Approx 300mm. I set it up so I could hold the bottom corners to dampen while being behind the mic, and the measurements only make sense relative to each other anyway since I have no SPL reference.Leob,

What is the distance mic/panel in your measurements?

Made the same observation and thought I forgot to disable the HPF I usually have on when listening to music on them. But it is not an issue with the measuring equipment. My regular speakers don't have the same drop off.Leob,

The HF roll off is not very steep so why not but the bass roll off is unusually steep. Almost the same for both panels is also strange. There is perhaps something to check.

View attachment 1033003

Possibly it can be related to the edges I have that dampens a bit. Doesn't really bother me though since I'm planning to use them with a sub, but also curious as to why.

Just here a 20x30cm XPS9mm measured at 50cm about. It is more typical of what I have seen from panels up to now. I had not good results with this material but I have some sheets available easy to cut at dimensions close to yours. In the next days I will try to measure it at different distance to see the influence of the measurement distance on the FR.Made the same observation and thought I forgot to disable the HPF I usually have on when listening to music on them. But it is not an issue with the measuring equipment. My regular speakers don't have the same drop off.

Possibly it can be related to the edges I have that dampens a bit. Doesn't really bother me though since I'm planning to use them with a sub, but also curious as to why.

You got me thinking Christian...so I had to put up the PC (500x400x6mm) panel. Both to confirm the LF and HF roll offs.

Red line is the PC panel, and the 3.8mm damped printed plate is orange (might have differing amp level):

The notion that they are brighter I probably got from a peak around 7k, or bad mounting in earlier tests, the printed panel actually has a better response overall. Will check tomorrow if perhaps HF improves a little after a while with the tape.

But yes, bass response is also dropping off abruptly. Will try ply later and see if the result is the same. Could it be the exciters? I used two different, and I would have thought a 50mm exciter should give deep response if anything.

Also, I'm doing the tests via BT APTX on this machine. Maybe not ideal, so will try from my desktop that has an analogue connection instead.

Red line is the PC panel, and the 3.8mm damped printed plate is orange (might have differing amp level):

The notion that they are brighter I probably got from a peak around 7k, or bad mounting in earlier tests, the printed panel actually has a better response overall. Will check tomorrow if perhaps HF improves a little after a while with the tape.

But yes, bass response is also dropping off abruptly. Will try ply later and see if the result is the same. Could it be the exciters? I used two different, and I would have thought a 50mm exciter should give deep response if anything.

Also, I'm doing the tests via BT APTX on this machine. Maybe not ideal, so will try from my desktop that has an analogue connection instead.

Leob.

Sharp roll off below 100hz is possible as in these pictures of a low grade eps with epoxy on one side only.

The first fr picture is from the exciter side which has the epoxy on.

The second is from the front.

The third is the offending panel using the exciter in the top left , the epoxy only goes down about a third of the panel.

These were measured at about 6inches.

Although the panel rolls off after about 3k which could be because of the epoxy skin ,or double sided tape or both ?

The sound does not sound too bad vocals sound full bodied with the obvious loss in hf.

I might try This on a proper eps panel and see What happens to the hf ?

This is a low grade eps material ,I could try it on a higher grade which I might still have somewhere ?

My phone microphone drops off like your plot but at 50hz ,you are probably measuring your microphone and panel response,you really need a microphone with a flat response from 20hz to 20k .

Steve.

Sharp roll off below 100hz is possible as in these pictures of a low grade eps with epoxy on one side only.

The first fr picture is from the exciter side which has the epoxy on.

The second is from the front.

The third is the offending panel using the exciter in the top left , the epoxy only goes down about a third of the panel.

These were measured at about 6inches.

Although the panel rolls off after about 3k which could be because of the epoxy skin ,or double sided tape or both ?

The sound does not sound too bad vocals sound full bodied with the obvious loss in hf.

I might try This on a proper eps panel and see What happens to the hf ?

This is a low grade eps material ,I could try it on a higher grade which I might still have somewhere ?

My phone microphone drops off like your plot but at 50hz ,you are probably measuring your microphone and panel response,you really need a microphone with a flat response from 20hz to 20k .

Steve.

Attachments

So you find that you get that roll off with low grade EPS in general? Or only with epoxy added?

Like I said, my mic measures bass response of my regular speakers fine. It is a measuring mic (Omnitronic MM-2USB) and should have a reasonably flat response.

Like I said, my mic measures bass response of my regular speakers fine. It is a measuring mic (Omnitronic MM-2USB) and should have a reasonably flat response.

Leob.

Sorry, for some reason I had the impression that you were having problems with you microphone ?

so this is the real panel response at 30cm , how goes it sound ?

my test epoxy panel.

This was an old low grade eps test panel that I coated the top end in left over epoxy, just one side though.

You should get a good response up to at least 10k with low grade eps and pva.

The epoxy formed a soft skin on the surface, maybe it needs the fibre glass to form a hard surface ?

The pva soaks into the surface and sounds and feels harder .

Epoxy is also heavier than the thinned pva.

Although it does not look promising, I should do proper tests before I make a final decision.

Basically ,I just stuck the exciter on this panel just to see how the epoxy affected the sound, but notice the response was quite similar to your panel.

Steve

by the way my new canvas panel with the ply on the front ,looks like a piece of art work, so it is official, I am now an artist 😂

which is similar to what my wife always calls me 😁

Hopefully I will get time to have a listen to the panel today.

Steve,

Sorry, for some reason I had the impression that you were having problems with you microphone ?

so this is the real panel response at 30cm , how goes it sound ?

my test epoxy panel.

This was an old low grade eps test panel that I coated the top end in left over epoxy, just one side though.

You should get a good response up to at least 10k with low grade eps and pva.

The epoxy formed a soft skin on the surface, maybe it needs the fibre glass to form a hard surface ?

The pva soaks into the surface and sounds and feels harder .

Epoxy is also heavier than the thinned pva.

Although it does not look promising, I should do proper tests before I make a final decision.

Basically ,I just stuck the exciter on this panel just to see how the epoxy affected the sound, but notice the response was quite similar to your panel.

Steve

by the way my new canvas panel with the ply on the front ,looks like a piece of art work, so it is official, I am now an artist 😂

which is similar to what my wife always calls me 😁

Hopefully I will get time to have a listen to the panel today.

Steve,

They sound good! I don't have much reference but the printed panels is definitely better than the polycarbonate and ply I tried. And seems to be able to handle more power as well despite being smaller.Leob.

Sorry, for some reason I had the impression that you were having problems with you microphone ?

so this is the real panel response at 30cm , how goes it sound ?

my test epoxy panel.

This was an old low grade eps test panel that I coated the top end in left over epoxy, just one side though.

You should get a good response up to at least 10k with low grade eps and pva.

The epoxy formed a soft skin on the surface, maybe it needs the fibre glass to form a hard surface ?

The pva soaks into the surface and sounds and feels harder .

Epoxy is also heavier than the thinned pva.

Although it does not look promising, I should do proper tests before I make a final decision.

Basically ,I just stuck the exciter on this panel just to see how the epoxy affected the sound, but notice the response was quite similar to your panel.

Steve

by the way my new canvas panel with the ply on the front ,looks like a piece of art work, so it is official, I am now an artist 😂

which is similar to what my wife always calls me 😁

Hopefully I will get time to have a listen to the panel today.

Steve,

I understand now "cheap mic" and there is now doubt about the measurements from the mic side. The specifications are good and the price not too high. Good to know! Sorry for the previous posts. I interpreted them as a chain with some low cost electret capsule...So you find that you get that roll off with low grade EPS in general? Or only with epoxy added?

Like I said, my mic measures bass response of my regular speakers fine. It is a measuring mic (Omnitronic MM-2USB) and should have a reasonably flat response.

@Veleric

Do you know a way to calculate the first resonance frequencies of a free plate? The reason I ask is, for test, I made some measurements of a "small" (20x30cm) panel just glued on the exciter and try to make a relation between the observed resonance frequencies and what could be predicted by calculation.

Thank you

Christian

Do you know a way to calculate the first resonance frequencies of a free plate? The reason I ask is, for test, I made some measurements of a "small" (20x30cm) panel just glued on the exciter and try to make a relation between the observed resonance frequencies and what could be predicted by calculation.

Thank you

Christian

It's a mixed bag at the moment with this new art panel.

The canvas panel is brighter with the ply on the front , but I can hear too much of the ply.

I have not coated the front with pva yet or the canvas ,so this could change, but I'm not that hopeful ?

I managed to glue on the exciter with the ringing voice coil again!!

But it's not too bad.

Hopefully with some of the alterations I'm going to make the sound will even out a little more ?

The response is very similar to the cascamite art panel ,but the hey do sound a little different.

I noticed that on loud bass guitar that the cascamite panel can honk in the 40hz to 50hz region, but this is about 10db higher in level than the rest of the frequencies.

This must be the panel resonance, a bit like the port on a bass reflex speaker.

Steve.

The canvas panel is brighter with the ply on the front , but I can hear too much of the ply.

I have not coated the front with pva yet or the canvas ,so this could change, but I'm not that hopeful ?

I managed to glue on the exciter with the ringing voice coil again!!

But it's not too bad.

Hopefully with some of the alterations I'm going to make the sound will even out a little more ?

The response is very similar to the cascamite art panel ,but the hey do sound a little different.

I noticed that on loud bass guitar that the cascamite panel can honk in the 40hz to 50hz region, but this is about 10db higher in level than the rest of the frequencies.

This must be the panel resonance, a bit like the port on a bass reflex speaker.

Steve.

Christian,@Veleric

Do you know a way to calculate the first resonance frequencies of a free plate? The reason I ask is, for test, I made some measurements of a "small" (20x30cm) panel just glued on the exciter and try to make a relation between the observed resonance frequencies and what could be predicted by calculation.

Thank you

Christian

Yes, I know how to estimate the frequencies of some of the most simple modes. But of course you have to know the elastic properties of the plate material to do it. Usually I just let my LISA finite element model do the calculations for me. It can calculate the frequencies for more modes than I can.

You can find the equations for the fundamental frequency in flexure and torsion here: https://en.wikipedia.org/wiki/Impul...tion technique (IET,of a material of interest.

Look at the equations in the "Experimental correlations" section. Note, they give E and G as a function of the appropriate fundamental frequency. To go the other way around, you will have to invert their equations to give f as a function or E (or G).

For your first try, ignore the correction factors they give (T and R).

But I have another suggestion for you first. If you tell me the elastic properties of your plate, I'll run the LISA model and estimate the resonance frequencies for you. I would just need:

Elastic Modulus (both directions if you have measured them)

Poission ratio or shear modulus (not as critical, if you don't know it I will make a guess!)

Thickness

Density

I would be happy to do it. It's simple (and fun for me, at least). You might find the results more insteresting than you imagine.

I have a second suggestion too, which I will put in a second post....you should try both!

Eric

Christian,

My second suggestion is to simply measure the resonance frequencies of your plate directly using the "tap test" that I mentioned in the other thread regarding the Impulse Excitation method.

The way to measure the resonant frequencies of a plates is to make a series of REW measurements at various points on the plate using the "tap" test. Each of the locations will reveal a different set of resonance frequencies.

For each tap location you:

1. suspend the panel a particular way, depending on which mode or modes of resonance you want to excite/isolate/identify.

2. place you mic very close to the surface of the plate (1-2 cm), at a particular location (again, depending on the mode(s) of resonance you want to excite).

3. tap the panel at the location of the mic

4. monitor the response in REW, (using the RTA function, spectrum mode, no smoothing and , 4,8, or 16 averages)

5. you will see several sharp peaks in the frequency response. Each one is a resonance frequency of the panel.

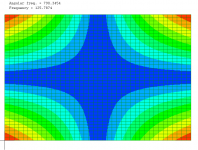

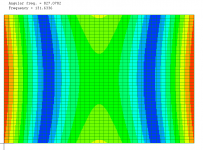

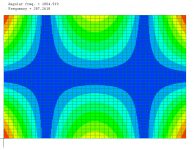

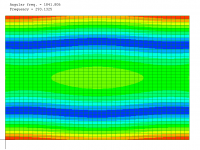

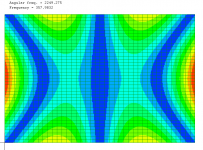

Below are images representing the first several modes. The shapes will be similar for most any plate with the same aspect ratio. These particular results are for a 20x30 cm plate, 4 mm thick with a Elastic Modulus of 5 GPa and a density of 0.6 g/cm^3. (Like plywood, but isotropic).

To measure the first mode (first image below), attach strings to the plate at the middle of two adjacent edges (where the image is blue for that mode), and place the mic (and tap) at any of the corners (where the image is red). I use alligator clips to attach to the plate, so the hanging locations can be moved easily. If the plate is light enough you can just use strips of tape. When you tap the plate, the lowest peak you observe in the REW spectrum is the fundamental in torsion.

To measure the fundamental in bending (2nd image), move the stings to one of the long edges, attached about 1/5 of the distance from each end (image is blue there). Position the mic and tap the panel along either of the short ends of the panel (where it's red). Now the lowest frequency peak you will observe corresponds to this mode. You my still see a peak for the torsion mode, but ignore that, as you already know what it is. You will also see many peaks at higher frequencies, corresponding to higher order modes.

Leave the strings in the same place, but tap and mic at one of the corners to find the frequency corresponding to the mode in the third image.

If you wish, continue the same way to get the frequencies of the next two modes. In each case, ignore frequencies that you have already "identified" from previous results.

Note, it can get a bit tricky as sometimes different modes can be very close in frequency. But by trying our different tapping and/or micing positions you can often figure out which is which. this is because tapping at "blue" locations won't excite that mode. So if you can find a place that's red for one mode and blue for the other, tap that place and the peak you get will correspond to the mode that's red at that spot.

Try it!

Eric

the thing I remember about shallac, was people on nxt rubbish squirting loads of it into the correlations and ending up with a bent heavy cardboard panel ?Hi Steve

I have a sample of the material you have inquired about on my work desk, It is extremely robust and resilient to compression with walls and ribs less that 1mm in thickness, I assume the material has a hardness produced to take the impact of heavy plant and point loading.

I just have to request for the permission to take a few full sheets home with myself, this will give me a base material that can be tried in different thicknesses and possibly even a Two Ply Lamination and to keep the contact between surfaces quite tight, use 0.8mm thick double sided Teflon tape as the bonding material.

As said I can make some of this available to be trialled, I'm sure I could package a few 400mm x 400mm 'ish' Panels to be posted, if my weekly Journey's are not passing local to an interested party.

I am also keen to try out a Natural Product and Canvas is very attractive, especially after hearing recordings on this Thread with it used as the DPS.

There is one more itch to scratch for a use of a Natural Material and that will be a very thin wood material with a soaking of Shellac, as I have seen in other threads where damping is a required property for a material that a Shellac Soak Coating can enhance the measurements recorded for damping and dissipation of a material.

Shellac is as Natural as it gets, as it is produced from secretions from the Lac Beetle insect, it is very stable and long lasting.

It also has very minimum elastic properties and is resistant to UV break down.

Most importantly, and to really get the party going, Is there any 'Exciters' I could purchase from a UK members redundant parts?

I can imagine shellac on wood could be an option as it could add weight and damping ?

I seem to remember it did not dry very quickly on the material I was using, months and months,

I seem to remember it was quite oily ,maybe that was why ?

I still have a bottle somewhere , from back then,but am not sure I want to risk it on my art panel.

where are the threads with the measurements of improvements shellac made ?

you will have to remind me what DPS means ?

I'm not sure if a 10watt exciter is going to be powerful enough for the panels you have, let alone if you are going to make a 2 ply using tape ?

before covid , I would have said bring the panel over , it will only take a couple of minutes to tape the exciter on and measure the response and see how it sounds.

I can do the tests for you if you want to send the panel over, or drop it off ,but I'm just off the M4 329M junction, so might be too far?

Steve.

The Link is to a Web Site that has been involved with testing materials for a long period of time, it has a information that DIY Hi Fi enthusiasts has drawn on over the years.

https://qualia.webs.com/newdampingfactors.htm

There will be additives available to accelerate the flash time for Shellac and additional additives that will make it absorb into a material other than form a coating layer.

DMS ?? I am sure I was meaning DML's.

I am happy to Post on a few samples for testing, I have done this in the past for the tester in the above link.

Can I have the Dimensions that are needed.

John

https://qualia.webs.com/newdampingfactors.htm

There will be additives available to accelerate the flash time for Shellac and additional additives that will make it absorb into a material other than form a coating layer.

DMS ?? I am sure I was meaning DML's.

I am happy to Post on a few samples for testing, I have done this in the past for the tester in the above link.

Can I have the Dimensions that are needed.

John

John.

What is the size of panel you are hoping to build with this panel ?

It can be any size you like.

Two would be handy as I could compare different types of mounting arrangements .

I could Even make a tectonic clone , in no way similar to Erics tectonic clone 😁,

I could Even make recordings and send them to a phone or computer, if you wished , of course.

if there was any problems or not you would be able to hear them?

Strangely enough I never tried shellac on wood , I just know it didn't work well on my corrugated cardboard panels .

on wood ,It might help change the tone a little ?

Thanks for the link by the way, I've only read his home intro , which sounds promising.

To be honest I have not sat down with my head clamped between to speakers with a frown on my forehead trying to hear minute changed in the sound of a performance ever since I started building dml panels.

I can stand on my head in the back of the room and hear the full joyful performance with dml !

Steve.

What is the size of panel you are hoping to build with this panel ?

It can be any size you like.

Two would be handy as I could compare different types of mounting arrangements .

I could Even make a tectonic clone , in no way similar to Erics tectonic clone 😁,

I could Even make recordings and send them to a phone or computer, if you wished , of course.

if there was any problems or not you would be able to hear them?

Strangely enough I never tried shellac on wood , I just know it didn't work well on my corrugated cardboard panels .

on wood ,It might help change the tone a little ?

Thanks for the link by the way, I've only read his home intro , which sounds promising.

To be honest I have not sat down with my head clamped between to speakers with a frown on my forehead trying to hear minute changed in the sound of a performance ever since I started building dml panels.

I can stand on my head in the back of the room and hear the full joyful performance with dml !

Steve.

I frequently do not get the updated posts to this forum, and only see them by going to a days-old post and hit 'update' to see them. Can something be done about this?

Jaxboy.

I've been having the same problem, it's a bit of a pain isn't it.

The new system doesn't seem any better than the old one ?

Steve.

I've been having the same problem, it's a bit of a pain isn't it.

The new system doesn't seem any better than the old one ?

Steve.

Steve,

Yeah, it is! I also follow the 'DIYAudio 15 song album' forum, and it's even worse over there. About every 2 weeks, I get skipped with the updates

Yeah, it is! I also follow the 'DIYAudio 15 song album' forum, and it's even worse over there. About every 2 weeks, I get skipped with the updates

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker