I was collecting data, I'll pass you everything I found from 0.40x.I was recently gifted a pair of 3fe25 and thought that I would make a pair of foam board Karlsonators. I've been looking through this thread for a while trying to find plans for the cabinet. Is this one in the first post the plans for the single 3fe25 version?

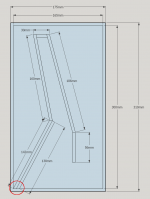

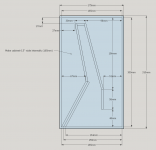

The measurements you put in don't match the measurements MuddJester posted on their pdf.

I was looking at it and if it is true that there are measures that do not match, let's see if the most knowledgeable take us out of doubt. I am also waiting for the drivers to make a 0.40x. I'm not sure about the thickness either, one seems to be 10mm and the other 5mm

Attachments

Last edited:

I was considering doing this on a .40x. I got a few sheets of 10mm foam board, so doubling this on the driver baffle ends up being very thick. My plan was to glue 6mm ply to the front of the driver baffle. There's probably some different folding measurements to be considered when working with 10mm foam core. As far as I know, the "throat" measurements need to remain the same.I think a good "upgrade" is to use Lite Ply for the driver baffle

So i built one box and played it for a while. Nobody told me getting the cuts straight would be such a PITA! 😅 This was the practice run, so to speak, and the next box will look better and need less glue...Thanks for the quick response, and Bruveiker for the plans! I'll probably have some time in the weekend to play around with the Karlsonator, and will report my findings. That video is pretty good encouragement...

The sound is airy and has a nice clear midrange which makes it very nice with singer/songwriter-stuff. I didn't get much bass though, and I've checked and rechecked for leaks. But more than that, the sound of the box itself made me shelf the K for now and put them in some old JVC fullrange cabs. The more I listened, the more that "boxy", one note honk sound grew on me.

Also, Ho do you stuff them? Should the stuffing be loose or packed, how do you tame the reverberations of the box itself? I tried it according to the pdf Bruveiker posted.

The link to the plans doesn't work, unfortunately. Is it this pdf? Guess only thing to do is start cutting! (And do it better this time...)

Attachments

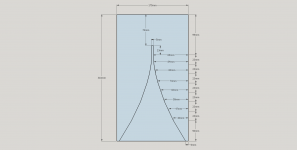

The 0.40x Karlsonator in foamcore score-and-fold plans are awesome. This is one of the highest bang for the buck DIY speakers you can make in an evening on your kitchen table. They sound amazing and will impress most anyone who hears them. Sort of like hearing what a fullrange speaker is all about. I should make a video on how to make this. The plans by Mudjester linked above are super. This would be a nice project if it was laser precut and sold as a kit with a TC9FD, a hot melt glue gun and some wiring, foam, and stuffing. Self contained speaker in a kit.

I am making some progress on the 0.40x K flat pack idea. Contacted a laser CNC house today. Waiting for quote. MuddJester was very generous in offering to provide me the CAD plans for the score and fold so that the CNC house can cut the foam.

Would anyone be interested in a group buy for a flat pack for this speaker? It would be incredibly easy to build if all the cutting was done for you already.

I have no idea on the pricing yet so we will have to see.

Would anyone be interested in a group buy for a flat pack for this speaker? It would be incredibly easy to build if all the cutting was done for you already.

I have no idea on the pricing yet so we will have to see.

I am interested, to see price and shipping costs to Spain.I am making some progress on the 0.40x K flat pack idea. Contacted a laser CNC house today. Waiting for quote. MuddJester was very generous in offering to provide me the CAD plans for the score and fold so that the CNC house can cut the foam.

Would anyone be interested in a group buy for a flat pack for this speaker? It would be incredibly easy to build if all the cutting was done for you already.

I have no idea on the pricing yet so we will have to see.

Regards

I’m interested in a flat pack. I have a pair of ps95s lying around that I’m looking to build cabinets for.I am making some progress on the 0.40x K flat pack idea. Contacted a laser CNC house today. Waiting for quote. MuddJester was very generous in offering to provide me the CAD plans for the score and fold so that the CNC house can cut the foam.

Would anyone be interested in a group buy for a flat pack for this speaker? It would be incredibly easy to build if all the cutting was done for you already.

I have no idea on the pricing yet so we will have to see.

I ordered a set of precut foam core 0.40x Karlsonator to test out and see how well it works. It takes 3 full sheets for a pair of speakers with 24 pieces including bracing and double thickness K aperture. should be here in maybe 10 days.

Once you guys can see what it looks like and I’ll even make a video showing how to build it, we can see how much interest there is to get a group buy preorder going to get the costs lower. It’s not cheap for a sample of 3 sheets. Cost to me is $150.

Once you guys can see what it looks like and I’ll even make a video showing how to build it, we can see how much interest there is to get a group buy preorder going to get the costs lower. It’s not cheap for a sample of 3 sheets. Cost to me is $150.

Good idea to record a video of the montageI ordered a set of precut foam core 0.40x Karlsonator to test out and see how well it works. It takes 3 full sheets for a pair of speakers with 24 pieces including bracing and double thickness K aperture. should be here in maybe 10 days.

Once you guys can see what it looks like and I’ll even make a video showing how to build it, we can see how much interest there is to get a group buy preorder going to get the costs lower. It’s not cheap for a sample of 3 sheets. Cost to me is $150.

The laser cut flat pack for the 0.40x Karlsonators just arrived. It came as 3 flat sheets packed flat in its original master sheet so you know exactly what part goes where. The cuts are amazingly precise. The best from the laser also melts the foam into a solid non-porous sold under-lip. There is a slight smoky aroma to the foam - not strong or anything but a hint of the process used for the precision cuts.

Overall, I am quite happy with the result. This will make building and assembling the speaker much easier.

Overall, I am quite happy with the result. This will make building and assembling the speaker much easier.

- Home

- Loudspeakers

- Full Range

- Mini Karlsonator (0.53X) with Dual TC9FDs