How big should the holes be in a Unity horn?

If I were you, I wouldn't use holes. The design of the ducts on the Synergy horn and the Yorkville Unity horn is superior. This makes a BIG and measurable difference on the performance. If you *must* use a hole, put it at a location that's 1/4 wavelength from the upper limit of the midrange. So if you want to run the midrange to 2000hz, put the center of the hole 1.6875 inches from the throat. (13500 inches per second / 2000hz / 4)

[*]Consider using a different midrange. After using a "real" unity midrange, and a cheap tang band on a Unity horn, I personally prefer the Tang Band. It isn't easy to work with, since you have to seal the enclosure by hand. But once you do that, the W2-852SH is small enough to couple very VERY close to the throat of the waveguide and this allows you to cross the compression driver higher, run the midranges higher, and use smaller ducts. All three things improve the midrange of a Unity horn.

Thanks for that. Somewhat OT, but since you started the thread and brought it up, I've wanted to raise the crossover point from the CD to the mids. I'd like to push it up closer to 2kHz. The Tang Bands look interesting. Can you point to some pictures of the mid entry holes/ducts that you recommend? Any additional tips on positioning? Thoughts on rear enclosure size?

Sheldon

Thanks for that. Somewhat OT, but since you started the thread and brought it up, I've wanted to raise the crossover point from the CD to the mids. I'd like to push it up closer to 2kHz. The Tang Bands look interesting. Can you point to some pictures of the mid entry holes/ducts that you recommend? Any additional tips on positioning? Thoughts on rear enclosure size?

Sheldon

I am running the Tang Bands in my car on Unity waveguides, along with the Misco sealed back midranges on a horn. A pair of Tang Bands has slightly higher efficiency, and measures better, than the Misco mids.

This was completely unexpected - you would think a crummy little 2" computer speaker wouldn't perform so well.

Admittedly, the horns that I'm using for the Misco are *anything* but ideal, while the waveguides that I'm using for the Tang Bands are close to perfect, so that has a lot to do with it.

Anyways, the TBs are very unique, and offer excellent performance.

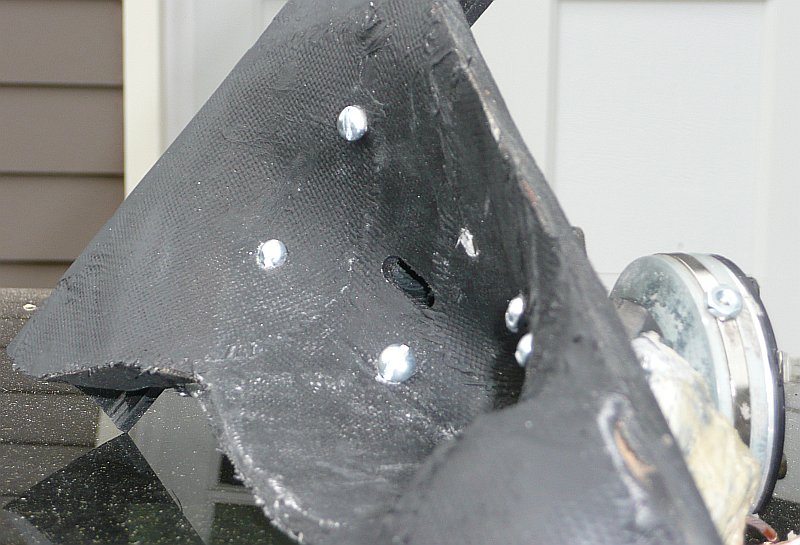

Here's some pics of the entry slit. The front side is copied off the Yorkville Unity, and the back side is copied off the Synergy Horn. You want the holes as shallow as humanly possible; that's why I went to all the trouble of grinding down the plate where the midranges enter the horn. With the Misco mids, you could probably get up to 2khz if you made the holes shallower. But it has to be a smooth transition, to reduce turbulence. It's basically a miniature version of the last picture, which is a subwoofer port.

The Durango '95 - diyAudio

Also, it's a holiday, so I'm building a Unity horn for the house. It will like be used outdoors. It's pretty darn close to the Lambda Unity Horn, so it should be an interesting read.

Thanks. One reason I was interested in trying some smaller drivers, has to do with phasing (if that's the right word here). The original 5" drivers have about a 4" diaphragm. This is significant, as compared the the higher wavelength at the higher frequencies near crossover. As the entry holes are near the edge of the cone, I would think that there would have to be some effect on these frequencies.

In a compression driver, the phasing plug equalizes the path length from diaphragm to the smaller exit. I would think we would want the same thing here, but it's not practical. However, by using a much smaller diameter driver, we might minimize this issue (to the extent that it is an audible issue). The 2" driver should be better in this regard, than the regular driver. TB also makes several 1" drivers. Parts-Express.com: Tang Band W1-1828S 1" Neodymium Full Range Driver | Tang Band W1-1828S 1" speaker Full Range Driver full range tb speakers neodymium driver line array point source midrange home theater computer speaker center channel set tube ampl I'm tempted to play with them. Thoughts?

Sheldon

In a compression driver, the phasing plug equalizes the path length from diaphragm to the smaller exit. I would think we would want the same thing here, but it's not practical. However, by using a much smaller diameter driver, we might minimize this issue (to the extent that it is an audible issue). The 2" driver should be better in this regard, than the regular driver. TB also makes several 1" drivers. Parts-Express.com: Tang Band W1-1828S 1" Neodymium Full Range Driver | Tang Band W1-1828S 1" speaker Full Range Driver full range tb speakers neodymium driver line array point source midrange home theater computer speaker center channel set tube ampl I'm tempted to play with them. Thoughts?

Sheldon

Yes, that is exactly what I would recommend. Put the horn in a box, and add a roundover to the enclosure.

I think maybe you agree too quickly? I'm not entirely sure we are agreeing

to agree to the same agreement yet, or yet something entirely different?

You do realize I am talking a flexible roundover (like the foam surrounding

a cone loudspeaker) applied as a passive radiator over a tuned peripheral

slot (tuned to buck the baffle step frequency from too easily turning the

corner), and abusing any air inside the box (on the back of the horn) to

achieve that tuning???

My concern was the baffle step frequency must drive the volume of air

trapped in the box (the Chaparral ring), but not the whole half space

behind the enclosure. Is this correct math for how such a slot would

work, or not? That was the question!

PB, I've read your comment in a few places that you would go with a slot rather than a circular hole but haven't noticed the explanation behind it. (I likely just overlooked it). Is there something that shows up in the measurements or this purely a subjective preference. Having heard both a lambda based unity system and the U215, I felt the Lambda was very clearly better, but I had just explained it away as the difference between a hifi speaker and a commercial speaker, the latter of which would have been held to significantly stricter budget constraints. Did the yorkville change from a round hole to a slot, or did I not look as closely as I thought I did? I heard the U215 shortly after its release, so I could be just dealing with a noncurrent design.

Can you point me to an explanation or post one here?

Also, I would anticipated that when you say you want the material as thin as possible, that you'd need to adjust the area of the port opening as well?

Can you point me to an explanation or post one here?

Also, I would anticipated that when you say you want the material as thin as possible, that you'd need to adjust the area of the port opening as well?

Last edited:

Hi PB,

From your experience, if I would like to experiment with the midrange horn for auto use (under dash), which driver you recommend now? Does the shape of the horn even matter? Any calculation for your design?

Also, for treble waveguide for use with compression driver, which can I use that has good performance but not too expensive?

Can I use 3/8" mdf to make a horn? That seems easy enough to do. I really like to experiment with compression driver & waveguide like the USD one.

Thanks and regards,

Ben

From your experience, if I would like to experiment with the midrange horn for auto use (under dash), which driver you recommend now? Does the shape of the horn even matter? Any calculation for your design?

Also, for treble waveguide for use with compression driver, which can I use that has good performance but not too expensive?

Can I use 3/8" mdf to make a horn? That seems easy enough to do. I really like to experiment with compression driver & waveguide like the USD one.

Thanks and regards,

Ben

Hi PB,

From your experience, if I would like to experiment with the midrange horn for auto use (under dash), which driver you recommend now?

It would be wonderful if horns worked like conventional enclosures, where you can basically tweak a few parameters, and get smooth response over five or six octaves.

Unfortunately, horns don't work like that. Horns are bandpass devices, and they work over a narrow spectrum.

This thread explains all the math:

http://www.diyaudio.com/forums/multi-way/88237-suitable-midrange-cone-bandpass-mid-unity-horn.html

In a nutshell, I cannot recommend a woofer to you because I do not know what frequency range you are trying to cover. But the math is right there in the thread. If you pick a woofer with the wrong parameters, you won't get good results. Finding a woofer with the correct parameters is the key.

Does the shape of the horn even matter? Any calculation for your design?

IMHO, people obsess way too much over the shape of the horn. The USD and Image Dynamics horns are grossly misshapen, but they work. I think they're a good example of how far you can bend the rules when it comes to horn shape.

IMHO, what IS important is your choice of horn driver, the termination of the horn, the construction of the horn, and to a certain extent, the shape. I can't stress how important termination is.

Also, for treble waveguide for use with compression driver, which can I use that has good performance but not too expensive?

The Celestion CDX1-1425 is the only compression driver under a hundred bucks that's impressed me. I haven't used the new Seleniums, but I've heard good things.

Celestion CDX1-1425 (drivervault)

Can I use 3/8" mdf to make a horn? That seems easy enough to do. I really like to experiment with compression driver & waveguide like the USD one.

Thanks and regards,

Ben

Fiberglass works a lot better 😉

But sure, wood works. Have you checked out my Durango '95 project? That's a wood horn, and it's really easy to build. It uses 3/8" plywood, which works a lot better than MDF.

I've been messing with Smith horns of late. These present a particularly

convenient pair of flat surfaces for mounting midrange drivers as a Unity.

Is the idea completely broken before it begins?

This is kind of a tricky one. In the last post I basically said that horn shape doesn't matter a whole lot. But I have to tell you, the waveguides on my dash measure waaaaaaay better than the horns under my dash. I've published the results - you can see for yourself.

The problem isn't the SHAPE, it's the size. That's what's screwing up the response. As the size of a horn gets too small, the frequency response starts to go to hell. As a horn plays lower and lower, the horn starts to buzz quite a bit too.

Hope that helps. If you're going to use a horn that's dramatically mis-shaped and smaller than it should be, be prepared to deal with some serious dips and peaks in the frequency response.

This is one of the reasons I like tapped horns so much - you can make them very VERY small, without screwing up the response.

I'll be quite interested in your assessment of the imaging of the final revision. "Common" sense would seem to indicate blooming and collapsing as you transition from two midrange sources to a single high frequency source. You seem to be headed for a disperse field behind the listener for the midbass which is a fairly well developed strategy and shouldn't be too challenging to integrate. Overall, this thread has drawn me like a black hole and I greatly appreciate your sharing of results that might take me years to work out for myself.

This morning I received the following email:

Subject: Summa Auto Replica

> From: someone@somewhere.com

>

> This is the message:

>

> Hello Bateman,

>

> I have sent you a couple emails before with no responses. I am sure you get plenty of emails from diyma members wanting to know something or another.

>

> I love your posts but always go back to one question in my mind. If we both have the Summa as a reference then why not just try to replicate a similar solution?

>

> Directivity control is there, mounting a shallow horn in the kick panel should be realistic and getting the mids under the dash is doable with the use of small drivers. Granted, this does not get the image up on the dash but I just don't see something looking half-way decent unless it is a mid covering 1k and up loaded on the a-pillar.

>

> So, why not just use this as the goal?

>

The best polar response that I've ever measured in a car was using a Geddes-style waveguide.

This is the polar response of a treated and untreated Geddes style waveguide, driven by a Celestion compression driver, mounted in the kick panels of my Accord coupe. You can see that the polar response is about as good as it's going to get in a car. (A 1khz sound wave is 13.5" long, so controlling directivity below that point is very difficult due to the sheer wavelength.)

This is the polar response of a treated and untreated Geddes style waveguide, driven by a Celestion compression driver, mounted in the kick panels of my Accord coupe. You can see that the polar response is about as good as it's going to get in a car. (A 1khz sound wave is 13.5" long, so controlling directivity below that point is very difficult due to the sheer wavelength.)

Here's a pic of the waveguides. I took this pic off Brandon's page.

Here's a pic of the waveguides. I took this pic off Brandon's page.

The reason that I don't use this solution, and would not recommend it, is that I don't like my soundstage at knee-level. Also, I've found that the Summas are very sensitive to diffraction. For instance, if there's anything within a foot or two of the waveguide, it makes an audible difference. Most speakers don't behave like this. (I think this is because most speakers have so much diffraction off the cabinet, additional diffraction from the room itself is less noticeable.)

Anyways, even though the waveguides measure nice in the kick panel, I couldn't live with diffraction and reflection off the driver, passenger, and steering wheel. That's why my waveguides are on the dash.

You really gotta hear it, the difference isn't subtle.

Subject: Summa Auto Replica

> From: someone@somewhere.com

>

> This is the message:

>

> Hello Bateman,

>

> I have sent you a couple emails before with no responses. I am sure you get plenty of emails from diyma members wanting to know something or another.

>

> I love your posts but always go back to one question in my mind. If we both have the Summa as a reference then why not just try to replicate a similar solution?

>

> Directivity control is there, mounting a shallow horn in the kick panel should be realistic and getting the mids under the dash is doable with the use of small drivers. Granted, this does not get the image up on the dash but I just don't see something looking half-way decent unless it is a mid covering 1k and up loaded on the a-pillar.

>

> So, why not just use this as the goal?

>

The best polar response that I've ever measured in a car was using a Geddes-style waveguide.

The reason that I don't use this solution, and would not recommend it, is that I don't like my soundstage at knee-level. Also, I've found that the Summas are very sensitive to diffraction. For instance, if there's anything within a foot or two of the waveguide, it makes an audible difference. Most speakers don't behave like this. (I think this is because most speakers have so much diffraction off the cabinet, additional diffraction from the room itself is less noticeable.)

Anyways, even though the waveguides measure nice in the kick panel, I couldn't live with diffraction and reflection off the driver, passenger, and steering wheel. That's why my waveguides are on the dash.

You really gotta hear it, the difference isn't subtle.

... if there's anything within a foot or two of the waveguide, it makes an audible difference. Most speakers don't behave like this. (I think this is because most speakers have so much diffraction off the cabinet, additional diffraction from the room itself is less noticeable.)

A point that I have noticed as well and commented on. I see pictures all the time of speakers sitting with clutter all around. I hope no one does this with my speakers, because it makes a difference.

I've been emailed about replicating this project, and it got me thinking about some of the issues with the project, and how they can be solved.

Here's the polar response of the project. This includes the BMS compression drivers, the TangBand midranges on the Unity waveguide, and the Misco horns under the dash.

This graph shows you the problems with the project:

Here's the power response and the polar response of a USD Audio horn, which fits under the dash of my car. The top graph is with the "stock" compression driver. The bottom is with a JBL 2470, which I've modded extensively. The modifications include an aluminum diaphragm, a roundover on the horn, and Geddes-style foam inside.

Here's the power response and the polar response of a USD Audio horn, which fits under the dash of my car. The top graph is with the "stock" compression driver. The bottom is with a JBL 2470, which I've modded extensively. The modifications include an aluminum diaphragm, a roundover on the horn, and Geddes-style foam inside.

The JBL clearly can't match the extension of my Unity waveguides, but it's hard to ignore that it gets down to 500hz. The BMS can't even get close; it's too small.

I won't lie, I'm not a big fan of horns under the dash. But here's an idea I had. The big problem with the project that I've documented in this thread is that there's a big fat hole in the response from 100hz to 400hz. That's only two octaves, but it's a very important one.

I won't lie, I'm not a big fan of horns under the dash. But here's an idea I had. The big problem with the project that I've documented in this thread is that there's a big fat hole in the response from 100hz to 400hz. That's only two octaves, but it's a very important one.

So here's a crazy idea. It's an under dash Unity horn. By using the JBL compression drivers instead of the BMS, we can drop the F3 on the Unity horns from 400Hz to 200Hz, maybe even 150Hz.

The only other option that I can think of to solve this is to make the Unity waveguides on the dash into a three-way. In this pic, you can see that there's really no more room. The problem with putting the waveguide on the dash isn't fitting the waveguide - it's fitting the woofers! There's not a lot of room up there, particularly on the driver's side.

The only other option that I can think of to solve this is to make the Unity waveguides on the dash into a three-way. In this pic, you can see that there's really no more room. The problem with putting the waveguide on the dash isn't fitting the waveguide - it's fitting the woofers! There's not a lot of room up there, particularly on the driver's side.

Here's the polar response of the project. This includes the BMS compression drivers, the TangBand midranges on the Unity waveguide, and the Misco horns under the dash.

This graph shows you the problems with the project:

- We have enough efficiency to EQ this any way we'd like. Which is what I'm doing at the moment. The problem is that we don't have enough displacement to play below 400hz, and the polar response from 400 to 1600hz is poor.

- No amount of DSP or EQ can fix the problems with displacement and polar response; this can only be fixed with a larger waveguide, larger woofers, or woofers with more excursion.

The JBL clearly can't match the extension of my Unity waveguides, but it's hard to ignore that it gets down to 500hz. The BMS can't even get close; it's too small.

So here's a crazy idea. It's an under dash Unity horn. By using the JBL compression drivers instead of the BMS, we can drop the F3 on the Unity horns from 400Hz to 200Hz, maybe even 150Hz.

Instead of building a new horn under the dash, or trashing my USD horns, I decided to use one of my old designs to see if this will work.

(Read the last post for more info on today's project.)

IIRC, I built this horn almost a decade ago, back in 2002 or so. It's a tractrix profile that's been chopped down to fit under the dash of a car. It's similar to the USD horns, but without a diffraction slot, and no bend. (The bend in the USD horn creates a notch in the response, see some of my old threads for the measurements.)

I'm turning the horn into a Unity horn. Up until now, I've used woofers that are good for horn loading on my Unity horns. This time around, I decided to use a cheap a/v speaker from Peerless. This particular unit is $15 from Parts Express and Madisound. It's parameters are crummy for horn loading, but I'm curious to see if it will work.

I'm turning the horn into a Unity horn. Up until now, I've used woofers that are good for horn loading on my Unity horns. This time around, I decided to use a cheap a/v speaker from Peerless. This particular unit is $15 from Parts Express and Madisound. It's parameters are crummy for horn loading, but I'm curious to see if it will work.

Here's the throat chamber, which mates to the horn. I really wanted to take a good pic of this, since the shape is an important part of the Unity design. In this detail pic you can see that the area of the port is deeply routed. This reduces turbulence, and basically makes a small port act like a bigger one. This is because the average diameter of the port is larger than if the walls were straight. Check out the patent on the Synergy Horn for more details. Also, the port is a slot instead of a cylinder. A cylindrical port, like the ones on the Lambda Unity, doesn't seem to work as well as a slot port. The Yorkville Unity uses a slot port.

Here's the throat chamber, which mates to the horn. I really wanted to take a good pic of this, since the shape is an important part of the Unity design. In this detail pic you can see that the area of the port is deeply routed. This reduces turbulence, and basically makes a small port act like a bigger one. This is because the average diameter of the port is larger than if the walls were straight. Check out the patent on the Synergy Horn for more details. Also, the port is a slot instead of a cylinder. A cylindrical port, like the ones on the Lambda Unity, doesn't seem to work as well as a slot port. The Yorkville Unity uses a slot port.

The volume of the rear chamber and the front chamber is rather important. If the rear chamber is too big, the Fb of the enclosure will be too low. If the Fb is too low, there will be gap in the response between the compression driver and the midrange. For the Peerless, I aimed for an Fb of 350hz. That should give us a bandwidth of about 175hz to 700hz.

The volume of the rear chamber and the front chamber is rather important. If the rear chamber is too big, the Fb of the enclosure will be too low. If the Fb is too low, there will be gap in the response between the compression driver and the midrange. For the Peerless, I aimed for an Fb of 350hz. That should give us a bandwidth of about 175hz to 700hz.

Of course all of this is just theory - we really won't know how much bandwidth we'll get from the Peerless until we build the thing, which is why I did this "proof of concept."

Staring down the throat, you can see that the slot port is a nice match for this horn. You can also see that the two sources are very close together, which is a huge part of "the unity magic."

Staring down the throat, you can see that the slot port is a nice match for this horn. You can also see that the two sources are very close together, which is a huge part of "the unity magic."

There are pros and cons to moving the port very close to the compression driver; if anyone is curious about those pros and cons I can write a post about that.

As mentioned in my last post, one of the issues I ran into with the Unity waveguides up on the dash is that there's literally no room for more woofers. Normally the waveguides gets to be too big, but in my case, the sheer size of the drivers themselves is a real problem. I already have two woofers and a compression driver on the dash; there's not room for any more. I took this pic to demonstrate the sheery size of of the 2470 compression driver, with the Peerless woofer bolted onto the horn in a Unity configuration. To the left is an 18sound waveguide. As you can see, the drivers themselves take up more space than the horn! Luckily, there's quite a bit of space UNDER the dash. It's getting things ON the dash that's a problem.

As mentioned in my last post, one of the issues I ran into with the Unity waveguides up on the dash is that there's literally no room for more woofers. Normally the waveguides gets to be too big, but in my case, the sheer size of the drivers themselves is a real problem. I already have two woofers and a compression driver on the dash; there's not room for any more. I took this pic to demonstrate the sheery size of of the 2470 compression driver, with the Peerless woofer bolted onto the horn in a Unity configuration. To the left is an 18sound waveguide. As you can see, the drivers themselves take up more space than the horn! Luckily, there's quite a bit of space UNDER the dash. It's getting things ON the dash that's a problem.

I still prefer the sound of waveguides ON the dash - it's the ultimate soundstage. But there's no ignoring the fact that it's easier to mount drivers UNDER the dash. Located there, the horns are virtually invisible, particularly if you paint them to match the car.

I've finished some crude ground plane measurements of this Unity horn, and I'll post those in the next few days.

(Read the last post for more info on today's project.)

IIRC, I built this horn almost a decade ago, back in 2002 or so. It's a tractrix profile that's been chopped down to fit under the dash of a car. It's similar to the USD horns, but without a diffraction slot, and no bend. (The bend in the USD horn creates a notch in the response, see some of my old threads for the measurements.)

Of course all of this is just theory - we really won't know how much bandwidth we'll get from the Peerless until we build the thing, which is why I did this "proof of concept."

There are pros and cons to moving the port very close to the compression driver; if anyone is curious about those pros and cons I can write a post about that.

I still prefer the sound of waveguides ON the dash - it's the ultimate soundstage. But there's no ignoring the fact that it's easier to mount drivers UNDER the dash. Located there, the horns are virtually invisible, particularly if you paint them to match the car.

I've finished some crude ground plane measurements of this Unity horn, and I'll post those in the next few days.

It seems like it would be easy enough to cut holes in the dash and mount the drivers inside and design a horn that would come up out of the dash by the windshield.

You might have to re route some HVAC ducts and lose the passenger side airbag but it seems possible

-Josh

You might have to re route some HVAC ducts and lose the passenger side airbag but it seems possible

-Josh

It seems like it would be easy enough to cut holes in the dash and mount the drivers inside and design a horn that would come up out of the dash by the windshield.

You might have to re route some HVAC ducts and lose the passenger side airbag but it seems possible

-Josh

If you pay close attention to the dimensions near the waveguide, you can reduce it's footprint by fifty or even eighty percent. This allows you to get good coverage with a waveguide that's much smaller than it should be. Basically the boundaries extend the WG. I have abandoned the project documented in this thread, and started a new one. If you'd like to follow the new one, here it is:

Unity V: The Midbass Strikes Back - DIY Mobile Audio

Patrick Bateman;1921456That's not my cat. But she does a good job of demonstrating the scale of this waveguide