Gino,

If you are interested in the stiff and damped enclosure approach, here's a link to a table of damping loss factors for different materials. The site is for turntable base plinths, but the basic information applies to enclosure walls too.

damping factor values : damping factors

If you are interested in the stiff and damped enclosure approach, here's a link to a table of damping loss factors for different materials. The site is for turntable base plinths, but the basic information applies to enclosure walls too.

damping factor values : damping factors

Thanks a lot for the extremely interesting link (i read great things of Vivid Audio) but this will take me all the weekend to read 😱

and i will read it carefully for sure

Just to end for now, the nice thing is that i read one thing from a designer and the exact opposite from another, and they are both extremely praised.

So it seems that both have got it right in the end following an opposite approach 😕

The opposite case being, if i get it right, Magico where the drivers are bolted to an extremely solid and unbelievably stiff structure, an internal frame.

The baffle is not holding the drivers and the panels just seal the cabinet like covers.

So maybe there is more than one truth 🙄

But i will read first ... i just need time

Thanks again, gino

There are allways several ways of meeting a design criteria. They differ in cost and complexity.

But what you just said about Magico is not the opposite. It's just a different version of the same. The different drivers are mounted to different internal sub structures (mass anchor) and float in regards to eachother and the outer walls?

I might be wrong as I'm no Magico expert.

The opposite case being, if i get it right, Magico where the drivers are bolted to an extremely solid and unbelievably stiff structure, an internal frame.

The baffle is not holding the drivers and the panels just seal the cabinet like covers.

Depends which Magico you are talking about.

The Q7 has the woofers bolted to the 1st baffle and the baffle bolted to the cabinet, with the mid also bolted to 1st baffle but on top of a vibration isolating layer or gasket if you will, and with the tweeter mounted from behind to the 2nd, exterior front baffle which itself is also isolated from the 1st baffle with another soft layer and with the 2nd baffle attached with threaded rods.

That's my understanding anyways.

Gino, If you are interested in the stiff and damped enclosure approach,

Hi and thanks for the kind reply. Why did you get that impression ? 😀

Yes in general to cabinet construction because i heard in some very rudimental tests the differences

Just adding some mass to the cabinet walls cleaned up the bass remarkably

So i am here to learn something more but it is difficult for me 😱

here's a link to a table of damping loss factors for different materials.

The site is for turntable base plinths, but the basic information applies to enclosure walls too.

damping factor values : damping factors

Thanks a lot again. All reading postponed to the weekend when i will be more free, i hope

Kind regards, gino

There are allways several ways of meeting a design criteria. They differ in cost and complexity.

But what you just said about Magico is not the opposite. It's just a different version of the same. The different drivers are mounted to different internal sub structures (mass anchor) and float in regards to eachother and the outer walls?

I might be wrong as I'm no Magico expert.

Some links to the "heavyweights" in speaker enclosures.

Magico

http://magico.net/Technology/Enclosures/Enclosures_02.php

http://www.ultraaudio.com/index.php...-world-the-q3-loudspeakers&catid=44&Itemid=37

Rockport Technologies

http://www.rockporttechnologies.com/#/enclosures/Rockport

Perfect 8 Technologies

http://www.perfect8.com/nav/pdf/Encl...fleStudies.pdf

Von Schwikert

http://dagogo.com/a-whitepaper-the-...end-method-of-reduction-of-audible-coloration

Ascend (Bamboo Enclosure)

http://forum.ascendacoustics.com/showthread.php?2597-Sierra-The-Cabinet

Last edited:

Depends which Magico you are talking about.

The Q7 has the woofers bolted to the 1st baffle and the baffle bolted to the cabinet, with the mid also bolted to 1st baffle but on top of a vibration isolating layer or gasket if you will, and with the tweeter mounted from behind to the 2nd, exterior front baffle which itself is also isolated from the 1st baffle with another soft layer and with the 2nd baffle attached with threaded rods.

That's my understanding anyways

Hi and thanks a lot for the very interesting explanation.

If i understand correctly the woofer is "rigidly" fixed to the stiff structure while mid and tweeter are decoupled by means of a soft layer ?

Maybe this could be the right arrangement ? in this way the high freq vibes of the cabinet are not passed to the mid and tweeter ?

Very interesting. But still the structure is extremely rigid and the woofer is bolted to it. This is what i wanted to know in the end 😉

And this is what i see in high end subwoofers as well.

Very rigid structure and woofer rigidly bolted to it.

In the case of a two ways of course the mid-woofer is bolted to the structure as we can see here

6moons audio reviews: Magico Mini

from what i see here i have the feeling that just a very stiff front baffle could be enough. And behind it just a decent wooden cabinet.

I believe in the importance of the execution of the front baffle more than other panels of the cabinet.

Front emission is what counts much more in the end.

And good to know that there are type of woods stiff enough to replace metal as a construction material for the baffle.

Maybe laminated ones ? anyway an extremely interesting topic. Thanks a lot to anyone sincerely for the valuable advice.

Kindest regards, gino

Last edited:

Gino,

If you are interested in the stiff and damped enclosure approach, here's a link to a table of damping loss factors for different materials.

The site is for turntable base plinths, but the basic information applies to enclosure walls too.

damping factor values : damping factors

Hi i have just given a look at the table ... extremely interesting.

The values for aluminium are impressive ...

damping factor 0.004

transmissibility 177.13

stiffer than steel ! it looks the perfectly rigid material ?

I cannot help but noticing that i see more and more brands adopting this material for cabinets, even if this implies huge production costs.

Maybe using a sheet of aluminium only for the extremely critical front baffle could be enough

Thanks a lot again for the very interesting link.

Kind regards, gino

SoundStage! Ultra | SoundStageUltra.com (UltraAudio.com) | SoundStage! Ultra | SoundStageUltra.com (UltraAudio.com)The front baffle consists of a constrained-layer-damped sandwich: two aluminum elements separated by a viscous damping material. The remaining panels are affixed to the underlying structure in such a way that the only clues that the Q1 is not cut from a single billet of aluminum are found on the back and bottom.

The Aluminium baffle is a constrained layer construction, not just a thick piece of aluminium.

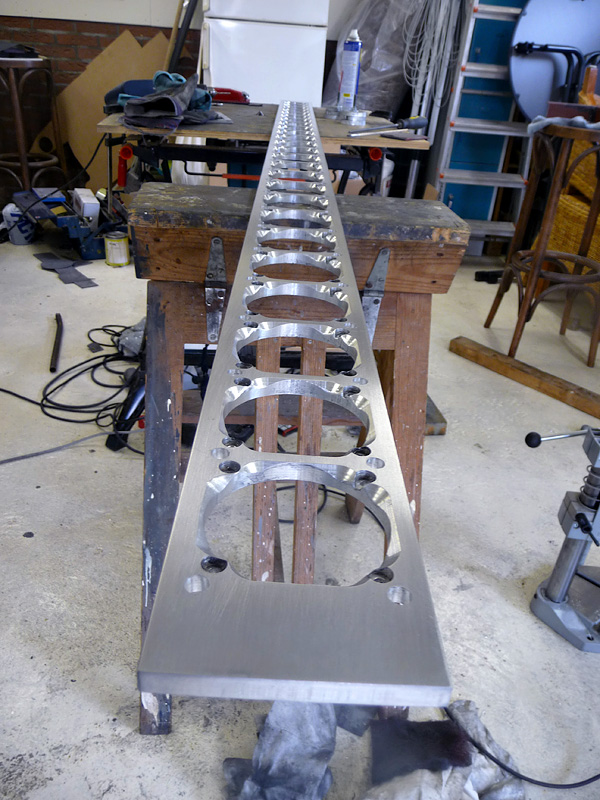

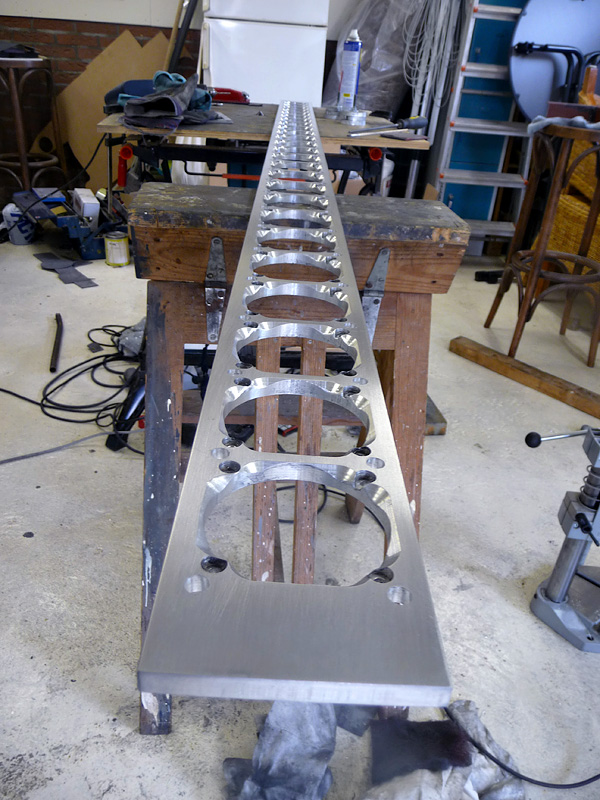

But aluminium is a material a serious DIY-er can work with (with some care). I cut my aluminium baffles with a Router. I used a sandwich construction as well.

http://www.diyaudio.com/forums/full-range/242171-making-two-towers-25-driver-full-range-line-array-42.html#post4044547

SoundStage! Ultra | SoundStageUltra.com (UltraAudio.com) | SoundStage! Ultra | SoundStageUltra.com (UltraAudio.com)

The Aluminium baffle is a constrained layer construction, not just a thick piece of aluminium.

But aluminium is a material a serious DIY-er can work with (with some care). I cut my aluminium baffles with a Router.

I used a sandwich construction as well.

http://www.diyaudio.com/forums/full-range/242171-making-two-towers-25-driver-full-range-line-array-42.html#post4044547

Hi and first of all sincere congratulations for the exceptional work done.

Really impressive and i am sure it sounds just wonderful.

Speaking instead of the baffle i see both approaches used

And i have the feeling the both can work equally well.

here is another one that also seems to work quite well and the metal sheet is single with the drivers bolted to it

The Alya’s construction is unique in the Rockport Technologies line, and utilizes an aircraft grade, 6061-T6 aluminum alloy billet front baffle, compression mounted to an 11 ply, high density fiber board enclosure - See more at: Rockport Technologies - Alya - Audio dream

i guess that a very stiff wood (maybe thicker) would give the same effect after all without the difficulty of working metal.

The same brand adopts for another even higher level model a wooden solid 6" thick baffle. So stiff and thick wood is also very good at least for the baffle.

A compromise maybe but a good one.

Congratulations again for your great works !

Kind regards, gino

Last edited:

Interesting reading indeed. Much attention seems to be directed towards production costs and effect of the measures. Knowledge is gold, in addition is overkill the DIYers privilege. Just pick the cherries.

Hi i have just given a look at the table ... extremely interesting.

The values for aluminium are impressive ...

damping factor 0.004

transmissibility 177.13

stiffer than steel ! it looks the perfectly rigid material ?

I cannot help but noticing that i see more and more brands adopting this material for cabinets, even if this implies huge production costs.

Maybe using a sheet of aluminium only for the extremely critical front baffle could be enough

Thanks a lot again for the very interesting link.

Kind regards, gino

This is not true. Steel is 3 times as stiff as aluminium. But for a given mass (alu is about 1/3 as dense), alu will usually be stiffer, because the panel is thicker. And thickness is a large factor in calcuating stiffness of a panel.

What that table says is that alu rings like a bell when driven to the ressonance frequency. It needs to be damped, or the drivers must be decoupled so they don't trigger the ressonance....

Last edited:

Hi i have just given a look at the table ... extremely interesting.

The values for aluminium are impressive ...

damping factor 0.004

transmissibility 177.13

stiffer than steel ! it looks the perfectly rigid material ?

I cannot help but noticing that i see more and more brands adopting this material for cabinets, even if this implies huge production costs.

Maybe using a sheet of aluminium only for the extremely critical front baffle could be enough

Thanks a lot again for the very interesting link.

Kind regards, gino

Steel is 3 times the stiffness of aluminum. Stiffness is measured by the modulus of elasticity, also know as Young's Modulus.

A short list of material stiffnesses. Multiply by 6.9 to convert to metric units (GPa).

Material.........................Modulus of Elasticity (psi)

Ceramic..........................45,000,000 - 55,000,000

Steel..............................30,000,000

Copper...........................19,000,000

Brass.............................17,000,000 - 19,000,000

Titanium.........................17,000,000 - 19,000,000

Aluminum.......................10,000,000

Glass...............................7,000,000 - 12,000,000

Marble.............................7,000,000 - 10,000,000

Carbon Fiber Composite.....6,000,000 - 10,000,000

Granite............................5,000,000 - 10,000,000

Kevlar Composite..............4,300,000

Soapstone........................3,800,000

Ipe (Brazilian Walnut)........3,200,000

Permali (Compr Plywood)...2,600,000

Concrete..........................2,500,000 - 4,400,000

Hickory............................2,200,000

Jabroc (Compr Plywood).....2,100,000

Plaster of Paris..................2,100,000

Oak.................................1,900,000

Hard Maple.......................1,800,000

Douglas Fir.......................1,800,000

Phenolic X Grade...............1,800,000

Ash..................................1,700,000

Beech...............................1,700,000

Pyrotek NAD-11 (Comp).....1,600,000

Bamboo............................1,500,000

Corian..............................1,400,000

Pine.................................1,300,000

Fiberglass Comp, Woven.....1,200,000 - 1,700,000

Baltic Birch Plywood............1,100,000

Fiberglass Comp, Mat...........700,000

HDF...................................700,000

Epoxy Resin........................450,000 - 850,000

Particle Board......................450,000

MDF...................................350,000 - 450,000

Polycarbonate......................260,000 - 380,000

Plexiglass............................250,000 - 450,000

The transmissibility deals with sound and vibration moving through the material.

Aluminum is poorly damped, with a loss factor of 0.004, so applying some form of damping would be best.

Last edited:

This is not true. Steel is 3 times as stiff as aluminium. But for a given mass (alu is about 1/3 as dense), alu will usually be stiffer, because the panel is thicker.

And thickness is a large factor in calcuating stiffness of a baffle

Hi and thanks and this actually i was thinking.

Al stiffer than steel .. a little strange indeed. But i see now better.

What that table says is that alu rings like a bell when driven to the ressonance frequency. It needs to be damped, or the drivers must be decoupled so they don't trigger the ressonance...

are you sure that a bell made out of Al actually rings ?

Because i am not so sure ... i have to find something in Al and try to hit it

There is a very telling way to see how resonant is a cabinet

I have been shown by a serious speaker designer at an audio fair

The tool was something like this one ...

An externally hosted image should be here but it was not working when we last tested it.

He had of course his speakers and another one to compare

You put this mechanism on a speaker panel and action it.

If the cabinet is resonant the sound of the mechanism is amplified remarkably

On his speakers it was muted almost completely

Amazing, ultra heavy stiff and expensive speakers.

I am sure than on my speakers this mechanism would throw me out of the window for the noise ... 🙁

I will look in ebay to buy one ... very easy way to check for cabinet resonnances

Thanks again, gino

I feel we are getting a bit off topic now, but yes an alu bell or an alu tuning fork will ring... More than steel, less than Titanium if I remember correctly.

https://www.youtube.com/watch?v=altWaEyqa2c

https://www.youtube.com/watch?v=altWaEyqa2c

Try different materials together, look at this video from 5:20 on

https://www.youtube.com/watch?v=gh9n9v4bNhY

https://www.youtube.com/watch?v=gh9n9v4bNhY

I feel we are getting a bit off topic now, but yes an alu bell or an alu tuning fork will ring...

More than steel, less than Titanium if I remember correctly.

https://www.youtube.com/watch?v=altWaEyqa2c

You are very right ! i had not thought about it ... another clear example of metal ringing ... impressive and worrying also 😱

https://www.youtube.com/watch?v=Yvx1Hw0Yqkg

Then i do not understand why many designers use Al for their cabinets

Just a marketing strategy ?

At least for the very bass a rigid cabinet seems the correct choice

Maybe they put something to tame the resonances i do not know

Thanks again, gino

We already posted Magico uses constrained layer damping in their baffle.

I'm sure the other firms use some sort of damping as well. Aluminium definitely rings.

It is stiff but needs damping.

I'm sure the other firms use some sort of damping as well. Aluminium definitely rings.

It is stiff but needs damping.

Hi and thanks and clearly Al rings ... but then just look how popular is in high end brands ... it is surprising how many use it.

Instead this material Panzerholz .... really impressive

Do you know of anyone using it for spekars cabinets ?

I guess it is extremely rare and expensive ?

But maybe it could be a great option at least for baffles (the most critical panel i think) ?

A suitable thick baffle made out of this material should provide both stiffness and damping.

Why it is not more popular ? i guess it is much easier to work than metal.

Thanks again, gino

Last edited:

Try different materials together, look at this video from 5:20 on

https://www.youtube.com/watch?v=gh9n9v4bNhY

Hi and again very impressive 😱 two ringing materials bolted together they do not ring 😕

So even just a flange of the right material place in front of or behind the woofer flange could improve things remarkably ?

A material that must be both stiff and acoustically dead ?

Unbelievable ... this is great.

Maybe just two flanges of Panzerholz just for the woofers would give perceptible benefits ? ... great idea ?

Thanks again, gino

a very interesting video ... about a board of this Panzerholz

https://www.youtube.com/watch?v=P0b2gZRF1WQ

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- how to brace a speaker cabinet?