You said a small baffle will produce a lot of diffraction and the location of the higher order modes will affect the way they average.

I was hoping for more of an explanation of what you mean, whether this is something you have measured, tested, simulated or have something to show to make it clearer.

I was hoping for more of an explanation of what you mean, whether this is something you have measured, tested, simulated or have something to show to make it clearer.

AllenB I have same questions as fluid, it is hard to understand what you mean.

Demonstrated many times on this thread that if transducer is scaled with the baffle the diffraction (features) stays the same, the features only move up or down in frequency on a frequency response plot (measured from any direction). Features move up in frequency as the system gets smaller and down when it gets bigger. Relation of the size of transducer, construct and wavelength stay the same, features stay the same, only the wavelength (frequency) varies. If you want to have more diffraction, the diffracting bandwidth needs to be increased, enlarging the baffle while keeping the transducer size the same would do it.

If stated that "narrow baffle diffracts more" then it reads to me the transducers on that baffle need to be even narrower in comparison to system what you reference against, which in turn makes the small system wide baffle relative to size of transducer and not narrow baffle even if being smaller than what you compare against. Yes small baffle will make lot of diffraction when the transducer is small in relation, in order it to radiate towards the edge. Same happens with scaled up system, only thing changes is the frequencies you see the diffraction on frequency response plot, but the amount is same.

For more diffraction we need more sound to the edge, either louder than direct sound or wider bandwidth. Since the construction is considered narrower and longer wavelengths just wrap around we would need more higher frequencies on the edge to compensate, and to get even more diffraction as baffle size gets smaller even more shorter wavelengths should reach the edge. This means smaller direct radiating transducer to fullfill claim that small baffle diffracts a lot, in other words this is relatively wide baffle diffracts more. We need to increase the diffracting bandwidth to get more diffraction. Bigger direct radiating transducers don't radiate high frequencies towards the edge due to beaming and thus least diffraction is achieved with relatively smallest baffle = narrow baffle, as narrow to just accommodate the transducer. Roudovers would reduce diffraction even more, even if means widening the baffle, just don't add any flat baffle beside the transducer which starts to make the roundovers ineffective against longer wavelength that the baffle now supports. Relation between physical size and wavelength.

Is this what you are saying or something else? If something else it doesn't correlate with the simulations, unless something I've failed to see from the experiments. Might be just misunderstanding so pardon if this feels an assault, trying to get bottom of it.

Demonstrated many times on this thread that if transducer is scaled with the baffle the diffraction (features) stays the same, the features only move up or down in frequency on a frequency response plot (measured from any direction). Features move up in frequency as the system gets smaller and down when it gets bigger. Relation of the size of transducer, construct and wavelength stay the same, features stay the same, only the wavelength (frequency) varies. If you want to have more diffraction, the diffracting bandwidth needs to be increased, enlarging the baffle while keeping the transducer size the same would do it.

If stated that "narrow baffle diffracts more" then it reads to me the transducers on that baffle need to be even narrower in comparison to system what you reference against, which in turn makes the small system wide baffle relative to size of transducer and not narrow baffle even if being smaller than what you compare against. Yes small baffle will make lot of diffraction when the transducer is small in relation, in order it to radiate towards the edge. Same happens with scaled up system, only thing changes is the frequencies you see the diffraction on frequency response plot, but the amount is same.

For more diffraction we need more sound to the edge, either louder than direct sound or wider bandwidth. Since the construction is considered narrower and longer wavelengths just wrap around we would need more higher frequencies on the edge to compensate, and to get even more diffraction as baffle size gets smaller even more shorter wavelengths should reach the edge. This means smaller direct radiating transducer to fullfill claim that small baffle diffracts a lot, in other words this is relatively wide baffle diffracts more. We need to increase the diffracting bandwidth to get more diffraction. Bigger direct radiating transducers don't radiate high frequencies towards the edge due to beaming and thus least diffraction is achieved with relatively smallest baffle = narrow baffle, as narrow to just accommodate the transducer. Roudovers would reduce diffraction even more, even if means widening the baffle, just don't add any flat baffle beside the transducer which starts to make the roundovers ineffective against longer wavelength that the baffle now supports. Relation between physical size and wavelength.

Is this what you are saying or something else? If something else it doesn't correlate with the simulations, unless something I've failed to see from the experiments. Might be just misunderstanding so pardon if this feels an assault, trying to get bottom of it.

Last edited:

No, why do you say "a lot" of diffraction for a narrow baffle and in what way does the higher order modes affect the averaging.That sound would diffract at the edge of a narrow baffle?

Thanks !Hifijim, nice progress!🙂

The difference in DI between tweeter and mid driver at 2k is only 1.5 dB. A smaller mid driver would be better from a DI standpoint, and there are some candidates such as scanspeak 10f and Eton 3-212... However, Considering that this simulation is using idealized drivers, a DI of +/- 1 db from 700 to 7k is good enough I believe. I want these sims to be applicable to the widest selection of drivers possible. I firmly believe it is a mistake to sacrifice other areas of performance in order to make directivity look perfect on a graph. Good enough is good enough. And remember, I am not in the process of designing a new speaker, I just want to explore what is possible and probe the limits of VituixCad simulation.If you look at the Slide3 and 4 on your post and compare the DI graphs you'll see there is match only at about 1kHz, which would be even better crossover point in this arrangement directivity wise. You'd need smaller woofer to get the DI match higher to your crossover point, or bigger tweeter to get crossover down, basically bring the two closer in size.

I am only interested in 3-way speakers at this point, but this exercise is about mid and tweeters from 500 to 20k, so I am not bothering with simulating woofers.... due to 10cm flange of direct radiating tweeter you'd need about >5cm radius round over around it in order to get diffraction down just from the tweeter as you found out. Use 10cm woofer to get DI of both woofer and tweeter closer to match. This would make it 3-way system territory though as there wouldn't be much bass SPL capability on such small woofer. This is the compromise on such 2-way systems, having extended highs and lows means some compromise on mids. Pick any two from lows, highs, mids and the third has some kind of compromise requiring third way for "better performance". Third way comes with another set of compromises and you might just like the two ways better event with minor issues, they might not be that important.

Kimmo has emphasized that the tweeter should have little to no on-axis baffle gain below the crossover... i.e the diffraction hump. I had to prove it to myself, and of course, he is right. A typical rectangular baffle of 250mm wide creates directivity in the 800 to 2k region. Above that the tweeter becomes more omnidirectional, and directivity falls. Then higher up the tweeter begins to beam and directivity rises again. So the tweeter diffraction hump should be as small as possible. For a while I was focused on where the diffraction hump was located relative to the crossover frequency, or relative to the point where the mid driver began to beam. I concluded that those factors are not as important as simply minimizing the size of the hump. If it can be reduced to just 1 dB, everything else falls into place.

Another interesting thing I found is that no matter how wide the box is made, the flat portion of the baffle needs to be 100 mm (or smaller if the flange allows it). For example, a 250mm wide cabinet should have a radius/bevel of 75mm, which leaves a flat baffle of 100 mm. This performs better than my post #193 example of a 200mm wide + 50mm radius/bevel. An even better cabinet is a 300 mm wide cabinet with 100 mm radius/bevels, and here the performance is excellent. In fact, the vertical position of the tweeter starts to become insignificant, and the diffraction hump is less than 1 dB no matter where the tweeter is positioned. However the size of the radius/bevels starts to become very difficult to construct.

j.

Nice, got pretty much same conclusion from the experiments posted here few days ago, roundovers it is, only way to get the hump less. The hump can be passed to some frequency but as the hump is quite wide and all practical cabinet sizes fall into roughly 500-2kHz wavelength the hump is gonna be there, more or less, until roundovered away 😀 This is also from VituixCAD sim: as the roundover r is about driver diameter, or in this case the flange diameter, then the hump is about gone, the point where the system becomes reasonable approximation of a sphere. Slants / bevels / roundovers, are mandatory or there is going to be narrowing. Although, perhaps waveguide + woofer system the woofer can get without, smallest baffle without roundovers gives nice rising DI, easy to match DI with a waveguide.

Not more or less, but indeed there is diffraction. Are you perhaps implying that because the plots look good then there isn't any diffraction? Or are you just saying that while there is diffraction, the plots show that it's not a problem?No, why do you say "a lot" of diffraction for a narrow baffle

Yeah the edge shape size needs to be in proportion to wavelength, small edge shape affects down to small wavelengths, big edge shape affects down to big wavelengths. GM showed some calculation for this some time a go on some thread I don't remember currently. You could easily test this with diffraction simulator, how big a roundover needs to be to remove a) possible ripple above the main diffraction hump b) also the main diffraction hump.

Main diffraction hump happens on frequency whose wavelength is about baffle width or more depending on the shape of the baffle, something between longest and shortest dimension. It looks like one needs at least "flat baffle dimension" worth radius on the roundover to really lessen the main hump. Example, if there is 20cm flat baffle and you add additional roundovers to it, you get 60cm wide baffle with 20cm radius roundovers. If it was naked 1" tweeter without any flange around the transducer instead, ~3" total width with 1" radius roundovers would be about enough but if you put this tweeter on the same baffle with 20cm woofer, 20cm flat baffle, you need to go to the 20cm radius roundovers. The key is to approximate sphere and the baffle (or at least driver, a minimum size baffle situation) defines how big you need to go with roundovers to get a sphere as the flat part is a slice on it and makes flat a part with edge 😀

Of course, if enclosure was smaller than wavelength it reproduces no roundovers are needed because the sound just wraps around. On a loudspeaker there is at least one bafflestep somewhere and diffraction hump no matter what, with woofers you can potentially crossover to smaller one below bafflestep but at very last the tweeter would need to handle it because there is nothing to crossover to above. Roundovers it is. In general, the smaller the baffle area (including the transducer(s)) the smaller roundovers are enough.

This is simplified and only considering "flat" direct radiating drivers on reasonably symmetric flat baffle. so excluding waveguides for example, or highly asymmetric shapes like slim towers which might spread the main diffraction hump a lot making it reasonably smooth already. However it looks like the diffraction goes away completely only with big roundovers, with a sphere. ATH script generated freestanding waveguides seem to get away with reasonably small roundover compared to wavelength for example.

Main diffraction hump happens on frequency whose wavelength is about baffle width or more depending on the shape of the baffle, something between longest and shortest dimension. It looks like one needs at least "flat baffle dimension" worth radius on the roundover to really lessen the main hump. Example, if there is 20cm flat baffle and you add additional roundovers to it, you get 60cm wide baffle with 20cm radius roundovers. If it was naked 1" tweeter without any flange around the transducer instead, ~3" total width with 1" radius roundovers would be about enough but if you put this tweeter on the same baffle with 20cm woofer, 20cm flat baffle, you need to go to the 20cm radius roundovers. The key is to approximate sphere and the baffle (or at least driver, a minimum size baffle situation) defines how big you need to go with roundovers to get a sphere as the flat part is a slice on it and makes flat a part with edge 😀

Of course, if enclosure was smaller than wavelength it reproduces no roundovers are needed because the sound just wraps around. On a loudspeaker there is at least one bafflestep somewhere and diffraction hump no matter what, with woofers you can potentially crossover to smaller one below bafflestep but at very last the tweeter would need to handle it because there is nothing to crossover to above. Roundovers it is. In general, the smaller the baffle area (including the transducer(s)) the smaller roundovers are enough.

This is simplified and only considering "flat" direct radiating drivers on reasonably symmetric flat baffle. so excluding waveguides for example, or highly asymmetric shapes like slim towers which might spread the main diffraction hump a lot making it reasonably smooth already. However it looks like the diffraction goes away completely only with big roundovers, with a sphere. ATH script generated freestanding waveguides seem to get away with reasonably small roundover compared to wavelength for example.

Last edited:

I'm glad we cleared up that when you said a lot you meant not more or less but some...Not more or less, but indeed there is diffraction. Are you perhaps implying that because the plots look good then there isn't any diffraction? Or are you just saying that while there is diffraction, the plots show that it's not a problem?

No implication and it is not polite to answer a question with a question unless one is in therapy and paying for the privilege.

I am making good progress on my foamboard mockup. The goal of this project is to evaluate the capability of VituixCad2 to simulate the diffraction performance of a beveled/faceted box, i.e. an Avalon-style baffle. This style of cabinet seems to be the current state of the art for managing directivity of a non-waveguide tweeter. Vcad allows the user nearly unlimited freedom to create a baffle shape, but the edge radius is a fixed value which applies to all edges of the baffle. So when we want to simulate a beveled/faceted baffle, we are going to have to make some assumptions and approximations.

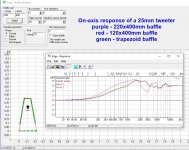

I started with a simple rectangular box, 200mm wide and 425mm tall. The tweeter I am using is the SB26CDC-C000-4, which I had on hand for use in a future project. This tweeter has it's first resonance above 20k, and the infinite baffle response is very flat. This makes it a good driver to compare to ideal driver responses. The tweeter is symmetrically located 100 mm from the top and 100 mm from each side. This box will have bevels cut into it, but first I wanted to take some baseline data.

I use ARTA with an Audix TM1 mic, measuring distance of 1m, and my gating window was about 5 ms. I took horizontal and polar measurements from 0 to 180 degrees, in 15 degree increments.

j.

I started with a simple rectangular box, 200mm wide and 425mm tall. The tweeter I am using is the SB26CDC-C000-4, which I had on hand for use in a future project. This tweeter has it's first resonance above 20k, and the infinite baffle response is very flat. This makes it a good driver to compare to ideal driver responses. The tweeter is symmetrically located 100 mm from the top and 100 mm from each side. This box will have bevels cut into it, but first I wanted to take some baseline data.

I use ARTA with an Audix TM1 mic, measuring distance of 1m, and my gating window was about 5 ms. I took horizontal and polar measurements from 0 to 180 degrees, in 15 degree increments.

j.

Attachments

The results with the rectangular box are shown below. I also compare the measured performance to the VituixCad2 prediction. What I am most interested in is the simulation DI between 800 Hz and 4k, and how it compares to the measurement DI. Above 4k, the tweeter's directivity is probably dominated by the driver itself, not the baffle.

Overall, I am impressed by how closely the Vcad prediction follows reality. The simulation DI and the measurement DI match really closely over the 800-4k frequency range. The horizontal polar maps have a similar shape. In general, the measured driver has slightly narrower dispersion (higher directivity) than the simulation, but they are close enough for design purposes IMO.

j.

Overall, I am impressed by how closely the Vcad prediction follows reality. The simulation DI and the measurement DI match really closely over the 800-4k frequency range. The horizontal polar maps have a similar shape. In general, the measured driver has slightly narrower dispersion (higher directivity) than the simulation, but they are close enough for design purposes IMO.

j.

Attachments

I used my table saw to cut bevels in the foamboard box, but my saw blade does not cut deep enough to fully make the cut. I had to finish the cut with a hand saw. My intention was to make bevels which were 35 degrees from the baffle face (based on https://heissmann-acoustics.de/en/schraege-fasen/ )... However, after my hand saw cutting was cleaned up with a block plane, the bevel became more of a gentle radius which starts at 35 degrees at the baffle face and transitions to about 45 degrees at the box side.

The tapered baffles on the side were sized to just touch the tweeter flange. They have a 50 mm depth at the tweeter horizontal centerline, and a greater depth above the tweeter. The entire length of the vertical bevel is about 300 mm. The left side and right side bevels are not exactly the same, but measurements indicate that the performance left vs right differences are insignificant.

The hand plane left a roughly textured surface on the foam, and i was concerned this might have some absorption properties, so I covered the rough areas with tape.

I am still evaluating and documenting the data.... more to come

j.

The tapered baffles on the side were sized to just touch the tweeter flange. They have a 50 mm depth at the tweeter horizontal centerline, and a greater depth above the tweeter. The entire length of the vertical bevel is about 300 mm. The left side and right side bevels are not exactly the same, but measurements indicate that the performance left vs right differences are insignificant.

The hand plane left a roughly textured surface on the foam, and i was concerned this might have some absorption properties, so I covered the rough areas with tape.

I am still evaluating and documenting the data.... more to come

j.

Attachments

The measurements for the beveled box look very promising. The directivity is very even, and there is no on-axis baffle gain. The diffraction hump is nonexistent. Fluid was right to recommend this kind of baffle shape 😎.

My first attempt at simulation is also the simplest simulation: A uniform 50mm edge radius applied to the rectangular 200mm x 425mm box. The comparison to reality is pretty good. The measured data has 1 dB higher directivity from 2.5k to 4k, and I do not know if this is a characteristic of the driver or an error of the simulation. But the overall trend and shape of the simulation is a good match to measured reality.

I am going to continue experimenting with other simulation shapes to see if I can get a better match to reality... but even if I can get no improvement on the above simulation, I would say it is good enough for design purposes.

My first attempt at simulation is also the simplest simulation: A uniform 50mm edge radius applied to the rectangular 200mm x 425mm box. The comparison to reality is pretty good. The measured data has 1 dB higher directivity from 2.5k to 4k, and I do not know if this is a characteristic of the driver or an error of the simulation. But the overall trend and shape of the simulation is a good match to measured reality.

I am going to continue experimenting with other simulation shapes to see if I can get a better match to reality... but even if I can get no improvement on the above simulation, I would say it is good enough for design purposes.

Attachments

Nice job 🙂 The Rockport Atria style simulates well too, found this interesting buildThe measurements for the beveled box look very promising. The directivity is very even, and there is no on-axis baffle gain. The diffraction hump is nonexistent. Fluid was right to recommend this kind of baffle shape 😎.

https://www.diyaudio.com/community/threads/rockport-style-2way-speaker-diy-project.341956/

@tmuikku Why have you omitted the filter equalization that is required to remove the effect of the baffle step? The baffle step is clearly +6dB in size. The equalization would consist of some extra subtractive filtering on the top end of the woofer's response, and some overall attenuation of the tweeter response. This would lead to a flatter summed frequency response for this two-way system. Without such changes, won't the DI plot be much less accurate?Include both drivers and crossover and things change, now there would be additional anomaly in the DI if woofer has narrower directivity than tweeter at crossover. It is just too big size difference between 8" and 1" drivers to do anything else on this than get smaller woofer or waveguide for the tweeter and try again.

View attachment 1037599

Yes, it's difficult to get rid of the inherent radiation characteristics of the woofer and tweeter. Some level of DI mismatch is going to occur when using 8"+1" and 5"+1" driver combinations. These results seem to point to the need for a 3-way system with 10"+4"+1" drivers if good control of DI is to be achieved without the use of a waveguide on the tweeter.Some DI anomaly is expected around crossover on such speaker concept, although the DI hump was reduced some by juggling around with minimal baffle, roundovers and reducing woofer size compared to direct radiating tweeter, and finetuning c-c spacing.

Another awesome rockport style build by the same person.. 😀Nice job 🙂 The Rockport Atria style simulates well too, found this interesting build

https://www.diyaudio.com/community/threads/rockport-style-2way-speaker-diy-project.341956/

https://www.diyaudio.com/community/threads/rockport-avior2-styled-3way-speaker-diy.372873/

Hi, yeah one could use baffle step compensation and compensate the diffraction hump above it by EQ but this does not affect DI, which is determined how the system radiates around acoustically, by the drivers and the construct.@tmuikku Why have you omitted the filter equalization that is required to remove the effect of the baffle step? The baffle step is clearly +6dB in size. The equalization would consist of some extra subtractive filtering on the top end of the woofer's response, and some overall attenuation of the tweeter response. This would lead to a flatter summed frequency response for this two-way system. Without such changes, won't the DI plot be much less accurate?

Such EQ could fix the on axis flat but simultaneously it affects power response, sound all around, and compromise between on-axis/power needs to be made. If one wants both good, DI needs to be better which means different physical construct, a construct that is arranged to make smooth DI (or what ever the goal is).

Yeah one can play with diffraction simulator to find these out and that is about right, inherent narrowing of the drivers makes DI hump and if crossover is fixed then smaller woofer is needed. One just has to be able to crossover below narrowing happens. I used 8"-1" in the example to make the DI hump very clear. Baffle diffraction hump further narrows the response and needs to be taken account as hifijim just has.Yes, it's difficult to get rid of the inherent radiation characteristics of the woofer and tweeter. Some level of DI mismatch is going to occur when using 8"+1" and 5"+1" driver combinations. These results seem to point to the need for a 3-way system with 10"+4"+1" drivers if good control of DI is to be achieved without the use of a waveguide on the tweeter.

I 'm not sure how big audible difference smoothing the DI make if it already is relatively smooth, but obviously it is seen in the graphs and should not be ignored if one wants to make real good performing speaker. Certainly one wouldn' t want to use 8" woofer with direct radiating 1" tweeter. Waveguide would fix that, or smaller woofer. Using smaller woofer might mean the SPL capability is now too limited and third way for bass would fix that. Three way system is very logical result when thinking loudspeakers on almost any perspective be it the SPL capability, cabinet resonances or electro mechanical properties, room acoustics and perhaps even hearing system.

Last edited:

Super cool results. Congrats! And thanks for the effort!The measurements for the beveled box look very promising. The directivity is very even, and there is no on-axis baffle gain. The diffraction hump is nonexistent. Fluid was right to recommend this kind of baffle shape 😎.

Thanks for your answer. Is the VituixCAD model of this 8"+1" system available for download? I'm interested in adjusting some of the settings in this model, and your configuration would be a good starting point.Hi, yeah one could use baffle step compensation and compensate the diffraction hump above it by EQ but this does not affect DI, which is determined how the system radiates around acoustically, by the drivers and the construct.

- Home

- Loudspeakers

- Multi-Way

- VituixCad Simulations with Ideal Drivers