I'd like to see xrk971 sim a 12L in the stock Karlsonator 12. For a midbass horn substitute, it would work well in a K12. I have a thing with the distributed slit vent K12- that can help make a smoother graph, but a single / less resistive vent will have less distortion at fb and below. K12 had two cabinet shape - the first K12 aka "Karlsonette" from late 1964, then K12 from about 1956 that was published in the July 1958 issues of Popular Mechanics.

Although John Karlson warned in the January 1954 issue or Radio and Television News against direct 0.8 scaling of K15, I think it would work well. I had a 0.8 scale K15 but never tested a strong motor 12 like EV12L. It ran a Sammi, an Alllied Knight (Jensen) coax and a JBL D123 I think the front shelf gap should be greater than 0.8 scaled as that shelf seemed to segregate some high frequencies from reaching the upper front chamber. BTW- one fellow made ~0.75 scale (~K12 size) K-cabinets like K15. X can sim the K15 case for you. A K-tube on top would be good - I guess a modern waveguide would work too as would classic horns.

In the 1960's Karlson was offering a K12 kit with a blank port panel - it re-introduced the full width rear shelf. I'd like X's comments on that feature

Although John Karlson warned in the January 1954 issue or Radio and Television News against direct 0.8 scaling of K15, I think it would work well. I had a 0.8 scale K15 but never tested a strong motor 12 like EV12L. It ran a Sammi, an Alllied Knight (Jensen) coax and a JBL D123 I think the front shelf gap should be greater than 0.8 scaled as that shelf seemed to segregate some high frequencies from reaching the upper front chamber. BTW- one fellow made ~0.75 scale (~K12 size) K-cabinets like K15. X can sim the K15 case for you. A K-tube on top would be good - I guess a modern waveguide would work too as would classic horns.

In the 1960's Karlson was offering a K12 kit with a blank port panel - it re-introduced the full width rear shelf. I'd like X's comments on that feature

also, I have a driver which is reasonably close to a 12L - the B&C 12pe31 - I have it in a 6-slit vent K12 and could move it to a Karlsonator 12 once wings, back and driver are pulled (I have to pull the back to gain access to a crossover board which will be transplanted) 12pe31, like 12L is an school horn driver parameter-wise.

In a K12, 12pe32 is a bit leaner on the bottom than a Pyle pym1298, which is like the modern Kappa 12A. The Karlsonator 12 is tuned a good half octave or more lower than a K12 (~37Hz tuning vs ~62Hz tuning)

12pe-32 Thiele-Small Parameters

Resonant Frequency (Fs) 51 Hz

DC Resistance (Re) 5.8 ohms

Voice Coil Inductance (Le) 1.2 mH

Mechanical Q (Qms) 7.6

Electromagnetic Q (Qes) 0.19

Total Q (Qts)0.18

Compliance Equivalent Volume (Vas) 3.56 ft.³ (100.82 liter)

BL Product (BL) 19.1 Tm

Diaphragm Mass Inc. Airload (Mms) 37g

Maximum Linear Excursion (Xmax) 2.8 mm

Surface Area of Cone (Sd) 522 cm²

Here's a comparison of a Karlsonette (1954 K12)loaded with Pyle pym1298. with its regular port moved and substituted with a 12 sqaure inch, Vs a 6-slit port K12 loaded with a B&C 12pe32 Vs a "Large Advent" - K12 is not much larger than the Advent.

Although we gave up some lows, the little K with pro 12 has some sensitivity and dynamic advantages

square-ish port Vs

In a K12, 12pe32 is a bit leaner on the bottom than a Pyle pym1298, which is like the modern Kappa 12A. The Karlsonator 12 is tuned a good half octave or more lower than a K12 (~37Hz tuning vs ~62Hz tuning)

12pe-32 Thiele-Small Parameters

Resonant Frequency (Fs) 51 Hz

DC Resistance (Re) 5.8 ohms

Voice Coil Inductance (Le) 1.2 mH

Mechanical Q (Qms) 7.6

Electromagnetic Q (Qes) 0.19

Total Q (Qts)0.18

Compliance Equivalent Volume (Vas) 3.56 ft.³ (100.82 liter)

BL Product (BL) 19.1 Tm

Diaphragm Mass Inc. Airload (Mms) 37g

Maximum Linear Excursion (Xmax) 2.8 mm

Surface Area of Cone (Sd) 522 cm²

Here's a comparison of a Karlsonette (1954 K12)loaded with Pyle pym1298. with its regular port moved and substituted with a 12 sqaure inch, Vs a 6-slit port K12 loaded with a B&C 12pe32 Vs a "Large Advent" - K12 is not much larger than the Advent.

Although we gave up some lows, the little K with pro 12 has some sensitivity and dynamic advantages

square-ish port Vs

Last edited:

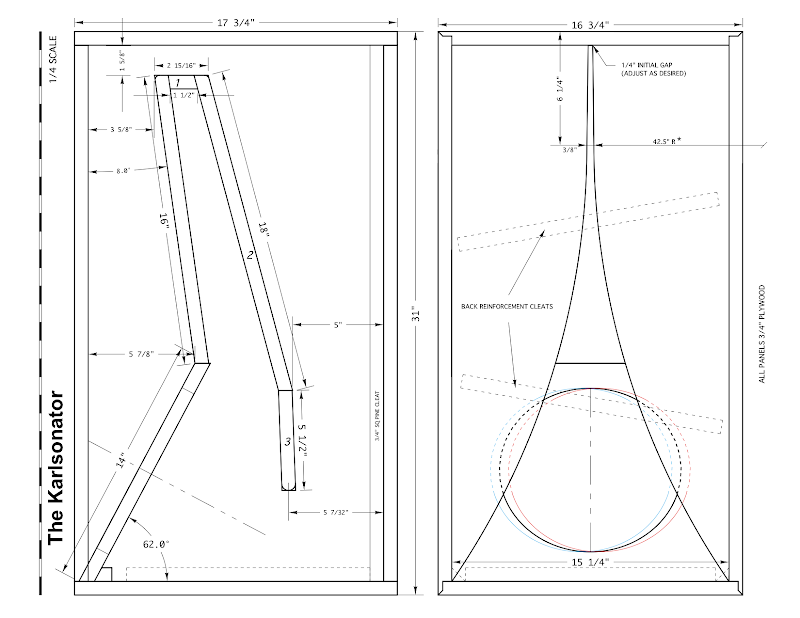

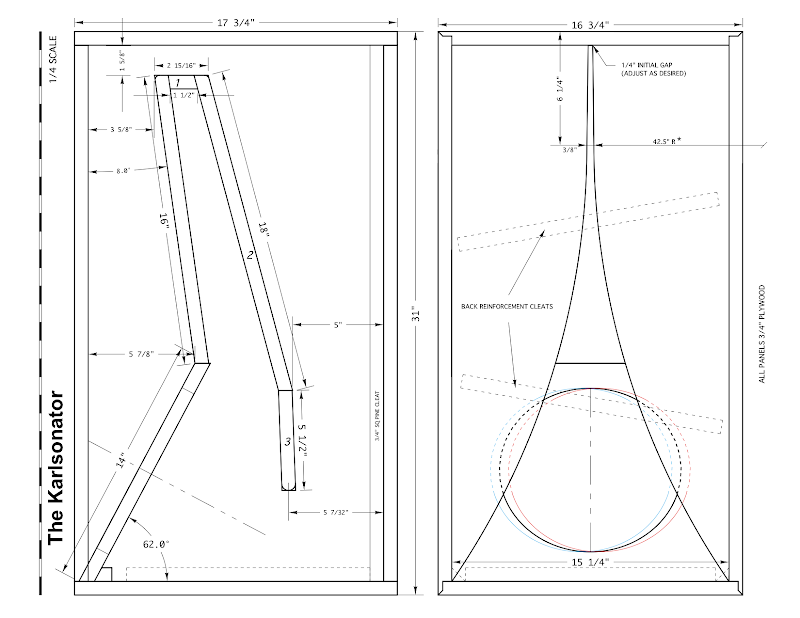

I've been eyeing the Karlsonator 12. After reading many of your posts, and then reading some more to more understand what i think i understand, that where I've landed. it will give me potentially more on the bottom end (trying to avoid a higher crossed sub), and seems better for the 511 horns. If that's also peaked your curiosity, then it can't be that horrible of an idea! I was thinking of increasing the baffle thickness to 1 1/8 with some absurdly dense and heavy mdf, making the surface flush with the face of the surrounds. Any benefit? thanks for the response.

You don't need such a thick baffle or to make it flush. 3/4in ply should be fine for 12in driver. Flush helps reduce diffraction on open face speakers. Here, the K-aperture is a diffraction lens and homogenizes whatever diffraction you had upstream. The K-aperture is under a lot of pressure so making it 1in thick would not hurt. Thick dense K-aperture vs baffle (which doesn't need it). 1.125 in thick K-aperture would be even better.

re: wing pressure, I think the woofer and/or port needs to see the narrow portion of the slot for maximum effects. If say a K12 size K-coupler had its vent closed, I don't think there would be a lot of pressure against the wings with the driver sitting mostly in the shallow portion of the cavity and facing the widest portions of the aperture.

I have seen 3/4" wings move plus and minus 3/8" with a sealed rear chamber 18" klam and a pretty tight aperture at the beginning.

Acoustic Control's 115BK used 3/8" allthread wing bracing with T-nuts embedded in the wings.

3/4" plywood should be good for any 12K - even with 300 watt input peaks (not uncommon for brief duration with percussion)

X - could Karlsonator 12 be tuned a bit higher to advantage for such speakers as the EV12L ? 37Hz seems pretty low for qts 0.18-0.25.

I may try to put 12pe32 into a Karlsonator12 - just don't have any energy.

I have seen 3/4" wings move plus and minus 3/8" with a sealed rear chamber 18" klam and a pretty tight aperture at the beginning.

Acoustic Control's 115BK used 3/8" allthread wing bracing with T-nuts embedded in the wings.

3/4" plywood should be good for any 12K - even with 300 watt input peaks (not uncommon for brief duration with percussion)

X - could Karlsonator 12 be tuned a bit higher to advantage for such speakers as the EV12L ? 37Hz seems pretty low for qts 0.18-0.25.

I may try to put 12pe32 into a Karlsonator12 - just don't have any energy.

Well today was productive, i got all the top/bottom/back & internal parts cut, baffle cut out, and the 4 non-baffle internals glued fastnened and filled. 3/4" MDF for all that, might use ply for the sides as i'm running out of MDF scraps. Brought the baffle squares home so i can check the sizing and mark for the bolts. I've been filling all the exposed mdf edges as well so no roughness. Even if i decide to make a box with different tuning, I'm sure i can find someone who'll want these. WAF is a minor factor, but still there... The wings. I can make them 1.125", and it's nicely veneered stuff too so it'll look all pretty. But do i round those edges or keep them sharp? And if i understand it correctly, I'd keep the distance to the baffle and driver the same, and let the increased thickness push forward? That might work well as i can dado out the sides and fit it across the front so it has a nice strong 90 joint. should have some threaded inserts around too, i'll bolt from the side and top, not face. I'll bring the rest of the face out to match the thickness increase. That stuff is about 2.5x the weight of normal MDF, I doubt there's any chance of it flexing before the cabinet itself explodes. Even if there's no benefit from the thickness, the stiffness and density should be beneficial. (I think) I'll also try to remember to take pictures. I'm using the plan from http://www.diyaudio.com/forums/full-range/256758-karlsonator-12-12lta.html (and other spots). When I'm all done I'll have to find a way to evaluate them... Thanks again!

how's your Uberkarlsonator12 coming along ? I've seen wing edges beveled from the outside - some say it might be more helpful inside.

Acoustic did some mild rounding of their wings on thier 115BK - the blue is really pretty and its a great little K-coupler - the "sparkles" are artifacts from a cheap camera = it would look nice in metalflake

Acoustic did some mild rounding of their wings on thier 115BK - the blue is really pretty and its a great little K-coupler - the "sparkles" are artifacts from a cheap camera = it would look nice in metalflake

I'll try the custom Eminence seen below in my Karlsonator12 with an ASD1001- It was made for a sealed box application for a former president of Cetec-Gauss. The cone is a bit heavier than Beta12cx and the surround is like that of the modern B102/10cx, it has a cast frame and 54 ounce magnet. I have 12cx with more motor but this one might be a good fit I'm hoping it (with decent xover) to be lots better than Beta10cx in this application. Karlsonator12 is a good home for Beta 12LTA and Nirvana Super 10.

X - if you are reading, can I somewhat raise Karlsonator12's tuning by removing the bottom stub plate?

X - if you are reading, can I somewhat raise Karlsonator12's tuning by removing the bottom stub plate?

You mean reduce the TL length by shortening the divider wall? Yes, that would raise the tuning, but it might turn it into more of a BR if you took out too much of it.

- by removing the 5.5" access piece (mine are held by 4 screws) - wonder what that would do to the response ? - wonder what would be a reasonable start for a passive crossover for the 12cx above? - its "something" like a Beta12cx - I'll try Eminence's 2K5cx values first as the board is already in the cabinet .

Last edited:

Here's the almost finished first mini K that I'm building for my portable set up. It still needs a few mostly cosmetic touches added to it. I used 4 ohm 4FE35 drivers. I will be adding a 55 hz PLLXO to allow me to play these a little louder outdoors.

I constructed it a bit different than I've seen others do here. This pair is going to have to survive the rigors of an international flight, so I wanted it to be a bit more sturdy than just foam core. But I didn't want it to be as heavy as a full ply one, since I'm gonna be carrying it around.

I basically am turning the entire speaker into a big sandwich panel, with the core (internal folds of the horn, baffle, top, bottom, back, and K aperture) being made out of 1/4 ply to give some crush strength. The internal bracing is all foam core. The sides are also foam core, but I used sheets of PEEK pressure sensitive adhesive to bond an extra layer of thick card stock to the foam core to give it a little extra strength and to cover up a few blemishes.

The entire outside is going to get coated in black epoxy paint, and the sides and K aperture are going to get at least one ply of twill weave fiberglass laminated to it with epoxy.

For the internal dampening, I used some 3/8" thick grooved melamine foam that has a metalized PEEK backer. I then bonded 1/8" Nomex felt on top of the melamine foam. This layup went on the upper stub, bottom, speaker cavity walls, and rear wall in the line of sight of the driver.

The internal divider directly behind the speaker got a thicker layer of the melamine foam, I believe its about an inch thick.

So far I have only been able to hear this speaker played with a FC cab for the second speaker, and initial impressions are very good.

I constructed it a bit different than I've seen others do here. This pair is going to have to survive the rigors of an international flight, so I wanted it to be a bit more sturdy than just foam core. But I didn't want it to be as heavy as a full ply one, since I'm gonna be carrying it around.

I basically am turning the entire speaker into a big sandwich panel, with the core (internal folds of the horn, baffle, top, bottom, back, and K aperture) being made out of 1/4 ply to give some crush strength. The internal bracing is all foam core. The sides are also foam core, but I used sheets of PEEK pressure sensitive adhesive to bond an extra layer of thick card stock to the foam core to give it a little extra strength and to cover up a few blemishes.

The entire outside is going to get coated in black epoxy paint, and the sides and K aperture are going to get at least one ply of twill weave fiberglass laminated to it with epoxy.

For the internal dampening, I used some 3/8" thick grooved melamine foam that has a metalized PEEK backer. I then bonded 1/8" Nomex felt on top of the melamine foam. This layup went on the upper stub, bottom, speaker cavity walls, and rear wall in the line of sight of the driver.

The internal divider directly behind the speaker got a thicker layer of the melamine foam, I believe its about an inch thick.

So far I have only been able to hear this speaker played with a FC cab for the second speaker, and initial impressions are very good.

Attachments

Very nice. I like the attention you payed to damping materials. Very important for best sound from these speakers.

I posted on the 2 way forum but had no replies yet. Maybe better to ask here.

My only builds so far were giant bipole spiral horns with fostex fe166en and Karlsonator 8 with fostex fe206en.

For my next build I want to go past the one driver fullrange limitations. I had many different ideas that went in very opposing directions. But I have now settled on trying to build the best 2 way Karlson possible (or impossible 🙂

12" driver or larger tuned as deep as can. I can only get Eminence here in Thailand. Which would be the best choice.....the Delta 12a or the Kappa 12a or Kappa pro 12a. I will cross over through DSP roughly around 1500Hz. Crossover will largely depend on the tweeter. Would there be any benefit to go larger? Kappa 15LFA perhaps? Or would a Karlsonator 15 be too much of a good thing? I want to absolutely positively not have any need for subwoofers.

I will use a Faital Pro HF10AK with a K coupler slotted pipe. I will experiment with length, slot shapes and materials....PVC..Copper...layered wood veneer. I am not yet sure where to place the k-pipe. On top or sticking through the "curtain". I like it close to the woofer but if it has to stick through the "curtains" there is quite a long run of pipe before the slot starts. I read somewhere that this creates quite a large roll off in the upper frequencies, so on top might be better. I would like some help determining the best k pipe position.

The whole setup will be bi amped, crossed over, room corrected and phase corrected with miniDSP hd.

Drivers available here are:

delta pro-12a 99.2 dB fs 51 Hz QTS 0.35 VAS 81.7 liters Xmax 4.6 mm

delta-12a 98.3 dB fs 55 Hz QTS 0.43 VAS 81.3 liters Xmax2.4 mm

kappa-12a 99.3 dB fs 45 Hz QTS 0.27 VAS 112.1 liters Xmax 3.2 mm

kappa pro-12a 97.1 dB fs 37 Hz QTS 0.24 VAS 121 liters Xmax 4.8 mm

To me the Delpta Pro 12a looks best.......but what do I know?

I still think the Kappa 15LFA looks awesome. But I am afraid the cabs for these would require a crane to move them....

Resonant Frequency (Fs)39 HzDC Resistance (Re)5.40 ohms

Electromagnetic Q (Qes)0.41Total Q (Qts)0.38

Compliance Equivalent Volume (Vas)5.62 ft.³

Mechanical Compliance of Suspension (Cms)0.15 mm/N

Diaphragm Mass Inc. Airload (Mms)105g

Maximum Linear Excursion (Xmax)5.5 mm

My only builds so far were giant bipole spiral horns with fostex fe166en and Karlsonator 8 with fostex fe206en.

For my next build I want to go past the one driver fullrange limitations. I had many different ideas that went in very opposing directions. But I have now settled on trying to build the best 2 way Karlson possible (or impossible 🙂

12" driver or larger tuned as deep as can. I can only get Eminence here in Thailand. Which would be the best choice.....the Delta 12a or the Kappa 12a or Kappa pro 12a. I will cross over through DSP roughly around 1500Hz. Crossover will largely depend on the tweeter. Would there be any benefit to go larger? Kappa 15LFA perhaps? Or would a Karlsonator 15 be too much of a good thing? I want to absolutely positively not have any need for subwoofers.

I will use a Faital Pro HF10AK with a K coupler slotted pipe. I will experiment with length, slot shapes and materials....PVC..Copper...layered wood veneer. I am not yet sure where to place the k-pipe. On top or sticking through the "curtain". I like it close to the woofer but if it has to stick through the "curtains" there is quite a long run of pipe before the slot starts. I read somewhere that this creates quite a large roll off in the upper frequencies, so on top might be better. I would like some help determining the best k pipe position.

The whole setup will be bi amped, crossed over, room corrected and phase corrected with miniDSP hd.

Drivers available here are:

delta pro-12a 99.2 dB fs 51 Hz QTS 0.35 VAS 81.7 liters Xmax 4.6 mm

delta-12a 98.3 dB fs 55 Hz QTS 0.43 VAS 81.3 liters Xmax2.4 mm

kappa-12a 99.3 dB fs 45 Hz QTS 0.27 VAS 112.1 liters Xmax 3.2 mm

kappa pro-12a 97.1 dB fs 37 Hz QTS 0.24 VAS 121 liters Xmax 4.8 mm

To me the Delpta Pro 12a looks best.......but what do I know?

I still think the Kappa 15LFA looks awesome. But I am afraid the cabs for these would require a crane to move them....

Resonant Frequency (Fs)39 HzDC Resistance (Re)5.40 ohms

Electromagnetic Q (Qes)0.41Total Q (Qts)0.38

Compliance Equivalent Volume (Vas)5.62 ft.³

Mechanical Compliance of Suspension (Cms)0.15 mm/N

Diaphragm Mass Inc. Airload (Mms)105g

Maximum Linear Excursion (Xmax)5.5 mm

Last edited:

Delta 12A sports a 2.4mm xmax while 12LTA claims 3.2mm. 12LTA IIRC has a physical voice coil overhang of only 0.08 inches so is probably compressing after a point of movement. The Qts of Delta 12A 0.41 (unmodified by crossover resistance & inductance) would be good for the Karlsonator. If I can gather energy, I might mount a low Q 12 such as pym1298 into a Karlsonator 12 and see how it does with the ~37Hz tuning.

The original Karlson 15 and 12 are very good - K15 outdoors goes ~flat to about 60Hz (indoors probably to 50), K12 ~80 (70). They are very punchy with the right speakers. K15 with a 15" can do some jaw dropping bass passages with very little cone movement. K12 does well but doesn't have the reach - but that makes K12 a nice choice when augmented by a subwoofer which can reach 30Hz or lower with good power. I like K12 better than my Klipschorns but they are much different. The distributed slit vent, under pure sinewave conditions will distort like hell - but under music conditions, seem acceptable. Is most music mainly comprised of transients too brief to go into a steady state condition? (I think sustained electronic organ pedals additional overtones may be heard on narrow slit vent K12's with some drivers -??)

Here's the K15 plan from the January 1954 issue of Radio and Television News

http://classicaudio.ru/forum/uploads/monthly_08_2011/post-329-1385471361,079.png

What does XRK971 think about low Q 12" in the Karlsonator12? as I've seen, the real world tuning is about 37Hz and response with the weak motor 12LTA perhaps not real different than K15 with a good 15"

100 grams moving mass for a 15" seems a bit high for traditional Karlson duty - but seen before.

A K-tube can be placed pretty high ans subjectively blend with a woofer below. I've had one perched on top of a 4 foot high cabinet.

The original Karlson 15 and 12 are very good - K15 outdoors goes ~flat to about 60Hz (indoors probably to 50), K12 ~80 (70). They are very punchy with the right speakers. K15 with a 15" can do some jaw dropping bass passages with very little cone movement. K12 does well but doesn't have the reach - but that makes K12 a nice choice when augmented by a subwoofer which can reach 30Hz or lower with good power. I like K12 better than my Klipschorns but they are much different. The distributed slit vent, under pure sinewave conditions will distort like hell - but under music conditions, seem acceptable. Is most music mainly comprised of transients too brief to go into a steady state condition? (I think sustained electronic organ pedals additional overtones may be heard on narrow slit vent K12's with some drivers -??)

Here's the K15 plan from the January 1954 issue of Radio and Television News

http://classicaudio.ru/forum/uploads/monthly_08_2011/post-329-1385471361,079.png

What does XRK971 think about low Q 12" in the Karlsonator12? as I've seen, the real world tuning is about 37Hz and response with the weak motor 12LTA perhaps not real different than K15 with a good 15"

100 grams moving mass for a 15" seems a bit high for traditional Karlson duty - but seen before.

A K-tube can be placed pretty high ans subjectively blend with a woofer below. I've had one perched on top of a 4 foot high cabinet.

Last edited:

@Freddi, I just saw a post from you from 2005 where you ask:

are there virtues to be had with a Karlsonator 15 vs K15? - would it roughly be a 15/12 Karlsonator 12 - or somewhat different? what field of parameters would be desirable for a Karlsonator 15? would it fix the hole seen in the simple type below?

That is my question as well more than a decade later

I am also interested in that picture you posted. What is it called and has anybody built it. How does it sound compared to a Karlsonator? I like the form factor....

are there virtues to be had with a Karlsonator 15 vs K15? - would it roughly be a 15/12 Karlsonator 12 - or somewhat different? what field of parameters would be desirable for a Karlsonator 15? would it fix the hole seen in the simple type below?

That is my question as well more than a decade later

I am also interested in that picture you posted. What is it called and has anybody built it. How does it sound compared to a Karlsonator? I like the form factor....

It would cost me more than anticipated but the Kappa Lite 3015 looks very very good...

Usable Frequency Range 40 Hz - 4 kHz

Sensitivity* 100.8 dB

Resonant Frequency (fs) 45 Hz

Total Q (Qts) 0.34

Compliance Equivalent Volume (Vas) 153 liters / 5.4 cu.ft.

BL Product (BL) 18.6 T-M

Diaphragm Mass Inc. Airload (MMs) 84 grams

Efficiency Bandwidth Product (EBP) 125

Maximum Linear Excursion (Xmax) 5.9 mm

How would this fare in a scaled up Karlsonator? If XRK971 gives a big thumbs up I would consider to build it

Usable Frequency Range 40 Hz - 4 kHz

Sensitivity* 100.8 dB

Resonant Frequency (fs) 45 Hz

Total Q (Qts) 0.34

Compliance Equivalent Volume (Vas) 153 liters / 5.4 cu.ft.

BL Product (BL) 18.6 T-M

Diaphragm Mass Inc. Airload (MMs) 84 grams

Efficiency Bandwidth Product (EBP) 125

Maximum Linear Excursion (Xmax) 5.9 mm

How would this fare in a scaled up Karlsonator? If XRK971 gives a big thumbs up I would consider to build it

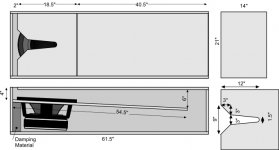

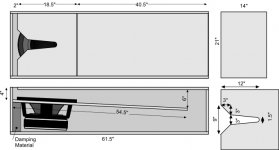

regarding that one-fold speaker diagram from "Nineleaves", since its end driven, there's a suckout. Here's one I made of warped flooring plywood and about the same bulk as a Karlson K15. The response would be smoother if the driver were effectively moved down the line as in MMJ's "Karlflex"

since this was about the same bulk of K15, it should be possible to get lower response than K15 in the same bulk with a possible tradeoff of weaker upper bass response. A more open aperture would move the LF cutoff upwards.

Maybe there is a good Karlsonator 15 alignment about the same external bulk of K15 but with lower reach - - there could be a removable sub-plate to hold the K-tube and its compression driver. Perhaps tuning around 40Hz would preserve some "punch", assuming no peaking on the low end.

the 15 here was a Dayton 295-070 - I did not like in K15 due to poor midrange - it worked well in the simple folded pipe and my Edgar "Monolith" horn.

Dayton 295-070 105oz magnet, power = 250 watts, Voice Coil = 3 in., Spl=95.23dB, Re= 5.4ohm, Fs = 26.4, Qms=8.25/Qes=0.300, Vas= 11.986 cu.ft., Qts=0.29, Le = 1.4mH, BL = 18.2, Xmax = 7.8mm, Sd = 132.7 sq.in.

weight ~20lb, no = 2.007%

Look at the graph of 295-070 in the folded pipe vs K15 with Audio Nirvana Super10 in K15 at 40Hz. The pipe had 12dB more output at 40. A little of this was the Nirvana 10" having fs near 50Hz. The pipe in a corner was pretty flat to 32Hz.

TB46 might have some good ideas for a Karlsonized cabinet with good 1/4 wave path

https://www.youtube.com/watch?v=UJTctkDPKpE

since this was about the same bulk of K15, it should be possible to get lower response than K15 in the same bulk with a possible tradeoff of weaker upper bass response. A more open aperture would move the LF cutoff upwards.

Maybe there is a good Karlsonator 15 alignment about the same external bulk of K15 but with lower reach - - there could be a removable sub-plate to hold the K-tube and its compression driver. Perhaps tuning around 40Hz would preserve some "punch", assuming no peaking on the low end.

the 15 here was a Dayton 295-070 - I did not like in K15 due to poor midrange - it worked well in the simple folded pipe and my Edgar "Monolith" horn.

Dayton 295-070 105oz magnet, power = 250 watts, Voice Coil = 3 in., Spl=95.23dB, Re= 5.4ohm, Fs = 26.4, Qms=8.25/Qes=0.300, Vas= 11.986 cu.ft., Qts=0.29, Le = 1.4mH, BL = 18.2, Xmax = 7.8mm, Sd = 132.7 sq.in.

weight ~20lb, no = 2.007%

Look at the graph of 295-070 in the folded pipe vs K15 with Audio Nirvana Super10 in K15 at 40Hz. The pipe had 12dB more output at 40. A little of this was the Nirvana 10" having fs near 50Hz. The pipe in a corner was pretty flat to 32Hz.

TB46 might have some good ideas for a Karlsonized cabinet with good 1/4 wave path

https://www.youtube.com/watch?v=UJTctkDPKpE

Last edited:

regarding that one-fold speaker diagram from "Nineleaves", since its end driven, there's a suckout. Here's one I made of warped flooring plywood and about the same bulk as a Karlson K15. The response would be smoother if the driver were effectively moved down the line as in MMJ's "Karlflex"

since this was about the same bulk of K15, it should be possible to get lower response than K15 in the same bulk with a possible tradeoff of weaker upper bass response. A more open aperture would move the LF cutoff upwards.

Maybe there is a good Karlsonator 15 alignment about the same external bulk of K15 but with lower reach - - there could be a removable sub-plate to hold the K-tube and its compression driver. Perhaps tuning around 40Hz would preserve some "punch", assuming no peaking on the low end.

the 15 here was a Dayton 295-070 - I did not like in K15 due to poor midrange - it worked well in the simple folded pipe and my Edgar "Monolith" horn.

Dayton 295-070 105oz magnet, power = 250 watts, Voice Coil = 3 in., Spl=95.23dB, Re= 5.4ohm, Fs = 26.4, Qms=8.25/Qes=0.300, Vas= 11.986 cu.ft., Qts=0.29, Le = 1.4mH, BL = 18.2, Xmax = 7.8mm, Sd = 132.7 sq.in.

weight ~20lb, no = 2.007%

Look at the graph of 295-070 in the folded pipe vs K15 with Audio Nirvana Super10 in K15 at 40Hz. The pipe had 12dB more output at 40. A little of this was the Nirvana 10" having fs near 50Hz. The pipe in a corner was pretty flat to 32Hz.

TB46 might have some good ideas for a Karlsonized cabinet with good 1/4 wave path

https://www.youtube.com/watch?v=UJTctkDPKpE

VAS for that Dayton looks very high. More than double that of the Kappa Lite 3015

- Home

- Loudspeakers

- Full Range

- Mini Karlsonator (0.53X) with Dual TC9FDs