It's a very forgiving design - I can't guarantee it will work as that would need a simulation to be sure but I am on vacation at the moment.

Lavoce makes a very nice 3" driver which is less than $12 at Partsexpress, which should substitute for 3FE25 - it seems to only come in 8 ohms (?)

I still can't figure out who made the W5-2143 on this thread?

Mini Karlsonator (0.53X) with Dual TC9FD's

Plans look good and sims look very nice.

Mini Karlsonator (0.53X) with Dual TC9FD's

Plans look good and sims look very nice.

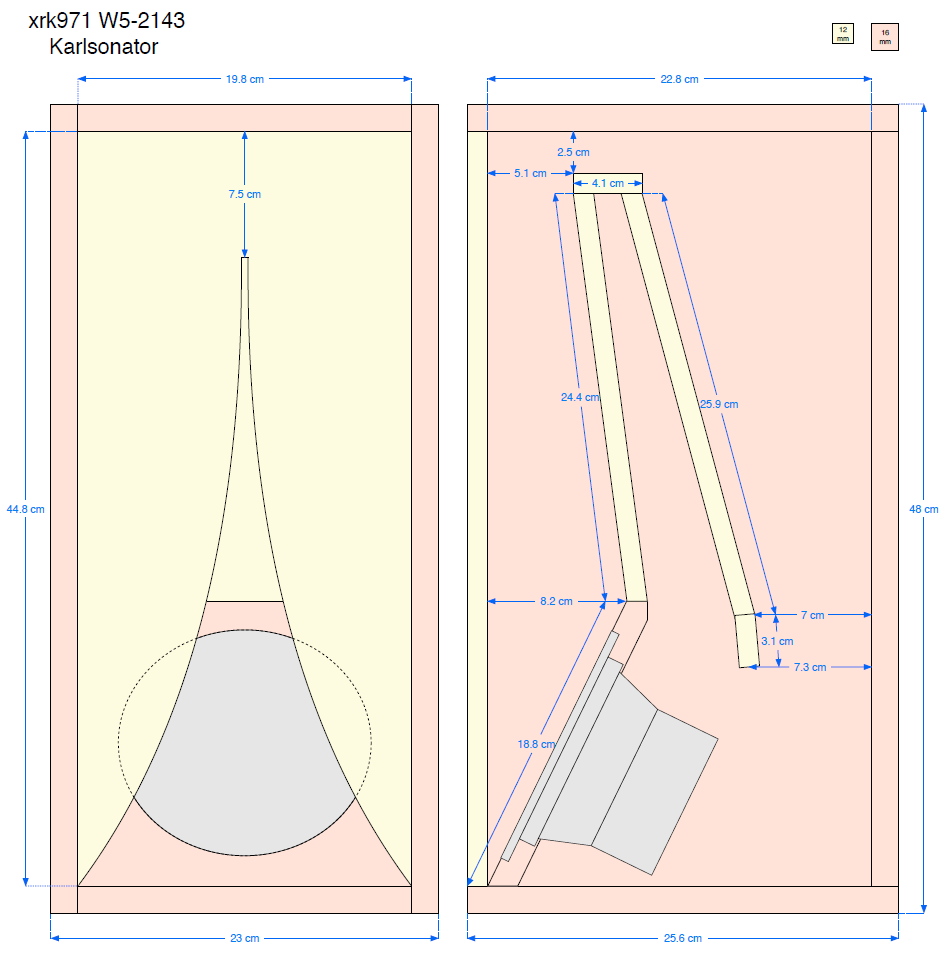

So Im underway with my build of the 0.53x Karlsonator using TB W5-2143 driver.

My first foamboard build. I began with EVA but felt it might not be quite rigid enough. Will reutilise the material with a smaller driver, probably Faital Pro four inch 8ohm, the 4FE32.

Meantime I've spent a Sunday cutting out all the bits and pieces, using 10mm foamboard. Seems hard-ish to cut but solid enough seemingly to hold the TB. Not a lightweight driver. So rather than double up I fashioned a wooden baffle out of 5mm hardboard and will glue that to the foamboard baffle for added rigidity and so I can screw the driver home properly.

Next part is gluing then.

On the plan there is a small 31mm section a bit over an inch long, at the end of the internal baffle at a slightly different angle to the 259mm section it attaches to, just in behind where the driver sits. Does it matter if it is not at a slight angle to the longer piece? Can I just continue it on as one straight line (to make it a 290mm straight line)?

My first foamboard build. I began with EVA but felt it might not be quite rigid enough. Will reutilise the material with a smaller driver, probably Faital Pro four inch 8ohm, the 4FE32.

Meantime I've spent a Sunday cutting out all the bits and pieces, using 10mm foamboard. Seems hard-ish to cut but solid enough seemingly to hold the TB. Not a lightweight driver. So rather than double up I fashioned a wooden baffle out of 5mm hardboard and will glue that to the foamboard baffle for added rigidity and so I can screw the driver home properly.

Next part is gluing then.

On the plan there is a small 31mm section a bit over an inch long, at the end of the internal baffle at a slightly different angle to the 259mm section it attaches to, just in behind where the driver sits. Does it matter if it is not at a slight angle to the longer piece? Can I just continue it on as one straight line (to make it a 290mm straight line)?

Attachments

Last edited:

It's not hard to score it and bend the foam for that shallow angle. If you must keep it one length, adjust the position so that the throat of it is the same 7cm gap.

First project

I am in on the dual 3fe 25 0.53 for my first project. Thanks in advance to all who have contributed to this thread and the main man, Mr X.

x4 3FE25-16 and 10mm black foamcore have been ordered so no turning back. Other odds and ends are being sourced. All relevant plans and pictures have been saved. Apologies in advance for any stupid questions.

Their home will be our new kitchen diner. Lots of reflective surfaces. Low ceiling. The even dispersion across a wide frequency range could have benefits in this room - as does their relative price (after spending all the money on the kitchen and having two very curious young 'uns).

The plan is to build in 10mm foam core then clad in 2mm ply when working properly.

I am in on the dual 3fe 25 0.53 for my first project. Thanks in advance to all who have contributed to this thread and the main man, Mr X.

x4 3FE25-16 and 10mm black foamcore have been ordered so no turning back. Other odds and ends are being sourced. All relevant plans and pictures have been saved. Apologies in advance for any stupid questions.

Their home will be our new kitchen diner. Lots of reflective surfaces. Low ceiling. The even dispersion across a wide frequency range could have benefits in this room - as does their relative price (after spending all the money on the kitchen and having two very curious young 'uns).

The plan is to build in 10mm foam core then clad in 2mm ply when working properly.

RBU81

Ensure you have a real good read of X's build log before beginning.

I think it starts on page 4 of one of his original threads.

Here: Mini Karlsonator (0.53X) with Dual TC9FD's

It details what not to do as well as what to do!

Plus it is in two parts; the second one is a few pages further on.

And things are quite different for 10mm black foamcore. Most of X's builds have used 5mm material so you won't need anything like as many braces. The 10mm board is quite rigid.

Get heaps of hot melt glue sticks; running out at the wrong time risks throwing it away and starting afresh.

Gorilla glue for the final side panel works a treat so long as you dont have too many big gaps, especially if you're covering the whole thing in ply later. Fill these potential gaps first with hot melt glue. And don't forget to use felt in behind the driver on the back wall.

Finally, there isn't any info on the terminal cup. You can cut a hole and hot glue a circular cup in place or simply cut a hole small enough for a wire and hot glue afterwards. Im up to this stage and plan to use a small square piece that attaches by a couple of screws and I will hotglue the main terminal screws themselves on the inner aspect before attaching the rear panel.

If this sounds like advice from someone who hasn't actually listened to the finished product, that's because it is; I just happen to be partway through and have stumbled across a few issues because most of my previous builds are like Homer Simpson projects, or so says she who knows about these things.

Ensure you have a real good read of X's build log before beginning.

I think it starts on page 4 of one of his original threads.

Here: Mini Karlsonator (0.53X) with Dual TC9FD's

It details what not to do as well as what to do!

Plus it is in two parts; the second one is a few pages further on.

And things are quite different for 10mm black foamcore. Most of X's builds have used 5mm material so you won't need anything like as many braces. The 10mm board is quite rigid.

Get heaps of hot melt glue sticks; running out at the wrong time risks throwing it away and starting afresh.

Gorilla glue for the final side panel works a treat so long as you dont have too many big gaps, especially if you're covering the whole thing in ply later. Fill these potential gaps first with hot melt glue. And don't forget to use felt in behind the driver on the back wall.

Finally, there isn't any info on the terminal cup. You can cut a hole and hot glue a circular cup in place or simply cut a hole small enough for a wire and hot glue afterwards. Im up to this stage and plan to use a small square piece that attaches by a couple of screws and I will hotglue the main terminal screws themselves on the inner aspect before attaching the rear panel.

If this sounds like advice from someone who hasn't actually listened to the finished product, that's because it is; I just happen to be partway through and have stumbled across a few issues because most of my previous builds are like Homer Simpson projects, or so says she who knows about these things.

No wuckers.

Will let you all know how the 0.53x Karlsonator with W5-2143 sounds after I complete the build, hopefully in lockdown this weekend if all goes according to plan.

Will let you all know how the 0.53x Karlsonator with W5-2143 sounds after I complete the build, hopefully in lockdown this weekend if all goes according to plan.

3fe 16 vs 4ohm?

Blue Arran have stock issues with the 3FE 16ohms. They thought they had them in stock, but apparently they don't. And they don't know when they will.

Would there be any noticeable difference in performance in getting the 4ohm version and wiring them in series?

Blue Arran have stock issues with the 3FE 16ohms. They thought they had them in stock, but apparently they don't. And they don't know when they will.

Would there be any noticeable difference in performance in getting the 4ohm version and wiring them in series?

I have not tried it but Qts parameters are different and two 4ohm wired in series has less sensitivity as two 16ohm wired in parallel. It could work though as the box is fairly accepting of different drivers. I think you will have about 90dB sensitivity vs 96dB sensitivity with dual 4ohms in series. At 8ohms the current is cut in half vs 4ohms but the area is doubled so it’s a wash. Whereas double 16ohms in parallel doubles the current and doubles the area.

So I've been thinking around making these 3d printed parts in PETG to reinforce my 2x 3FE-16 karlsonators, would those inserts (all mirrored, the top right one on all the other orthogonal corners) be sufficient? the baffle has 7mm thickness and the others 2,4mm, and extends 30mm inward. Also, would they need to be covered?

In case of success i'll post the pieces on thingiverse and add it to this thread.

I just cut them by hand out of foamcore. Are you making these for foamcore speakers or wooden ones? Thanks for offering it on thingyverse though.

Foamcore, it's just for some added resistance basically, as in my architecture model times i couldn't trust it's corners to remain Sharp, a problem with the local supply maybe

Blue Arran have stock issues with the 3FE 16ohms. They thought they had them in stock, but apparently they don't. And they don't know when they will.

Would there be any noticeable difference in performance in getting the 4ohm version and wiring them in series?

try lean business, they seem to have better prices anyways for the FaitalPro drivers:

PAIR PACK (X2) FaitalPRO 3FE25 8ohm 3 20watt Ferrite Speaker

Oh, but they only seem to do the 8ohm version, sorry...

I sourced my 16Ohms for Axiomedia in Italy. And although it had to be shipped halfway around the globe, total cost wasn't a deal breaker. I could also buy only 4 drivers, not a full tray.

3FE25-16 from Axiomedia.it

3FE25-16 from Axiomedia.it

My realistic 40-1197 have been stolen, luckily I have 2 TC9FDs...do the 0.4x karlsonators image better than Nola Brio clones? I am interested in image/ soundstage and clarity of mids, bass and SPL are not important to me. I hesitate between the karlsonators and Nola clones.

make the effort to find and audition a pair of Tannoy Revolution Series XT Mini they do require burn in mine took six or more weeks to really start to shine but you can hear what they can do out of the box. I bought a pair of the XT mini (has a 3.25" wide cone and a 0.75" tweeter) and I also bought the XT6 with a larger woofer and one inch tweeter. The smaller XT Mini stage and image noticeably better. These are without a doubt the finest most technically advanced Dual Concentric loudspeakers Tannoy has ever produced. Find a pair of the XT Mini and give them a listen. Note they will show you what up stream components are doing so be aware.

- Home

- Loudspeakers

- Full Range

- Mini Karlsonator (0.53X) with Dual TC9FDs