Why not just use a simple notch filter?

Surely trying a couple of components is better than chopping up a driver?

Passive narrow notch filters are actually a little tricky, and require simulation to get them to work, at least for me.

Mechanical means are the best way to fix mechanical problems. A notch filter is just a bandaid. The resonance(s) will still be there: obscured but not fixed.

Anyhow, IME passive LCR filters work better as broad (low Q) type filters, to correct rising response, baffle step, etc.

I used to occasionally make laser interferometers as part of my day job. They are good for measuring very small displacements. There is a lot of motion here. Maybe a fiber optic scattering probe can be used to pick up where the various frequencies are located.

Well then, you are the perfect person for the job.

Very roughly, I suspect most drivers are pistonic up to (very roughly) 1kHz or higher, and where this would be useful is the break up region above this. The cone displacements at these high freq are very small.

I guess what I'm referring to is actually called holographic interferometry. (not the 'simple' interferometry from physics lab) I have no idea how it is done, but it's been around 50 years or so.

An externally hosted image should be here but it was not working when we last tested it.

https://acoustics.org/pressroom/httpdocs/140th/rossing.htm

Last edited:

a soft glue ring at the junction of the cone and surround might work - ? High Efficiency Speakers

Coaxial Daytonator

I made a coaxial tweeter mount (hollow to allow wires to pass thru to back via magnet vent hole) with a 3d printer. Then I mounted a small Mylar dome tweeter to it (Weltersys gave me a bunch of these a while back - they are very sensitive and measure flat in an OB above 3.5kHz). With assistance of Byrtt, whom gave me a value of 0.45mH for a 6kHz 1st order LPF for the PA130-8. And using some tables for 4ohm drivers on line, I saw that 6.6uF was needed to get a 6kHz 1st order HPF. I chose 6kHz to let the PA130 do its full range magic in the telephone band and let the tweeter take over the supertweeter duties. I wound my own inductor to 0.44mH (as measured with DATS), added a 5ohm resistor to pad the tweeter and mounted it all up onto the PA130.

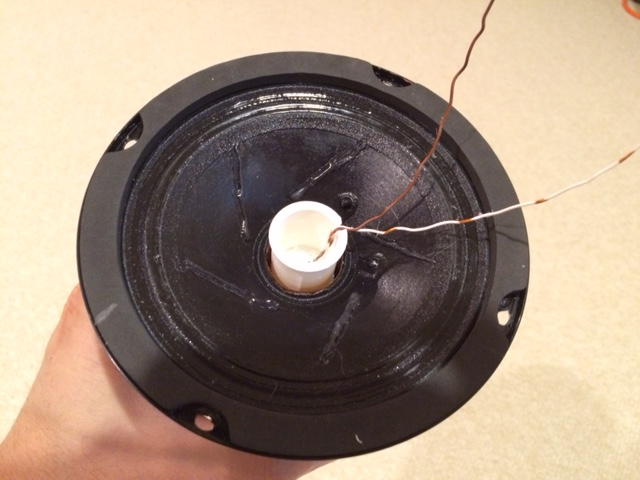

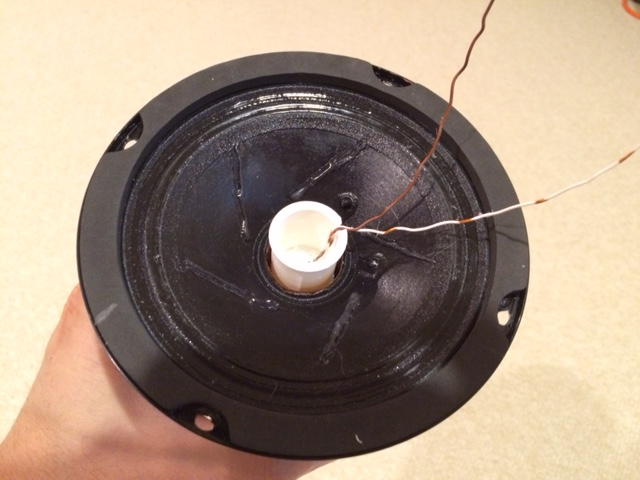

Here is photo of the coax tweeter mount sticking out of voice coil bore:

Here is the 6kHz crossover as mounted on back of magnet (actual uses 5R and only single 3.3uF):

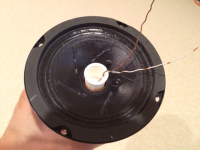

Here is the completed coaxial Daytonator:

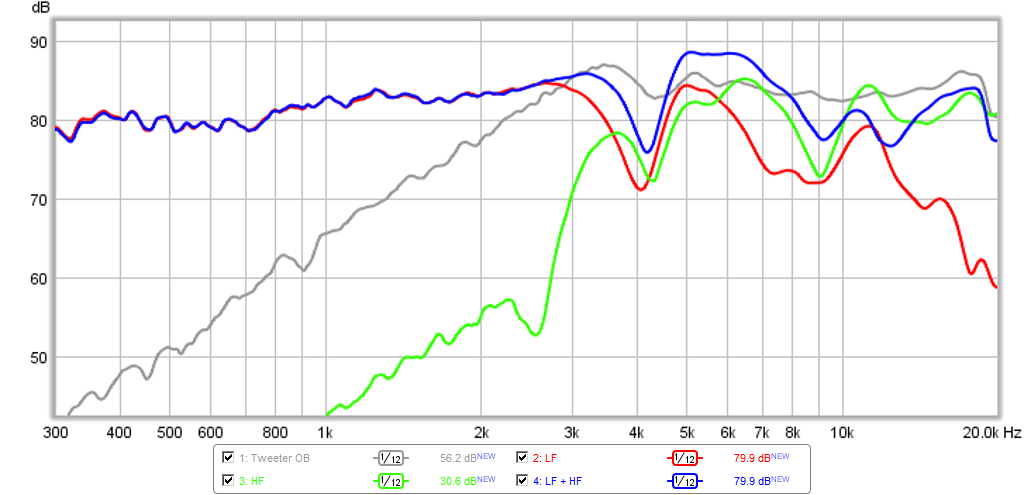

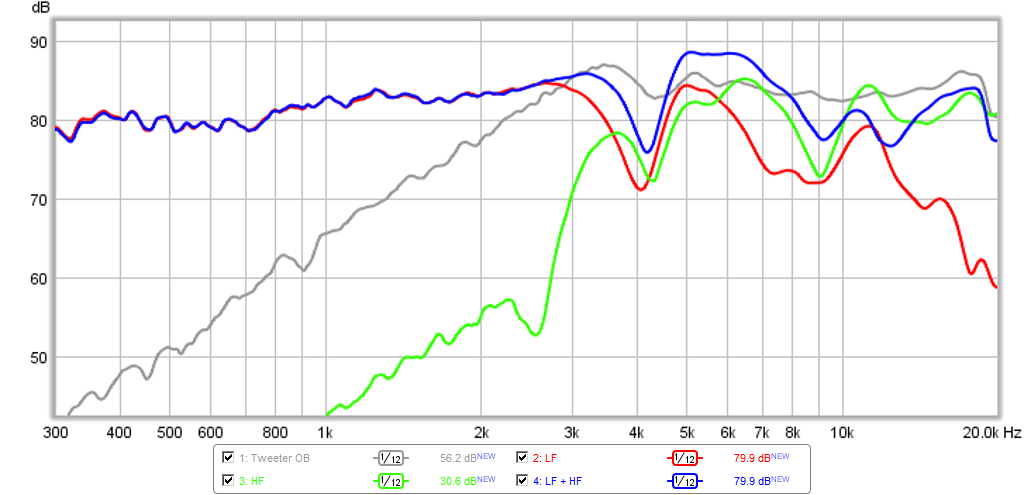

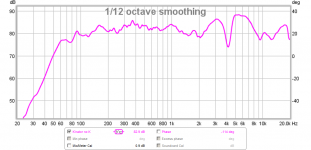

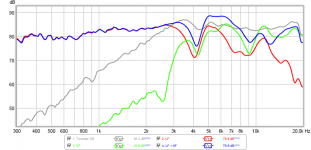

Here is the measured response with a 3.3uF cap (6.6 was too much, and 3.3uF is still too way much as XO freq appears to be in the range of 3kHz still) in a Nautaloss sealed spiral TL (gray line is tweeter in a small rectangular baffle to see native response - the round tweeter body diffraction wreaks havoc (green) on the otherwise smooth response of the tweeter(gray)):

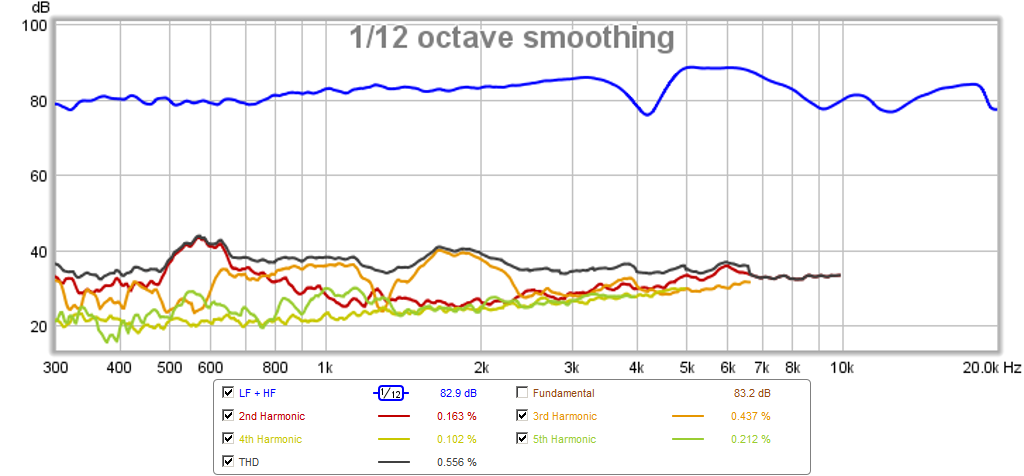

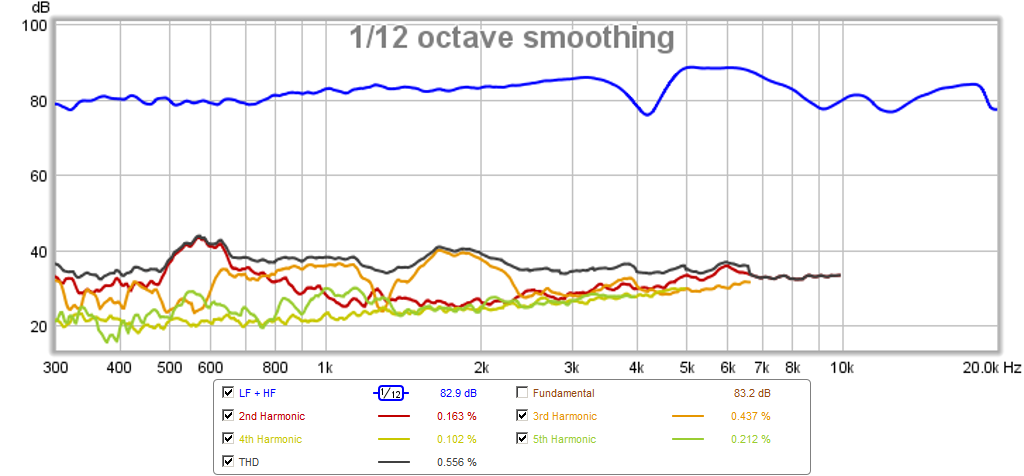

Here is the measured distortion:

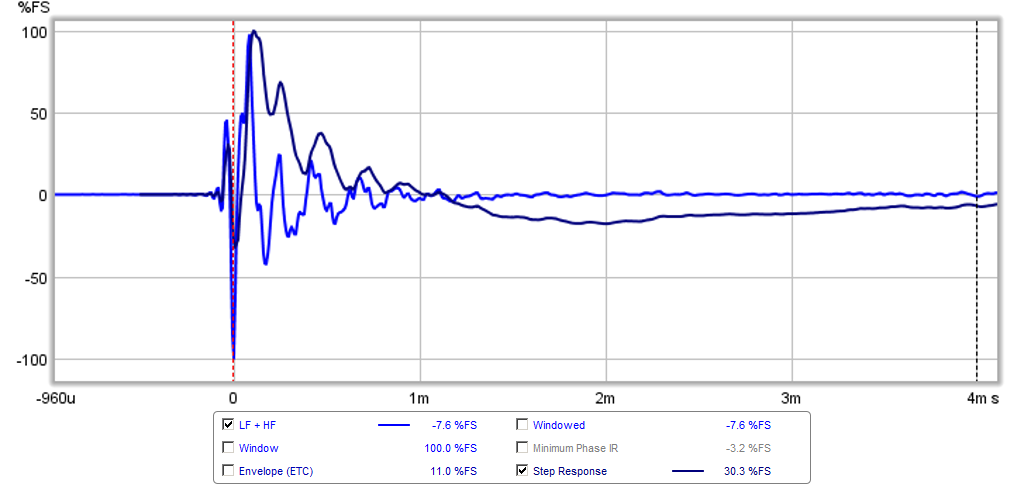

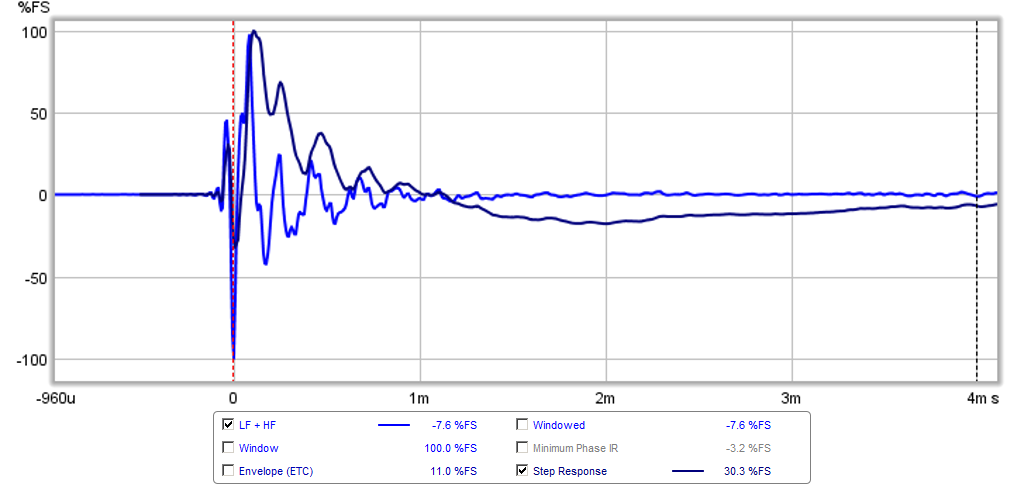

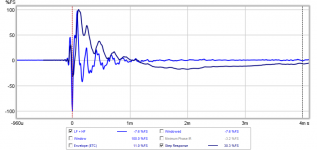

Here is the measured impulse and step:

Now, here is the new coax mounted in an XKi:

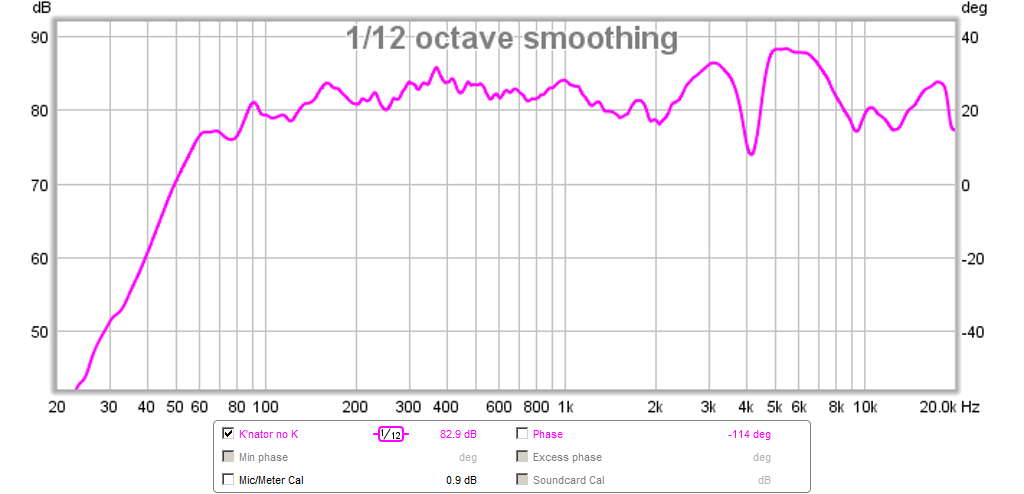

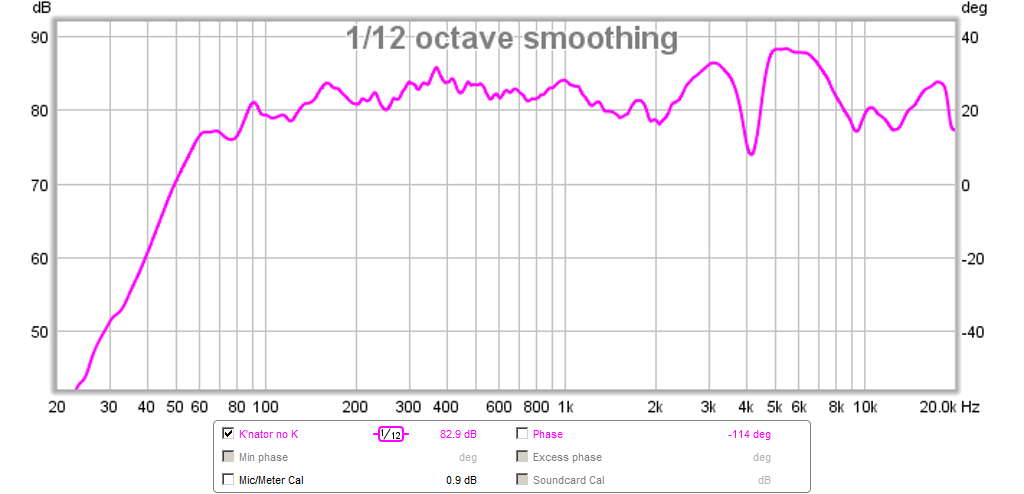

This is the measured response in the XKi without the K aperture:

Initial listening tests are very promising - very clear and sharp percussion, great vocals. A bit bright at the 6kHz peak though, however, with K aperture that smooths out quite a bit. Very loud (sensitive) and doesn't take much amp power for great volume. Nice bass from XKi.

I made a coaxial tweeter mount (hollow to allow wires to pass thru to back via magnet vent hole) with a 3d printer. Then I mounted a small Mylar dome tweeter to it (Weltersys gave me a bunch of these a while back - they are very sensitive and measure flat in an OB above 3.5kHz). With assistance of Byrtt, whom gave me a value of 0.45mH for a 6kHz 1st order LPF for the PA130-8. And using some tables for 4ohm drivers on line, I saw that 6.6uF was needed to get a 6kHz 1st order HPF. I chose 6kHz to let the PA130 do its full range magic in the telephone band and let the tweeter take over the supertweeter duties. I wound my own inductor to 0.44mH (as measured with DATS), added a 5ohm resistor to pad the tweeter and mounted it all up onto the PA130.

Here is photo of the coax tweeter mount sticking out of voice coil bore:

Here is the 6kHz crossover as mounted on back of magnet (actual uses 5R and only single 3.3uF):

Here is the completed coaxial Daytonator:

Here is the measured response with a 3.3uF cap (6.6 was too much, and 3.3uF is still too way much as XO freq appears to be in the range of 3kHz still) in a Nautaloss sealed spiral TL (gray line is tweeter in a small rectangular baffle to see native response - the round tweeter body diffraction wreaks havoc (green) on the otherwise smooth response of the tweeter(gray)):

Here is the measured distortion:

Here is the measured impulse and step:

Now, here is the new coax mounted in an XKi:

This is the measured response in the XKi without the K aperture:

Initial listening tests are very promising - very clear and sharp percussion, great vocals. A bit bright at the 6kHz peak though, however, with K aperture that smooths out quite a bit. Very loud (sensitive) and doesn't take much amp power for great volume. Nice bass from XKi.

Attachments

-

pa130-coax-photo-1.png421.6 KB · Views: 1,444

pa130-coax-photo-1.png421.6 KB · Views: 1,444 -

pa130-coax-xki-no-aperture.png59.8 KB · Views: 1,348

pa130-coax-xki-no-aperture.png59.8 KB · Views: 1,348 -

pa130-coax-ir.png63.5 KB · Views: 1,354

pa130-coax-ir.png63.5 KB · Views: 1,354 -

pa130-coax-hd.png100.9 KB · Views: 1,365

pa130-coax-hd.png100.9 KB · Views: 1,365 -

pa130-coax-freq-xo.png88.8 KB · Views: 1,425

pa130-coax-freq-xo.png88.8 KB · Views: 1,425 -

pa130-coax-photo-4.png375.4 KB · Views: 3,006

pa130-coax-photo-4.png375.4 KB · Views: 3,006 -

pa130-coax-photo-3.png441.8 KB · Views: 3,652

pa130-coax-photo-3.png441.8 KB · Views: 3,652 -

pa130-coax-photo-2.png487.1 KB · Views: 3,245

pa130-coax-photo-2.png487.1 KB · Views: 3,245

Last edited:

nice mod ! - what currently available tweeters would fit?

It's pretty flexible as I just make the supporting post for the tweeter higher to accommodate a larger dia tweeter. It helps to have a smaller dia tweeter body including the magnet. So here, a neodymium magnet tweeter is ideal. My tweeter has a pretty small magnet so I am guessing it might be neodymium given that it is about 94dB sensitive and tiny. I really want to know what brand tweeter this is as it measures amazingly flat above 3.5kHz if given a proper flat baffle and flush mounting.

I think most run of the mill Mylar domes can work as long as under 2in overall dia.

I think Apex Jr tweeter may be perfect given the small size:

http://apexjr.com/speakerstuff.html

The Vifa coax here looks very promising as an XKi coax. Note the non round bezel on tweeter. I may try that to help reduce the massive diffraction from the round bezel. Round is worst shape for diffraction.

This polycarbonate tweeter may work too:

Last edited:

Wow! Gotta put this on my 'To do' list!

Great job, xrk!

Thanks! This was fun and I can see possibilities with all sorts of drivers as long as there is a vent hole in the magnet. Otherwise you have a wire crossing the front of cone - which isn't all that big of a deal just doesn't look as "OEM". You don't need a 3d printer - find convenient dia plastic piping and cut to length and use hot melt or epoxy to glue in place. Be careful not to glue voice coil. I accidentally had excess hot melt squeeze out and glued the VC to the pole piece. Lucky for me hot melt comes off Kapton and painted iron with a firm pull. Epoxy would have been a tragic ending.

If you have active XO via DSP no need to make passive XO. I just wanted a simple standalone speaker. This unit is now ready to go on travel with a simple class D amp for listening pleasure anywhere in house or in backyard. This is my first usable passive XO. I made one for the Ref monitors but as a FAST XO at 500Hz, much more difficult to get right.

I think you are right about the only thing better is to mount in old dustcap position to use cone as waveguide. There is not much to be done about edge diffraction on tweeter body. I wonder how car audio coaxials measure? They certainly don't use as nice a XO. I made my XO from half a $2 coil so $1 cost and cap is $0.6 and resistor is $0.6 so $2.20 total for XO parts. Tweeters are typical $1 to $2 for buyouts. So coax can be made for about $22 total cost. Pretty high performing coax for the money IMO.

Great job xrk971 The Daytonator driver did then get its life back : )

As you talked about, mounting tweeter inside coil diameter 5th element milled down a ND16 tweeter in mod below.

More info that one http://www.htguide.com/forum/showthread.php?38667-B-amp-W-FST-mid and http://www.htguide.com/forum/showthread.php?42114-The-Odd-Couple&p=593742&viewfull=1#post593742.

As you talked about, mounting tweeter inside coil diameter 5th element milled down a ND16 tweeter in mod below.

More info that one http://www.htguide.com/forum/showthread.php?38667-B-amp-W-FST-mid and http://www.htguide.com/forum/showthread.php?42114-The-Odd-Couple&p=593742&viewfull=1#post593742.

Attachments

How about this? Price is for a pair - https://www.parts-express.com/tang-band-13-1761s-1-2-silk-dome-tweeter-pair--264-841

I think you are right about the only thing better is to mount in old dustcap position to use cone as waveguide. There is not much to be done about edge diffraction on tweeter body. I wonder how car audio coaxials measure? They certainly don't use as nice a XO. I made my XO from half a $2 coil so $1 cost and cap is $0.6 and resistor is $0.6 so $2.20 total for XO parts. Tweeters are typical $1 to $2 for buyouts. So coax can be made for about $22 total cost. Pretty high performing coax for the money IMO.

Hi X,

I have been following this thread and the XKI, great threads. I've had a pair of PA-130's for a boom box project but will build a XKI instead, probably out of MDF. Here is a thread for a coaxial Pioneer BOFU. It shows how to drill a hole through the magnet and mount the super tweeter. I plan on doing this for a future project. I will attempt a coaxial PA-130. Thanks for your hard work !!!

http://www.diyaudio.com/forums/full...-b20-coaxial-tweeter-install.html#post1675046

How about this? Price is for a pair - https://www.parts-express.com/tang-band-13-1761s-1-2-silk-dome-tweeter-pair--264-841

Thanks for the tip! These are sweet and the perfect size to go into the voice coil bore (0.93in ID). They might even be the perfect depth to let the cone act as a waveguide.

The FST actually has a 30mm diameter voice coil which is a very tight fit for most decent tweeters.

The ND16 is a great little driver for the price but was being pushed a tiny bit too hard with the 2.5kHz xover required for a good directivity match between the two.

As was said in the other thread I have since changed over to some new old stock Aura NS1 tweeters that are far more capable and actually measure much nicer. I should really take a picture of that.

Here though things look quite nice except from the null you're seeing at 8kHz with the tweeter. This is due to it being mounted on a stalk. If you could get a tweeter down into the voice coil that would be ideal.

Interestingly to gain the directivity controlling aspect of a coax you really do have to have the tweeter down in the coil. If it stands proud the wavefront doesn't load the cone properly and all your left with is a tweeter on a stalk to contend with. Of course you will still benefit from having aa c2c distance of nothing.

The ND16 is a great little driver for the price but was being pushed a tiny bit too hard with the 2.5kHz xover required for a good directivity match between the two.

As was said in the other thread I have since changed over to some new old stock Aura NS1 tweeters that are far more capable and actually measure much nicer. I should really take a picture of that.

Here though things look quite nice except from the null you're seeing at 8kHz with the tweeter. This is due to it being mounted on a stalk. If you could get a tweeter down into the voice coil that would be ideal.

Interestingly to gain the directivity controlling aspect of a coax you really do have to have the tweeter down in the coil. If it stands proud the wavefront doesn't load the cone properly and all your left with is a tweeter on a stalk to contend with. Of course you will still benefit from having aa c2c distance of nothing.

Check out this coax.

http://www.diyaudio.com/forums/multi-way/279383-coaxials-flat-woofers.html

Flat!

http://www.diyaudio.com/forums/multi-way/279383-coaxials-flat-woofers.html

Flat!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- The Daytonator - PA130-8X