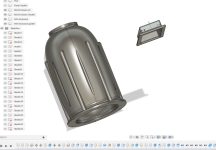

These are the mid woofer enclosures I was talking about in my other thread. They mount to the inside of the front baffle behind the mid.

You think I should stuff this with some wadding or just leave them the way they are?

I added the STEP file for the enclosure if anyone wants to use it. You can scale it up or down for whatever size driver you are using. Anyone with a 3d printer you know can print it out for you and scale inside of their slicing program

You think I should stuff this with some wadding or just leave them the way they are?

I added the STEP file for the enclosure if anyone wants to use it. You can scale it up or down for whatever size driver you are using. Anyone with a 3d printer you know can print it out for you and scale inside of their slicing program

Attachments

Probably the most common material in the U.S. is a bag of Polyfill from JoAnne's fabrics (or maybe Amazon). You could line with denim damping material or felt (felt is pretty expensive) and then stuff with Polyfill. Some people buy cheap pillows and take the stuffing out.l

Stuffing would be recommended.They are 100mm deep.

Oh we have lots of polyfill around the house. Wife is big into crafting. I steal it and shove it in enclosures all the timeProbably the most common material in the U.S. is a bag of Polyfill from JoAnne's fabrics (or maybe Amazon). You could line with denim damping material or felt (felt is pretty expensive) and then stuff with Polyfill. Some people buy cheap pillows and take the stuffing out.l

You could also try a liner of flat acoustical foam plus poly-fil, or felt liner plus poly-fil, an inner cage where you can compress some poly-fil near the wall then loosely fill also, etc.

In such a small space, you'll likely get some benefit from doing something beyond just loose poly-fil.

In such a small space, you'll likely get some benefit from doing something beyond just loose poly-fil.

Really? I figured those were all sealed upWhich driver is used for midrange and How many liters is the chamber?

I would also make small closed chamber for tweeter. More likely than not, chamber of tweeter is not airtight.

It's a zaph 5 inch midWhich driver is used for midrange and How many liters is the chamber?

I would also make small closed chamber for tweeter. More likely than not, chamber of tweeter is not airtight.

I calculated the internal volume at 110 inch square.

Zaph Audio ZA14W08 5" Aluminum Cone Mid/Woofer

There have been some instances where this is beneficial. Sometimes seeing the tweeter to the baffle is difficult. I've had some planar be open in the back and be required. Sometimes thin plastic faces will not take the woofer pressures well, and will flex under duress.

Necessary? Sometimes. Not a bad idea as far as isolation goes.

Necessary? Sometimes. Not a bad idea as far as isolation goes.

Square is area, cubed is volume.It's a zaph 5 inch mid

I calculated the internal volume at 110 inch square.

Zaph Audio ZA14W08 5" Aluminum Cone Mid/Woofer

Really? I figured those were all sealed up

It looks like it. Can say a friend tried airsealing SB Satori tweeter and was rather amazed of the improvement. I bet most tweeters will improve from not having the woofer hammer waves from behind. In commercial speakers most of the time tweeter share volume with midrange, where pressure is less.

About volume of midrange chamber, google translate it to 1.8 liters. I guess it will work, but general advice is bigger volume improve midrange. You could try with 5-6 liters and compare.

I can make it a bit bigger. It's 3d print so I can do whatever I want at minimal cost. I did run the saph through WINISD just to be sure and the 90 inch cube seemed fine. Gave me a little boost actually right around when I'm going to cross it.It looks like it. Can say a friend tried airsealing SB Satori tweeter and was rather amazed of the improvement. I bet most tweeters will improve from not having the woofer hammer waves from behind. In commercial speakers most of the time tweeter share volume with midrange, where pressure is less.

About volume of midrange chamber, google translate it to 1.8 liters. I guess it will work, but general advice is bigger volume improve midrange. You could try with 5-6 liters and compare.

I'll design a mini shield for the planar tweeter

- Home

- Loudspeakers

- Multi-Way

- 3d Printed Mid Enclosure - Should I stuff it?