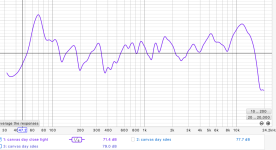

A few pictures of the basic veneer panel and responses ,before any alterations.

The first plot is at about 5inches just to show what is going on on the panel, a pretty wide frequency response.

Plot 2

Is at half a metre.

Plot 3

Is at 1m.

And Plot 4.

Is from my seating position at 3m.

Surprisingly this is quite a well behaved panel.

Ignore the last two responses below 80hz as this is mainly outside road noise.

I did make a recording, but made it too large, so will have to cut it or start again.

I will use some of my methods to flatten the hf out and extend the low end a little.

But first I will sort out that basic panel recording first.

Steve.

The first plot is at about 5inches just to show what is going on on the panel, a pretty wide frequency response.

Plot 2

Is at half a metre.

Plot 3

Is at 1m.

And Plot 4.

Is from my seating position at 3m.

Surprisingly this is quite a well behaved panel.

Ignore the last two responses below 80hz as this is mainly outside road noise.

I did make a recording, but made it too large, so will have to cut it or start again.

I will use some of my methods to flatten the hf out and extend the low end a little.

But first I will sort out that basic panel recording first.

Steve.

Attachments

I had to make a new recording.

A pretty good sounding panel to start with.

Hopefully, things can only get better.

I was playing the veneer panel louder than the right chanel so that it could be heard better.

They were both on 0db but the veneer was more efficient.

Steve.

A pretty good sounding panel to start with.

Hopefully, things can only get better.

I was playing the veneer panel louder than the right chanel so that it could be heard better.

They were both on 0db but the veneer was more efficient.

Steve.

Attachments

For the core I think compressive strength is important for HF reproduction. XPS is typically a couple of hundred kPa at most, while nomex is measured in MPa.I'm assuming he meant to cover the nomex honeycomb cells with epoxy and fiberglass? While looking at various datasheets for different honeycomb cores it seems like the very lightest have the same density as my XPS: about 24kg/m3. Honeycomb will be stiffer I think, but not any lighter, interestingly.

The advantage of the composite approach is largely that you can get good compressive strength combined with low weight, so using styrofoam as a core does somewhat seems to defeat the purpose of doing a composite to start with.

@Goldmund do you have REW measurements of that nomex panel you can share? What are the 4 holes for, and did you find that rounding the corners actually helped?

I have done some experiments where I've pushed supports through the foam and fiberglassed them in but none of my experiments have been better than foam with no internal supports, overall. Next time I do that I'll try concentrating the supports around the driver more.

I have done some experiments where I've pushed supports through the foam and fiberglassed them in but none of my experiments have been better than foam with no internal supports, overall. Next time I do that I'll try concentrating the supports around the driver more.

I once made a thin XPS panel with a very heavy coat of hide glue. It was somewhere around 5-8mm thick. I had to do both sides at the same time (which is pretty difficult without help) because I knew it would warp. Even with both sides done at the same time it still warped quite a lot. After it fully dried I was amazed at how rigid and light it was! Unfortunately it had some really bad ringing and it reminded me a lot of piano strings that ring for so long after they're struck. With an exciter attached the sound has a strong chorus / reverb effect making it sound like a it's playing in a large hall with no sound absorption. It's a cool effect but not desired on most things, and when played in stereo the center image definition is lost.

Hi Andre,And now for an almost different subject altogether...

A piece of board (any board, EPS, cardboard, polycarb, PE, etc etc) has a bass response which can be improved by gluing it into a framed canvas panel. I suspect this improved bass response has something to do with the 'surround' created by the space between the inserted board and the hard edge of the frame, and which allows the board to vibrate as a piston at its fundamental frequency.

1. This construction possibly creates a very high QTS driver (consisting of exciter motor, board, surround and frame) which is exactly what is required for open baffle woofers.

Indeed, I tried taking TS parameters using REW, and it seems like the little A3-sized panel I'm testing, with good bass response down to 60hz, has a Qts of 12. This is either very important, or it's wrong.

2. Resonant frequency can be controlled by board weight and canvas tightness. Qts can be controlled by the damping of the surround.

This should make it possible to adjust Fs to the natural frequency of the board by itself, or maybe to that frequency between between the first few modes where you get that inevitable notch on the bass response.

There's much to think about.

I tried this out this week and was very surprised by the extent of the bass, I used an approximately A3 canvas and had a bit of HD EPS with an exciter 3/5 2/5 already mounted, I glued it to the canvas with contact adhesive as I was not wanting to wait. Initially the highs were dull so I cut out the canvas over the exciter area and this much improved the highs. It had good output down to 45HZish with a hump around 60HZ but when louder it seemed to be distorting from the far side of the rectangle panel moving more than the short side. It had better response when I held this end and measured.

I was wondering if you centred your exciter rather than off set as usual? Thinking this may be better as the panel is unbalanced when moving so much. I also had 25mm canvas around the panel which is probably too loose. Have you tried square or round canvas or just rectangular? Also Spedge liked canvas mounting I remember and may have insight.

Don't take too much from the measurements as they were quick and dirty.

Thanks.

Attachments

I made a very cool discovery tonight. I don't have test data for it yet but I think this weekend I'll work on it. I did a brief test on a sample panel and I can definitely tell with hand and ear that there's major improvement. Will have to wait and see how it presents in the measured data.

I was looking into this because I did some hand and ear testing with CLD tape in the garage and I am not convinced that CLD tape makes any noticable improvement when it is placed near the edge. When a large piece is placed in the center it does make a bit of difference, but it seems like the whole panel would have to be covered for significant improvement and that would be so heavy and affect so many things that it doesn't seem like a good idea anymore. Butyl rope mounts does still make good sense though for more rigid mounts.

So, today I asked GPT-4o for some ideas for damping panels and one thing it suggested was a spray-on coating. I asked it for examples and it suggested a 3M undercoating product. I looked around a bit and found there's actually a bunch of products on the market for spray-on undercoating to reduce noise in cars. GPT says they are pretty light, and while I didn't believe that I thought I'd try it anyway.

I found the 3M product was supposed to be in stock at a local store so I went to get it but they didn't have it... They did have Dupli-Color rubberized undercoat for $8 though and the clerk said it's basically the same as 3M so I grabbed a can. I'm sure 3M is actually better, but this is just a cheap test anyway. At home I tested it on some cardboard and it blasted out of the can quite fast and dried pretty quick. Then I tested on bare XPS expecting the solvent to dissolve it, but it did not! Such luck I thought I was only going to be able to use it on epoxy or maybe PVA coated panels, but it works on bare XPS without any interaction.

I thought I was only going to be able to use it on epoxy or maybe PVA coated panels, but it works on bare XPS without any interaction.

Then I went ahead and grabbed a bigger piece of foam, split it in half, and sprayed one side of one half. Each half is about 20cm x 30cm, and probably around 1.5cm thick. I sprayed it on pretty heavy but that was because it comes out so fast and dried so quick before that I thought it would be fine. Turns out that on this ~60F day it took many hours to cure on XPS and I even used a hair dryer for a while. I'll definitely use multiple light coats next time, and hopefully on a warm sunny day.

Before coating the panel weighed 20g and after curing it weighs 26g. At that spray-on thickness on my normal test panels that should be about 15g added to a side. That's practically nothing compared to the 50g epoxy I just put on one side of one Idk if front or back or both sides of panels should be coated, I'll have to test it out. And different coating thicknesses too...

Idk if front or back or both sides of panels should be coated, I'll have to test it out. And different coating thicknesses too...

Because I split a piece of rectangular foam in half I now have two identical smaller panels, one coated and one not. This allows me to do lots of A/B tap testing while feeling and hearing the difference. It's hard to describe it but there is definitely a big improvement with the spray coating. I estimate that for a given tap on the bare panel, the same arrangement on the coated panel rings for just half the time. Maybe less. The coated panel has a significantly lower resonant frequency as well. All my taps impacted the un-coated underside of the panel.

I'll find out tomorrow how durable the bond is between the spray and the XPS. I'm super excited about this because of how well it damps, though I'm also concerned that it may lower sensitivity too much, or behave inconsistently across the FR, or reduce the soundstage depth.

I was looking into this because I did some hand and ear testing with CLD tape in the garage and I am not convinced that CLD tape makes any noticable improvement when it is placed near the edge. When a large piece is placed in the center it does make a bit of difference, but it seems like the whole panel would have to be covered for significant improvement and that would be so heavy and affect so many things that it doesn't seem like a good idea anymore. Butyl rope mounts does still make good sense though for more rigid mounts.

So, today I asked GPT-4o for some ideas for damping panels and one thing it suggested was a spray-on coating. I asked it for examples and it suggested a 3M undercoating product. I looked around a bit and found there's actually a bunch of products on the market for spray-on undercoating to reduce noise in cars. GPT says they are pretty light, and while I didn't believe that I thought I'd try it anyway.

I found the 3M product was supposed to be in stock at a local store so I went to get it but they didn't have it... They did have Dupli-Color rubberized undercoat for $8 though and the clerk said it's basically the same as 3M so I grabbed a can. I'm sure 3M is actually better, but this is just a cheap test anyway. At home I tested it on some cardboard and it blasted out of the can quite fast and dried pretty quick. Then I tested on bare XPS expecting the solvent to dissolve it, but it did not! Such luck

Then I went ahead and grabbed a bigger piece of foam, split it in half, and sprayed one side of one half. Each half is about 20cm x 30cm, and probably around 1.5cm thick. I sprayed it on pretty heavy but that was because it comes out so fast and dried so quick before that I thought it would be fine. Turns out that on this ~60F day it took many hours to cure on XPS and I even used a hair dryer for a while. I'll definitely use multiple light coats next time, and hopefully on a warm sunny day.

Before coating the panel weighed 20g and after curing it weighs 26g. At that spray-on thickness on my normal test panels that should be about 15g added to a side. That's practically nothing compared to the 50g epoxy I just put on one side of one

Because I split a piece of rectangular foam in half I now have two identical smaller panels, one coated and one not. This allows me to do lots of A/B tap testing while feeling and hearing the difference. It's hard to describe it but there is definitely a big improvement with the spray coating. I estimate that for a given tap on the bare panel, the same arrangement on the coated panel rings for just half the time. Maybe less. The coated panel has a significantly lower resonant frequency as well. All my taps impacted the un-coated underside of the panel.

I'll find out tomorrow how durable the bond is between the spray and the XPS. I'm super excited about this because of how well it damps, though I'm also concerned that it may lower sensitivity too much, or behave inconsistently across the FR, or reduce the soundstage depth.

Does the canvas add distortion? I used duct tape surround in a frame for a bunch of tests and it did improve LF (though not nearly as much as this canvas) but I think for LF and even mid-bass at 80dB the duct tape flapped causing very audible noise along with much higher distortion in measurements.Hi Andre,

I tried this out this week and was very surprised by the extent of the bass, I used an approximately A3 canvas and had a bit of HD EPS with an exciter 3/5 2/5 already mounted, I glued it to the canvas with contact adhesive as I was not wanting to wait. Initially the highs were dull so I cut out the canvas over the exciter area and this much improved the highs. It had good output down to 45HZish with a hump around 60HZ but when louder it seemed to be distorting from the far side of the rectangle panel moving more than the short side. It had better response when I held this end and measured.

I was wondering if you centred your exciter rather than off set as usual? Thinking this may be better as the panel is unbalanced when moving so much. I also had 25mm canvas around the panel which is probably too loose. Have you tried square or round canvas or just rectangular? Also Spedge liked canvas mounting I remember and may have insight.

Don't take too much from the measurements as they were quick and dirty.

Thanks.

One issue with taking these DMLs so low is power handling. They are not made to handle the watts required for LF, and the heat they generate can damage panels as well. I could be wrong about this but I've figured that I shouldn't cross a DML any lower than 100hz. 150hz is probably safer. I guess if you're using a bunch of exciters you could go lower but all of my tests have been with 1 exciter only.

That is a massive peak at 70hz!It had good output down to 45HZish with a hump around 60HZ but when louder it seemed to be distorting from the far side of the rectangle panel moving more than the short side.

Generally, this means that the panel or the surround is resonating in an uncontrolled manner, flapping around, and this is what causes the distortion. The 25mm gap all around is pretty big, and which means that there might be too little control over the edges of the panel you're using.

No, I used live RTA to move the driver around until I got good top end response and without too much mid-range peaking. I'm working the bass end with panel weight, canvas tightness, and the size of the gap around the edges.I was wondering if you centred your exciter rather than off set as usual?

I've used a plain rectangle, following the size of the frame, and I've used a shaped 'X' with the points of the 'X' extending into the corners of the frames specifically to reduce uncontrolled flapping and distortion.Have you tried square or round canvas or just rectangular?

I have not yet tried to round or truncate the corners. But that's my next task if I cannot get distortion down below at least 1%.

Yes, any kind of flapping or rattling will definitely increase distortion dramatically.Does the canvas add distortion? I used duct tape surround in a frame for a bunch of tests and it did improve LF (though not nearly as much as this canvas) but I think for LF and even mid-bass at 80dB the duct tape flapped causing very audible noise along with much higher distortion in measurements.

The normal ear will not identify speaker distortion below about 5% on instrumental assembles. You MIGHT pick up a pure sine wave distorted at 0.5%, butt that's only in A/B testing.

So if you can hear any kind of flapping, rattling, "self" noise, edges causing wind noise, then you can guarantee that your measurements will display this very clearly.

Not power handling as much as excursion. Bottom end is determined by the volume of air that is moved, therefore a small panel will need a large Xmax, and a large panel will not.One issue with taking these DMLs so low is power handling.

2 x 15" open-baffle speaker drivers will give you gut-wrenching bass down to below 40Hz. Without an enclosure. Even with only 4mm Xmax. The secret is to design a DML panel that will have its fundamental resonance where you want it, and then ensure you have the same surface area as, say, 2 x 15" drivers, and also a reasonably high Qts, just like an open baffle speaker.

Well I THINK that's the theory, but only testing will prove it.

After doing some sums...2 x 15" open-baffle speaker drivers will give you gut-wrenching bass down to below 40Hz. Without an enclosure. Even with only 4mm Xmax.

A standard 15" speaker driver has a surface area (assuming a flat piston due to its geometry) of around 860 sq.cm or so. This includes a bit for the surround.

Example: Eminence Alpha 15a, open baffle driver.

Fs : 41Hz.

Qts : 1.26

Diaphragm mass : 59g

Xmax : 3.8mm

Surface Area : 856.3sq.cm

As cheap and nasty as it is, this driver works beeootifully down to 50Hz in an open baffle just slightly larger than the driver itself.

This curve is for a single Alpha15a driver with a 1st-order LPF rolling off slowly above 300Hz or so.

Assumption:

A (small?) DML panel 260 x 360mm in size has a surface area of 936sq.cm. There's no reason why a DML panel of those dimensions should not out-perform an open-baffle-optimised 15" cone speaker on the bass end. No, not just the bass end, but probably in every other respect too.

Comments?

I've also finally made some panels that look and sound good enough for the lounge. I haven't measured since being home but when I was making them they were pretty flat 100-10000Hz (about 5db up and down from centre at 1/6th smoothing)and will probably add a tweeter in the corner as they dropped around 6db above 10khz but they sound fantastic with the sub crossed 110hz.

I made the back panel with insulation to mitigate the rear reflections off the wall that were causing the sound to have too much space and lack a centre. It seems to cut about 10db+ from approx 600hz up which has solved that issue for me. Might be the room or placement related but I prefer the sound now.

I made the back panel with insulation to mitigate the rear reflections off the wall that were causing the sound to have too much space and lack a centre. It seems to cut about 10db+ from approx 600hz up which has solved that issue for me. Might be the room or placement related but I prefer the sound now.

Attachments

Assumption:

A (small?) DML panel 260 x 360mm in size has a surface area of 936sq.cm. There's no reason why a DML panel of those dimensions should not out-perform an open-baffle-optimised 15" cone speaker on the bass end. No, not just the bass end, but probably in every other respect too.

Agree, I'm far from an expert here but the first thing that I noticed is that we usually have panels with a very high qts and very low bl. Could this be the problem? I will order some XT32-4 (the only exciter with a good datasheet) and try some experiments, I'll keep you updated

I like your frame a lot and am planning to try something similar in future. I see you use aluminum L bar. Just an idea - if one uses flat bar with adjustable brackets at the back, you would be able to adjust the space needed for the foam strips on either side of the panel. Apart from adjusting how tight the foam holds the panel, it would also give you the ability to accommodate different thickness foam strips and even panel materials.I've also finally made some panels that look and sound good enough for the lounge.

I see room for misunderstanding... I shaped the panel that sticks onto the bsck of the canvas. I haven't used any other shape frame/canvas except rectangular.Thanks Andre, I appreciate your input. Confirms my thinking about the uncontrolled flapping. I'll have another go and will try other shaped canvas too.

Yes, I was just discussing this with Jerry Twocents.Agree, I'm far from an expert here but the first thing that I noticed is that we usually have panels with a very high qts and very low bl. Could this be the problem? I will order some XT32-4 (the only exciter with a good datasheet) and try some experiments, I'll keep you updated

The Bl is an issue but only because of the length of coil wire the pole gap. Of course, a 150W, 15" driver will have a higher Bl by virtue of the fact that it has a 1.5"dia voice coil. But you can get a similar Bl with only two decent exciters connected in parallel. This implies 8-ohm drivers such as the XT32-8's.

I guess one problem is that there are no 200w exciters, and that it is still a quite modest power handling for a sub?After doing some sums...

A standard 15" speaker driver has a surface area (assuming a flat piston due to its geometry) of around 860 sq.cm or so. This includes a bit for the surround.

Example: Eminence Alpha 15a, open baffle driver.

Fs : 41Hz.

Qts : 1.26

Diaphragm mass : 59g

Xmax : 3.8mm

Surface Area : 856.3sq.cm

As cheap and nasty as it is, this driver works beeootifully down to 50Hz in an open baffle just slightly larger than the driver itself.

View attachment 1324180

This curve is for a single Alpha15a driver with a 1st-order LPF rolling off slowly above 300Hz or so.

Assumption:

A (small?) DML panel 260 x 360mm in size has a surface area of 936sq.cm. There's no reason why a DML panel of those dimensions should not out-perform an open-baffle-optimised 15" cone speaker on the bass end. No, not just the bass end, but probably in every other respect too.

Comments?

4x40w like I use is quite close to the eminence 15" 200w on paper, but not sure how exciters are rated. I suspect that you will get heat issues if you feed them lots of LF content, and it seems like thermal performance has a lot to do not only with spectrum, but also how the exciters are mounted and the plate used.

If you have a loose suspension around the frame, allowing the whole plate to move as freely as a cone, you still have around half the Xmax of the 15" driver, so you would need double the surface area. Since 4x Xite 32 has more than double the BL of an eminence 15", it should be able to push that air and almost match the output of the 200w cone driver.

If it should be efficient I guess you would have to mount the plate in a sub cabinet

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker