make that make sense.

It makes all the sense in the world.

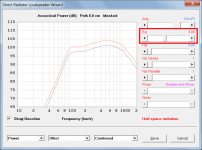

Double-clicking on the Pmax slider label selects the Maximum SPL mode (see the Help file for details).

Leave the Pmax and Xmax sliders disabled and simply adjust the Eg slider if you want to change the input level (2.83V = 1W into 8 ohms, 4.00V = 2W into 8 ohms, etc).

Attachments

the thing that makes no sense is that sound is only emitted from one source when there should be two in the wavefront sim.

I suggest that you forget about the Wavefront Simulator, it won't really help you with your transmission line design. It serves a different purpose.

'Closing the loop'  so to speak, Rick Schultz's Alpha TL, Omega MLTL two part 8/03 AudioXpress articles based on Mr. Augspurger's JAES 5/2000 paper:

so to speak, Rick Schultz's Alpha TL, Omega MLTL two part 8/03 AudioXpress articles based on Mr. Augspurger's JAES 5/2000 paper:

http://diyaudioprojects.com/Technical/Papers/Alpha-Transmission-Lines.pdf

http://diyaudioprojects.com/Technical/Papers/Loudspeakers-on-Damped-Pipes.pdf

GM

http://diyaudioprojects.com/Technical/Papers/Alpha-Transmission-Lines.pdf

http://diyaudioprojects.com/Technical/Papers/Loudspeakers-on-Damped-Pipes.pdf

GM

Im just a noob at hornresp, that’s all

Besides, I may doing too much. Sealed mid/bass and slot ported sub...I’m not loosing if I just keep it simple.

What do you guys use for fill?

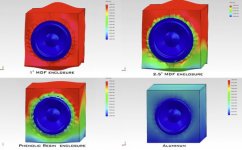

I’ve been looking up enclosure design, seems like 1” mdf would be fine with minimal bracing and some acoustic dampening material on the walls and call it a day?

Besides, I may doing too much. Sealed mid/bass and slot ported sub...I’m not loosing if I just keep it simple.

What do you guys use for fill?

I’ve been looking up enclosure design, seems like 1” mdf would be fine with minimal bracing and some acoustic dampening material on the walls and call it a day?

According to Magico:

Source: Q Sub — Magico Loudspeakers

They build a sub that can do a bit more than what you're asking:

But the pictures make me think some bracing would not have to be a bad idea. Now yours will be ported though, not sealed like their monster subs...

Source: Q Sub — Magico Loudspeakers

They build a sub that can do a bit more than what you're asking:

Built around the renowned Q platform, the Q-Subs set new standards in low frequency sound reproduction. Capable of delivering 136 dB sound pressure level with less than 1% total harmonic distortion at 20Hz, the message is simple: if you think you have heard low frequencies before, think again.

But the pictures make me think some bracing would not have to be a bad idea. Now yours will be ported though, not sealed like their monster subs...

Attachments

Im just a noob at hornresp, that’s all

Besides, I may doing too much. Sealed mid/bass and slot ported sub...I’m not loosing if I just keep it simple.

What do you guys use for fill?

I’ve been looking up enclosure design, seems like 1” mdf would be fine with minimal bracing and some acoustic dampening material on the walls and call it a day?

To some of us you are, but stuffing the cab/vent brings you close enough for most folks.

I'm old fashioned as I prefer fiberglass insulation since it has the 'right' properties for it [or at least did].

Don't have my calculator available, but from memory it takes 1.125" thick MDF to match close enough to 3/4" [19 mm] no void marine grade, BB and apple plywood's ~1.8 mil psi stiffness [MOE], which with any decent size sub will still require significant bracing to make it 'ring' like metal where it ideally needs to be and while bracing increases stiffness quicker than thickness it will still require a lot more, so ideally start with 10 ga CRS with cast iron angle bracing and 'U' channel iron fork lift skid plates to move it around and with this much stiffness, mass it won't need anything but a motor brace.

While a cab designed to deal with the hum of an electro-mechanical 10 kV motor controller is a bit overkill for your app, it's not as excessive as you might think when trying to eek the most acoustic efficiency practical out of a speaker cab, so think 'stiff' first and foremost with mass a close second to keep it 'planted', which if a separate cab can have removable mass on top.

GM

Ron, the Magico specs don't add up.

Even using the 6000W 230v double 18", a 90dB sensitivity would equal about 127-128dB assuming zero compression, which is nuts.

To say there's only 1% distortion at 136dB is surely fantasy, for any double 18"s on earth imho.

I'd say they are most likely tying to spec and price their subs by the pound/kilo

Even using the 6000W 230v double 18", a 90dB sensitivity would equal about 127-128dB assuming zero compression, which is nuts.

To say there's only 1% distortion at 136dB is surely fantasy, for any double 18"s on earth imho.

I'd say they are most likely tying to spec and price their subs by the pound/kilo

I think it might be a touch over-engineered.

Not IME nor at least one that set out to [dis]prove my claims:

Mass Loading ALTEC A7 VOTT 825 enclosures - drlowmu - High Efficiency Speaker Asylum

High Efficiency Speaker Asylum

Compared to this single low power/Xmax 15", one might could argue that for dual high power 18", the 'bean counters' prevailed.

GM

I was reading about dual panel walls with sand in between the layers. That’s a thing I guess.

It's about increasing stiffness, mass loading, to provide a stable, inert working platform for the driver while not being excited by it, but when I 'ran the numbers' decades ago it wasn't heavy enough to either push the cab's resonance below it's tuning or stiff enough to raise it well above it, so while certainly an above average performer, wasn't all it could be and why I prefer pushing the cab's resonance ~ an octave above the drivers pass band with high MOE materials, proper bracing.

GM

Last edited:

I looked it up and was kinda shocked that 1” 6061 aluminum plate weighs 70.56 lbs per sq’ !

I don’t know what it’s made from but probably something like that to weigh that much.

I would have guessed 20-30lbs at most per sq’ for 1” Al ....crazy!

It's more like 14 lbs per square foot for 1" 6061.

- Home

- Loudspeakers

- Multi-Way

- Is it possible to cover the whole spectrum, high SPL, low distortion with a 2-way?