Thanks to all!

Yeah, I've stretched out this build about as long as I can

In the meantime I've built all new cables and run them along the ceiling for a more permanent installation and had to rewire my rack a little to support the 2nd woofer and array while making provision to use my synergies as side surrounds. So I'm almost afraid to turn it back on and have something not work.

But here goes (as soon as I click reply)

Yeah, I've stretched out this build about as long as I can

In the meantime I've built all new cables and run them along the ceiling for a more permanent installation and had to rewire my rack a little to support the 2nd woofer and array while making provision to use my synergies as side surrounds. So I'm almost afraid to turn it back on and have something not work.

But here goes (as soon as I click reply)

I loved it with the filters you supplied and I'm still using and loving them but they need to be redone because placement has changed and now I've got two arrays and two corner woofers.

First question is how close the two arrays match each other. If they don't, I'll have to figure out why and likely fill and redrill the driver mounting holes.

Then I've got to master DRC.

But I'm distracting myself with a search for a fanless amp because the fan noise is killing my enjoyment.

Looking at doing a 4x(250-500W) icepower since modules are off the shelf from PartsExpress

First question is how close the two arrays match each other. If they don't, I'll have to figure out why and likely fill and redrill the driver mounting holes.

Then I've got to master DRC.

But I'm distracting myself with a search for a fanless amp because the fan noise is killing my enjoyment.

Looking at doing a 4x(250-500W) icepower since modules are off the shelf from PartsExpress

Hi Jack, don't know if you care, but I have 2 miniDSP plate amps, PWR-ICE250's

PWR-ICE250 | DSP plate amplifier powered by IcePower technology.

Guaranteed fine, pair shipped for $600.

I got then just to experiment with...no real use on them...

(Mods, pls forgive if this should have been a PM or put in Swap Meet..

I will list them there very shortly...)

PWR-ICE250 | DSP plate amplifier powered by IcePower technology.

Guaranteed fine, pair shipped for $600.

I got then just to experiment with...no real use on them...

(Mods, pls forgive if this should have been a PM or put in Swap Meet..

I will list them there very shortly...)

Hi Jack, don't know if you care, but I have 2 miniDSP plate amps, PWR-ICE250's

PWR-ICE250 | DSP plate amplifier powered by IcePower technology.

Guaranteed fine, pair shipped for $600.

I got then just to experiment with...no real use on them...

(Mods, pls forgive if this should have been a PM or put in Swap Meet..

I will list them there very shortly...)

Thanks Mark but plate amps are not what I'm looking for. rack mount

today I'm not so eager to DIY an amp. looking for a proaudio with quiet fans. >= 250W/ch at 8 ohms . Crown I trust to be quiet as I have a couple. QSC I don't have experience but its cheaper.

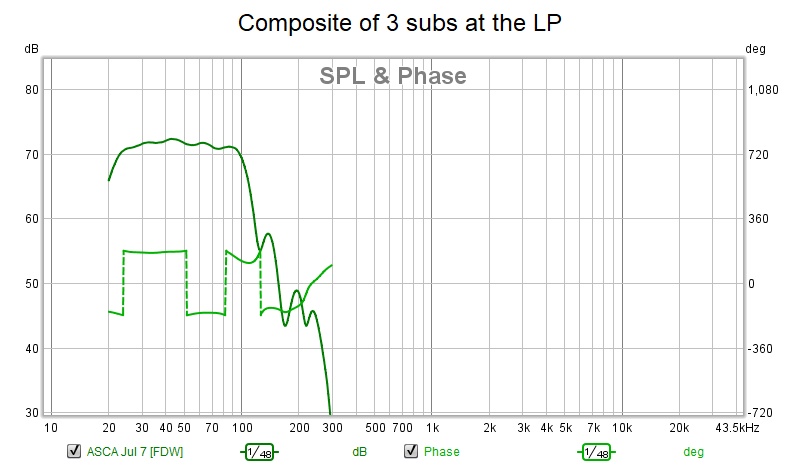

I did some measurements today and got some good news and some bad news.

First a really nice subwoofer frequency response after equalization albeit at a single position:

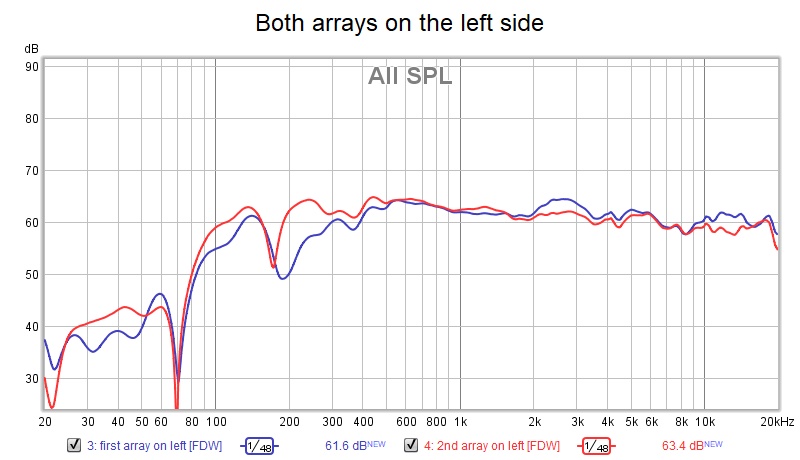

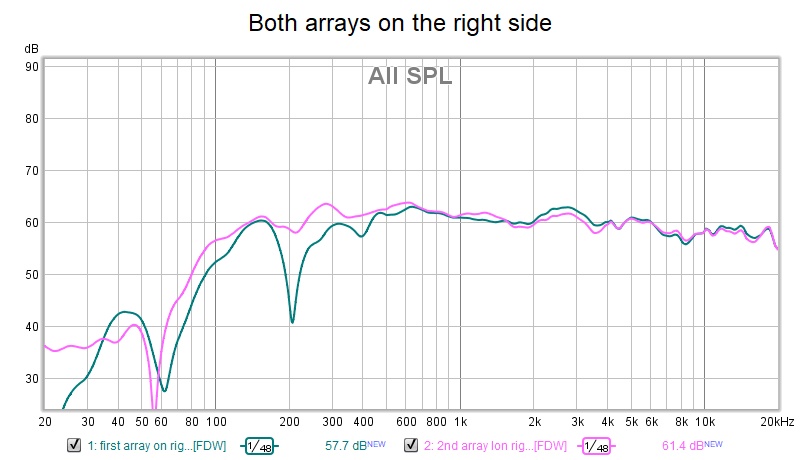

Unfortunately, when I moved on to the arrays, I found their low end responses were substantially different, even when measured at the same positions:

The pink trace is the new array with the 1/16" pilot holes. I didn't realize the first array had 1/8" pilot holes until I did the 2nd array.

I suspect this means the drivers in the first array aren't sealed tightly enough against the baffle so I will have to dismount them and then fill and redrill the mounting holes.

So we had some fun today but it was of the are we having it yet variety

First a really nice subwoofer frequency response after equalization albeit at a single position:

Unfortunately, when I moved on to the arrays, I found their low end responses were substantially different, even when measured at the same positions:

The pink trace is the new array with the 1/16" pilot holes. I didn't realize the first array had 1/8" pilot holes until I did the 2nd array.

I suspect this means the drivers in the first array aren't sealed tightly enough against the baffle so I will have to dismount them and then fill and redrill the mounting holes.

So we had some fun today but it was of the are we having it yet variety

Attachments

I didn't realize the first array had 1/8" pilot holes until I did the 2nd array.

I suspect this means the drivers in the first array aren't sealed tightly enough against the baffle so I will have to dismount them and then fill and redrill the mounting holes.

Why not just use screws with a larger shank? It would save all of that time filling, sanding, and redrilling.

Interesting the differences in #1 and #2. I hope it just pans out to the screw holes and sealing differences.

I've always been amazed how much better my vented sub and mid designs measure when fully tightened, up vs looser initial prototyping measurements.

re your amp search....pls post what you end up with...I'd love a perfectly quiet rack mount solution too.

The qsc CX line is the quietest, most affordable, proaudio solution I've found so far.. at least livable.

I've always been amazed how much better my vented sub and mid designs measure when fully tightened, up vs looser initial prototyping measurements.

re your amp search....pls post what you end up with...I'd love a perfectly quiet rack mount solution too.

The qsc CX line is the quietest, most affordable, proaudio solution I've found so far.. at least livable.

We shall see about the holes. Could also be I need more screws on the removable back. Both are really pretty easy to do, albeit time consuming, but at least I have the other array to listen to while I do it.

Thanks for the tip on QSC CX, it confirms a couple of reviews I've read. Seriously considering QSC PLD4.2 long term. I think for immediate future I will try substituting a quiet fan.

I do have a perfectly quiet rack mount solution for the arrays and future surrounds. The fanless, 1U, 8x125W@8ohm Crown CT-8150, which I see now sells for almost twice what I was able to get it for.

Thanks for the tip on QSC CX, it confirms a couple of reviews I've read. Seriously considering QSC PLD4.2 long term. I think for immediate future I will try substituting a quiet fan.

I do have a perfectly quiet rack mount solution for the arrays and future surrounds. The fanless, 1U, 8x125W@8ohm Crown CT-8150, which I see now sells for almost twice what I was able to get it for.

We shall see about the holes. Could also be I need more screws on the removable back. Both are really pretty easy to do, albeit time consuming, but at least I have the other array to listen to while I do it.

Thanks for the tip on QSC CX, it confirms a couple of reviews I've read. Seriously considering QSC PLD4.2 long term. I think for immediate future I will try substituting a quiet fan.

I do have a perfectly quiet rack mount solution for the arrays and future surrounds. The fanless, 1U, 8x125W@8ohm Crown CT-8150, which I see now sells for almost twice what I was able to get it for.

Hi Jack, I have PLD4.5's and they are fan noisy SOB's. My bet is any of the PLDs have loud fans.

Fan noise is my only real complaint with the PLD/CXDs, and with QSC in general...q-sys I/O frames are loud too, which I like to use with CX amps...uhg to fan noise

that is too bad about the PLDs. Maybe its worth it to pay the price for the Crown technology.

quiet fan ordered for my Peavey. hoping it has enough airflow for my situation, which should not be too demanding. Saw noise ratings from 19 db up to 50 db for a range of airflow ratings and fan quality

quiet fan ordered for my Peavey. hoping it has enough airflow for my situation, which should not be too demanding. Saw noise ratings from 19 db up to 50 db for a range of airflow ratings and fan quality

well it appears I don't or might not have to dismount my drivers and fill and redrill their mounting holes. That weakness remains but I see another potentially worse problem.

The joint where the short wall meets the baffle, with a 22.5 degree bevel on each failed. I guess I didn't have enough clamping pressure on it when I glued it originally. I had multiple clamps from driver holes out to the edge of the box but apparently not enough of them or not enough glue or .... I could tell I was in trouble when I implemented Mark's tape technique on the 2nd box which put pressure uniformly along the entire joint. Knocking the array over when I was repositioning absorber panels around it didn't help either.

This might not be a serious air leak but its a serious weakness that allows the panels to move.

So my plan is to get 1"x piece of trim, cut a bevel on it and glue it in place over the joint. And to shoot brads in where the glue didn't take. and then see how it works

The joint where the short wall meets the baffle, with a 22.5 degree bevel on each failed. I guess I didn't have enough clamping pressure on it when I glued it originally. I had multiple clamps from driver holes out to the edge of the box but apparently not enough of them or not enough glue or .... I could tell I was in trouble when I implemented Mark's tape technique on the 2nd box which put pressure uniformly along the entire joint. Knocking the array over when I was repositioning absorber panels around it didn't help either.

This might not be a serious air leak but its a serious weakness that allows the panels to move.

So my plan is to get 1"x piece of trim, cut a bevel on it and glue it in place over the joint. And to shoot brads in where the glue didn't take. and then see how it works

- Home

- Loudspeakers

- Full Range

- Full range line array for wall or corner placement