal , J ?

PS - does that small trafo (Vpp-24-830) fit the Arduino ?

OS

The small transformer fits the protection board that the Arduino plugs into. All the pieces are coming for it as well.

No problem. I stock .093" and .125" 5052 aluminum. Give me a drawing. Preferably in inches.

2 X (5" X 7") - .093 is alright , does not matter.

.125" X 7" (3/4") angle for the above 2 plates.

4 X (2" X 4") -(.093") for the big slewmaster drivers.

IPS's - I can just cut some flashing for the VAS semi's.

They don't get hot at 5.5ma.

OS

I've got a bunch of heatsinks already made up for the output drivers and for the Symasuis as well if you want. I'm planning to use them for subwoofer plate amps so I was worried about the vibrations breaking the legs off the transistors. Instead of the angle and flat plate would you prefer a single bent part? I have a brake.

Attachments

I've got a bunch of heatsinks already made up for the output drivers and for the Symasuis as well if you want. I'm planning to use them for subwoofer plate amps so I was worried about the vibrations breaking the legs off the transistors. Instead of the angle and flat plate would you prefer a single bent part? I have a brake.

Those are pretty !

Yeah , If you can do bends on the 5 X 7"s - 1" bend on the 7" dimension.

That would be a 6 X 7 " with a bend on the longer length.

I had "Hudson metal" in albany do my metal work - they charged quite

a bit. But EBAY metal work costs even more.

PS - they actually have vendors on the "bay" that will take notes and

custom form (simple stuff) aluminum sheet.

OS

Jwilhelm,

Is it really cost effective to make your own heatsinks from aluminum blocks compared to purchasing an extrusion? I would think the raw material costs of just an aluminum block large enough to make a heatsink from would cost more than a commercial unit. Yes you can make them any size you may want but unless you are also making custom sized enclosures is it cost effective. I'm just thinking of the time to do a setup on a mill and the cutting time plus the cost of materials let alone your own labor.

Is it really cost effective to make your own heatsinks from aluminum blocks compared to purchasing an extrusion? I would think the raw material costs of just an aluminum block large enough to make a heatsink from would cost more than a commercial unit. Yes you can make them any size you may want but unless you are also making custom sized enclosures is it cost effective. I'm just thinking of the time to do a setup on a mill and the cutting time plus the cost of materials let alone your own labor.

- Home

- Amplifiers

- Solid State

- Slewmaster - CFA vs. VFA "Rumble"