Method is the key to find if it works for you, or even if it works at all!

This is science, so, if you can measure repeatedly and get similar results each time, then the method is well implemented.

If the results look good, they probably are, but always trust your ears as well.

You will learn more about audio related subjects, and about yourself, your preferences, etc.

This is science, so, if you can measure repeatedly and get similar results each time, then the method is well implemented.

If the results look good, they probably are, but always trust your ears as well.

You will learn more about audio related subjects, and about yourself, your preferences, etc.

🙁 It's difficult for someone trying to graduate from textbook crossovers to a thoughtfully designed and engineered one when there seems to be much differing opinions on how to approach it.

It's not so difficult. If your target is to design and optimize multi-way crossover with acoustical off-axis responses including rear sector, power response and directivity index:

- Ignore USB microphones (without internal dual channel loop-back feature) and other variable latency single channel measurement gear and authors/documents recommending it.

- Ignore minimum phase extraction and authors/documents recommending it.

- Measure timing including variation to off-axis 0-180 deg.

- Select crossover simulator which is able to handle acoustical off-axis responses 0-180 deg at least in two planes.

But if your target is to simulate axial response only or max. listening window, you can believe and follow almost anything mentioned on diyaudio (including Bagby's paper). Result could be good with some luck, but it's not so much in your control while simulation.

Select crossover simulator which is able to handle acoustical off-axis responses 0-180 deg at least in two planes.

OOPS we're in XSim thread so off-axis responses ~60-180 deg are not supported and limited obsolete XO design methods are still okay. Sorry about disturbance.

I intend to try as many simulators as reasonably possible (including yours) and compare results. I'm new here and unaware of previous interactions, but why the sarcasm? Making the case for your method would be a lot more helpful than tearing others down.OOPS we're in XSim thread so off-axis responses ~60-180 deg are not supported and limited obsolete XO design methods are still okay. Sorry about disturbance.

Last edited:

I have been using XSIM for three years now and find it very good and easy to use.

Sometimes I have one issue: The schematic window becomes blue and I no longer can modify the values of the parts and there is no output to the graph windows.

I do not know what provoques this ... can you please give me a hint ?

Sometimes I have one issue: The schematic window becomes blue and I no longer can modify the values of the parts and there is no output to the graph windows.

I do not know what provoques this ... can you please give me a hint ?

Attachments

I'm new here and unaware of previous interactions, but why the sarcasm? Making the case for your method would be a lot more helpful than tearing others down.

Sarcasm was not my intention. I don't want anymore new users for my software or recommended measurement method by criticizing others all around discussion forums. More new users -> more tech support and repeating needed for what? It's freeware. Documentation is available and hundreds of users able to write testimonials in English - for and against. But not here because this is for XSim which has it's own role for simple design tasks and studies with axial responses.

P.S. Measurement method I have recommended is not my invention for sure. For example LspCAD, justMLS and IJ's documentation does not have a word about minimum phase extraction. Products are more than 20 years old now. Why? Maybe because it's self evident that almost all radiator types are not minimum phase regardless of driver's properties; excess delay compared to 'sound source' and possible also polarity varies to different off-axis angles. It would be really absurd to claim that possible driver's minimum phase feature alone would define timing and phase if target is to simulate XO with any radiator/enclosure type to half...full space to get directivity, power & DI and so on.

Line of beginners is endless on diy forums, and there will always be more experienced individuals who don't care about features and more advanced simulation results to get good/better results faster than before.

Kim,

I understand about the endless repeating of the same thing over and over.

The answers are out there, but most people don't care about searching for it.

Nothing against you, tekuhn , as you seem to be opened to do some research by yourself to understand things better.

But, I do not understand this:

"there will always be more experienced individuals who don't care about features and more advanced simulation results to get good/better results faster than before."

Being against progress and stuck in the old ways of doing things just feels wrong to me (and I'm no spring chicken!)... there has been many clashes from the old guard who don't want to see or learn about the advancements in audio tools versus some newcomers who are also deeply involved in making great designs using the newest tools available.

To me, that's just stubbornness and the unwillingness of learning something new.

Not so long ago, enclosure and crossover design was reserved to a selected few who understood most of it.

These days, anybody has access to wonderful software from the likes of XSim, VituixCAD, HornResp, etc... people who have gracefully volunteered their skills to the benefit of others.

I am grateful.

Stagnation is a slow death.

Evolution is survival.

Just like music itself.

I understand about the endless repeating of the same thing over and over.

The answers are out there, but most people don't care about searching for it.

Nothing against you, tekuhn , as you seem to be opened to do some research by yourself to understand things better.

But, I do not understand this:

"there will always be more experienced individuals who don't care about features and more advanced simulation results to get good/better results faster than before."

Being against progress and stuck in the old ways of doing things just feels wrong to me (and I'm no spring chicken!)... there has been many clashes from the old guard who don't want to see or learn about the advancements in audio tools versus some newcomers who are also deeply involved in making great designs using the newest tools available.

To me, that's just stubbornness and the unwillingness of learning something new.

Not so long ago, enclosure and crossover design was reserved to a selected few who understood most of it.

These days, anybody has access to wonderful software from the likes of XSim, VituixCAD, HornResp, etc... people who have gracefully volunteered their skills to the benefit of others.

I am grateful.

Stagnation is a slow death.

Evolution is survival.

Just like music itself.

Last edited:

Hi Bill,

I´m late to the party, but have to say thanks for a great and very helpful piece of software, which has saved many many hours of work.

Thanks again and all the best

Mattes

I´m late to the party, but have to say thanks for a great and very helpful piece of software, which has saved many many hours of work.

Thanks again and all the best

Mattes

I apologize if I misinterpreted the intention of your comment.Sarcasm was not my intention.

BTW, in my case it is not a lack of desire to take the extra effort to make a good design a great one, just the opposite. It is a lack of understanding when reading documentation describing procedures that use terminology that is not fully understood for meaning, and therefore, importance. I found this two-part series of articles by Joe D'Appolitto that helped tremendously in understanding the advanced concepts that you advocate for. He also ranks characteristics of loudspeakers in order of importance for perceiving a design to sound good, or not. This is helpful in deciding how far to take a design to achieve goals of diminishing returns (that you might, or might not be able to hear).

Joe D'Appolito-Which Measurements Matter-Part 1

Joe D'Appolito-Which Measurements Matter-Part 2

Thanks to all who help - I'm grateful for the support.

Hello guys

I been reading a ton of these post, pretty much over my head. Lol

I have a set of towers that was someone else’s diy, he use a diy electron a crossover system with 3 diy amps

I really would like someone to help me make, or I should say design some crossovers for them. I can build them ,

I have REW and a mic and could ( with

Some directions ) do the measurements with the drivers inside the cabinet and also provide all the measurements from the factory

So is their someone up to the Challenge ?

Thanks and my email is carlthess@yahoo.com

And yes this is my junk email that I dont care about giving out in open forum, so no need to lecture me about it. Lol

Thanks for anyone willing to help

I been reading a ton of these post, pretty much over my head. Lol

I have a set of towers that was someone else’s diy, he use a diy electron a crossover system with 3 diy amps

I really would like someone to help me make, or I should say design some crossovers for them. I can build them ,

I have REW and a mic and could ( with

Some directions ) do the measurements with the drivers inside the cabinet and also provide all the measurements from the factory

So is their someone up to the Challenge ?

Thanks and my email is carlthess@yahoo.com

And yes this is my junk email that I dont care about giving out in open forum, so no need to lecture me about it. Lol

Thanks for anyone willing to help

I apologize if I misinterpreted the intention of your comment.

Not entirely misinterpreted. Some amount of unintentional sarcasm could exist though intention was not to be rude or disrespectful.

To be more on topic, someone native English should modify new version from Bagby's paper to support measured phase with dual channel loop-back or compatible gear and simple X-ray driver-mic geometry calculation in XO simulation without need of actual complex sound path length calculation and composed polarity due to minimum phase extraction. That would be compatible with all simulators allowing timing adjustment of measurement data also in seconds instead of mechanical distance (Z) only. Simple USB mics will not be supported but that's not big deal imo.

My documentation is quite truncated, "Finglish" and not so easy to catch the idea - especially if local traditions; methods and tools are haunting in the head.

You do quite well. I had a friend many years ago from Finland that taught me to fly radio-controlled model airplanes. First name was Viano, but he went by Vasky. I'm not sure if that is a common name/nickname or not.......My documentation is quite truncated, "Finglish" and not so easy to catch the idea - especially if local traditions; methods and tools are haunting in the head.

Hey guys,hoping you can help a newb here..

i have a pair of infinity Kappa 8A speakers,i Love these speakers,do not wish to upgrade or change them,the polydomes (midrange) drivers die out with time,they re originally 4 ohm drivers, i replaced them with scanspeak( will attach a spec picture) the new driver's 8 ohms, so my concern now is the crossover of the midrange, i know it needs to be modified but has no idea how, any help would be appreciated!

i ll attach a schematic of the crossover(page 2)

i have a pair of infinity Kappa 8A speakers,i Love these speakers,do not wish to upgrade or change them,the polydomes (midrange) drivers die out with time,they re originally 4 ohm drivers, i replaced them with scanspeak( will attach a spec picture) the new driver's 8 ohms, so my concern now is the crossover of the midrange, i know it needs to be modified but has no idea how, any help would be appreciated!

i ll attach a schematic of the crossover(page 2)

Attachments

^ Your stock crossover has the mid to tweeter filters tuned near 4k/10k. I can only imagine with these, and the way these drivers would behave at higher frequencies that this crossover is 'special' in it's own way.

In the above plot the driver is going through breakup give and take 4k. It also narrows.. It's difficult to say exactly what to do. You may find the solution by listening, even though I can think of a few ways that Xsim could be handy along the way.

Adding to this, I think the initial goal would be to have the new driver fit the same as the original, at least with regard to its tonal contribution. The fit isn't going to be identical, partly because the driver does not behave the same on all axes. First you would only intend to adjust the mid crossover. After this, the other crossovers might need minor tweaks to bring them into line, as long as you feel you've done what you can with the mid. However, in doing this you might find the new driver can't fulfill this role properly and you want to change the crossover frequencies a little.. or you decide you want to trim it's working band to cut out a problem and then adjust the other drivers to fill in.

In the above plot the driver is going through breakup give and take 4k. It also narrows.. It's difficult to say exactly what to do. You may find the solution by listening, even though I can think of a few ways that Xsim could be handy along the way.

Adding to this, I think the initial goal would be to have the new driver fit the same as the original, at least with regard to its tonal contribution. The fit isn't going to be identical, partly because the driver does not behave the same on all axes. First you would only intend to adjust the mid crossover. After this, the other crossovers might need minor tweaks to bring them into line, as long as you feel you've done what you can with the mid. However, in doing this you might find the new driver can't fulfill this role properly and you want to change the crossover frequencies a little.. or you decide you want to trim it's working band to cut out a problem and then adjust the other drivers to fill in.

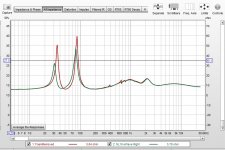

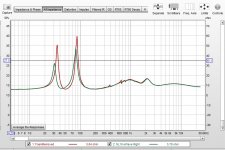

I spent some time this evening trying to fix my box tuning. I was aiming for 55Hz, but the impedance dip indicates it's tuned at 41Hz. I have been shortening and increasing diameter of the two ports and it is making very, very little change. Nowhere near as much as the calculator would indicate. I have managed to get it up to 47Hz, but it just won't go any higher. I tried covering one of the ports and tuning dropped to 35Hz (as expected). Are there other factors that could make the impedance dip show the wrong frequency or affect tuning such as stuffing? I am also testing through the x-over, but there is nothing weird in it to change the low frequency impedance. The cabinet is lined on the back and right and left sides with 2.5" acoustic foam. The higher frequency peak (50Ω) is much higher than the peak below the box tuning (34Ω), which I have read is also an indicator that the tuning is too low.yeah, that's the box tuning frequency. Ideally you'd fix that before doing the crossover, but realistically not many crossovers are doing anything down around 55Hz or lower (would take huge low-resistance inductors or capacitors). So you can go ahead with the crossover design, but do retune the box (make the ports shorter or wider) before you do much listening.

My ports are about 2.375" diameter by 1.25" long because I am not using tubes, just holes in the front baffle. Everything calculates fine on paper, but is there a minimum port length for the port to function well? If so I might have to go larger and longer. I am also testing very low-powered using sound card headphone out and looping to line-in with test box with 100Ω reference as detailed in XSim docs. It is producing textbook perfect impedance curves, so I really don't doubt the numbers.

Thank you for any suggestions!

Could be the calculador Is using the wrong end correction for these kind of port? Hence the the prediction is off..

Last edited:

I spent some time this evening trying to fix my box tuning. I was aiming for 55Hz, but the impedance dip indicates it's tuned at 41Hz. I have been shortening and increasing diameter of the two ports and it is making very, very little change. Nowhere near as much as the calculator would indicate. I have managed to get it up to 47Hz, but it just won't go any higher. I tried covering one of the ports and tuning dropped to 35Hz (as expected). Are there other factors that could make the impedance dip show the wrong frequency or affect tuning such as stuffing? I am also testing through the x-over, but there is nothing weird in it to change the low frequency impedance. The cabinet is lined on the back and right and left sides with 2.5" acoustic foam. The higher frequency peak (50Ω) is much higher than the peak below the box tuning (34Ω), which I have read is also an indicator that the tuning is too low.

My ports are about 2.375" diameter by 1.25" long because I am not using tubes, just holes in the front baffle. Everything calculates fine on paper, but is there a minimum port length for the port to function well? If so I might have to go larger and longer. I am also testing very low-powered using sound card headphone out and looping to line-in with test box with 100Ω reference as detailed in XSim docs. It is producing textbook perfect impedance curves, so I really don't doubt the numbers.

Thank you for any suggestions!

Should you be using a abnorm big indutor value >30mH or so then higher peak will look like black simulated graph model below 🙂 yellow graph is a model of TF1225 in 39 liters tuned 58,5Hz with two times 50mm diameter vents in lenght of 37mm.

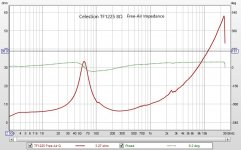

As a quality check for your impedance tester, did you test driver in free air and got some number close to datasheets 55,6Hz.

Attachments

Thank you for taking the time to analyze this. I have checked my impedance rig using non-inductive resistors and it always will produce a nice flat line showing the correct value, so I have confidence it is working well. Attached is a free-air impedance plot that I pulled of my actual driver. It's a good match to the factory provided one.Should you be using a abnorm big inductor value >30mH or so then higher peak will look like black simulated graph model below 🙂 yellow graph is a model of TF1225 in 39 liters tuned 58,5Hz with two times 50mm diameter vents in length of 37mm.

As a quality check for your impedance tester, did you test driver in free air and got some number close to datasheets 55,6Hz.

Next step is I will re-install the driver with no stuffing in the box and test again. I really believe I am going to have to install tubes and use longer ports for them to function correctly.

Last edited:

I re-installed the driver with no foam lining and the box tuning went up some, but it's still lower than the new size of the ports would dictate. I'm not sure if that's an indication that I had too much fill, but I will probably rethink my strategy for dampening the box. The ports were not obstructed, but the foam did come nearly to the edge of them. It just occurred to me that my son has a new 3D printer and I'm going to see if he will make me a custom pair of ports. I'll probably bump the diameter up to 3" to get the length somewhere near 2.5". Here's the impedance graphs before and after changing the ports and removing the foam. The green line is the original ports and foam installed. The red line is after opening and shortening the ports and removing the foam. You can see the box resonances in the upper frequencies with the foam removed. What explains the higher peaks on the red plot?

Last edited:

Kim,

I understand about the endless repeating of the same thing over and over.

The answers are out there, but most people don't care about searching for it.

Nothing against you, tekuhn , as you seem to be opened to do some research by yourself to understand things better.

But, I do not understand this:

"there will always be more experienced individuals who don't care about features and more advanced simulation results to get good/better results faster than before."

Being against progress and stuck in the old ways of doing things just feels wrong to me (and I'm no spring chicken!)... there has been many clashes from the old guard who don't want to see or learn about the advancements in audio tools versus some newcomers who are also deeply involved in making great designs using the newest tools available.

To me, that's just stubbornness and the unwillingness of learning something new.

Not so long ago, enclosure and crossover design was reserved to a selected few who understood most of it.

These days, anybody has access to wonderful software from the likes of XSim, VituixCAD, HornResp, etc... people who have gracefully volunteered their skills to the benefit of others.

I am grateful.

Stagnation is a slow death.

Evolution is survival.

Just like music itself.

What he said! ^2

- Home

- Design & Build

- Software Tools

- XSim free crossover designer