Does Burr-Brown still exist as company inside Texas Instruments so you can say the OPA1611 was developed by Burr-Brown?

I have to develop some SMD solder skills so using SMDs is not a limiting factor. If I am able to direct hot air very local so I don't overheat the component then I will try using hot air + wire solder in first place to see how it goes. I have got the holder you suggested. Very cheap…..but seems to do the job.

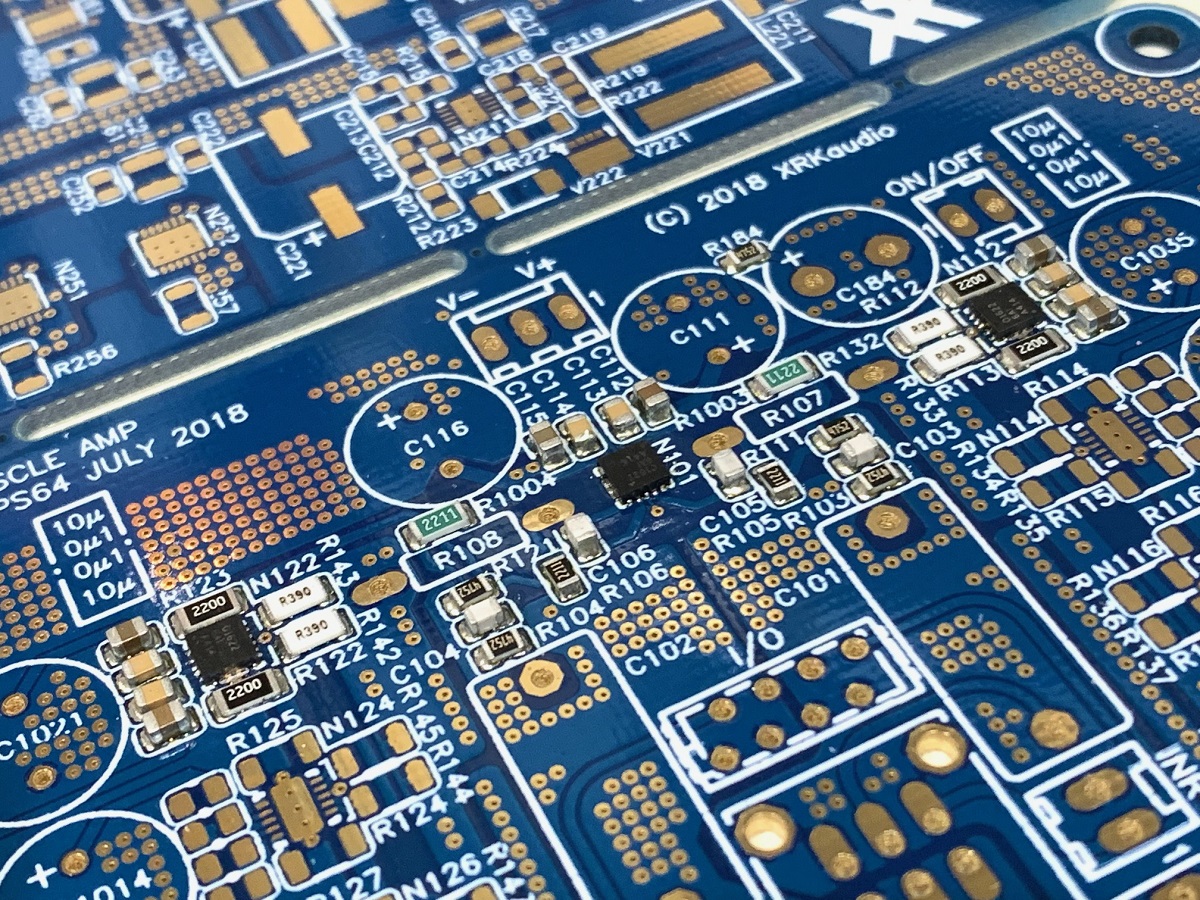

We can see that using partly SMDs some very nice small circuit PCBs can be made. It must have some positive effects on audio quality as signal path gets very short with all the benefits this gives.

Yes. BurBrown is fully integrated into TEXAS Instruments. There is no change in the design.

Get some solder paste in a syringe with hypo needle. Plus either an old hot plate skillet or hot air gun will give you professional looking results. Soldering iron works but paste is faster and cleaner and makes better joints with smooth fillet.

Best is to heat with hot plate from below to 130C then direct hot air pencil on top to section you want to solder. It’s much more even that way. This way, only parts immediately being put to liquidus experience the higher temps. Everything else is in preheat mode.

Here is example of the joints you can get with this method. No soldering iron.

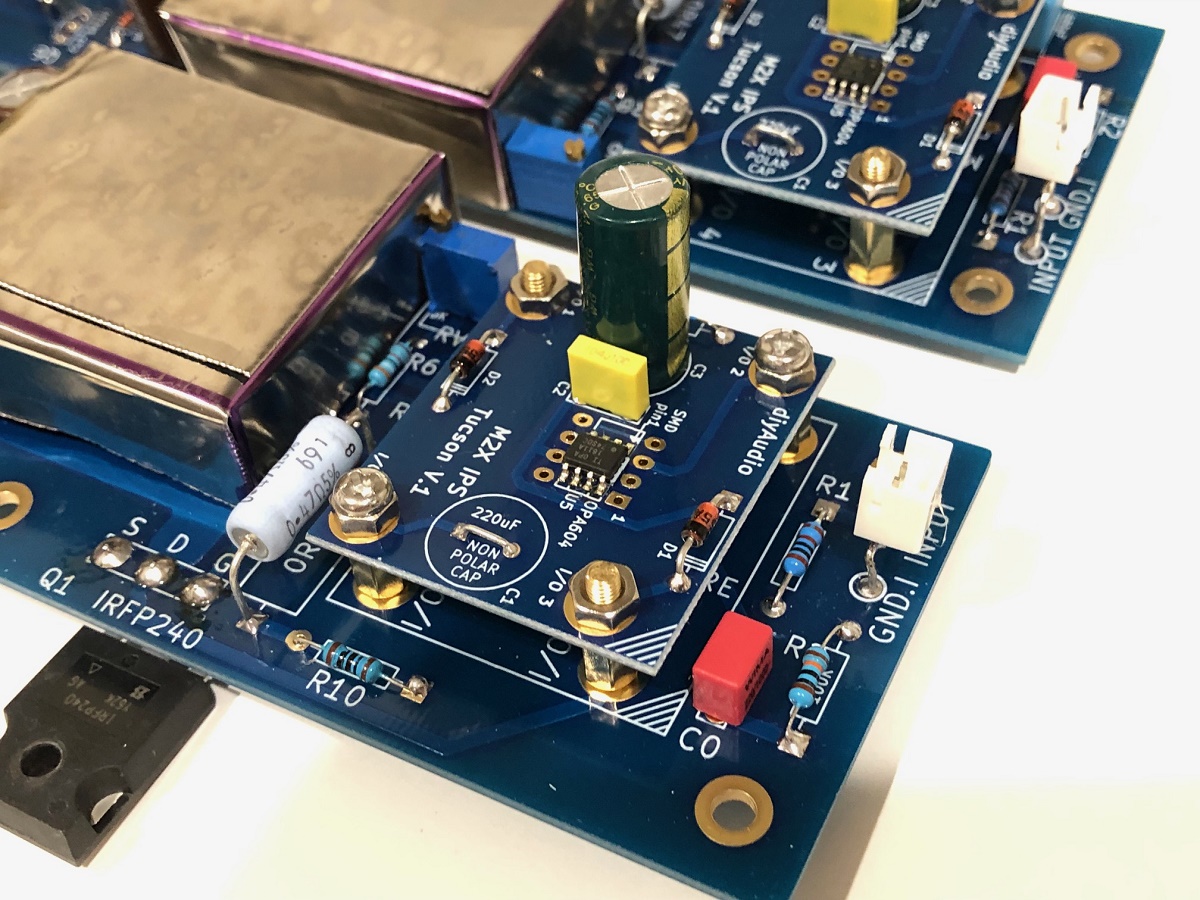

And here is my OPA1611 in the Tucson:

Best is to heat with hot plate from below to 130C then direct hot air pencil on top to section you want to solder. It’s much more even that way. This way, only parts immediately being put to liquidus experience the higher temps. Everything else is in preheat mode.

Here is example of the joints you can get with this method. No soldering iron.

And here is my OPA1611 in the Tucson:

Last edited:

Boy that is a WEIRD looking electrolytic capacitor C3 on your Tucson board. Could it be a Sam Yong super discount capacitor from eBay by any chance?

I happen to have a set of four Aavid 5752 sinks on hand for a different pair boards that I haven’t started building yet. They are definitely made more for the TO-92 style package. The application that I have in mind is dissipating about 500 mW from a set of ZVN3310A Mosfets. They definitely need all the help I can provide. The output devices on the Austin look like they’re each dissipating about 225 mW. One could bend the tabs of a 5752 to adapt it to the smaller E-Line package, but I have another idea. I have a roll of 3/4” copper tape that I use for shielding pickup cavities in my bass guitars. I could cut a length of this and fold it double around the pair of output devices. If I can get a good conformal fit around the transistors, that could improve the thermal resistance enough to help.Austin, moreso than the others, would greatly benefit from lower thermal resistance, ThetaJA. The Super E-Line package from Zetex is good but maybe you could find or create something even better. Either explicit aluminum TO92 heatsinks like AAVID 5752, or ghetto DIY sinks {glue xitors to US quarter-dollar coins?}, or the very hard to find "Tall Boy" TO-92 packages designed to drive dot matrix print heads, might offer non-negligible amounts of improvement.

_

Just remember to perform the modifications in such a way that you can easily listen to BEFORE, and AFTER, with no confusion.

Also remember that this might turn out to be an accidental or even deliberate focus upon a completely unimportant and stupendously irrelevant phenomenon. Don't fool yourself into imagining you hear differences where none exist.

Also remember that this might turn out to be an accidental or even deliberate focus upon a completely unimportant and stupendously irrelevant phenomenon. Don't fool yourself into imagining you hear differences where none exist.

I plan to leave the Austin boards as they are for the time being. They sound really good, and I suspect that the ZTX parts are operating at a good point with regards to temperature and quiescent current. Since the package is rated for 1+ W, there should be enough thermal margin that longevity is not negatively impacted.

Last edited:

The SMD soldering looks good. Will see what I can do with the equipment I have when I get thin wire solder and flux.

What is your DC offset from Tucson with not output cap?

What is your DC offset from Tucson with not output cap?

I recently built a pair of Austin IPS boards and installed them in my M2x. Prior to these, I have been listening to my version of the Mtn View input stage.

[snip]

*My veroboard Ishikawas suffered a setback due to a placement / construction error. I had to order another set of PunkyDawg's finest, as I'm afraid the P-types got fried.

Great news! Thank you for sharing your impressions.

Sorry for your loss. My condolences.

XRK - you really do want to use the star washers on the mounting posts. Without them the thermal delta will loosen those screws and nuts up in no time.

Austin is a 4-BJT "diamond buffer" with constant current source loads on the input followers.

The BJT diamond works beautifully on ICs where you are certain that all four transistors in the diamond operate at exactly the same temperature, because they're all on the same silicon substrate and very close together.

When you build the diamond circuit not on an IC, temperature-induced BJT variations are no longer perfectly cancelled. One way to minimize the temperature difference between transistors, is to operate them at very low currents. This reduces self heating but hurts circuit performance. Another way is to maximize heat removal (minimize ThetaJA), which also reduces self heating. Still more stunts and finesses for minimizing delta-Temperature, may suggest themselves to diligent and innovative designers.

The BJT diamond works beautifully on ICs where you are certain that all four transistors in the diamond operate at exactly the same temperature, because they're all on the same silicon substrate and very close together.

When you build the diamond circuit not on an IC, temperature-induced BJT variations are no longer perfectly cancelled. One way to minimize the temperature difference between transistors, is to operate them at very low currents. This reduces self heating but hurts circuit performance. Another way is to maximize heat removal (minimize ThetaJA), which also reduces self heating. Still more stunts and finesses for minimizing delta-Temperature, may suggest themselves to diligent and innovative designers.

Sometimes these small signal transistors are glued together (front by front) in pairs to achieve same temperature?

Can't remember if layout of Austin board is that smart 🙂

It may be difficult to glue all four together…….

Can't remember if layout of Austin board is that smart 🙂

It may be difficult to glue all four together…….

Boy that is a WEIRD looking electrolytic capacitor C3 on your Tucson board. Could it be a Sam Yong super discount capacitor from eBay by any chance?

It’s probably a fake “Sanyo” from Aliex. I didn’t have any other 220uF on hand at the time. This one is 50v rated. It’s just the rail smoothing cap so no audio signal flowing through it.

@meper - the DC offset was insignificant. About 1mV or so IIRC.

@6L6 - star washed noted - I never run this long enough before removing the boards to swap for something else. 🙂

Currently running Austin boards with all KSC1845’s/KSA992’s and a pair of 12v Zener diodes rather than the fancy 3-legged voltage references. Works very well with Zeners.

I've finished 1.0 stage of the build!

No comment on the sound yet. It's still hooked up to my test speakers with a laptop input, but all seems to be right with the world. 😀

A quick question for the group - my research has come up with nada.

- My toroid was (seemingly randomly) physically vibrating. It seems to have gone away for no apparent reason other than leaving the amp on all night. Is that normal? Should they vibrate? I did have what I thought was a completely unrelated issue where the cap across the mains got bent and was touching the toroid. I checked it after I noticed a small spark at the mains switch at turn on and bent it back.

[Edited to add] - it was my "noisy" bench top fluorescent lamp. It won't be an issue when in my rig. 😀

- The toroid is at ~70C. Is that normal? I checked specs online, and there was no spec for max operating temp.

Once again - thank you to everyone for the exceptional support! There is no way I could have done it without this community. 😀 I'll report back on any differences I hear with the input stages, but I'll be leaving Tucson (TI OPA604AP for now) in for a good while.

Here are a few shots. I was particularly happy to get the DC Offset to as low as my DMMs would measure. I'm sure it will drift, but simple pleasures.

On to 1.1 and maybe another FW Clone in the future. 😀😀

No comment on the sound yet. It's still hooked up to my test speakers with a laptop input, but all seems to be right with the world. 😀

A quick question for the group - my research has come up with nada.

- My toroid was (seemingly randomly) physically vibrating. It seems to have gone away for no apparent reason other than leaving the amp on all night. Is that normal? Should they vibrate? I did have what I thought was a completely unrelated issue where the cap across the mains got bent and was touching the toroid. I checked it after I noticed a small spark at the mains switch at turn on and bent it back.

[Edited to add] - it was my "noisy" bench top fluorescent lamp. It won't be an issue when in my rig. 😀

- The toroid is at ~70C. Is that normal? I checked specs online, and there was no spec for max operating temp.

Once again - thank you to everyone for the exceptional support! There is no way I could have done it without this community. 😀 I'll report back on any differences I hear with the input stages, but I'll be leaving Tucson (TI OPA604AP for now) in for a good while.

Here are a few shots. I was particularly happy to get the DC Offset to as low as my DMMs would measure. I'm sure it will drift, but simple pleasures.

On to 1.1 and maybe another FW Clone in the future. 😀😀

Attachments

Last edited:

It looks like you have a shorted turn (look it up) in your transformer mounting, the metal retaining plate seems to be touching the baseplate, that's going to cause problems. Mount the transformer a bit higher on the bracket so it doesn't touch.

70C is much too hot for the transformer. That's just not right. Double-triple check everything again and see is there is an error somewhere in the wiring.

70C is much too hot for the transformer. That's just not right. Double-triple check everything again and see is there is an error somewhere in the wiring.

Last edited:

@6L6 - AHA!

I did not know that was something to look out for. I will correct ASAP!

As always, thank you!

I did not know that was something to look out for. I will correct ASAP!

As always, thank you!

With a shorted turn, I am a bit surprised that your primary fuse didn't blow. Did you follow Nelson Pass's guideline for fuse selection?

I suspect that if this happened to me, I would over-react with the Once Bitten, Twice Shy response. I'd probably install a 4cm x 8cm "rest" on the chassis floor, made of a non magnetic material like 6mm plywood (example), which prevents the transformer mounting plate and bracket from touching the chassis floor.

_

I suspect that if this happened to me, I would over-react with the Once Bitten, Twice Shy response. I'd probably install a 4cm x 8cm "rest" on the chassis floor, made of a non magnetic material like 6mm plywood (example), which prevents the transformer mounting plate and bracket from touching the chassis floor.

_

Attachments

@6L6 / Jim -

You of course were correct. I did a quick check to verify and sure enough, the top mount was resting on the base plate. I had no idea that this was something to be concerned with. I did a quick read on the term "double turn" / "shorted turn" - new information for me. A mistake I won't make again.

For those following the game at home - pic below of the result. I raised the transformer in the mount, and secured it tightly with a lock nut. For extra safety, I cut a piece of rubber from another mount and placed it under the top plate in the rare event it could slip down.

After about 20 mins it's running at ~47C. That seems much more reasonable. I'll leave it unbuttoned for another day just in case anything else crops up, but I think we're good to go.

You of course were correct. I did a quick check to verify and sure enough, the top mount was resting on the base plate. I had no idea that this was something to be concerned with. I did a quick read on the term "double turn" / "shorted turn" - new information for me. A mistake I won't make again.

For those following the game at home - pic below of the result. I raised the transformer in the mount, and secured it tightly with a lock nut. For extra safety, I cut a piece of rubber from another mount and placed it under the top plate in the rare event it could slip down.

After about 20 mins it's running at ~47C. That seems much more reasonable. I'll leave it unbuttoned for another day just in case anything else crops up, but I think we're good to go.

Attachments

Last edited:

@Mark Johnson - Yes, that definitely gave me a bit of a surprise. I am glad I checked temps. Even not "knowing", it didn't seem right, so I asked this wonderful group after checking the internet.

It wasn't a bite per se but rather a self-inflicted wound. I had no idea about keeping the top plate separate from the chassis plate, so I installed it wrong. It seemed more stable resting on the base plate. DOH! I installed a 2.5A slow blow fuse. I agree with the "ounce of prevention" and the "once bitten" - So I installed the rubber "shield" below it in the rare event that it does shift downward after taking great measures to help ensure that it won't. 😉

I don't mind admitting my mistakes... maybe someone will read it and not want to be like me. I'm thankful that I (hopefully) did not do any permanent damage to the amp. That would have been a major bummer.

Right now - I just checked again - and it's sitting at a nice 47-48C after 2 hours of tunes. Happy me. 😀

I know confirmation bias and expectation bias are things, but WOW!

It wasn't a bite per se but rather a self-inflicted wound. I had no idea about keeping the top plate separate from the chassis plate, so I installed it wrong. It seemed more stable resting on the base plate. DOH! I installed a 2.5A slow blow fuse. I agree with the "ounce of prevention" and the "once bitten" - So I installed the rubber "shield" below it in the rare event that it does shift downward after taking great measures to help ensure that it won't. 😉

I don't mind admitting my mistakes... maybe someone will read it and not want to be like me. I'm thankful that I (hopefully) did not do any permanent damage to the amp. That would have been a major bummer.

Right now - I just checked again - and it's sitting at a nice 47-48C after 2 hours of tunes. Happy me. 😀

I know confirmation bias and expectation bias are things, but WOW!

- Home

- Amplifiers

- Pass Labs

- The diyAudio First Watt M2x