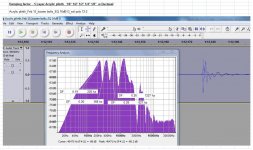

In post #510, I was optimistic about that 5 layer Acrylic combination when I tested a 4"x4" mock up. Here's the results for a 19" x 15" (plinth size). It was the same layers - 1/8", 1/4", 1/2", 1/4", 1/8" with Ductseal pressed in between the layers.

It's not as impressive as a full size combination. Every resonant point is well below my DF=0.35 target. I'm guessing it's still better than MDF or similar, but no cigar just yet.

H

It's not as impressive as a full size combination. Every resonant point is well below my DF=0.35 target. I'm guessing it's still better than MDF or similar, but no cigar just yet.

H

Attachments

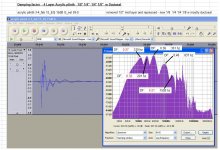

I removed the 1/2" layer from the middle and reassembled and clamped to get a 4 layer combination. This time it's 1/8", 1/4", 1/4" and 1/8" and mostly Ductseal as the 3 elastic layers in between... Better!

I'm thinking I may buy two more sheets an see how a 6 layer combination performs.

Cats Squirrel has also convinced me I should rework my test gear. You may see this one tested again later.

I'm thinking I may buy two more sheets an see how a 6 layer combination performs.

Cats Squirrel has also convinced me I should rework my test gear. You may see this one tested again later.

Attachments

I wonder if this would be a good and easy solution? - or sheets if available?I removed the 1/2" layer from the middle and reassembled and clamped to get a 4 layer combination. This time it's 1/8", 1/4", 1/4" and 1/8" and mostly Ductseal as the 3 elastic layers in between... Better!

I'm thinking I may buy two more sheets an see how a 6 layer combination performs.

Cats Squirrel has also convinced me I should rework my test gear. You may see this one tested again later.

Double Sided Butyl Tape Used for Membrane Jointing, Waterproofing, Pond Liner Repair (50MM X 1.5MM X 10M)

Brand: Polyloc

Mike,

Thanks. I think it would give some amount of damping. For CLD, the idea is to get the layers very thin, so 1.5mm may be a bit heavy. Is there a thinner version?

I think the Blue Skin is about 0.5 mm thick. I'll measure it if I buy some later. My scheme would be to use the self adhesive on one side and contact cement on the other.

I also found that the craft chain "Michaels" offers transfer tape at reasonable prices. I may try one of those too. It may infer whether the 3M version is worth buying.

Hugh

Thanks. I think it would give some amount of damping. For CLD, the idea is to get the layers very thin, so 1.5mm may be a bit heavy. Is there a thinner version?

I think the Blue Skin is about 0.5 mm thick. I'll measure it if I buy some later. My scheme would be to use the self adhesive on one side and contact cement on the other.

I also found that the craft chain "Michaels" offers transfer tape at reasonable prices. I may try one of those too. It may infer whether the 3M version is worth buying.

Hugh

Butyl tape always seems to be 1.5mm, i am not sure why.Mike,

Thanks. I think it would give some amount of damping. For CLD, the idea is to get the layers very thin, so 1.5mm may be a bit heavy. Is there a thinner version?

I think the Blue Skin is about 0.5 mm thick. I'll measure it if I buy some later. My scheme would be to use the self adhesive on one side and contact cement on the other.

I also found that the craft chain "Michaels" offers transfer tape at reasonable prices. I may try one of those too. It may infer whether the 3M version is worth buying.

Hugh

I guess it is simply to be robust in the areas its used?

M

Interesting thanks, my research centred on the cheap available on Amazon ones.............so, what thickness is best and is it suitable as the bonding layer for CFD like i thought it might be please?No, butyl tape is available from a variety of manufacturers, in a variety of thicknesses, in foamed or denser non-foamed grades, single-sided vs. double-sided etc.

M

Thanks for that Catalogue jcarr.No, butyl tape is available from a variety of manufacturers, in a variety of thicknesses, in foamed or denser non-foamed grades, single-sided vs. double-sided etc.

Mike,Interesting thanks, my research centred on the cheap available on Amazon ones.............so, what thickness is best and is it suitable as the bonding layer for CFD like i thought it might be please?

M

My 2 cents - I would guess the thinner the better. Blueskin seems to be about half a mm, but has adhesive only on one side. The ones jcarr posted are thinner and some look like they have adhesive on both sides.

Hugh

After clamping little blobs of Gardner Bender DS 110 Ductseal between the Acrylic layers, it's about 0.4 mm in thickness. The MSDS sheet calls it a "mastic".

https://file.ecmindustries.com/-/media/inriver/DS-130_TCHDAT_SDS.pdf?isdartitem=true

In sheet form, Butyl rubber is likely harder. Hopefully it works as well.

https://file.ecmindustries.com/-/media/inriver/DS-130_TCHDAT_SDS.pdf?isdartitem=true

In sheet form, Butyl rubber is likely harder. Hopefully it works as well.

Not really as i cannot find how to buy any?After clamping little blobs of Gardner Bender DS 110 Ductseal between the Acrylic layers, it's about 0.4 mm in thickness. The MSDS sheet calls it a "mastic".

https://file.ecmindustries.com/-/media/inriver/DS-130_TCHDAT_SDS.pdf?isdartitem=true

In sheet form, Butyl rubber is likely harder. Hopefully it works as well.

M

One of the thinnest tapes that can be acquired in a Double Sided Adhesive if a Teflon Tape.

This can be found down to approx' 0.1mm in thickness and the width of the tape is offered in many dimensions.

The Link will show a description of a product from one seller.

https://embossingtapesupplies.com.au/blog/post/all-types-of-teflon-tape-available-here

This can be found down to approx' 0.1mm in thickness and the width of the tape is offered in many dimensions.

The Link will show a description of a product from one seller.

https://embossingtapesupplies.com.au/blog/post/all-types-of-teflon-tape-available-here

But i don't think Teflon is regarded as visco-elastic which is what we are looking for in CLD? - the definition seems to beOne of the thinnest tapes that can be acquired in a Double Sided Adhesive if a Teflon Tape.

This can be found down to approx' 0.1mm in thickness and the width of the tape is offered in many dimensions.

The Link will show a description of a product from one seller.

https://embossingtapesupplies.com.au/blog/post/all-types-of-teflon-tape-available-here

What is the difference between elastic and viscoelastic materials?

Elastic materials strain when stretched and immediately return to their original state once the stress is removed. Viscoelastic materials have elements of both of these properties and, as such, exhibit time-dependent strain.

So what we are looking for is an inexpensive readily available easy to use thin (0.5mm) sheet of viscoelastic material, butyl sheet/tape seemed to offer a possibility but doesn't meet many of the list of desirable points above!

M

Butyl tapes made for building and construction applications usually have an internal coarse mesh, with a layer of butyl applied either to one side or both sides of the mesh. in this form butyl has a consistency similar to freshly spat-out chewing gum and is quite sticky; similar to adhesion and tenacity to high-adhesion carpet tape. No additional adhesive is required.

This kind of butyl is visco-elastic and exhibits good damping properties, which is why it is used as the core material for automotive sound deadener products such as Noico.

Another popular form of butyl tape is made for electrical applications, does not have the internal mesh, and is typically called "self-fusing tape".

In my experience, self-fusing tape is less suited than the building and construction grades for making CLD structures.

When stacking up a CLD structure using butyl, choose the tape thickness based on how lumpy or uneven the surfaces of the hard layers being bonded together are - the thicker the adhesive film, the better job it will do of bridging over or filling in lumpy or uneven surfaces (warming up the butyl with a hair-dryer can help make adhesion easier and faster).

As long as the adhesive film is able to properly and completely bond the hard layers together, the thinner grades of butyl tape will experience greater shear stresses and demonstrate better damping performance.

This kind of butyl is visco-elastic and exhibits good damping properties, which is why it is used as the core material for automotive sound deadener products such as Noico.

Another popular form of butyl tape is made for electrical applications, does not have the internal mesh, and is typically called "self-fusing tape".

In my experience, self-fusing tape is less suited than the building and construction grades for making CLD structures.

When stacking up a CLD structure using butyl, choose the tape thickness based on how lumpy or uneven the surfaces of the hard layers being bonded together are - the thicker the adhesive film, the better job it will do of bridging over or filling in lumpy or uneven surfaces (warming up the butyl with a hair-dryer can help make adhesion easier and faster).

As long as the adhesive film is able to properly and completely bond the hard layers together, the thinner grades of butyl tape will experience greater shear stresses and demonstrate better damping performance.

Attachments

Thats great thanks JCARR, and useful background info, so it seems 6922 or 6924 would suit well, so i have searched (In UK) and find nothing!!Butyl tapes made for building and construction applications usually have an internal coarse mesh, with a layer of butyl applied either to one side or both sides of the mesh. in this form butyl has a consistency similar to freshly spat-out chewing gum and is quite sticky; similar to adhesion and tenacity to high-adhesion carpet tape. No additional adhesive is required.

This kind of butyl is visco-elastic and exhibits good damping properties, which is why it is used as the core material for automotive sound deadener products such as Noico.

Another popular form of butyl tape is made for electrical applications, does not have the internal mesh, and is typically called "self-fusing tape".

In my experience, self-fusing tape is less suited than the building and construction grades for making CLD structures.

When stacking up a CLD structure using butyl, choose the tape thickness based on how lumpy or uneven the surfaces of the hard layers being bonded together are - the thicker the adhesive film, the better job it will do of bridging over or filling in lumpy or uneven surfaces (warming up the butyl with a hair-dryer can help make adhesion easier and faster).

As long as the adhesive film is able to properly and completely bond the hard layers together, the thinner grades of butyl tape will experience greater shear stresses and demonstrate better damping performance.

I might just put my head in at the building suppliers and see what they have and then look up its properties............M

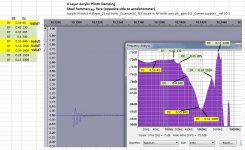

Here's a repeat of the 4 Layer Acrylic Plinth Spectrum and Damping from post 522. This time it's a better Accelerometer and Soundcard.

The method of attaching the accelerometer effects the results. I used nylon through bolts and silicone grease after some experimenting, but I can't swear it's the best way. There is also a difference in tapping the accelerometer side (back) vs. the face - partly due to the Viscous layers I think.

Cats Squirrel cautioned me that DF measurements below the resonant points are likely not valid tests of the material itself. I've highlighted those spots and a few others that I'm unsure of in yellow.

Overall, I'm delighted with the Damping results. The peaks above 1000 hz look a bit imposing, but I believe it's the performance below 1000 that counts. (Comments please).

The lowest resonance (if it's real) is a bit low. I probably could have used thicker layers to get more stiffness and more mass.

I will post a test on MDF to put this in perspective.

Hugh

The method of attaching the accelerometer effects the results. I used nylon through bolts and silicone grease after some experimenting, but I can't swear it's the best way. There is also a difference in tapping the accelerometer side (back) vs. the face - partly due to the Viscous layers I think.

Cats Squirrel cautioned me that DF measurements below the resonant points are likely not valid tests of the material itself. I've highlighted those spots and a few others that I'm unsure of in yellow.

Overall, I'm delighted with the Damping results. The peaks above 1000 hz look a bit imposing, but I believe it's the performance below 1000 that counts. (Comments please).

The lowest resonance (if it's real) is a bit low. I probably could have used thicker layers to get more stiffness and more mass.

I will post a test on MDF to put this in perspective.

Hugh

Attachments

I haven't cleaned all the Greenglue remains of the surfaces in these shots. Not really ready for prime time.

The top layer was painted on the back surface to hide everything underneath - except for a round area that exposes the compressed Ductseal.

The Bottom shot also shows the compressed ductseal. The green along one edge is Greenglue that hasn't cured yet. Trimming the nylon bolts await a decision whether to add more layers.

The top layer was painted on the back surface to hide everything underneath - except for a round area that exposes the compressed Ductseal.

The Bottom shot also shows the compressed ductseal. The green along one edge is Greenglue that hasn't cured yet. Trimming the nylon bolts await a decision whether to add more layers.

Attachments

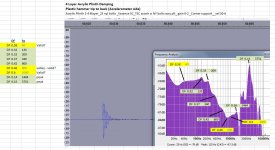

This is an MDF shelf that's about the size of a plinth, but wrong proportions for a plinth. Note the horrible damping at 229 hz, 690, 1131, etc.

Great damping from 40 to 83 hz, but these are likely not valid measurements of the MDF. I don't know FFTs well enough to explain this point, but I am curious.

Hugh

Great damping from 40 to 83 hz, but these are likely not valid measurements of the MDF. I don't know FFTs well enough to explain this point, but I am curious.

Hugh

Attachments

- Home

- Source & Line

- Analogue Source

- DIY CLD Plinth Design--A measured Approach