Ah ok Bob, so a 8" FR to glue to the spirit of the LX !

off topic (sorry) : I had an odd idea to glue to the design but with pro drivers : a 90 L rubber garbadge as a load for a 12" Beyma with the 5" PRV Audio (FR) à la LX above: http://www.signals.fr/poubelle-caoutchouc.html : in the spirit of an easy sealed enclosure with good damping (thick rubber material) with the 12" seing the ceiling like the LX .... just an odd idea ! (and putt the foamcore around the garbadge for a better design 😉 .

off topic (sorry) : I had an odd idea to glue to the design but with pro drivers : a 90 L rubber garbadge as a load for a 12" Beyma with the 5" PRV Audio (FR) à la LX above: http://www.signals.fr/poubelle-caoutchouc.html : in the spirit of an easy sealed enclosure with good damping (thick rubber material) with the 12" seing the ceiling like the LX .... just an odd idea ! (and putt the foamcore around the garbadge for a better design 😉 .

Last edited:

I also consider the difference in driver mass to be a factor in differences in measurement but to difference in the resonance of the baffle (and possibly other panels)

It seems to me, with such a material as foam core, saying panel contribution or acoustic transparency has a dismissable effect on the ultimate output is either naive, ignorant, or simply misleading.

(not that I'm claiming to have heard you state such)

Given the materials limitations, the results have been good.

I cannot help but to wonder how much clearer the picture could be, if the nautiloss/dagger were made in BB ply.

At least then, you could attach accelerometer (assuming you had the desire to know the panel modes) and measure box resonances without adding significant mass (in relation to panel mass) and skewing results.

It seems to me, with such a material as foam core, saying panel contribution or acoustic transparency has a dismissable effect on the ultimate output is either naive, ignorant, or simply misleading.

(not that I'm claiming to have heard you state such)

Given the materials limitations, the results have been good.

I cannot help but to wonder how much clearer the picture could be, if the nautiloss/dagger were made in BB ply.

At least then, you could attach accelerometer (assuming you had the desire to know the panel modes) and measure box resonances without adding significant mass (in relation to panel mass) and skewing results.

Should have said : for a better looking design as a rubber garbadge is not the best furniture in a living room 🙂 Though I'm not against industrial look ! So in any way an attack against the foamcore from me ! To say more, the Bob's post let me think to the Angeloitacare member and its Beyma 12p80nd which have a width polar map for a 12" and I said myself as it needs 90 liters to be FR from 50 hz to... 1600 Hz (in the Angeloitacare's design): why not use such a thick rubber garbadge for an economical ready made enclosure with Beyma putted horizontal like the LX Mini and the 5" FR from PRV Audio as a swap of the FURB10 ! In my mind the 12" could bet on a circular mdf panel on the mouth of the garbadge.... which rubber material could act as a damping! I founded such rubber thick garbadge with the good 90L volume Angeloitacare uses in him design !

As I said just a (odd) though from me !

... let come back to the topic

As I said just a (odd) though from me !

... let come back to the topic

Last edited:

I also consider the difference in driver mass to be a factor in differences in measurement but to difference in the resonance of the baffle (and possibly other panels)

It seems to me, with such a material as foam core, saying panel contribution or acoustic transparency has a dismissable effect on the ultimate output is either naive, ignorant, or simply misleading.

(not that I'm claiming to have heard you state such)

Given the materials limitations, the results have been good.

I cannot help but to wonder how much clearer the picture could be, if the nautiloss/dagger were made in BB ply.

At least then, you could attach accelerometer (assuming you had the desire to know the panel modes) and measure box resonances without adding significant mass (in relation to panel mass) and skewing results.

The round 4 was made with a plywood faced speaker. The thin ply was glued to the 1in thick XPS foam with a compliant adhesive for CLD. The sound of the front baffle is very dead when tapping on it. The low HD measurements of the 10F show that cabinet is not causing any HD problems. The HD measurments that I made later in the Al foam core Nautiloss is a little higher. That may be cabinet vibrations that cause that increase.

Last edited:

Soundclips FAST 10F/8424-SPH250KE

Had long time thinking about do some recordings as inspired by X : )

Eldam talked lot about the Miles Davis track "So what" so recorded that this night and was surprised how good it got therefor when setup was put there did four more recordings and now share them here.

Replay chain is computer/Jriver/HIFImeDIY-UAE23/optical/DEQ-2496/solid 0,4mm copper wire/Sansui AU-D9/solid copper 0,5mm wire/FAST speaker system. Recording chain SM81/multicore wire/XENYX 802/multicore wire/UCA222/computer/Audacity 2.1.1 at 48kHz/export as 16bit 48kHz flac.

In Jriver both left and right track are routet to mono speaker to get sound picture as one expect from the stereo track then recorded as monofile in Audacity 48kHz flac file and to have a reference to compare with same conditions CD stereo tracks are mixed to mono in Audacity and saved as 44,1kHz monotrack flac file.

All 10 tracks five recorded + five modified reference will take 138Mb disk space therefor they are found on a cloud drive. In below txt-file copy paste address into browser and press download at the cloud webpage.

Trakcs are:

Mark Knopler / Whenever i go

Miles Davis / So what

Norah Jones / Come with me

Van Halen / Eruption

Van Halen / Ice cream man

Had long time thinking about do some recordings as inspired by X : )

Eldam talked lot about the Miles Davis track "So what" so recorded that this night and was surprised how good it got therefor when setup was put there did four more recordings and now share them here.

Replay chain is computer/Jriver/HIFImeDIY-UAE23/optical/DEQ-2496/solid 0,4mm copper wire/Sansui AU-D9/solid copper 0,5mm wire/FAST speaker system. Recording chain SM81/multicore wire/XENYX 802/multicore wire/UCA222/computer/Audacity 2.1.1 at 48kHz/export as 16bit 48kHz flac.

In Jriver both left and right track are routet to mono speaker to get sound picture as one expect from the stereo track then recorded as monofile in Audacity 48kHz flac file and to have a reference to compare with same conditions CD stereo tracks are mixed to mono in Audacity and saved as 44,1kHz monotrack flac file.

All 10 tracks five recorded + five modified reference will take 138Mb disk space therefor they are found on a cloud drive. In below txt-file copy paste address into browser and press download at the cloud webpage.

Trakcs are:

Mark Knopler / Whenever i go

Miles Davis / So what

Norah Jones / Come with me

Van Halen / Eruption

Van Halen / Ice cream man

Attachments

Last edited:

Measurements FAST 10F/8424-SPH250KE

Here measurements done at same 54 cm distance as recording was done. Jriver DSP is responsible IRR EQ/IRR XO LR4 500Hz acoustic/0,21mS delay tweeter/FIR convolution to neutralize LR4 XO and IRR system low end HP. This is clear when looking at how relative flat system phase is and show also minimum phase as REW calculate based on frq response for a IRR system. System also quite capable to produce square waves as is although dream about being as good as wesayso, Barleywater and gmad to tweak system settings 😎.

Here measurements done at same 54 cm distance as recording was done. Jriver DSP is responsible IRR EQ/IRR XO LR4 500Hz acoustic/0,21mS delay tweeter/FIR convolution to neutralize LR4 XO and IRR system low end HP. This is clear when looking at how relative flat system phase is and show also minimum phase as REW calculate based on frq response for a IRR system. System also quite capable to produce square waves as is although dream about being as good as wesayso, Barleywater and gmad to tweak system settings 😎.

Attachments

-

Wavelet-2.png770 KB · Views: 126

Wavelet-2.png770 KB · Views: 126 -

CSD-2.png172.6 KB · Views: 136

CSD-2.png172.6 KB · Views: 136 -

HD-2.png160.2 KB · Views: 138

HD-2.png160.2 KB · Views: 138 -

IR_SR-3.png44 KB · Views: 123

IR_SR-3.png44 KB · Views: 123 -

FR_physcoacoustic-2.png55.8 KB · Views: 332

FR_physcoacoustic-2.png55.8 KB · Views: 332 -

FR_unsmoothed-2.png100.3 KB · Views: 335

FR_unsmoothed-2.png100.3 KB · Views: 335 -

SQw-3.png136.2 KB · Views: 108

SQw-3.png136.2 KB · Views: 108 -

SQw-2.png173 KB · Views: 119

SQw-2.png173 KB · Views: 119 -

SQw-1.png154 KB · Views: 127

SQw-1.png154 KB · Views: 127

Last edited:

@Brytt,

Nice track selection (1, 4 & 5: Though 'sultans of swing' has a nice sound)

@XKR,

Apologies, I missed that when I commented. Though the ply is looking thin (1/8"?)

Whilst the EVA foam idea (jeshi's?) is intriguing, I still cant help but think that such materials, whilst having some benefits, also have drawbacks - Id guess at a more broadband panel re-radiation, and the delay/phase issues, albeit with a much lower resonant Q than 'conventional' materials, it would seem logical that the ultimate radiation would be higher (especially across octave bands)

Now I'm not saying "it is bad" but without a measurement, noone xqn actually say its good either... So it all ends up as a cr@pshoot of opinion, non.of which can be backed up with any sort of fact - yet... 😀

Nice track selection (1, 4 & 5: Though 'sultans of swing' has a nice sound)

@XKR,

Apologies, I missed that when I commented. Though the ply is looking thin (1/8"?)

Whilst the EVA foam idea (jeshi's?) is intriguing, I still cant help but think that such materials, whilst having some benefits, also have drawbacks - Id guess at a more broadband panel re-radiation, and the delay/phase issues, albeit with a much lower resonant Q than 'conventional' materials, it would seem logical that the ultimate radiation would be higher (especially across octave bands)

Now I'm not saying "it is bad" but without a measurement, noone xqn actually say its good either... So it all ends up as a cr@pshoot of opinion, non.of which can be backed up with any sort of fact - yet... 😀

Brytt, X,

I said I will link two track from Tchaikovsky Symphony 4... (at least this is not the piano concerto linked with Youtube here in the thread beginning) I'm more jazz & rock, but listen to classic and world music (say 1/3 of my listenings) and I believe about dynamic and small level treble : it's even better than So What I talked about !

Ok , i will try to do it for tomorrow : I believe also the links given in one of my posts (n°21 iirc), especially track 1 or 2 are a nightmare for FR drivers ! (and those tracks are well recorded but the Harmonica which as a little saturation, but very transparent : I was in the live event from radioFrance the day of the reccording 🙂 )

I said I will link two track from Tchaikovsky Symphony 4... (at least this is not the piano concerto linked with Youtube here in the thread beginning) I'm more jazz & rock, but listen to classic and world music (say 1/3 of my listenings) and I believe about dynamic and small level treble : it's even better than So What I talked about !

Ok , i will try to do it for tomorrow : I believe also the links given in one of my posts (n°21 iirc), especially track 1 or 2 are a nightmare for FR drivers ! (and those tracks are well recorded but the Harmonica which as a little saturation, but very transparent : I was in the live event from radioFrance the day of the reccording 🙂 )

A Neodymium magnet could be smaller, allowing more rear ventilation. Maybe that's why Scanspeak created the 10F.

I'm sure that wasn't the reason in this case...

See the picture from BYRTT earlier in this thread:

The TC is more ventilated than the 10F, that was a big surprise for me when I actually held a live sample of the 10F in my hand.

Here measurements done at same 54 cm distance as recording was done. Jriver DSP is responsible IRR EQ/IRR XO LR4 500Hz acoustic/0,21mS delay tweeter/FIR convolution to neutralize LR4 XO and IRR system low end HP. This is clear when looking at how relative flat system phase is and show also minimum phase as REW calculate based on frq response for a IRR system. System also quite capable to produce square waves as is although dream about being as good as wesayso, Barleywater and gmad to tweak system settings 😎.

Those are some really great looking results there - great way you have shown to combine both IIR filters used conventionally with FIR processing to achieve a superb result. Looking forward to listening to the sound clips. You should make a new thread and tell us in detail how you do this. It appears to be different than gmad or Barleywater's implementation.

Xrk971,

I haven't read through all the threads, can you tell when will tell us the results i.e. which music clip corresponds to which driver?Thanks.

I haven't read through all the threads, can you tell when will tell us the results i.e. which music clip corresponds to which driver?Thanks.

Last edited:

Xrk971,

I haven't read through all the threads, can you tell when will tell us the results i.e. which music clip corresponds to which driver?Thanks.

There is a link in post 1 at bottom. I don't recall where it is - quite a few pages back.

Whilst the EVA foam idea (jeshi's?) is intriguing, I still cant help but think that such materials, whilst having some benefits, also have drawbacks - Id guess at a more broadband panel re-radiation, and the delay/phase issues, albeit with a much lower resonant Q than 'conventional' materials, it would seem logical that the ultimate radiation would be higher (especially across octave bands)

Now I'm not saying "it is bad" but without a measurement, noone xqn actually say its good either... So it all ends up as a cr@pshoot of opinion, non.of which can be backed up with any sort of fact - yet... 😀

The EVA foam was my idea. http://www.diyaudio.com/forums/full-range/277446-eva-foam-performance-speaker-enclosures.html

and so far the material is working really well for me both acoustically and in making nice looking enclosures. I love the fact that I can wet sand EVA foam to a very precise and smooth finish.

I have been playing around with some panel-resonance test ideas, but had not posted yet since the idea and tests were a bit "raw". But since it has come up here, I decided to post what I have so far.

http://www.diyaudio.com/forums/full...rmance-speaker-enclosures-16.html#post4456901

Please refer to that post, but I will show some highlights.

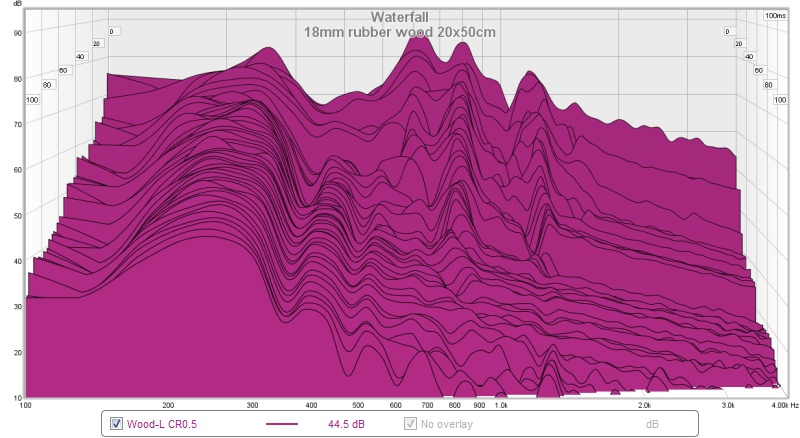

18mm rubber wood

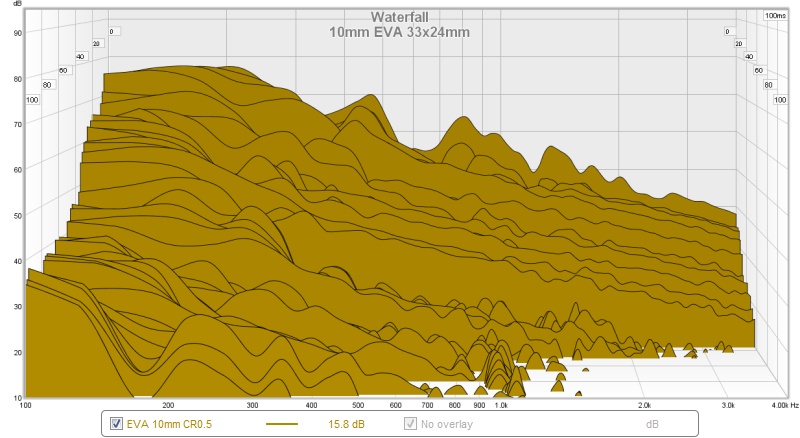

10mm EVA (sorry mislabeled the image, should be 33x24 cm not mm)

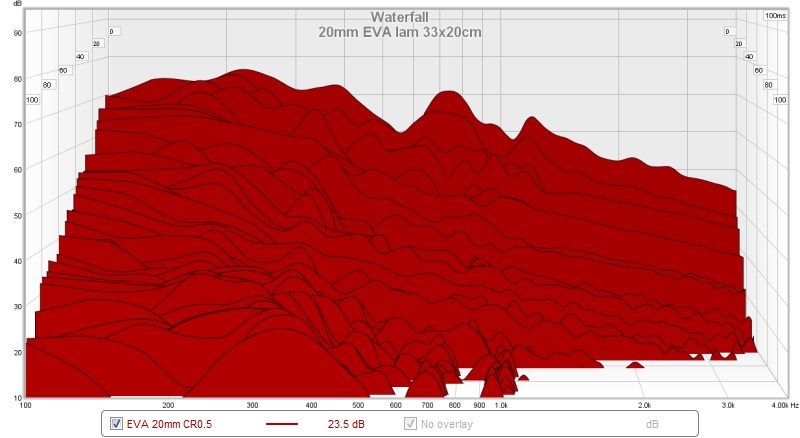

20MM laminated EVA (two 10mm panels laminated with rubber cement)

the wood transfers much more energy (higher DB response) to the korg contact microphone, extends to higher frequencies, and has a longer decay especially in the lower frequencies. The 10mm and 20mm EVA are more damped than the wood. Total energy transferred into the panel and to the mic is less. More high frequencies are absorbed, and decays much faster with almost no ringing or resonance. The 20mm and 10mm show a slight difference in the frequencies they transfer and damp. 20mm seems to damp the low frequencies faster.

I hope I can improve this test, and I have some ideas for reflection/absorbtion testing and transmission testing. These are the three modes where energy can transfer (within a panel, reflection off a panel, and transmission through a panel). I would also love to hear if there are some well known testing methods for this that doesn't involve expensive equipment (like a laser interferometer)

Last edited:

Certainly interesting Jeshi. It seems EVA is better than rubberwood. Mind you, I haven't seen rubberwood ever used for a speaker, nor is 'wood' often recommended. Id certainly like to see a comparison with birch ply, braced appropriately.

The problem you'll have is the weight of the accelerometer changing panel response. (something I have first hand knowledge of in my day job)

(saying that, I don't know how dense EVA is in comparison to birch ply)

How about making a capacitive proximity sensor? One 'plate' of thin foil tape on the enclosure panel, and the other on a stand positioned and 'gapped' using shims of some sort, which you remove to test.

Certainly cheaper (though maybe just as difficult to set up) as a laser interferometer.

The problem you'll have is the weight of the accelerometer changing panel response. (something I have first hand knowledge of in my day job)

(saying that, I don't know how dense EVA is in comparison to birch ply)

How about making a capacitive proximity sensor? One 'plate' of thin foil tape on the enclosure panel, and the other on a stand positioned and 'gapped' using shims of some sort, which you remove to test.

Certainly cheaper (though maybe just as difficult to set up) as a laser interferometer.

Certainly interesting Jeshi. It seems EVA is better than rubberwood. Mind you, I haven't seen rubberwood ever used for a speaker, nor is 'wood' often recommended. Id certainly like to see a comparison with birch ply, braced appropriately.

The problem you'll have is the weight of the accelerometer changing panel response. (something I have first hand knowledge of in my day job)

(saying that, I don't know how dense EVA is in comparison to birch ply)

How about making a capacitive proximity sensor? One 'plate' of thin foil tape on the enclosure panel, and the other on a stand positioned and 'gapped' using shims of some sort, which you remove to test.

Certainly cheaper (though maybe just as difficult to set up) as a laser interferometer.

thanks. These tests are very preliminary and that is why I didn't post them earlier. I am using a pick-up mic that korg makes for their tuners. Is a contact microphone the same as an accelerometer? I use this one

I agree that rubber wood is not a recommended speaker material, but it is all I had on hand (from another project). I plan to add MDF, acrylic/plexiglass and foamcore to my list (maybe particle board, standard plywood). I would love to try baltic birch ply, but it is impossible to find in Japan. I found one shop that carried some, but they were asking almost $200 for one sheet (1m x2m) and they only had it in that large size (omg).

The test is a raw panel (not part of an enclosure) so there is no bracing. I can take a picture of my setup later if that will help. My idea with these tests are to explore the native properties of the material in a simulation of how they might behave in an enclosure. My thinking is that bracing, felt, damping, shape, lamination... can be applied to all materials so is separate from the materials inherent properties. So if BBply is resonant at a certain frequency, but bracing removes that, then applying the same bracing to EVA should do the same thing.

I am not a materials scientist, so please take these as just exploration ideas. I want to continue this materials panel resonance in my EVA thread and not hijack X's thread too much 😀

Last edited:

Very small lightweight MEMs IC accelerometers (<$1) are used in phones, toy RC helicopters etc. They weigh nothing and are full of advanced capability. If someone can find one that is mounted to a small pcb and thin digital wires we would have something perfect for panel resonance. Scientific accelerometers using same principle are pricey in $1k range.

Here is an example of a 3 axis 16-bit one that is 3x3x1 mm in size.

http://www.st.com/st-web-ui/static/active/en/resource/technical/document/datasheet/DM00040962.pdf

Here is an example of a 3 axis 16-bit one that is 3x3x1 mm in size.

http://www.st.com/st-web-ui/static/active/en/resource/technical/document/datasheet/DM00040962.pdf

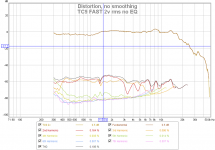

I think the main culprit is the 5k peak. The 1k-2k gives more presence but not annoying.

Here are some sound clips with two small PEQ's applied in the1-2k and the large cluster of peaks in the 10k range. So the sound now follows the dark blue response in the above xo plot.

I did not get rid of the 5k peak yet as that would be a rather "high Q" EQ and trying to avoid those for now.

God job big step up closer to this rounds level 🙂

These are from driver "C" that never made it into the polls. They are from the PS95-8 at 30 deg off axis but with one simple PEQ of -3dB Q=1.6 at 1.7kHz to flatten that bump in the response.

These may have gotten even more votes than "E" ?

Also upped glad it wasn't there in real had enough trouble regarding prediction or was it just guessing this time, managed hit all five incorrect 😱

.....The word on the street is that the TC9 is a total slut.....

Ha ha that's sad to hear, can't stop thinking about what Barleywater, wesayso and X had got out of the slut 🙄.

.....The TC is more ventilated than the 10F, that was a big surprise for me when I actually held a live sample of the 10F in my hand.

Lack of ventilation couldn't that actual mean use only above fs or it can't breathe and ventilate so combine with a real woofer for LF duty, or it's because of engine room is top secret sensitive tech therefor windows is casted and closed, its certently not a slot performance wise even lack of modern ventilation.

Last edited:

@Brytt,

Nice track selection (1, 4 & 5: Though 'sultans of swing' has a nice sound).....

Thanks, yes nice sound that track so its recorded now : )

Dire Straits/Sultans of swing same procedure to download, in below txt-file copy paste address into browser and press download at the cloud webpage.

Those are some really great looking results there - great way you have shown to combine both IIR filters used conventionally with FIR processing to achieve a superb result. Looking forward to listening to the sound clips. You should make a new thread and tell us in detail how you do this. It appears to be different than gmad or Barleywater's implementation.

Thanks and yes they FIR filters can do wonders as never before regarding phase timing, will think about it and maybe i finish some speakers at a time then stuff can fill as naturally tech in there, until then gmad wesayso and Barleywater had shared a lot of hints the subject one can surf for it at diyA. Hope okay share the sound clips here they on topic regarding investigate 10F as treble in FAST system.

Attachments

Here measurements done at same 54 cm distance as recording was done. Jriver DSP is responsible IRR EQ/IRR XO LR4 500Hz acoustic/0,21mS delay tweeter/FIR convolution to neutralize LR4 XO and IRR system low end HP. This is clear when looking at how relative flat system phase is and show also minimum phase as REW calculate based on frq response for a IRR system. System also quite capable to produce square waves as is although dream about being as good as wesayso, Barleywater and gmad to tweak system settings 😎.

Very nice! FIR filters for XO and system HP work very well. You could possibly get away with a bit of base extension and associated phase work and get good square wave down at lower frequencies.

-----------

I've done some survey measurements of 10f running as naked dipole.

I started with 440Hz sine wave, and was immediately taken to task for earlier post about audibility of HD at low levels. By ear the level didn't seem very high at all, but a distinct higher frequency signal was present that at certain points in room where fundamental has standing nulls really stood out. I set up a track with 440Hz and track with 5th harmonic and adjusted mix for hearing lowest level, and found this was with 2200Hz mixed -62dB to 440Hz. Respeating with 3080Hz, I could discern this mixed in at about -55dB. OK, hat eaten! With music signals these levels have little impact on perception, or according to Geddes no impact. IMD and transient IMD play bigger role in roughing up the sound.

A full range sweep at less than 2 volts rms (didn't get the volt meter out!):

Then sweep at 4.6 volts rms:

Next sweep at 2.0 volts rms, followed by 2 volt sweeps of TC9FD in sealed 4" diameter pipe, and of FU10RB in LXmini setup with driver mounted in front of well stuffed 3" diameter pipe 5" long.

10f:

TC9:

FU10RB:

Dipoles seem to incur 2nd harmonic peak below dipole peak. It will be interesting to see results of 10f mounted LXmini style. In a new thread.

- Home

- Loudspeakers

- Full Range

- A Subjective Blind Comparison of 2in to 4in drivers - Round 4