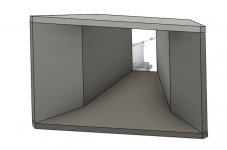

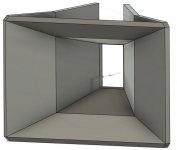

The Heil experiment I've worked on for a few years ... slow progress ... uses a fabricated waveguide. I just continued the 45 degree formed by the units magnet section and radiused that out to the baffle. The heil is set back inside the enclosure to help line up the acoustic center with the 15" woofer below. So, enough room for a decent sized (8" or so) radius to the baffle. The rear output of the heil is encased inside the enclosure.

I can drive the heil down to 1khz (acoustic) and use either a LR4 or a Butterworth4 for the xo to the 15". Any lower and 7-800hz resonances rear their head and frankly, the heil just can't make it lower and follow a proper xo slope.

The LR4 will have a dip in the response around the xo region of about 2db ... not objectionable at all. Vocals seem more laid back. The Butterworth4 is essentially flat through the xo region. So, a bit more vocal detail. I like both really. I've even used 2nd order xo in this region (1khz) and the heil works/sounds fine.

The waveguide does quite a bit to smooth the frequency response of the heil. I've found that shrinking the waveguide vertically starts to mask the vertical output angle even more. Still working on the bottom/top waveguide sections but I won't get any closer than the bottom/top flange of heils case. I've mocked up that part of the waveguide and it takes off flush with those flanges. The response is most even and smooth like that. Any steps or aberrant transitions here really upset the response.

When I get a chance I'll do more off axis measurements. The couple I did do ... just off hand ... weren't as bad as some would think, transitioning to a 15" woofer. They showed a 2db dip in the xo region out to 30-45 degrees off axis. I have to do better measurements/setup/spin to see if this holds. The heils are good drivers and a nice compromise to a CD/horn combination for home use.

Your waveguide looks good pelanj ... looking forward to your progress.

I can drive the heil down to 1khz (acoustic) and use either a LR4 or a Butterworth4 for the xo to the 15". Any lower and 7-800hz resonances rear their head and frankly, the heil just can't make it lower and follow a proper xo slope.

The LR4 will have a dip in the response around the xo region of about 2db ... not objectionable at all. Vocals seem more laid back. The Butterworth4 is essentially flat through the xo region. So, a bit more vocal detail. I like both really. I've even used 2nd order xo in this region (1khz) and the heil works/sounds fine.

The waveguide does quite a bit to smooth the frequency response of the heil. I've found that shrinking the waveguide vertically starts to mask the vertical output angle even more. Still working on the bottom/top waveguide sections but I won't get any closer than the bottom/top flange of heils case. I've mocked up that part of the waveguide and it takes off flush with those flanges. The response is most even and smooth like that. Any steps or aberrant transitions here really upset the response.

When I get a chance I'll do more off axis measurements. The couple I did do ... just off hand ... weren't as bad as some would think, transitioning to a 15" woofer. They showed a 2db dip in the xo region out to 30-45 degrees off axis. I have to do better measurements/setup/spin to see if this holds. The heils are good drivers and a nice compromise to a CD/horn combination for home use.

Your waveguide looks good pelanj ... looking forward to your progress.

@fedde ... I will post some progress pic's if pelanj doesn't mind.

A compromise to a CD/horn combination. C-C distance can be closer than with a CD/horn ... but you give up about 10db sensitivity with the heil compared to the CD. The heil has plenty output though for home use. I think the sound quality is on par with most higher end CD's. Like a good quality CD, the heil will get loud without it sounding strained/harsh. I've had mine over 100db @3 meters and it's just fine. You don't have a sense of the spl at all ... till you try to talk to somebody else in the room

A compromise to a CD/horn combination. C-C distance can be closer than with a CD/horn ... but you give up about 10db sensitivity with the heil compared to the CD. The heil has plenty output though for home use. I think the sound quality is on par with most higher end CD's. Like a good quality CD, the heil will get loud without it sounding strained/harsh. I've had mine over 100db @3 meters and it's just fine. You don't have a sense of the spl at all ... till you try to talk to somebody else in the room

I do not like the old biradial design enough to put it on a CNC, I need to start with a less ambitious project. I have some spare 18 mm MDF and CNCing flat components for conical horns is easier and faster than full 3D. I have 3 preliminary designs, not sure which one will be selected.Most probably the first one. The dimensions are 1: 500 x 306 x 300 mm, 2: 353 x 308 x 300 mm, 3: 560 x 306 x 335. There are additional 46 mm of horn depth in the 3D printed holder/synergy attachment. The dispersion is set to 50 (H) x 30 (V).

I intend to use this horn from cca 300 Hz up or maybe even a bit higher. I really need to finish this project now when I have all the tools and materials I need

I intend to use this horn from cca 300 Hz up or maybe even a bit higher. I really need to finish this project now when I have all the tools and materials I need

Attachments

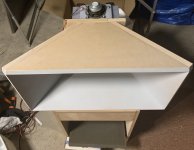

Kind of slow, but still progress The first horn is ready to install the drivers for testing. Just two layers of primer and little sanding. If it proves to be good, I will work a bit more on the finish and also on the plastic throat.

The first horn is ready to install the drivers for testing. Just two layers of primer and little sanding. If it proves to be good, I will work a bit more on the finish and also on the plastic throat.

Attachments

Years ago, some pro sound outfit had straight-sided horns with removeable 'cheeks', with differing curves for different venues.

Seems like a way to simplify construction and take advantage of 3D printing without all the time, expense, and structural weakness that can entail with larger projects.

But I'm old, I kind of like the idea of sculpting in clay, and making a mold for the inserts,

like they used to do for car bodywork.

As a fan of the big Heils(don't like the way that sounds), I like to see you guys trying things with them.

Seems like a way to simplify construction and take advantage of 3D printing without all the time, expense, and structural weakness that can entail with larger projects.

But I'm old, I kind of like the idea of sculpting in clay, and making a mold for the inserts,

like they used to do for car bodywork.

As a fan of the big Heils(don't like the way that sounds), I like to see you guys trying things with them.

Last edited:

Drivers installed. Some foam tape was used to seal the connection between AMT and the printed part. It is only a temporary mount, so 4 M6 bolts are holding it against compressed foam tape at the moment I hope to do some first measurements without any back chambers this afternoon.

I hope to do some first measurements without any back chambers this afternoon.

It took longer than expected, but it's alive now! I tried just some really quick setup 3FE22s in series, crossover at 1 kHz but it could go anywhere between 600 Hz and 1.2 kHz. The large Heils are really something special. The test was with open backs on all drivers and with my Paraflex kickbin below, which was not even properly time aligned. I must say wow. The horn works really well within its coverage pattern, the sound is really detailed compared to my SPL Runt inspired synergy horn (the DE500 being a weak point of it). The only thing I am not fully happy with is the narrow vertical coverage, but that is given by the size of the AMT I think. Making the horn wider vertically would not help much. I can learn to live with that

Now I need to create rear enclosures, since these will be placed close to a wall. The AMT will most probably get a 3D printed pyramid style box with polyfil, in total it should have same depth as the paraflex.

The AMT is basically flat with a gentle rolloff above 11 kHz and there will be a little EQ needed for the mids. The crossover will also need some work and proper measurements outside.

SPL wise it can do more than I am comfortable with, the details are there no matter how soft/loud I play.

I am so happy with the results that I consider a full redesign with 4NDF34s, I think even a single one would do. The new design would integrate the plastic and wooden part better and would also make mounting back enclosures easier.

Now I need to create rear enclosures, since these will be placed close to a wall. The AMT will most probably get a 3D printed pyramid style box with polyfil, in total it should have same depth as the paraflex.

The AMT is basically flat with a gentle rolloff above 11 kHz and there will be a little EQ needed for the mids. The crossover will also need some work and proper measurements outside.

SPL wise it can do more than I am comfortable with, the details are there no matter how soft/loud I play.

I am so happy with the results that I consider a full redesign with 4NDF34s, I think even a single one would do. The new design would integrate the plastic and wooden part better and would also make mounting back enclosures easier.

Attachments

- Home

- Loudspeakers

- Multi-Way

- ESS AMT-1 in my projects