12mm Baltic birch is suitable for small regular K's - perhaps 9mm for little K- when up to 10 inch size 15mm would be minimum then bracing desirable as transient peaks of 120dB (up close) may be desired. Dowel struts to the wings work as do steel alltread as used by Transylvania Power, KK Audio, Acoustic Control, etc. Really thin Baltic birch plywood would work like a "soundboard" and be far worse I think on music than foamcore.

18mm BB - BOFU

15mm BB - Beta10CX

18mm BB - BOFU

15mm BB - Beta10CX

Last edited:

Hi

Help

I cant find the plans,link seemes to be dead ?

Jan

All plans linked in post #1 work fine for me. Have you tried there yet?

Here is link from post 1 for the original 12in Karlsonator by which all others are scaled.

https://lh3.googleusercontent.com/-...ABik/txissf4J4PI/w678-h524-no/Karlsonator.png

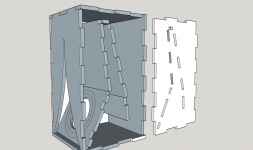

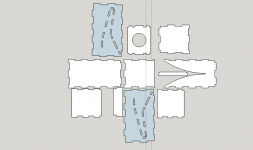

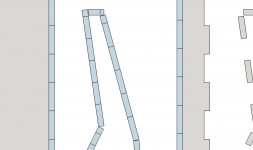

I've been learning some sketchup and created the fullsize Karlsonator as a lasercuttable self-bracing puzzle. It's easy to scale down to 0.63 for 12mm plywood.

The bad thing about lasercutting is that you're stuck with 90 degree angles, so some gaps have to be filled.

I might make a 0.53 version with 6mm plywood and some bracing. 6mm plywood should be stronger than foamboard, right? But that will require some resizing of the drawing.

But that will require some resizing of the drawing.

The bad thing about lasercutting is that you're stuck with 90 degree angles, so some gaps have to be filled.

I might make a 0.53 version with 6mm plywood and some bracing. 6mm plywood should be stronger than foamboard, right?

Attachments

I've been learning some sketchup and created the fullsize Karlsonator as a lasercuttable self-bracing puzzle. It's easy to scale down to 0.63 for 12mm plywood.

Sealing the box might be get tricky due to amount of holes in side panels.

Sealing the box might be get tricky due to amount of holes in side panels.

Good point. With good plywood and kerf adjustment I should be able to stay within 0.2mm accuracy. Some filling glue should do the job.

Hi

Thanks again xrk971

I been looking for some info about building in foam.

Is there a tread here ?

Type of foam ?

type of glue ?

.....

Thanks for your patience.

Jan

http://www.diyaudio.com/forums/full-range/223313-foam-core-board-speaker-enclosures.html

In the US we use paper faced foam core poster board from Adams Industries or Elmer's brand.

Post 1 in link shows what it is called in France. Cartouche Mousse.

Hot melt glue sticks and gun for initial tacking. PVA white glue or thicker adhesive from caulking gun for final glue.

Some like expanding Gorilla Glue. Messy.

My favorite lately is Liquid Nails non VOC. Neat, strong and fills gaps. Can be smoothed over with finger tip to make fillet like caulking. Inexpensive.

According to google:

Dutch: schuimkarton

Danish: skumplader

Gluing foam with PVA glue doesn't usually work because the glue takes forever to dry. Like x says, tack glue it first with hot melt glue -- or just do it all with hot melt glue.

If you've got really good joints water based contact cement will work, but it certainly won't fill gaps. Low solvent liquid nails sounds interesting. Presumably there's not enough solvent to melt the foam.

I can't say that I've built speakers with foam, but I have worked with it quite a lot building models and prototypes.

Dutch: schuimkarton

Danish: skumplader

Gluing foam with PVA glue doesn't usually work because the glue takes forever to dry. Like x says, tack glue it first with hot melt glue -- or just do it all with hot melt glue.

If you've got really good joints water based contact cement will work, but it certainly won't fill gaps. Low solvent liquid nails sounds interesting. Presumably there's not enough solvent to melt the foam.

I can't say that I've built speakers with foam, but I have worked with it quite a lot building models and prototypes.

The PVA actually works well because the foam is porous and it has paper facing which takes PVA well as it wicks moisture away.

Best stuff is Liquid Nails low VOC - no solvent at all. Takes longer to fully cure (days) but strong and fills gaps and takes on fillet nicely. Usable in 12hrs but don't apply full speaker pressure for 36 hrs.

Best stuff is Liquid Nails low VOC - no solvent at all. Takes longer to fully cure (days) but strong and fills gaps and takes on fillet nicely. Usable in 12hrs but don't apply full speaker pressure for 36 hrs.

We used to have that Pattex "No more Nails", I didn't use it for speaker construction but it was great to do other stuff with that. Everything I glued with that over 5 years ago is still very strong and doesn't show any sign of getting old.

Trouble is they stopped importing that a couple years ago... I've been searching for a replacement ever since...

Trouble is they stopped importing that a couple years ago... I've been searching for a replacement ever since...

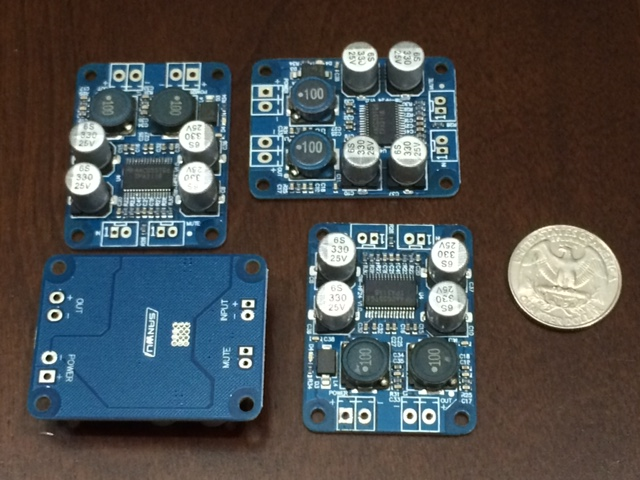

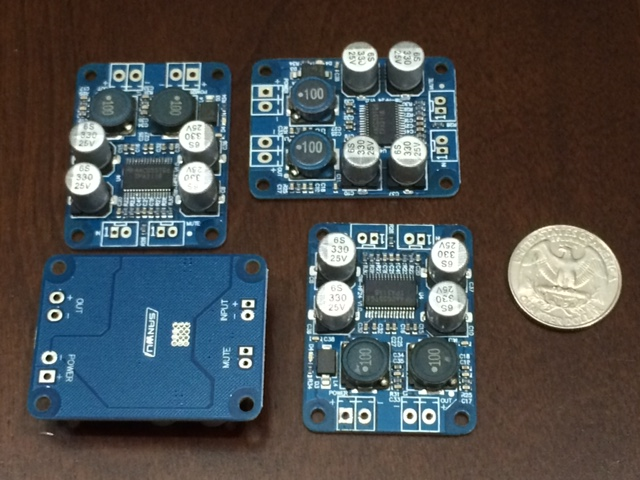

Some of you may be looking for a good compact 60 watt amp for your projects. I recently got some TPA3118D2 PBTL monoblocks for $9 ea. They sound excellent and truly can deliver 60 watts into 5ohms (and are stable with 2ohm loads). I used them to drive a 5ohm power resistor load to 17.36v without thermal shutdown. Get this, this amp has no heatsink! It uses the tiny PCB as its heatsink.

More info here:

http://www.diyaudio.com/forums/class-d/237086-tpa3116d2-amp-867.html#post4583670

Here is my 4-channel Xmas amp made from a cardboard magnetic snap lid chocolate box.

Sounds great, is inexpensive, can be installed inside a speaker without taking any room.

More info here:

http://www.diyaudio.com/forums/class-d/237086-tpa3116d2-amp-867.html#post4583670

Here is my 4-channel Xmas amp made from a cardboard magnetic snap lid chocolate box.

Sounds great, is inexpensive, can be installed inside a speaker without taking any room.

the TPA3118D2 hasn't landed in Taiwan yet... well kinda.

I looked it up on the local sites, and they sell this board for.... wait for it ... $300!

I'm so tempted to write to the seller and ask why, but then the seller would lose face... and that's not good in Asian culture...

I looked it up on the local sites, and they sell this board for.... wait for it ... $300!

I'm so tempted to write to the seller and ask why, but then the seller would lose face... and that's not good in Asian culture...

Attachments

Yeah, but that looks to be an official TI EVM.

Not Taiwan, because was made in Plano Tx.

Ask me how I know.

Intention is a learning tool for engineers, and

to sell the chip. Not to compete with TI's own

customers who are welcome to make and sell

products for users at a better price.

The store.ti.com price is only $149, not $300.

https://store.ti.com/AddToCart_TI.aspx?p=TPA3118D2EVM

Not Taiwan, because was made in Plano Tx.

Ask me how I know.

Intention is a learning tool for engineers, and

to sell the chip. Not to compete with TI's own

customers who are welcome to make and sell

products for users at a better price.

The store.ti.com price is only $149, not $300.

https://store.ti.com/AddToCart_TI.aspx?p=TPA3118D2EVM

Last edited:

They are really cheap here:

12 V 24 V Neue TPA3118 PBTL mono digitale verstrkerplatine 1X60 Watt POWER AMP in TPA3118 BTL Mono digitale Verstrkerpla aus Andere elektronische Komponenten auf AliExpress.com | Alibaba Group

But i'm not sure if it is possible to ship from China to Taiwan.

12 V 24 V Neue TPA3118 PBTL mono digitale verstrkerplatine 1X60 Watt POWER AMP in TPA3118 BTL Mono digitale Verstrkerpla aus Andere elektronische Komponenten auf AliExpress.com | Alibaba Group

But i'm not sure if it is possible to ship from China to Taiwan.

- Home

- Loudspeakers

- Full Range

- Mini Karlsonator (0.53X) with Dual TC9FDs