Hi X,

Thanks for your reply. I shall get the single sided layout done by someone as I am not comfortable with sprintlayout or other designing tools. But I wanted to make this one as my first class A amp

Regards

Sha

Thanks for your reply. I shall get the single sided layout done by someone as I am not comfortable with sprintlayout or other designing tools. But I wanted to make this one as my first class A amp

Regards

Sha

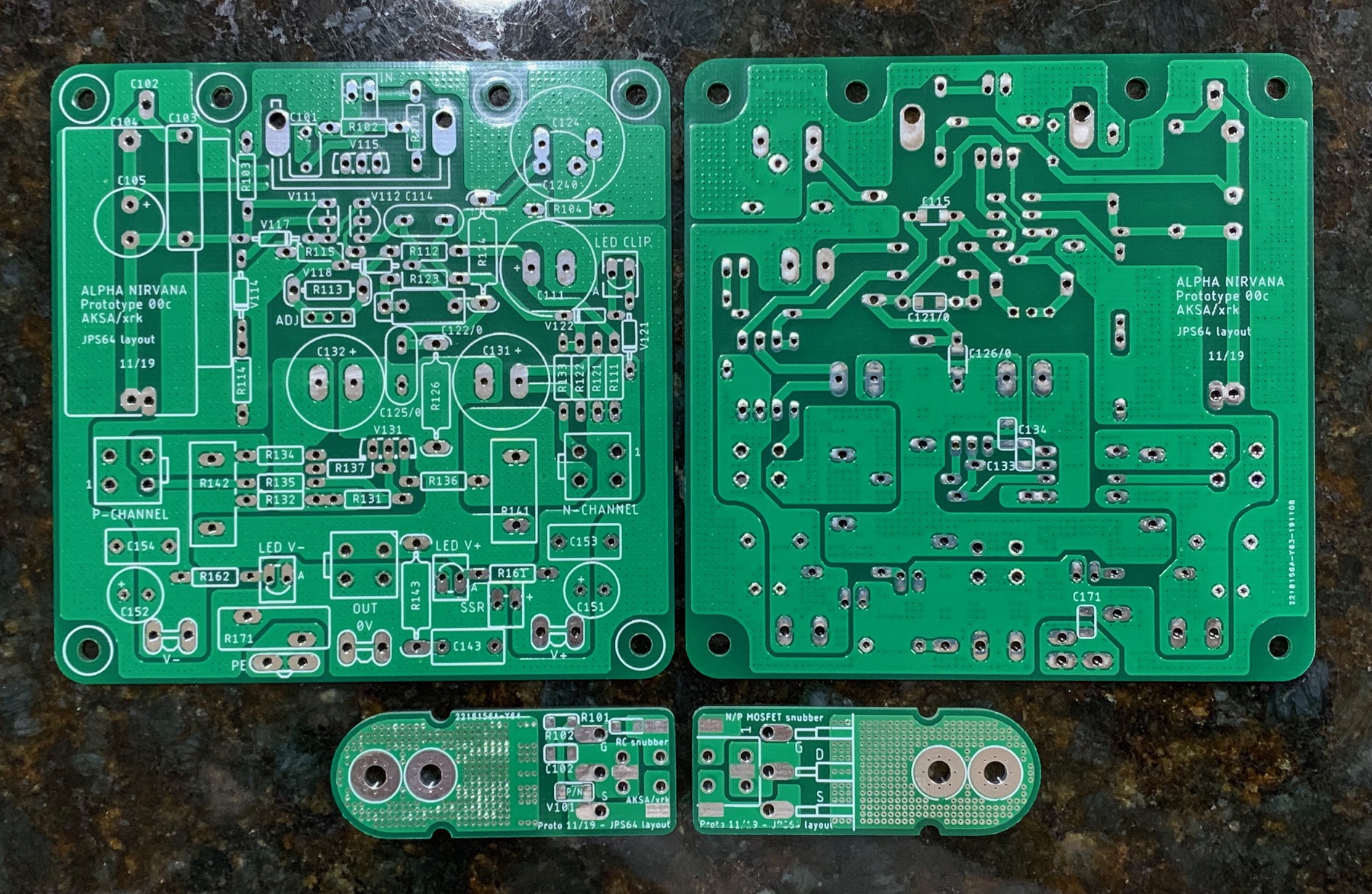

We do indeed have a tested PCB layout:

This is a public and open DIY project. You are free to make your own layout and PCB or do it point to point on perforated veroboard. Note that these are two-sides layouts - not easy to home etch.

avtech23 commented that some people like to draw and the etch their own boards. Whilst I can understand some people like to do this as it gives them the "full DIY experience" ... it's not something I would ever countenance - any more than making my own capacitors!

But here:

... we have a poster who won't actually be doing the PCB creation himself - but will get someone else to do it.

It doesn't make any sense to me that - given he doesn't seem to be driven by the need to do the "full DIY experience" - why he wouldn't choose the PCBs that X has already produced?

After all, it would be a considerable waste of time and money if he soldered all the components onto the boards that he had commissioned ... and then found that the amp didn't work because there was a fault in one of the traces!

At least with X's boards ... you can be confident that the traces are correct (as working amps have been built with them)!

Andy

But here:

Hi X,

Thanks for your reply. I shall get the single sided layout done by someone as I am not comfortable with sprintlayout or other designing tools. But I wanted to make this one as my first class A amp

Regards

Sha

... we have a poster who won't actually be doing the PCB creation himself - but will get someone else to do it.

It doesn't make any sense to me that - given he doesn't seem to be driven by the need to do the "full DIY experience" - why he wouldn't choose the PCBs that X has already produced?

After all, it would be a considerable waste of time and money if he soldered all the components onto the boards that he had commissioned ... and then found that the amp didn't work because there was a fault in one of the traces!

At least with X's boards ... you can be confident that the traces are correct (as working amps have been built with them)!

Andy

Hi Friend,

I can etch the PCBs by my own once I have the layout. Making the right layout for Audio Amps is something which I am lagging here. That's why I thought may be I can ask some one here in my local city to make the layout done.

Also, buying the PCB from X is an option, but ~100USD is a big amount for me.

Hope there is no confusion here

Thank you

Sha

I can etch the PCBs by my own once I have the layout. Making the right layout for Audio Amps is something which I am lagging here. That's why I thought may be I can ask some one here in my local city to make the layout done.

Also, buying the PCB from X is an option, but ~100USD is a big amount for me.

Hope there is no confusion here

Thank you

Sha

Hi Friend,

I can etch the PCBs by my own once I have the layout. Making the right layout for Audio Amps is something which I am lagging here. That's why I thought maybe I can ask some one here in my local city to make the layout done.

Also, buying the PCB from X is an option, but ~100USD is a big amount for me.

Hope there is no confusion here

Thank you

Sha

Understood, Sha.

I hope you are successful in getting someone to do the layout for you - and that it is correct.

Good luck,

Andy

@Andy

First, thanks for all your work on the BOMs. Also, keep us informed as you build the 4R version, I have some speakers rated there and am very interested in your results.

JT

Will do, JT.

But I don't expect to have my 2x stereo 4R Alpha Nirvanas completed ... for 4-6 months.

The aim of the exercise is to:

a) build a pair of stereo amps that can handle 2 ohm ribbons as well as my current (down-rated) NAKSA 80s do, and which

b) sound better!

Andy

Last edited:

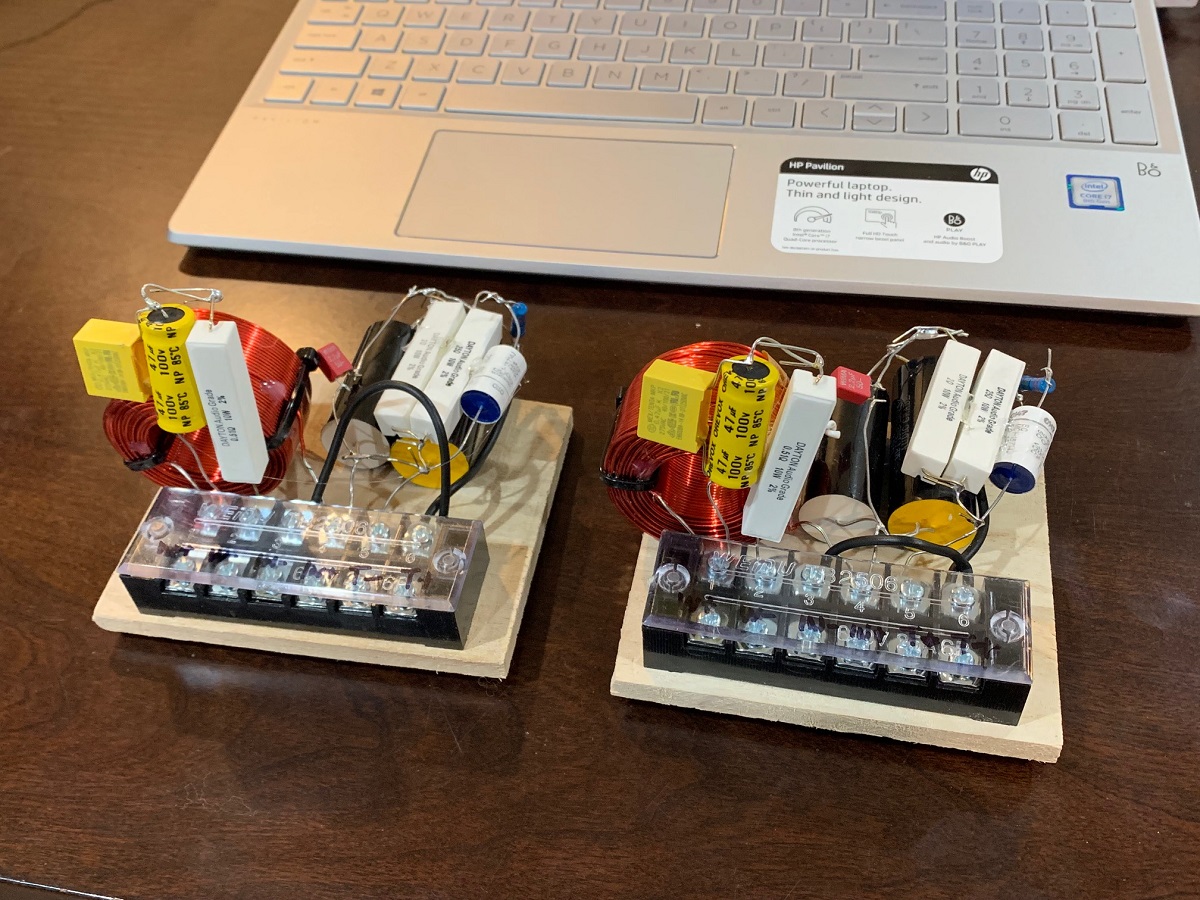

I just built a new set of speakers today and listening to them now with the Alpha Nirvana. They sound very nice - similar to the bigger 10F/RS225 FAST but smaller in a compact bookshelf form. These use the FR58EX full range and AC130F1 woofer in a FAST configuration. Uses a new passive crossover that I just designed a few days ago. I had the AC130F1's already and repurposed and old Boston HD5 cabinet.

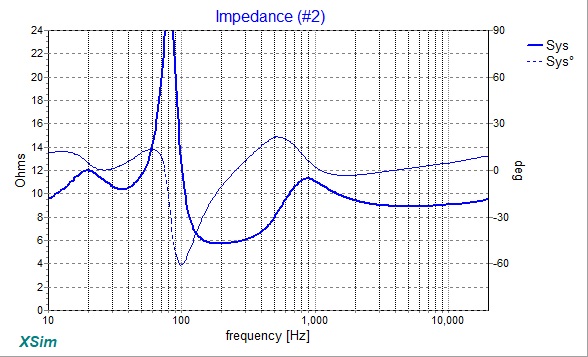

Although this XO dips down to 5.5ohms from nominal 8ohms, it sounds fine:

With the support of a subwoofer for stuff below 100Hz, the speaker works brilliantly.

X,

Good use of Scotchbrite!

Cheers,

Greg

Yes, cleans pots and pans AND improves imaging and soundstage!

Over the years I've tried many tweeter dampening schemese, and I've settled on that just thin strips of weather sealing foam with one additional piece in the vertical plane just below the dome works really well.

Of course, neoprene across the baffle is even better, but this quick solution generates really good results. This is one of those things there's a very slight difference with on-axis measurement, but what it really can fix is off-axis, late arrival reflections.

Cheers,

Greg

Attachments

Last edited:

This is a bit OT, but I will indulge myself one more time. I haven’t tried hanging a cantilever of foam in front of the tweeter. Is your photo supposed to be rotated 90 so that the cantilever is from bottom going up? Do you have measurements before and after?

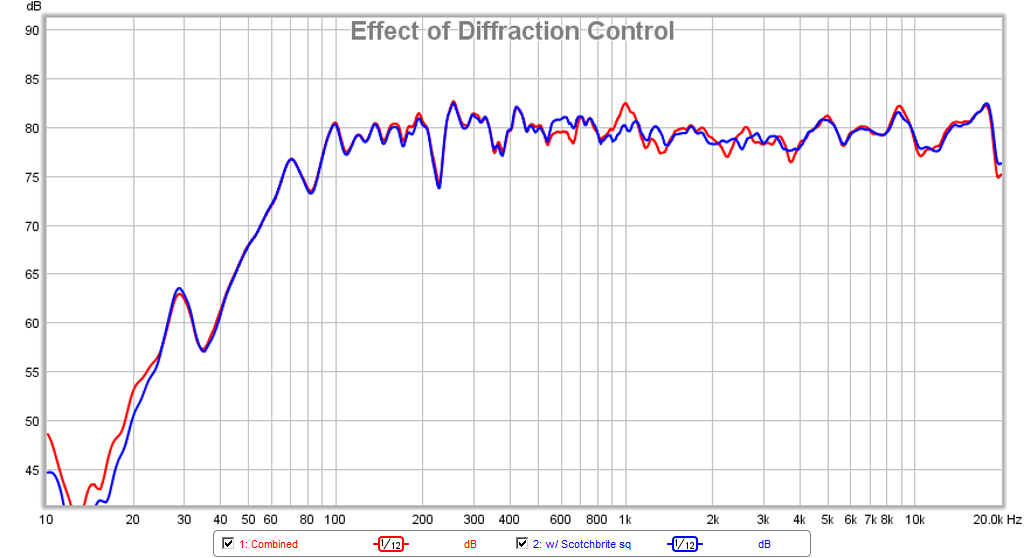

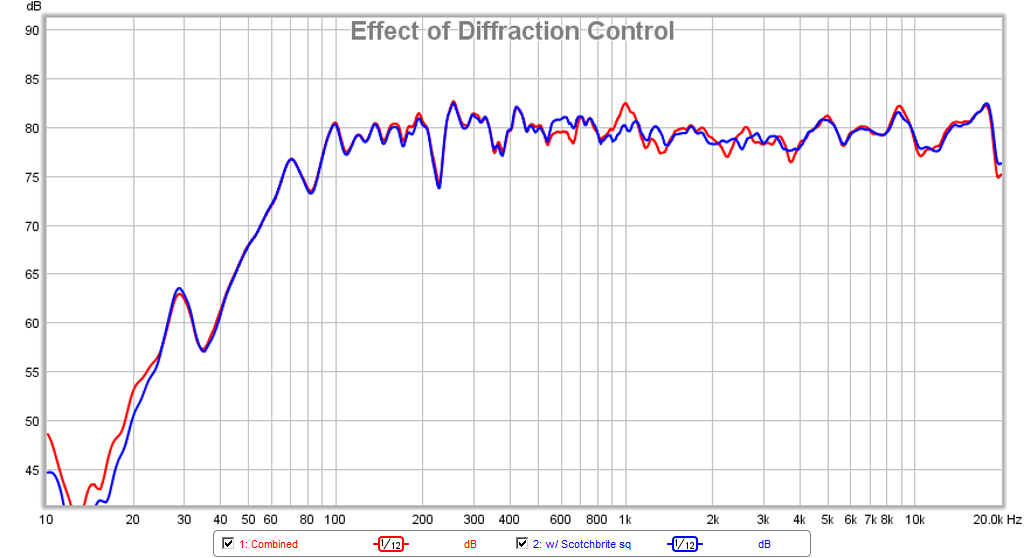

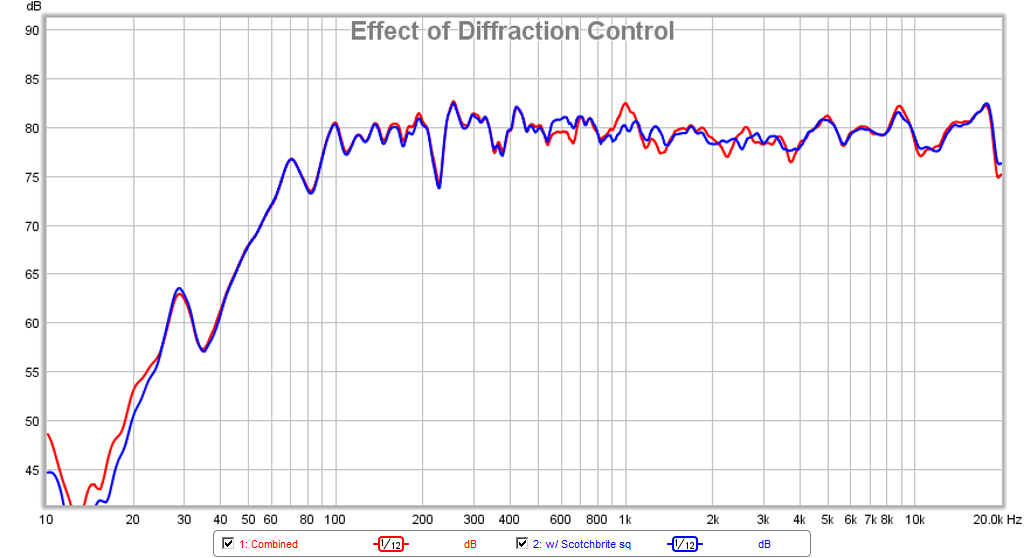

Here’s what the Scotchbrite does. Certainly one of the best bang for your buck mods to a speaker. If you look at the famous LS3/5A’s and also Dunlavey SC-IV, you’ll notice similar treatments.

More info here:

FR58EX and AC130F1 micro-FAST / WAW

Here’s what the Scotchbrite does. Certainly one of the best bang for your buck mods to a speaker. If you look at the famous LS3/5A’s and also Dunlavey SC-IV, you’ll notice similar treatments.

More info here:

FR58EX and AC130F1 micro-FAST / WAW

This is a bit OT, but I will indulge myself one more time. I haven’t tried hanging a cantilever of foam in front of the tweeter. Is your photo supposed to be rotated 90 so that the cantilever is from bottom going up? Do you have measurements before and after?

Here’s what the Scotchbrite does. Certainly one of the best bang for your buck mods to a speaker. If you look at the famous LS3/5A’s and also Dunlavey SC-IV, you’ll notice similar treatments.

More info here:

FR58EX and AC130F1 micro-FAST / WAW

Hi X - I'm interested in your explanation of why your plot shows a steep drop at about 18kHz.

I've measured a similar drop with my own system - although it was at a slighter lower frequency ... 16kHz!

Given my Maggie ribbons are specced to 40kHz ... my conclusion was this was a microphone measurement artefact - not a physical problem with the ribbons themselves.

However, another possibility is that the (down-rated) NAKSA 80 I am using to drive the ribbons is actually unable to cope well with my 2 ohm ribbons - so its FR droops above 16kHz?? (Hence my desire to try out an AN 4R on the ribbons!

What is your opinion of your FR droop, X?

Andy

If you are using a active setup with DSP, it may be the built in brick wall filter at 20kHz. I am using a miniDSP UMIK-1 which is USB based. It may also have a built in filter on the top. Many full range driver falloff at 16kHz. But in the case of your ribbons it is most likely the mic or ADC or the excitation source DAC.

If you are using a active setup with DSP, it may be the built in brick wall filter at 20kHz. I am using a miniDSP UMIK-1 which is USB based. It may also have a built in filter on the top. Many full range driver falloff at 16kHz. But in the case of your ribbons it is most likely the mic or ADC or the excitation source DAC.

Makes sense - thanks, X.

I'll have to wait until I can do a repeat REW measurement when the AN 4Rs are finished.

Andy

Beware: the Alpha Nirvana Mouser shopping cart posted on #1 is incomplete and probably the same applies to Andyr's BOMS.

1. snubber boards SMDs should be doubled (R1001, R1002, C1002, V1001)

2. TO-247 output insulators should be doubled as well.

It is very annoying to discover that after unpacking the Mouser shipment and getting ready to solder

Jacques

1. snubber boards SMDs should be doubled (R1001, R1002, C1002, V1001)

2. TO-247 output insulators should be doubled as well.

It is very annoying to discover that after unpacking the Mouser shipment and getting ready to solder

Jacques

Hi Jacques,

Sorry about what happened- but that is strange and I am not sure what happened but I just checked the link for the shopping cart and those items are there. I know that the BOM and shopping cart worked for both myself and Vunce. We did not have to order any “missing” parts. If you look at the shopping cart linked at the bottom of Post 1, row 15 (from top) is C1002, rows 53/54 are R1001/1002, V1001 is 8 rows down. We normally don’t spec thermal insulator pads as that is usually a choice people have - and I recommend ceramic ones with thermal paste since the heat output is very high. Silicone is probably not sufficient. These all seem to be related to the snubber boards so that doesn’t stop you from beginning your soldering.

Here is the link from the first post:

Mouser Electronics

Edit: I see you are saying the parts were there but quantity was insufficient for two snubbers. So all I can say is that it’s up to the user to double check and verify the quantities of a shopping cart with how many amps they intend to build. It was a great convenience to have a shopping cart, but it seems both Vunce and myself did not have the problem because we verify quantity as part of our standard operating procedure without thinking. I’ll put a note in Post 1 or see if I can edit the cart.

Sorry about what happened- but that is strange and I am not sure what happened but I just checked the link for the shopping cart and those items are there. I know that the BOM and shopping cart worked for both myself and Vunce. We did not have to order any “missing” parts. If you look at the shopping cart linked at the bottom of Post 1, row 15 (from top) is C1002, rows 53/54 are R1001/1002, V1001 is 8 rows down. We normally don’t spec thermal insulator pads as that is usually a choice people have - and I recommend ceramic ones with thermal paste since the heat output is very high. Silicone is probably not sufficient. These all seem to be related to the snubber boards so that doesn’t stop you from beginning your soldering.

Here is the link from the first post:

Mouser Electronics

Edit: I see you are saying the parts were there but quantity was insufficient for two snubbers. So all I can say is that it’s up to the user to double check and verify the quantities of a shopping cart with how many amps they intend to build. It was a great convenience to have a shopping cart, but it seems both Vunce and myself did not have the problem because we verify quantity as part of our standard operating procedure without thinking. I’ll put a note in Post 1 or see if I can edit the cart.

Last edited:

Hi X,

Thank you for your reply. As you mention, the initial BOM is not sufficient for one complete build.

Luckily I ordered a 2xBOM so I can at least complete two snubbers out of four and test one channel.

This is the first time I order a precompiled BOM and also the last time.

Lesson learnt

Jacques

Thank you for your reply. As you mention, the initial BOM is not sufficient for one complete build.

Luckily I ordered a 2xBOM so I can at least complete two snubbers out of four and test one channel.

This is the first time I order a precompiled BOM and also the last time.

Lesson learnt

Jacques

You will always need to check the parts in the cart and also the numbers, but this is a DIY. I applaud people that take the time to share, with no gain, other than to try and help the DIY community. I have found that the carts have saved me countless hours and frustration in getting my builds together. I can't tell you how many package errors I've made on my own.

Before anyone gets their panties in a wad, they might take a breath and realize people don't have an obligation to share and are less likely to do so when taken to task for trying to help.

JT

Before anyone gets their panties in a wad, they might take a breath and realize people don't have an obligation to share and are less likely to do so when taken to task for trying to help.

JT

Before anyone gets their panties in a wad, they might take a breath and realize people don't have an obligation to share and are less likely to do so when taken to task for trying to help.

JT

+1

- Home

- Amplifiers

- Solid State

- Alpha Nirvana 39w 8ohm Class A Amp