I have a Behringer ECM 8000. I have never done any serious audio testing except in the context of Guitar Building.

If you tell me what you want done and how- sure I can probably do some near field testing or simple FFT stuff. I am pure hobbyist. [emoji4]

I have been trying to upload images of the NXT panel to no avail.

If you tell me what you want done and how- sure I can probably do some near field testing or simple FFT stuff. I am pure hobbyist. [emoji4]

I have been trying to upload images of the NXT panel to no avail.

Here you go. Real NXT panel. Light duty exciter typical placement Nomex panel. Small weight on listening side for modal adjustment. Terrible sound.

Attachments

I should have placed the raw and smoothed REW measurements together. I also have an impulse graph.

These aren't useful for designing panels because my panels aren't good examples. It's just to present the concept that typical REW frequency response and impulse graphs aren't what you'd want out of a DML.

If you had a flat frequency response like a typical cone speaker you'd wind up with a strong correlation between your speaker and your first reflections. Typical cone speakers also want a flat tail on their impulse graph.

I don't know what good quality raw DML REW graphs are supposed to look like. NXT does, but I don't. However, we can at least listen for high intelligibility above Schroeder. You won't have any control below Schroeder so you can't beat yourself up over that (or run in circles trying to fix something you can't fix.)

These aren't useful for designing panels because my panels aren't good examples. It's just to present the concept that typical REW frequency response and impulse graphs aren't what you'd want out of a DML.

If you had a flat frequency response like a typical cone speaker you'd wind up with a strong correlation between your speaker and your first reflections. Typical cone speakers also want a flat tail on their impulse graph.

I don't know what good quality raw DML REW graphs are supposed to look like. NXT does, but I don't. However, we can at least listen for high intelligibility above Schroeder. You won't have any control below Schroeder so you can't beat yourself up over that (or run in circles trying to fix something you can't fix.)

Attachments

Here you go. Real NXT panel. Light duty exciter typical placement Nomex panel. Small weight on listening side for modal adjustment. Terrible sound.

That's useful. I thought they would be larger like a Tectonic panel. I can see why you'd prefer your home made panels. NXT absolutely knows how to make a good panel but they also had to try to sell them to a commercial market.

Yes. Computer/TV speakers is probably what NXT was aiming for. They might be good in a car, too.

NXT licensed the technology to manufacturers and I am not aware of any NXT manufactured speakers. Companies like Mission, Phillips etc bought licenses. The only applications I have seen off DML rather than BMR technology were budget speakers.

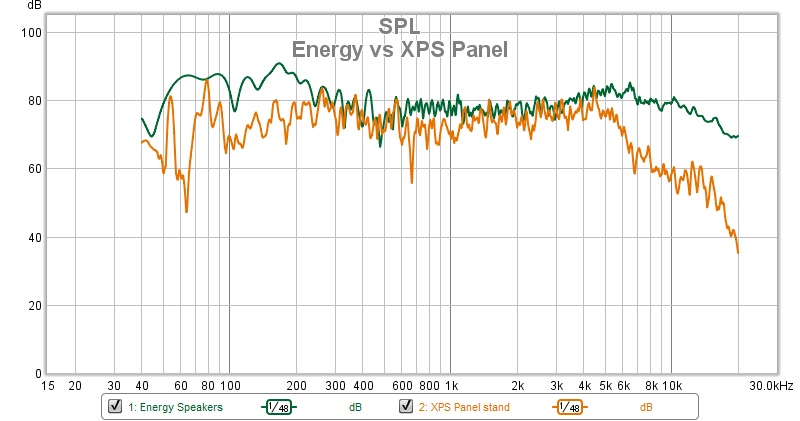

If you guys have a microphone, get the free REW software and collect much easier to read spectrum data vs little screens on your rack mount equipment. It’s better than nothing but would be nice to see vertical axis in 5dB major ticks and frequency labeled from 20Hz to 20kHz in log scale.

I can’t really make out the units on either axis here. Maybe -45dB to -50dB vertical and horizontal starts around 150Hz and goes up to?

Vs what BSP1304 posted earlier:

xrk.

Sorry again.

Couldn't get pics to upload,broadband pretty bad round hear at the moment!

The pic shows a 30db window trace ,40db down to 70db ,and follows the 50db line and is mainly within +and- 2.5db from 150hz to 20k with a bit of a lump at 9k probably tin can effect,but heavily damped after 10k by 1inch eps material so no hump in 10k to 20k as with 3mm ply.

I have dsp correction if I wish but there is No dsp or any correction at all used,what I would call a bog standard panel.

The rta is on all the time in my music room ,so I am very used to it ,if there is a problem with say an exciter coming loose I can spot it before I hear it.

Best thing I ever bought.

Steve

Last edited:

A friend of mine is the owner of Podium in France. His company manufactured and distributed Podium. The brand is currently inactive. I have the inside story.Judge for yourselves. 6moons audio reviews: Podium Sound Model 1

IMO Shelly Katz seems to be smarter then the average bear. lol

Here is detailed pic of a authentic NXT made panel. Historical value only for sure. Lots of these on EBay

Attachments

Last edited:

Here is detailed pic of a authentic NXT made panel. Historical value only for sure. Lots of these on EBay

Thats very interesting, thank you for posting.

Thanks for sharing. Interesting (for me) is that they use RCA connectors, which is what I use on my speakers (and on the amp side) too. I don't like banana connectors at all.Here is detailed pic of a authentic NXT made panel. Historical value only for sure. Lots of these on EBay

A friend of mine is the owner of Podium in France. His company manufactured and distributed Podium. The brand is currently inactive. I have the inside story.

That would be interesting to learn. Paul Burton, the original design engineer for Podium, is a member of this site. I think the relationship with Katz deteriorated somewhat ...

Podium Sound planars

Second post in the thread link above from Paul.

“Sorry being so long replying. I only just saw your post.

Yes, it was me. I designed and built the prototypes shown at the Heathrow (London) Hi Fi show last summer. See http://blog.stereophile.com/hifinews2006/ for a photo of the originals (about 2/3 of the way down the report). I finished working on the Podium project last October, and have had little contact since, so I am a bit out of date.

What are they? The Podium 1s are large bending wave panels, using a honeycomb cored, skinned composite panel excited by 5 high-powered NXT-type exciters, in a vertical tapered line array. This can be clearly seen in the photos in the Hi Fi world review just published.

They originals were efficient, wide-band (good to below 40Hz), and as you would expect for a bending wave panel, non-directional, even at high frequencies. They were a diffuse dipole sound source, and so produced a very large room enveloping soundscape with no sense of a sweet spot. They also projected across large rooms unusually well. The originals sounded very fast and dynamic, with good bass weight. Oh, and they played loud too.... even on really tough stuff like the Telarc 1812.

I do not know how many of these original types were sold (if any).

Shelley Katz re-designed the Podiums after I left the project. The new ones have a wood frame and these are what are reviewed in Hi Fi World (July edition). They appear to be based on the original acoustic system I developed, but they have a higher impedance, lower sensitivity, and by the look of the frequency response and comments in the review, a different tonal balance as well.

They were priced at £3,500, but now seem to have gone up to £6,900. Hmm...

The Podium web-site has been down for weeks. I have no idea what is going on, but I saw that they were at the Heathrow show in March, where they were also showing a smaller model with a copper coloured panel and a piano black frame.

Paul.”

Second post in the thread link above from Paul.

“Sorry being so long replying. I only just saw your post.

Yes, it was me. I designed and built the prototypes shown at the Heathrow (London) Hi Fi show last summer. See http://blog.stereophile.com/hifinews2006/ for a photo of the originals (about 2/3 of the way down the report). I finished working on the Podium project last October, and have had little contact since, so I am a bit out of date.

What are they? The Podium 1s are large bending wave panels, using a honeycomb cored, skinned composite panel excited by 5 high-powered NXT-type exciters, in a vertical tapered line array. This can be clearly seen in the photos in the Hi Fi world review just published.

They originals were efficient, wide-band (good to below 40Hz), and as you would expect for a bending wave panel, non-directional, even at high frequencies. They were a diffuse dipole sound source, and so produced a very large room enveloping soundscape with no sense of a sweet spot. They also projected across large rooms unusually well. The originals sounded very fast and dynamic, with good bass weight. Oh, and they played loud too.... even on really tough stuff like the Telarc 1812.

I do not know how many of these original types were sold (if any).

Shelley Katz re-designed the Podiums after I left the project. The new ones have a wood frame and these are what are reviewed in Hi Fi World (July edition). They appear to be based on the original acoustic system I developed, but they have a higher impedance, lower sensitivity, and by the look of the frequency response and comments in the review, a different tonal balance as well.

They were priced at £3,500, but now seem to have gone up to £6,900. Hmm...

The Podium web-site has been down for weeks. I have no idea what is going on, but I saw that they were at the Heathrow show in March, where they were also showing a smaller model with a copper coloured panel and a piano black frame.

Paul.”

Last edited:

Burnt coil,

Thank you so much for the update on the Podium panels and your involvement with them. I am interested in the panel material itself. I have never seen these drivers except in product literature on the internet.

I am a guitar maker and I have used nomex honeycomb on guitar tops ( double top guitars ). Podiums use of Nomex has peaked my curiosity for my DML adventure.

Do you know what the thin composite outer layer on the panel is made of? It appears semi translucent.

The biggest challenge with Nomex is the lamination process. These really appeal to me as an panel with potentially good area density to stiffness ratio

Thank you so much for the update on the Podium panels and your involvement with them. I am interested in the panel material itself. I have never seen these drivers except in product literature on the internet.

I am a guitar maker and I have used nomex honeycomb on guitar tops ( double top guitars ). Podiums use of Nomex has peaked my curiosity for my DML adventure.

Do you know what the thin composite outer layer on the panel is made of? It appears semi translucent.

The biggest challenge with Nomex is the lamination process. These really appeal to me as an panel with potentially good area density to stiffness ratio

Hi davelang,

I have posted a quote from Paul Burton the original designer/developer of the Podium system, I had nothing to do with them, I should be so lucky!

If you click on the link at the top of the post "Podium Sound planars", in blue, it will take you to the original thread. Sorry If I confused you.

I do know a little bit about the Podium panel material, I am interested in making a variant myself.The outer skin of the Podium is a thin MYLAR film, or PET as the generic material. It can be adhered to a Nomex honeycomb using Araladite. However, you may have a better solution to hand with the material used for guitar tops. Nomex honeycomb combined with a thin ply skin could be very good-its the direction I am looking to. If you have made guitars you already know how to laminate them but I make a few suggestions below.

This is a UK source for thin Finnish birch ply which you can get as thin as 0.4mm !

Thin Finnish Birch | Birch Plywood Panels | Latham Timber

I expect you will be able to get a US source as well.

If you want to try the MYLAR route this is a supplier

Mylar Rolls : TAP Plastics

On the lamination process I plan to do the following. I have built large ESL's using a variation on this method and it works quite well.

1) Use slow setting Araldite - there is no need to use the fast setting stuff it will just rush the assembly process

2) Stretch the MYLAR film out over an MDF panel and tape it down to remove wrinkles.

3) Using a roller, roll the Araldite onto one side of the NOMEX Honeycomb

4) Lower the honeycomb onto the MYLAR film

5) Place a second MDF sheet on top of the NOMEX honeycomb.

6) Leave the assembly until the Araldite has set completely- at least 12 hours- you will be stressing the skin when you flip the NOMEX/MYLAR assembly over and you must have a complete bond before doing so

7) When the Araldite has set, move the assembly to one side while you prepare the MYLAR sheet for the second skin.

Repeat the process above for the second side.

If you are making big panels I would suggest you get help from a friend as handling large sheets of NOMEX covered in glue is going to be tricky.

Don't worry about using a bit too much Araldite, it will add relatively little mass and and excess will form beads between the MYLAR film and the NOMEX core- this is a good thing.

CAPS used for clarity, not for shouting I promise!

I hope that helps

Burnt

I have posted a quote from Paul Burton the original designer/developer of the Podium system, I had nothing to do with them, I should be so lucky!

If you click on the link at the top of the post "Podium Sound planars", in blue, it will take you to the original thread. Sorry If I confused you.

I do know a little bit about the Podium panel material, I am interested in making a variant myself.The outer skin of the Podium is a thin MYLAR film, or PET as the generic material. It can be adhered to a Nomex honeycomb using Araladite. However, you may have a better solution to hand with the material used for guitar tops. Nomex honeycomb combined with a thin ply skin could be very good-its the direction I am looking to. If you have made guitars you already know how to laminate them but I make a few suggestions below.

This is a UK source for thin Finnish birch ply which you can get as thin as 0.4mm !

Thin Finnish Birch | Birch Plywood Panels | Latham Timber

I expect you will be able to get a US source as well.

If you want to try the MYLAR route this is a supplier

Mylar Rolls : TAP Plastics

On the lamination process I plan to do the following. I have built large ESL's using a variation on this method and it works quite well.

1) Use slow setting Araldite - there is no need to use the fast setting stuff it will just rush the assembly process

2) Stretch the MYLAR film out over an MDF panel and tape it down to remove wrinkles.

3) Using a roller, roll the Araldite onto one side of the NOMEX Honeycomb

4) Lower the honeycomb onto the MYLAR film

5) Place a second MDF sheet on top of the NOMEX honeycomb.

6) Leave the assembly until the Araldite has set completely- at least 12 hours- you will be stressing the skin when you flip the NOMEX/MYLAR assembly over and you must have a complete bond before doing so

7) When the Araldite has set, move the assembly to one side while you prepare the MYLAR sheet for the second skin.

Repeat the process above for the second side.

If you are making big panels I would suggest you get help from a friend as handling large sheets of NOMEX covered in glue is going to be tricky.

Don't worry about using a bit too much Araldite, it will add relatively little mass and and excess will form beads between the MYLAR film and the NOMEX core- this is a good thing.

CAPS used for clarity, not for shouting I promise!

I hope that helps

Burnt

Last edited:

Mylar? That is surprising. I used to built electrostatics so I still have a little on hand. Thanks for the info! I was a little concerned about asking about a potential trade secret.

For my double top guitars I use epoxy for attaching the nomes to thin spruce veneers. I use epoxy for it thixotropic properties. It will form a nice fillet between the nomex and the veneer and can be applied very sparingly. I vacuum bag one side at a time. That way I can thickness sand the panel, flip it and epoxy the other side and bag it.

I will have to read about Aldarite - never heard of it.

I used to have a Mylar stretching frame... now to find it!

Thanks Burnt for the info and for “clearing up my misunderstanding

Dave

For my double top guitars I use epoxy for attaching the nomes to thin spruce veneers. I use epoxy for it thixotropic properties. It will form a nice fillet between the nomex and the veneer and can be applied very sparingly. I vacuum bag one side at a time. That way I can thickness sand the panel, flip it and epoxy the other side and bag it.

I will have to read about Aldarite - never heard of it.

I used to have a Mylar stretching frame... now to find it!

Thanks Burnt for the info and for “clearing up my misunderstanding

Dave

Mylar? That is surprising. I used to built electrostatics so I still have a little on hand. Thanks for the info! I was a little concerned about asking about a potential trade secret.

For my double top guitars I use epoxy for attaching the nomex to thin spruce veneers. I use epoxy for it thixotropic properties. It will form a nice fillet between the nomex and the veneer and can be applied very sparingly. I vacuum bag one side at a time. That way I can thickness sand the panel, flip it and epoxy the other side and bag it.

I will have to read about Aldarite - never heard of it.

I used to have a Mylar stretching frame... now to find it!

Thanks Burnt for the info and for “clearing up my misunderstanding

Dave

For my double top guitars I use epoxy for attaching the nomex to thin spruce veneers. I use epoxy for it thixotropic properties. It will form a nice fillet between the nomex and the veneer and can be applied very sparingly. I vacuum bag one side at a time. That way I can thickness sand the panel, flip it and epoxy the other side and bag it.

I will have to read about Aldarite - never heard of it.

I used to have a Mylar stretching frame... now to find it!

Thanks Burnt for the info and for “clearing up my misunderstanding

Dave

@davelang

No worries, a light blue link colour on a blue background isn't the most helpful

I haven't heard of Alderite either so don't search for too long : )

You sound as though you are well set if you have a stretching frame, good luck!

Burnt

No worries, a light blue link colour on a blue background isn't the most helpful

I haven't heard of Alderite either so don't search for too long : )

You sound as though you are well set if you have a stretching frame, good luck!

Burnt

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker